ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2016,

№

6

(66)

нетрадиційні

види транспорту. машини та механізми

UDC 621.867.3

V. M.

BOHOMAZ1*,

M. V. BORENKO2*,

S. V. PAtsanovskyI3*,

O. O. TKachov4*

1*Dep.

«Military training of specialists of the State special service of

transport», Dnipropetrovsk National University

of Railway

Transport named after Academician V. Lazaryan,

Lazaryan St., 2, Dnipro,

Ukraine, 49010,

tel. +38 (056) 373

19 09, e-mail

wbogomas@i.ua, ORCID 0000-0001-5913-2671

2*Dep.

«Military training of specialists of the

State special service of transport»,

Dnipropetrovsk National University

of

Railway Transport named after

Academician V. Lazaryan,

Lazaryan St., 2, Dnipro,

Ukraine, 49010,

tel. +38 (056) 373

19 09,

e-mail

bmw1961@ukr.net,

ORCID 0000-0001-9578-3906

3*Dep.

«Military training of specialists of the

State special service of transport»,

Dnipropetrovsk National University

of

Railway Transport named after

Academician V. Lazaryan,

Lazaryan St., 2, Dnipro,

Ukraine, 49010,

tel. +38 (056) 373

19 09,

e-mail psven68@i.ua,

ORCID 0000-0002-1628-3733

4*Dep.

«Military training of specialists of the

State special service of transport»,

Dnipropetrovsk National University

of

Railway Transport named after

Academician V. Lazaryan,

Lazaryan St., 2, Dnipro,

Ukraine, 49010,

tel. +38 (056) 373

19 09,

e-mail

otkachov@i.ua, ORCID 0000-0002-1857-7567

ANALYSIS OF INFLUENCe

OF design

characteristics

OF

INCLINED bucket elevator

on the POWER of ITS DRIVE

Purpose. One of the main elements of the inclined belt bucket

elevators is their drive. To determine the drive power, it is

necessary to carry out calculations according to standard methods,

which are described in the modern literature. The basic design

parameters are the productivity, lifting height, type and properties

of the transported material, the angle of inclination. It is

necessary to build a parametric dependence of the driving power of

the elevator on its design parameters, which takes into account the

standard sizes and types of buckets and belts. Methodology.

Using the methodology of traction calculation of inclined belt bucket

elevator there were built parametric dependences of efforts in

specific points of the route of the elevator, as well as the

parametric dependences of the drive power of high-speed elevators

with deep and shallow buckets on their design parameters and

characteristics. Findings. On

the basis of constructed parametric dependencies, it was found that

the function of changing the value of the elevator’s power from

design capacity (at fixed lifting height, type of cargo, belt speed)

is piecewise constant and monotonically increasing. It was built a

graphical representation of elevator drive power on the angle of its

inclination within acceptable limits of change. The resulting

relationship is non-linear and monotonically decreasing. In general

terms the intervals of project performance values, which provide a

constant value of drive power of inclined elevator were defined. As

an example of the obtained results it was observed the process of

dependence construction of the drive power on design capacity and

inclination angle of the elevator for transporting the fine coal.

Originality. For the first time there were constructed the

parametric dependences of drive power of inclined bucket

elevator on its design parameters that take into account the standard

sizes and types of buckets and belts. Practical value. Using

the constructed dependencies enables relatively quick determination

of the approximate value of the drive power of high-speed inclined

elevators with deep and shallow buckets at the design stage and

high-quality selection of its basic elements in the design of

specific characteristics: type of cargo, productivity, lifting

height, angle of inclination.

Keywords: inclined elevator; bucket;

drive; power; productivity; cargo; angle of

inclination

Introdiction

Increasing

the pace of economic development is impossible without technical

re-equipment of production. The successful solution of this problem

is largely determined by implementation of new technologies with the

use of stream-flow transportation machines. They have great

performance and length of transportation and can replace batch

machines in traditional application fields, such as hauling,

handling and warehousing operations. These machines have become very

popular in mass and high-volume production with wide use of

automatic lines. A special type of stream-flow transportation

machines is inclined belt bucket elevators. Generally, elevators are

the lifts that are used for vertical and steeply inclined (at an

angle 60–82о)

displacement of bulk and piece cargo without intermediate loading

and unloading. Their use when transporting materials increase the

efficiency of the production process in many industries: chemical,

metallurgical, engineering, etc.

