ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2016, № 6 (66)

транспортне

будівництво

транспортне

будівництво

UDC

692.47:624.012.45-034.14

G. M. GASII1*

1*Dep.

«Structures from Metal, Wood and Plastics», Poltava National

Technical Yuri Kondratyuk University,

Pershotravnevyi Av., 24,

Poltava, Ukraine, 36011, e-mail grigoriigm@gmail.com, ORCID

0000-0002-1492-0460

Types of steel and concrete

composite cable space

frames

Purpose. Modern terms of the construction

generate the need to find new structures, including roof systems that

would meet modern requirements. An important aspect in finding

constructive solutions for new structures is the use of reliable and

advanced materials. Considering this, the decision to develop the new

space structures to a wide implementation in practice of domestic and

foreign construction are relevant and perspective direction of

building structures development. Methodology. Given the

results of previously conducted theoretical research of existing

types of space roof structures find promising areas of improvement or

creation of new structures that should be devoid of weaknesses and

imperfections of analogs and they should have an economic effect

through rational use of materials. Findings. Types of steel

and concrete composite cable space frames and structural features of

its elements are developed and considered. The steel and concrete

composite cable space frame is a completely new kind of space

structure system that has the original structural concept and it was

designed to cover large-span industrial and public buildings. The

basic elements of that structure system are modular element of the

bottom chord and space steel and concrete composite module that

consists of tubular rods and reinforced concrete slab. All modular

elements are made in the factory. With bottom chord modular elements

and space steel and concrete composite modules can be assembled three

types of longitudinal elements. It is the beam element, arched

element and hanging element. Also with the modules can be assembled

various structure system and their combinations. Number of space

steel and concrete composite modules and bottom chord modular

elements, which is needed to collect steel and concrete composite

cable space frames, is determined by calculation and optimal

designing. Recommended dimensions of the modular elements of the

steel and concrete composite cable space frames are presented.

Originality. The new efficient construction roofs that

appointment for covering large-span buildings were developed by the

author. Practical value. Developed steel and concrete

composite grid-gable roofs are designed for industrial and civil

construction. Applications of developed designs for the construction

of large-span covering objects provides a significant economic

benefit through the efficient use of materials.

Keywords: plate; tube; bar; bolt; module; top

chord; bottom chord

Introduction

There is a problem often in

building sector, which lies in the complexity of work and material

overruns due to no effective use. This situation in the construction

has developed due non-compliance existing industry design solutions

to modern requirements that over time morally and physically

obsolete. These factors directly affect the overall cost and

duration of the construction project, so there is a requirement to

improve and finding the new structures systems, including space

structures that would permit largely achieve savings of materials

and reduce complexity of technological processes.

This was the cause of the idea

of developing the new concept of the space steel and concrete

composite systems that not only will combine in themselves the

results of previous studies [5, 6, 10] and will have positive

properties of existing spatial structures, but will have own unique

properties are specific to them.

Analysis of recent sources of

research and publications has shown that steel and concrete

composite is a material that were used very widely in various fields

of construction [3, 8, 9, 11, 14, 15]. Currently the main directions

of research the steel and concrete space structures are related with

the improvement of methods of calculation and constructive solutions

as well as study influence of different types of load on the

stress-strained state and so on [4, 7, 12, 13].

The analysis of previous

studies has shown that most of the steel and concrete space

structures are monolithic. However, prefabricated structures, which

would allow building curved surface, have not developed yet.

Purpose

To develop

and present main types of steel and concrete composite cable space

frames that will allow building large-span

roof system applied to transport infrastructure.

Methodology

and Findings

There is an opportunity to

build cover buildings various sizes and shapes, including various

membrane curvature, domes, and others due to that steel and concrete

composite cable space frames is modular. Considering the novelty of

the structure concept of the steel and concrete composite cable

space frames a priority task is to define the field of application

these structures and to develop several types of forms and

structural elements. Concurrently all samples that were developed

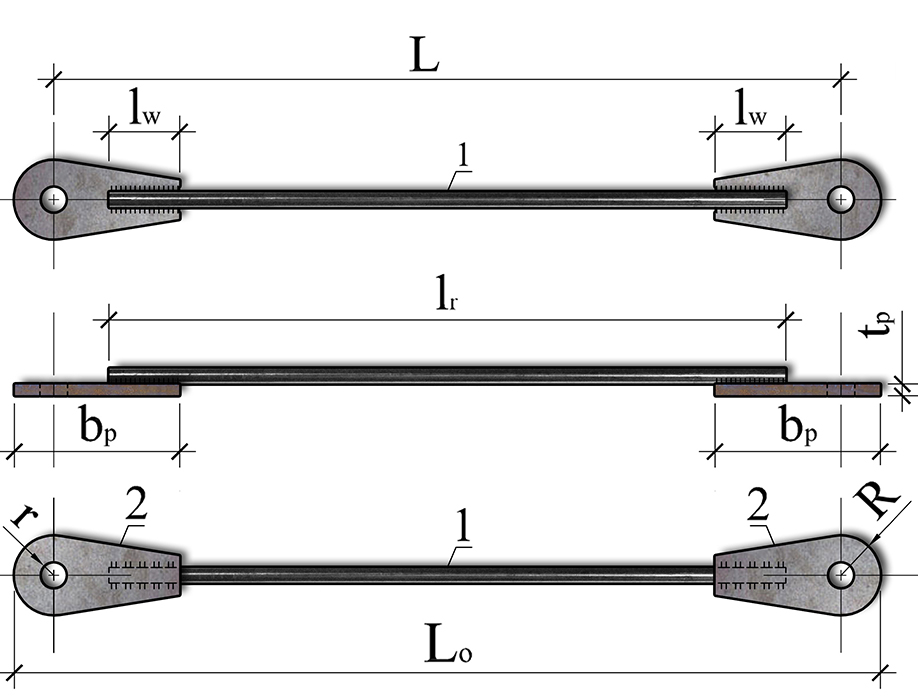

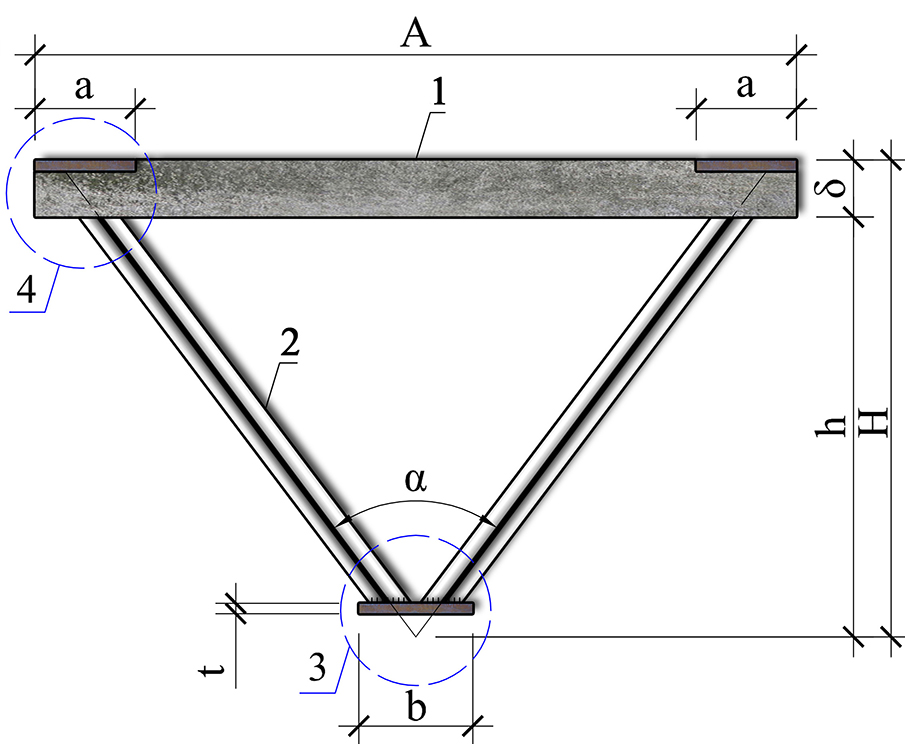

were patented. The basic elements of that structure system are

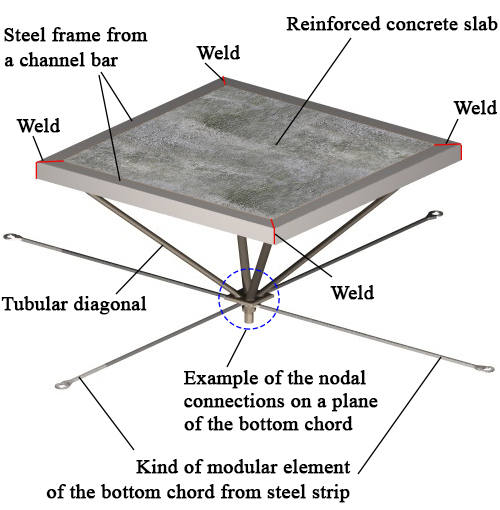

modular elements of the bottom chord (Fig. 1) and the steel and

concrete composite space modules that consists of tubular diagonal

and reinforced concrete slab (Fig. 2) [2].