The main publications

describing the structure, design features, performance and design

parameters of elevators, including the inclined ones are the

following works [5-9, 11-15]. To determine the drive power of

inclined elevator it is necessary to conduct a detailed calculation

of its elements and perform a selection of basic elements of the

drive. The order of these calculations is described in detail in the

works [8, 9]. It should be noted that the use of traditional

calculation methodology of the elevator’s drive requires a lot of

time. To improve the design process of the inclined elevator’s

drive it is necessary to define a scheme that makes it possible to

determine the required drive power value depending on the specific

design parameters: the type of load, lifting height, track

inclination angle and performance using simpler calculations. The

works [2-4] of one of the authors include similar scheme for

vertical elevators and conveyor belts. The natural generalization

and continuation of these works will be the construction of schemes

for inclined elevators. This is because the inclined elevators as

opposed to the vertical ones include the component of tension force

related to the force of belt friction on the support elements.

Purpose

The article

is aimed to construct and

analyze the parametric

dependence of inclined

elevator’s drive power on its design

parameters (type of load, lifting height, angle

of inclination, performance) taking into

account the standard sizes and parameters

of buckets and

belts.

Methodology

In general, for design of

stream-flow transportation machines one should have the following

basic data:

– diagram

of machine track with indicated places of loading and unloading;

– appointment,

conditions and operation mode of machine and the place of its

installation;

– the

required performance;

– characteristics

of transported cargoes.

Thus, the initial data for

design calculation of the elevator are such values as the

transported material (its density and physical and mechanical

properties) lift height of cargo, inclination angle of elevator to

the horizon, required performance.

To construct general dependence

of drive power on the performance there will be used the required

coefficients at the values that make it possible to calculate the

corresponding values of the required drive power for specific types

of cargoes.

By analogy

with [3] let us consider the value

that takes into account the properties of transported cargo for

further studies:

that takes into account the properties of transported cargo for

further studies:

. (1)

. (1)

Linear

content of the elevator’s bucket:

, (2)

, (2)

where

– is a value that takes into account characteristics of the cargo

and is calculated using dependence (1),

t m/l h;

– is a value that takes into account characteristics of the cargo

and is calculated using dependence (1),

t m/l h;

–

is a coefficient of bucket fill (according to the physical and

mechanical properties of cargo);

–

is a coefficient of bucket fill (according to the physical and

mechanical properties of cargo);

– is a spacing of the buckets,

m;

– is a spacing of the buckets,

m;

– is a cargo density, t/m3;

– is a cargo density, t/m3;

– is a speed of the belt movement, m/s.

– is a speed of the belt movement, m/s.

According to

the value of linear content of elevator’s bucket calculated from

the formula (2) the type and spacing of buckets in accordance with

the table 1 recommended by the wok [9]

are selected. Selection of buckets type depends on the properties of

the material, which is being transported. Deep buckets are used for

free-flowing, dusty and small pieced cargoes; the shallow ones –

for non-free-flowing cargoes.

To take

account physical and mechanical properties of the cargo, which is

being transported in further calculations let us construct the

correspondence tables of elevator parameters specified in the Table

1 to the performance value expressed by the formula (2) in the parts

of coefficient

.

The obtained data will be tabulated in the Tables 2, 3 for elevators

with deep and shallow buckets respectively.

.

The obtained data will be tabulated in the Tables 2, 3 for elevators

with deep and shallow buckets respectively.

Based on the design value of

elevator productivity and the type of material, which is being

transported according to the Tables 2 and 3, the bucket parameters,

their spacing on the belt and the required width of the belt are

selected. Characteristics of deep and shallow buckets are shown in

the Tab. 4.