In general, the basis of the

steel and concrete composite space module is reinforced concrete or

steel-concrete square slab. It plays the role of the top chord of

the steel and concrete composite cable space frames. In general,

dimensions of the reinforced concrete slab can be different and are

calculated, but the recommended dimensions of the slab in the plan

are 1.5×1.5 m or 3×3 m. The diagonals are made of circular cross

section, preferably with a tube, which plays the role of the lattice

of the structure. The angle between tubular diagonal and their

horizontal projections α can be for as conventional space grid

structures, but recommended 45°. The steel and concrete composite

space modules are combined to each other by means of the nodal

connections in a plane of the top chord (Node 2, see. Fig. 3) in the

plane of the bottom chord (Node 1 see. Fig. 4), construction of

which can be different design depending on the type of steel and

concrete composite cable space frames [1].

Fig. 1. Modular elements of the bottom chord of steel

and concrete composite cable space frames:

1

– steel rode; 2

– steel plate with hole

Fig. 2. Steel and concrete composite space module:

1

– reinforced concrete slab;

2

– tubular diagonal

3

– node on top chord (node 1);

4

– node on bottom chord (node 2)

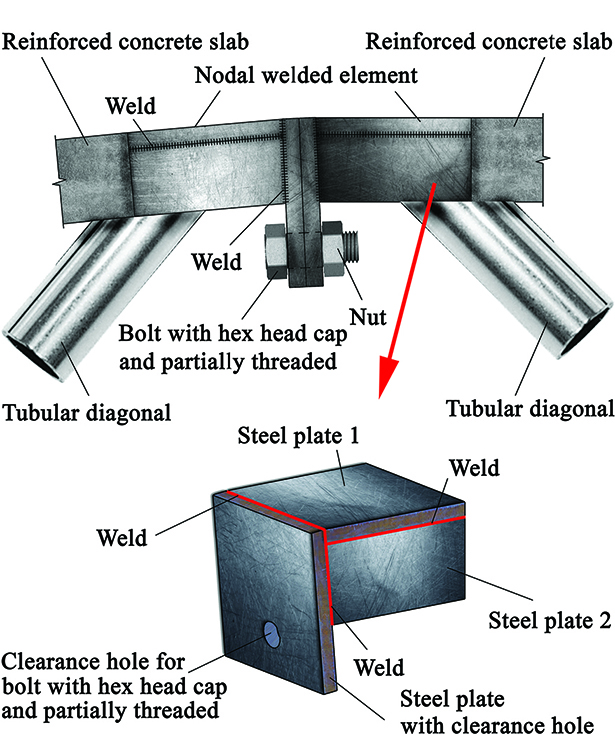

Fig. 3. Example of the nodal connections

on

a plane of the top chord (Node 2)

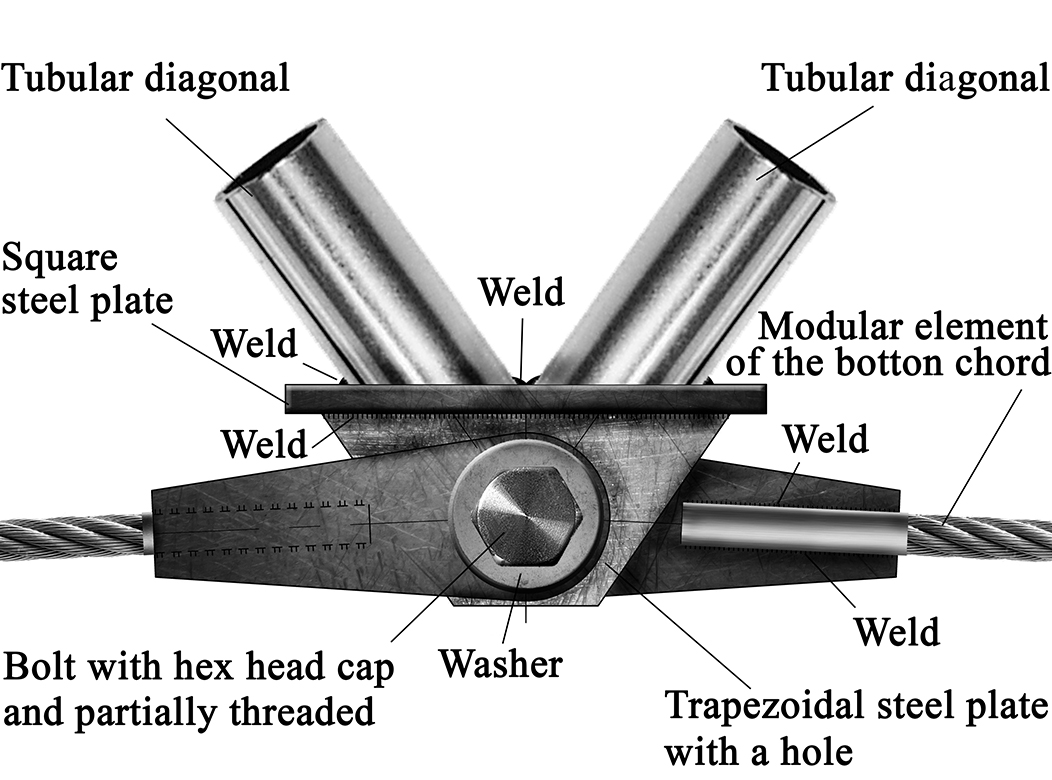

Fig. 4. Example of the nodal connections on a plane

of

the bottom chord (Node 1)