Table 1

Value

of linear content of buckets

|

Bucket

width

,

mm ,

mm

|

Belt

width

,

mm ,

mm

|

Spacing

of the buckets

,

mm ,

mm

|

Bucket

|

|

|

|

|

deep

|

shallow

|

|

|

|

|

,

l ,

l

|

,

l/m ,

l/m

|

,

l ,

l

|

,

l/m ,

l/m

|

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

|

100

|

125

|

200

|

0.2

|

1

|

0.1

|

0.5

|

|

125

|

150

|

320

|

0.4

|

1.3

|

0.2

|

0.66

|

|

160

|

200

|

320

|

0.6

|

2

|

0.35

|

1.17

|

|

200

|

250

|

400

|

1.3

|

3.24

|

0.75

|

1.87

|

|

250

|

300

|

400

|

2.0

|

5

|

1.4

|

3.5

|

|

320

|

400

|

500

|

4.0

|

8

|

2.7

|

5.4

|

|

400

|

500

|

500

|

6.3

|

12.6

|

4.2

|

8.4

|

|

500

|

650

|

630

|

12

|

19

|

-

|

-

|

|

650

|

800

|

630

|

18

|

28.6

|

-

|

-

|

|

800

|

1000

|

800

|

32

|

40

|

-

|

-

|

|

1000

|

1200

|

800

|

45

|

56.25

|

-

|

-

|

Table 2

Dependence of parameters of deep buckets

on the elevator’s

productivity

|

Bucket

width

,

mm ,

mm

|

Belt

width

,

mm ,

mm

|

Spacing

of the buckets

,

mm ,

mm

|

Bucket

capacity

,

l ,

l

|

Elevator

productivity, t/h

|

|

100

125

160

200

250

320

400

500

650

800

1000

|

125

150

200

250

300

400

500

650

800

1000

1200

|

200

320

320

400

400

500

500

630

630

800

800

|

0.2

0.4

0.6

1.3

2.0

4.0

6.3

12

18

32

45

|

α

1.3α

2α

3.24α

5α

8α

12.6α

19α

28.6α

40α

56.25α

|

Table 3

Dependence of parameters of shallow buckets

on the elevator’s

productivity

|

Bucket

width ,

mm ,

mm

|

Belt

width

,

mm ,

mm

|

Spacing

of the buckets

,

mm ,

mm

|

Bucket

capacity

,

l ,

l

|

Elevator

productivity, t/h

|

|

100

125

160

200

250

320

400

|

125

150

200

250

300

400

500

|

200

320

320

400

400

500

500

|

0.1

0.2

0.35

0.75

1.4

2.7

4.2

|

0.5α

0.66α

1.17α

1.87α

3.5α

5.4α

8.4α

|

Table 4

Description of elevator

buckets

|

Bucket

type

|

Internal

size of bucket, mm

|

Bucket

capacity,

|

|

|

width

|

outreach

|

height

|

|

|

Rounded

deep one D

|

100

100

125

160

200

250

320

400

500

650

800

1000

|

50

75

90

105

125

140

175

195

235

250

285

310

|

65

80

95

110

135

150

190

210

255

275

325

355

|

25

25

30

35

40

45

55

60

75

80

85

95

|

0.1

0.2

0.4

0.6

1.3

2.0

4.0

6.3

12

18

32

45

|

|

Bucket

type

|

Internal

size of bucket, mm

|

Bucket

capacity,

|

|

width

|

outreach

|

height

|

|

|

Rounded

shallow one S

|

125

160

200

250

320

400

|

65

75

95

120

145

170

|

85

100

130

160

190

220

|

30

35

40

55

70

85

|

0.2

0.35

0.75

1.4

2.7

4.2

|

For

clearness of further research let us take the conveyor belt

according to State Standard 20-85 of the type BKNL-150 as traction

body of elevator. The actual number of spacer plates of the belt can

be 3-6.

The belt thickness is

determined by the formula

, (3)

, (3)

where

mm,

mm,

mm – is

the thickness of rubber coatings from the working and non-working

sides of the belt;

mm – is

the thickness of rubber coatings from the working and non-working

sides of the belt;

mm – is

the thickness of fabric insert ply,

mm – is

the thickness of fabric insert ply,

– is the number of fabric insert plies.

– is the number of fabric insert plies.

The weight of one running meter

of belt is determined by the formula

, (4)

, (4)

where

kg/m3

– belt density.

kg/m3

– belt density.

Involving

the formulas (3)-(4)

in the calculation let us present the table of correspondence of

width and linear weight of the belt with a different number of

insert plies to design values of elevator productivity for deep and

shallow buckets.

Table 5

Linear

weight of belts for deep buckets

|

Bucket

width ,

mm ,

mm

|

Linear

weight of the belt at

,

N/m ,

N/m

|

Linear

weight of the belt at

,

N/m ,

N/m

|

Linear

weight of the belt at

,

N/m ,

N/m

|

Linear

weight of the belt at

,

N/m ,

N/m

|

Elevator

productivity, t/h

|

|

125

150

200

250

300

400

500

650

800

1000

1200

|

12.5

15.0

20.1

25.1

30.1

40.1

50.1

65.2

80.2

100.3

120.3

|

14.7

17.6

23.5

29.4

35.3

47.0

58.8

76.4

94.0

117.5

141.0

|

16.8

20.2

27.0

33.7

40.4

53.9

67.4

87.6

107.8

134.8

161.7

|

19.0

22.8

30.4

38.0

45.6

60.8

76.0

98.8

121.6

152.0

182.4

|

α

1.3α

2α

3.24α

5α

8α

12.6α

19α

28.6α

40α

56.25α

|

Table 6

Linear weight of belts for shallow

buckets

|

Bucket

width

,

mm ,

mm

|

Linear

weight of the belt at

,

N/m ,

N/m

|

Linear

weight of the belt at

,

N/m ,

N/m

|

Linear

weight of the belt at

,

N/m ,

N/m

|

Linear

weight of the belt at

,

N/m ,

N/m

|

Elevator

productivity, t/h

|

|

125

150

200

250

300

400

500

|

12.5

15.0

20.1

25.1

30.1

40.1

50.1

|

14.7

17.6

23.5

29.4

35.3

47.0

58.8

|

16.8

20.2

27.0

33.7

40.4

53.9

67.4

|

19.0

22.8

30.4

38.0

45.6

60.8

76.0

|

0.5α

0.66α

1.17α

1.87α

3.5α

5.4α

8.4α

|

Distributed weight of cargo per

1 m of belt is determined by the formula:

, (5)

, (5)

where

– coefficient

depending on

the belt

speed, N·s/kg·m.

– coefficient

depending on

the belt

speed, N·s/kg·m.

The dependence of value of

distributed weight of cargo on the design productivity calculated by

the formula (5) is given in the Table 7.

Table 7

Distributed

weight of cargo

|

Bucket

width

,

mm ,

mm

|

Distributed

cargo weight during operation of

elevator with shallow buckets

N/m

|

Elevator

productivity with shallow buckets, N/m

|

Distributed

cargo weight during operation of

elevator with deep buckets

N/m

|

Elevator

productivity with deep buckets, N/m

|

|

100

125

160

200

250

320

400

500

650

800

1000

|

0.5αλ

0.66αλ

1.17αλ

1.87αλ

3.5αλ

5.4αλ

8.4αλ

-

-

-

-

|

0.5α

0.66α

1.17α

1.87α

3.5α

5.4α

8.4α

-

-

-

-

|

αλ

1.3αλ

2αλ

3.24αλ

5αλ

8αλ

12.6αλ

19αλ

28.6αλ

40αλ

56.25αλ

|

α

1.3α

2α

3.24α

5α

8α

12.6α

19α

28.6α

40α

56.25α

|

Linear

weight of the belt

with buckets is

determined by

the formula:

, (6)

, (6)

where

– bucket weight,

kg (Tab.

8).

– bucket weight,

kg (Tab.

8).

Linear burden on the loaded

strand is determined using the formula:

. (7)

. (7)

The

estimated weight of

deep and shallow buckets is given

in the Table 8

[9].

Involving

the formulas (6)-(7) in the calculation and taking into account data

from the Table 8 let us determine the dependency of linear load on

the loaded strand of elevator on the productivity values for deep

and shallow buckets. The obtained results of calculations for belts

with different number of insert plies

is presented in the Tables 9, 10.