The node on

plane of the top chord includes the nodal welded element, which

consist of three steel parts: rectangular steel plate 1, rectangle

trapezoid steel plate 2 and rectangular steel plate with clearance

hole. These steel plates are connected with electric arc

welding. Two nodal welded elements that are part of steel and

concrete composite space modules are connected with partially

threaded bolt with hex head cap through the clearance hole.

The node on plane of the bottom

chord includes the nodal welded element, which consists of two steel

parts: square steel plate and trapezoid steel plate with clearance

hole. These steel plates are connected with electric arc welding.

To reduce the weight of the

steel and concrete composite space module was offered improved

design solution, the essence of which was to use the plate as the

top chord, which is made from lightweight concrete or ferrocement,

as well as tubular rods were used, which are made from high-strength

steel. As a result, the lightweight element of structure was

patented. Lightweight element of structure is part of the steel and

concrete composite cable space frames and can be used in the

construction of large-span public and industrial buildings. The

effectiveness of lightweight elements consists in low weight, ease

of installation, low complexity manufacturing, short period of the

construction. It should be noted that lightweight elements are made

entirely in the factory.

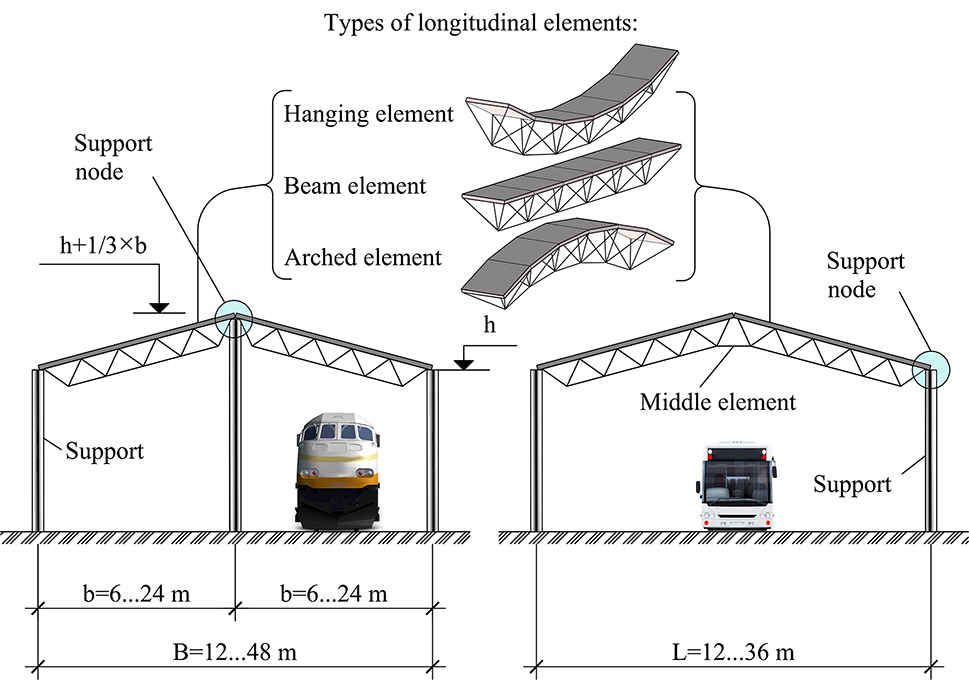

With bottom chord modular

elements (see Fig. 1) and space steel and concrete composite

modules (see Fig. 2) can be assembled three types of longitudinal

elements. It is the beam element, arched element and hanging element

(Fig. 5).

Longitudinal elements can be

used equally effectively as cover for large and small spans (Fig. 5)

and be an alternative to precast concrete system, which consist of

hollow or ribbed panels that are mounted on truss or beams, also

composite steel deck concrete roof system.

Longitudinal

elements, which do not exceed the length of the dimensions of

transportation are completely manufactured and assembled in the

factory. In this case, longitudinal elements are delivered to the

building site as a complete construction. This will greatly reduce

the complexity of assembly and installation and reduce the total

duration of the construction steel and concrete composite cable

space frames. The effectiveness of complete factory manufacturing of

the modular or longitudinal elements is especially evident in the

case when elements have constructive improvements that are designed

to simplify and reduced the length of works. For example, Fig. 6

shows the steel and concrete composite space module with a

steel frame, the effectiveness of this solution lies in the frame

that serves as not only a means to strengthen the slab, but also to

connect the modules to each other in the case of welding. In

addition, steel frame also serves as a permanent form during

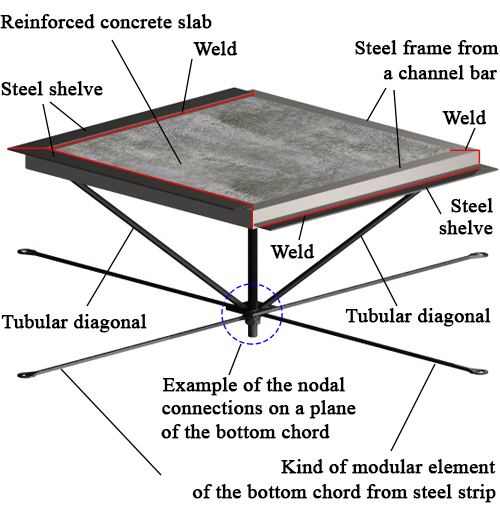

concreting of module. Fig. 7 shows another example. It is the steel

and concrete composite space module, which besides steel frame has

additional elements – steel shelves, which serve as an aid in the

installation the construction.

Fig. 5. Variants of roof system are made from

longitudinal elements

Fig. 6. Improved designs of the steel and concrete

composite space module with a steel

frame

Fig. 7. Improved designs of the steel and concrete

composite space module with steel

shelves

Curvature of longitudinal

elements or steel and concrete composite cable space frames is

provided by reducing or increasing the length of the modular element

of the bottom chord L (see Fig. 1), in consequence of which between

steel and concrete composite space modules is formed mutual angle.

However, it should be noted that the curvature of the arch of steel

and concrete composite cable space frames is limited and depends on

conditions of fixing. While designing of steel and concrete

composite cable space frames need to remember that the modular

element of the bottom chord are designed to work only in tension.

Thus designing these systems should take the following geometric

dimensions of its constituent elements and geometric parameters that

will prevent the emergence of effort compression elements in the

modular element of the bottom chord. Determining some optimum

geometrical parameters of these structures were presented in [2]. In

general, for steel and concrete composite cable space frames with

recommended dimensions of the steel and concrete composite space

module and angle between diagonal and its horizontal projection, the

relationship between the length of the modular element of the bottom

chord and angle has barely noticeable curvilinear nature.

Originality

and practical value

The steel and concrete

composite cable space frames are the new kind of effective space

grid structures that allow saving of material resources and reducing

construction laboriousness because the bottom chord of the frames

are made of flexible rods. These rods in its essence and idea are

not designed for compression, so for the manufacture of such rods

there is no need to apply rigid and massive types of metal rolling

to provide a load carrying capacity and rigidity of the frames. This

specifics of the designed frames are closely associated with the

utilize of high-strength steels for manufacturing elements of the

bottom chord, because as we know in tension elements effectively

apply high-strength steels. This fact was found after comparison

between developed frames and typical design solutions of long-span

roof system had been conducted. It has been found that the steel and

concrete composite cable space frames can be lighter than typical

roof systems about at 32–72%.

Conclusions

The steel and concrete

composite cable space frames are the new kind of large-span

structures, which have significant advantages, in particular, they

are lighter and have lower complexity of manufacturing and assembly

than analogues. The basic elements of that structure system are

modular elements of the bottom chord and space steel and concrete

composite modules. Modular elements of the bottom chord, steel and

concrete composite space modules and three types of longitudinal

elements are used for construction large-span industrial and public

buildings. Thanks to its modular design the steel and concrete

composite cable space frames can be varied expressive architectural

outline and shape. Flat double-layer grid is the simplest type of

the steel and concrete composite cable space frames. This type of

structures is used efficiently for small spans like that structure

that installed on individual supports or on a contour.

In general, from modular

elements can be erected not only the proposed system but also many

others, including steel and concrete composite cable space frames,

which have complex shapes or combinations for covering hangars for

aircraft, machinery or equipment, etc.

LIST OF reference LINKS

Гасій, Г. М. Аналіз

напружено-деформованого стану

трапецієподібної сталевої пластини

вузла з’єднання елементів нижнього

пояса експериментальної структурно-вантової

сталезалізобетонної циліндричної

оболонки / Г. М. Гасій // Зб. наук. пр.

УкрДУЗТ. – Харків, 2016. – Вип. 162. –

С. 41–47.

Стороженко, Л. І. Особливості

конструктивного рішення та проектування

повнорозмірного експериментального

зразка структурно-вантового

сталезалізобетонного покриття /Л.