Table

8

Estimated

mass of elevator’s buckets

|

Bucket

width, mm

|

Wall

thickness, mm

|

Weight

of one bucket, kg

|

|

,

|

|

Deep

|

Shallow

|

|

100

|

2

|

0.5

|

0.4

|

|

125

|

2

|

0.7

|

0.6

|

|

160

|

2

|

0.9

|

0.7

|

|

200

|

3

|

2

|

1.5

|

|

250

|

3

|

3

|

2

|

|

320

|

3

|

5

|

5

|

|

400

|

4

|

11

|

10

|

|

500

|

5

|

18

|

-

|

|

650

|

5

|

23

|

-

|

|

800

|

6

|

28

|

-

|

|

1000

|

6

|

33

|

-

|

Table

9

The

linear load on the loaded strand for deep buckets

|

Bucket

width

,

mm ,

mm

|

Distributed

weight of cargo

,

N/m ,

N/m

|

Linear

load on loaded strand at the belt with

,

N/m ,

N/m

|

Linear

load on loaded strand at the belt with

,

N/m ,

N/m

|

Linear

load on loaded strand at the belt with

,

N/m ,

N/m

|

Linear

load on loaded strand at the belt with

,

N/m ,

N/m

|

Elevator

productivity, t/h

|

|

100

125

160

200

250

320

400

500

650

800

1000

|

αλ

1.3αλ

2αλ

3.24αλ

5αλ

8αλ

12.6αλ

19αλ

28.6αλ

40αλ

56.25αλ

|

37+αλ

36.4+1.3αλ

47.7+2αλ

74.1+3.24αλ

103.6+5αλ

138.1+8αλ

265.7+12.6αλ

345.2+19αλ

438+28.6αλ

443.3+40αλ

524.6+56.3αλ

|

39.2+αλ

39+1.3αλ

51.1+2αλ

78.4+3.24αλ

108.8+5αλ

145+8αλ

274.4+12.6αλ

356.4+19αλ

451.8+28.6αλ

460.5+40αλ

545.3+56.3αλ

|

41.3+αλ

41.6+1.3αλ

54.6+2αλ

82.7+3.24αλ

113.9+5αλ

151.1+8αλ

283+12.6αλ

367.6+19αλ

465.6+28.6αλ

477.8+40αλ

566+56.3αλ

|

43.5+αλ

44.2+1.3αλ

58+2αλ

87+3.24αλ

119.1+5αλ

158+8αλ

291.6+12.6αλ

378.8+19αλ

479.4+28.6αλ

495+40αλ

586.7+56.3αλ

|

α

1.3α

2α

3.24α

5α

8α

12.6α

19α

28.6α

40α

56.25α

|

Table 10

The

linear load on the loaded strand for shallow buckets

|

Bucket

width

,

mm ,

mm

|

Distributed

weight of cargo

,

N/m ,

N/m

|

Linear

load on loaded strand at the belt with

,

N/m ,

N/m

|

Linear

load on loaded strand at the belt with

,

N/m ,

N/m

|

Linear

load on loaded strand at the belt with

,

N/m ,

N/m

|

Linear

load on loaded strand at the belt with

,

N/m ,

N/m

|

Elevator

productivity, t/h

|

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

|

100

|

0.5αλ

|

32.1+0.5αλ

|

34.3+0.5αλ

|

36.4+0.5αλ

|

38.6+0.5αλ

|

0.5α

|

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

|

125

160

200

250

320

400

|

0.66αλ

1.17αλ

1.87αλ

3.5αλ

5.4αλ

8.4αλ

|

33.4+0.66αλ

41.5+1.17αλ

61.9+1.87αλ

79.1+3.5αλ

138.1+5.4αλ

246.1+8.4αλ

|

36+0.66αλ

44.9+1.17αλ

66.2+1.87αλ

84.3+3.5αλ

145+5.4αλ

254.8+8.4αλ

|

37.8+0.66αλ

48.4+1.17αλ

70.5+1.87αλ

89.4+3.5αλ

151.1+5.4αλ

263.4+8.4αλ

|

40.4+0.66αλ

51.8+1.17αλ

74.8+1.87αλ

94.6+3.5αλ

158+5.4αλ

272+8.4αλ

|

0.66α

1.17α

1.87α

3.5α

5.4α

8.4α

|

Traction

calculation of inclined bucket elevator is performed by the method

of encirclement, the basic principle of which is to identify

specific points of the track where the belt tension is changed. At

this tension in the next ( )

point is equal to the sum of belt tension in this (

)

point is equal to the sum of belt tension in this ( )

point and the belt movement resistance in the area between these

points:

)

point and the belt movement resistance in the area between these

points:

. (8)

. (8)

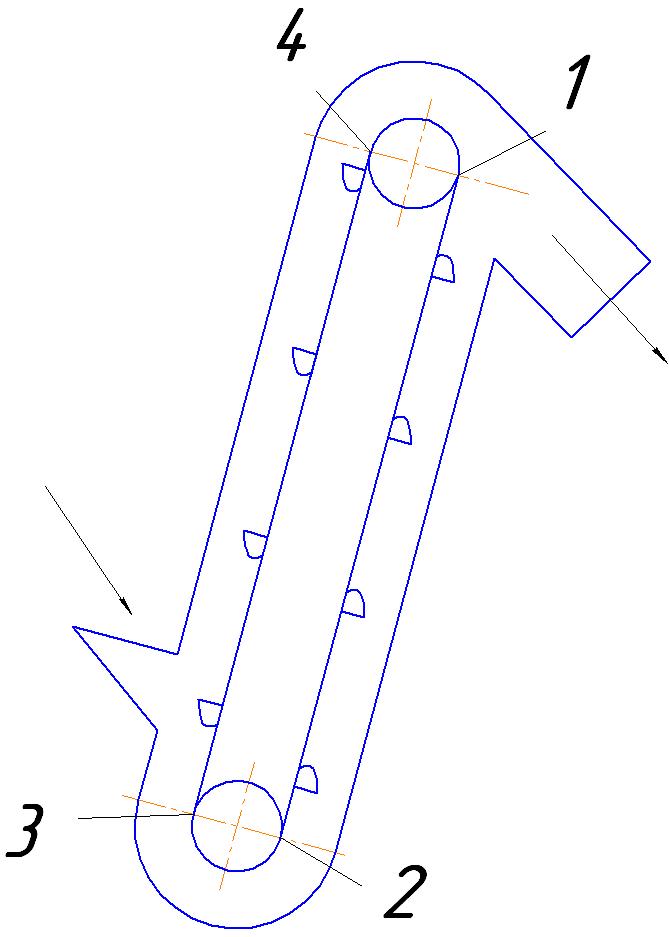

In case of

drive drum rotation (Fig. 1) in clockwise order the minimum tension

will be at the point 2 –

.

This tension in the belt during normal scooping satisfies the

following condition:

.

This tension in the belt during normal scooping satisfies the

following condition:

.

(9)

.

(9)

The belt

tension force at the point 3 consists of tension force ,

drum resistance and resistance to scooping of cargo

,

drum resistance and resistance to scooping of cargo :

:

, (10)

, (10)

where

– coefficient of

tension increase in the belt with buckets

when bending around the drum.

– coefficient of

tension increase in the belt with buckets

when bending around the drum.

Fig. 1. Scheme of inclined bucket elevator

Resistance

to material scooping is determined using the formula:

, (11)

, (11)

where

– is

a coefficient

of scooping

(Nm/kg),

which is determined by

specific work expended for

scooping of 1 kg

of material. At

the speed of buckets

– is

a coefficient

of scooping

(Nm/kg),

which is determined by

specific work expended for

scooping of 1 kg

of material. At

the speed of buckets

m/s

m/s

Nm/kg for powdered and small pieced materials, and

Nm/kg for powdered and small pieced materials, and Nm/kg – for

medium pieced material.

Nm/kg – for

medium pieced material.

Thus, substituting formulas (8)

and (11) to (10), we have:

. (12)

. (12)

Choosing the

value N m/kg (which meets all cargoes) we have:

N m/kg (which meets all cargoes) we have:

. (13)

. (13)

We assume that the belt with

buckets at the track sections 3-4 and 1-2 (Fig. 1) is supported by

direct roller supports.

The specific weight of moving

parts of roller supports for loaded (section 3-4) and unloaded

(section 1-2) strands is determined by the formulas:

. (14)

. (14)

. (15)

. (15)

where

– weight of

rotating parts of the upper and lower rolers.

– weight of

rotating parts of the upper and lower rolers.

For further calculations the

tables of estimated values of the distances between rollers of

loaded strand (Tab. 11) and the characteristics and sizes of roller

supports shown in the Table 12 will be used.