І. Стороженко, Г. М. Гасій // Зб. наук. пр.

Серія : Галузеве машинобудування,

буд-во / Полтав. нац. техн. ун-т ім. Ю.

Кондратюка. – Полтава, 2016. – Вип. 1 (46).

– С. 51–59.

Шмуклер, В. С. Экспериментальные

исследования пролетного строения

пешеходного моста нового типа / В. С.

Шмуклер, Е. С. Краснова, С. Н. Краснов //

Вестн. Харьк. нац. автомоб.-дорож. ун-та.

– Харьков, 2012. – Вып. 58. – С. 70–77.

Altoubat, S. Effect of fibers and

welded-wire reinforcements on the diaphragm behavior of composite

deck slabs / S. Altoubat, H. Ousmane, S. Barakat // Steel and

Composite Structures. – 2015. – Vol. 19. – Iss. 1. – P.

153–171. doi.10.12989/scs.2015.19.1.153.

Bai, Y. Novel Joint for Assembly of

All-Composite Space Truss Structures: Conceptual Design and

Preliminary Study / Y. Bai, X. Yang // J. of Composites for

Construction. – 2013. – Vol. 17. – Iss. 1. – P.

130–138. doi: 10.1061/(asce)cc.1943-5614.0000304.

Dan, D. Theoretical and

experimental study on composite steel–concrete shear walls with

vertical steel encased profiles / D. Dan, A. Fabian, V. Stoian

// J. of Constructional Steel Research. – 2011. – Vol. 67. –

Iss. 5. – P. 800–813. doi:

10.1016/j.jcsr.2010.12.013.

Gasii, G. M. Technological and

design features of flat-rod elements with usage of composite

reinforced concrete / G. M. Gasii // Metallurgical and Mining

Industry. – 2014. – № 4. – P. 23–25.

Ivanyk, I. Research of composite

combined prestressed constructions / I. Ivanyk, Y. Vybranets, Y.

Ivanyk // Acta Scientiarum Polonorum.

Architectura. – 2014. – Т. 13, № 2. – С. 81–88.

Johnson, R. P. Composite Structures

of Steel and Concrete: Beams, Slabs, Columns, and Frames for

Buildings / R. P. Johnson. – 3d

еd. – Oxford : Blackwell, 2004.

– 252 p.

Nathan, W. A. Composite Structural

Steel and Prestressed Concrete Beam for Building Floor Systems / W.

А. Nathan. – Lincoln : University of

Nebraska, 2012. – 112 p.

Oehlers, D. J. Composite Steel and

Concrete Structures: Fundamental Behavior / D. J. Oehlers, M. A.

Bradford. – Oxford : Elsevier, 2013. –

588

p.

Tang, R. Q. The static study on

steel truss concrete slab composite structure / R. Q. Tang, Y.

Huang // J. of Guizhou University (Natural Sciences). – 2013. –

Vol. 5. – Р. 23.

Uy, B. Applications, behaviour and

design of composite steel-concrete structures / B. Uy // Advances

in Structural Engineering. – 2012. – Vol. 15. – Iss. 9. –

P. 1559–1572. doi:

10.1260/1369-4332.15.9.1559.

Vayas, I. Design of steel-concrete

composite bridges to Eurocodes / I. Vayas, A. Iliopoulos. – Boca

Raton ; London ; New York : CRC Press, 2013. – 584 p. doi:

10.1201/b15690.

Yang, X. Structural performance of

a large-scale space frame assembled using pultruded GFRP composites

/ X. Yang, Y. Bai, F. Ding // Composite Structures. – 2015. –

Vol. 133. – P. 986–996. doi: 10.1016/j.compstruct.2015.07.120.

Г. М. ГАСІЙ1*

1*Каф.

«Конструкції з металу, дерева та

пластмас», Полтавський національний

технічний університет

імені Юрія

Кондратюка, пр-т Першотравневий, 24,

Полтава, Україна, 36011, e-mail grigoriigm@gmail.com,

ORCID 0000-0002-1492-0460

Типи просторових структурно-

вантових

сталезалізобетонних

конструкцій

Мета. Умови існуючого

будівництва породжують необхідність

пошуку нових конструкцій, зокрема

покриттів, які б задовольняли

сучасним вимогам. Важливим моментом у

пошуку конструктивних рішень нових

конструкцій є використання надійних

і сучасних матеріалів. Враховуючи це,

рішення розробити нові просторові

конструкції з метою широкого впровадження

в практику вітчизняного й зарубіжного

будівництва є актуальним і перспективним

напрямком розвитку будівельних

конструкцій. Методика.

З урахуванням результату попередньо

проведеного теоретичного дослідження

існуючих типів просторових конструкцій

покриттів знайдено перспективні

напрямки їх удосконалення або створення

нових конструкцій, які були б не лише

позбавлені недоліків та недосконалостей

аналогів, але й мали економічний ефект

за рахунок раціонального використання

матеріалів. Результати.

Розроблено та розглянуто типи просторових

структурно-вантових сталезалізобетонних

конструкцій та конструктивні особливості

їх елементів. Просторові структурно-вантові

сталезалізобетонні конструкції –

абсолютно новий вид просторових несучих

систем із оригінальним конструктивним

рішенням, що призначені для покриття

великопролітних промислових та

громадських будівель і споруд. Основними

елементами таких конструкцій є модульні

елементи нижнього пояса та просторові

сталезалізобетонні модулі, які

складаються із плит та трубчастих

стрижнів. Всі модульні елементи

виготовляються в заводських умовах. З

просторових сталезалізобетонних

модулів і модульних елементів нижнього

пояса можуть збиратися три типи лінійних

елементів: балковий, арковий і висячий,

а також різні несучі системи та їх

комбінації. Кількість просторових

сталезалізобетонних модулів та модульних

елементів нижнього пояса, що необхідні

для збирання просторових конструкцій,

визначається розрахунком та варіантним

проектуванням. Наведено рекомендовані

розміри модульних елементів

структурно-вантової сталезалізобетонної

конструкції. Наукова

новизна. Автором

розроблені нові ефективні конструкції

покриттів, які призначені для перекриття

великопролітних будівель та споруд.

Практична значимість.

Розроблені сталезалізобетонні

структурно-вантові покриття призначені

для промислового та цивільного

будівництва. Застосування розроблених

конструкцій для зведення покриття

великопролітних будівель та споруд

дозволяє отримати значний економічний

ефект за рахунок раціонально використаних

матеріалів.

Ключові слова:

пластина; труба; стрижень; болт; модуль;

верхній пояс; нижній пояс

Г. М. ГАСИЙ1*

1*Каф.

«Конструкции из металла, дерева и

пластмасс», Полтавский национальный

технический университет

имени

Юрия Кондратюка, пр-т Первомайский, 24,

Полтава, Украина, 36011, e-mail grigoriigm@gmail.com,

ORCID 0000-0002-1492-0460.

Типы пространственных

структурно-

вантовых сталежелезобетонных

конструкций

Цель. Условия существующего

строительства порождают необходимость

поиска новых конструкций, в

частности покрытий, которые бы

удовлетворяли современным требованиям.

Важным моментом в поиске конструктивных

решений новых конструкций является

использование надежных и современных

материалов. Учитывая это, решение

разработать новые пространственные

конструкции с целью широкого внедрения

в практику отечественного и зарубежного

строительства является актуальным и

перспективным направлением развития

строительных конструкций. Методика.

С учетом результата предварительно

проведенного теоретического исследования

существующих типов пространственных

конструкций покрытий найдены перспективные

направления их усовершенствования или

создания новых конструкций, которые

были бы не только лишены недостатков

и несовершенств аналогов, но и имели

бы экономический эффект за счет

рационального использования материалов.

Результаты.

Разработаны и рассмотрены типы

пространственных структурно-вантовых

сталежелезобетонных конструкций и

конструктивные особенности их элементов.

Пространственные структурно-вантовые

сталежелезобетонные конструкции –

абсолютно новый вид пространственных

несущих систем с оригинальным

конструктивным решением, предназначены

для покрытия большепролетных промышленных

и общественных зданий и сооружений.

Основными элементами таких конструкций

являются модульные элементы нижнего

пояса и пространственные сталежелезобетонные

модули, состоящие из плит и трубчатых

стержней. Все модульные элементы

изготавливаются в заводских условиях.

С пространственных сталежелезобетонных

модулей и модульных элементов нижнего

пояса могут собираться три типа линейных

элементов: балочный, арочный и висячий,

а также различные несущие системы и их

комбинации. Количество пространственных

сталежелезобетонных модулей и модульных

элементов нижнего пояса, необходимое

для сбора пространственных конструкций,

определяется расчетом и вариантным

проектированием. Приведены рекомендуемые

размеры модульных элементов

структурно-вантовой сталежелезобетонной

конструкции. Научная

новизна. Автором

разработаны новые эффективные конструкции

покрытий, которые предназначены для

перекрытия большепролетных зданий и

сооружений. Практическая

значимость. Разработанные

сталежелезобетонные структурно-вантовые

покрытия предназначены для промышленного

и гражданского строительства. Применение

разработанных конструкций для возведения

покрытий большепролетных зданий и

сооружений позволяет получить

значительный экономический эффект за

счет рационально использованных

материалов.

Ключевые слова: пластина;

труба; стержень; болт; модуль; верхний

пояс; нижний пояс

REFERENCES

Gasii G.M. Analiz napruzheno-deformovanoho stanu

trapetsiiepodibnoi stalevoi plastyny vuzla ziednannia elementiv

nyzhnoho poiasa eksperymentalnoi strukturno-vantovoi

stalezalizobetonnoi tsylindrychnoi obolonky [Analysis of

stress-strain state of the trapezoidal steel plate used for joint

of elements of the bottom chord of the experimental composite steel

and concrete grid-cable barrel shell]. Zbirnyk naukovykh prats

Ukrainskoho derzhavnoho universytetu zaliznychnoho transportu

[Proc. of Ukrainian State University of Railway Transport], 2016,

issue 162, pp. 41-47.

Storozhenko

L.I., Gasii G.M. Osoblyvosti konstruktyvnoho rishennia ta

proektuvannia povnorozmirnoho eksperymentalnoho zrazka

strukturno-vantovoho stalezalizobetonnoho pokryttia [The features

of structural concept and designing of the full-length experimental

module of the composite steel and concrete grid-cable roof].

Zbirnyk naukovykh prats Poltavskoho natsionalnoho

tekhnichnoho universytetu imeni Yu. Kondratiuka. Seriia

«Haluzeve mashynobuduvannia, budivnytstvo»

[Proc. of Poltava National Technical Yuri Kondratyuk University.

Series «Industrial Engineering, Construction»], 2016,

issue 1 (46), pp. 51-59.

Shmukler

V.S., Krasnova Ye.S., Krasnov S.N. Eksperimentalnyye issledovaniya

proletnogo stroyeniya peshekhodnogo mosta novogo tipa [Experimental

studies of pedestrian bridge span structures of new type]. Vestnik

Kharkovskogo natsionalnogo avtomobilno-dorozhnogo universiteta

[Bulletin of Kharkov National Automobile and Highway University],

2012, issue 58, pp. 70-77.

Altoubat

S., Ousmane H., Barakat S. Effect of fibers and welded-wire

reinforcements on the diaphragm behavior of composite deck slabs.

Steel and Composite Structures, 2015, vol. 19, no. 1, pp.

153-171. doi: 10.12989/scs.2015.19.1.153.

Bai

Y., Yang X. Novel Joint for Assembly of all-composite space truss

structures: conceptual design and preliminary study. Journal of

Composites for Construction, 2012, vol. 17, no. 1, pp. 130-138.

doi: 10.1061/(ASCE)CC.1943-5614.0000304.

Dan

D., Fabian A., Stoian V. Theoretical and experimental study on

composite steel-concrete shear walls with vertical steel encased

profiles. Journal of Constructional Steel Research, 2011,

vol. 67, no. 5, pp. 800-813. doi: 10.1016/j.jcsr.2010.12.013.

Gasii

G.M. Technological and design features of flat-rod elements with

usage of composite reinforced concrete. Metallurgical and

Mining Industry, 2014, no. 4, pp. 23-25.

Ivanyk

I., Vybranets Y., Ivanyk Y. Research of composite combined

prestressed constructions. Acta Scientiarum Polonorum.

Architectura, 2014, vol. 13, no. 2, pp. 81-88.

Johnson

R.P. Composite Structures of Steel and Concrete: Beams, Slabs,

Columns, and Frames for Buildings. 3d еd. Oxford,

Blackwell, 2004. 252 p.

Nathan

W. A Composite Structural Steel and Prestressed Concrete Beam for

Building Floor Systems. Lincoln, University of Nebraska Publ.,

2012. 112 p.

Oehlers

D.J., Bradford M.A. Composite Steel and Concrete Structures:

Fundamental Behavior. Oxford, Elsevier Publ., 2013. 588 p.

Tang

R.Q., Huang Y. The static study on steel truss concrete slab

composite structure. Journal of Guizhou University (Natural

Sciences), 2013, no. 5, 23 p.

Uy

B. Applications, behaviour and design of composite steel-concrete

structures. Advances in Structural Engineering, 2012, vol.

15, no. 9, pp. 1559-1572. doi: 10.1260/1369-4332.15.9.1559.

Vayas

I., Iliopoulos A. Design of steel-concrete composite bridges to

Eurocodes. Boca Raton, London, New York, CRC Press Publ., 2013. 584

p.

Yang

X., Bai Y., Ding F. Structural performance of a large-scale space

frame assembled using pultruded GFRP composites. Composite

Structures, 2015, no. 133, pp. 986-996. doi:

10.1016/j.compstruct.2015.07.120.

Prof. L. I. Storozhenko, D.

Sc. (Tech.) (Ukraine); Prof. D. O. Bannikov, D. Sc. (Tech.)

(Ukraine) recommended this article to be published

Accessed: Sep. 07, 2016

Received: Dec. 01, 2016