Ordinary

roller supports of the strand

1-2 are set with the spacing ,

twice as high as

,

twice as high as

.

The dependence of the weight of ordinary roller supports on the belt

width is presented in the Table 12.

.

The dependence of the weight of ordinary roller supports on the belt

width is presented in the Table 12.

To

facilitate further studies, it is assumed that the cargo has a

density in the range of 1 … 2 t/m3.

Using the formulas (14)-(15)

let us present the values of specific weight of moving parts of

roller supports for loaded and unloaded strands depending on the

belt width and width of the bucket. Calculated values of the

specific weight will be presented in the Table 13.

Table

11

The estimated value of distances between supports

of loaded strand

|

Material

density

,

t/m3 ,

t/m3

|

Distances

between supports of loaded strand at

the belt width, mm

|

|

|

400

|

500

|

650

|

800

|

1000

|

1200

|

1400…1600

|

1800…2000

|

|

1

|

1500

|

1500

|

1400

|

1400

|

1300

|

1300

|

1200

|

1100

|

|

1…2

|

1400

|

1400

|

1300

|

1300

|

1200

|

1200

|

1100

|

1100

|

|

more than 2

|

1300

|

1300

|

1200

|

1200

|

1100

|

1100

|

1100

|

900

|

Table

12

Weight of ordinary direct roller supports

|

Belt

width B,

mm

|

Weight,

kg

|

|

400

|

6.0

|

|

500

|

7.5

|

|

650

|

10.5

|

|

800

|

18.5

|

|

1 000

|

22.0

|

|

1 200

|

25.0

|

Table 13

The estimated values of the specific weight of

moving parts of roller supports

for

loaded and unloaded strands

|

Specific weight of moving

parts

|

Bucket

width

,

mm ,

mm

|

|

|

320

|

400

|

500

|

650

|

800

|

1000

|

|

loaded strand

,

N/m ,

N/m

|

40

|

50

|

75

|

132

|

169

|

192

|

|

uloaded strand

,

N/m ,

N/m

|

20

|

25

|

37.5

|

66

|

84.5

|

96

|

For

clearness of further calculations at the buckets with width less

than 320 mm, let us take the value of specific weight of moving

parts of roller supports for loaded and unloaded strands branches

N/m,

N/m,

N/m, respectively. We also accept that working conditions of the

elevator will be difficult; therefore, the resistance coefficient of

the belt movement along the rollers in future will be equal to 0.03.

N/m, respectively. We also accept that working conditions of the

elevator will be difficult; therefore, the resistance coefficient of

the belt movement along the rollers in future will be equal to 0.03.

Traction

forces at the points 1 and

4 are determined using the formulas:

, (16)

, (16)

, (17)

, (17)

where

– lift height of cargo,

m;

– lift height of cargo,

m;

– inclination angle of elevator,

degree;

– inclination angle of elevator,

degree;

– resistance coefficient of the belt

movement along the rollers.

– resistance coefficient of the belt

movement along the rollers.

The

dependence of traction forces values at the point 4 calculated by

the formula (16) on the value of design productivity, bucket type

and amount of insert plies are summarized in the Tables 14-15.

The

dependence of the values of tension force at the point 1 calculated

by the formula (17) on the value of design productivity, bucket type

and amount of insert plies of the belt are

summarized in the Tables

16-17.

Tractive effort accounting

rotational resistance of the drive drum is determined using the

formula:

, (18)

, (18)

where

– is a

resistance coefficient

of drive drum rotation.

– is a

resistance coefficient

of drive drum rotation.

After

algebraic transformations

in the

formula (18)

we have:

. (19)

. (19)

The values

of tractive effort taking into account the drum rotation resistance

depending on the values of design performance, bucket type (deep and

shallow) and the number of insert plies of the belt are summarized

in the Tables 18-19.

Table 14

Traction

force at the point 4 at deep buckets

|

Bucket

width

,

mm ,

mm

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Elevator

productivity, t/h

|

|

100

|

37H+αλ

(7.95+H)+

+(77+αλ)

cHctgβ

|

39.2H+αλ

(7.95+H)+

+(79.2+αλ)

cHctgβ

|

41.3H+αλ(7.95+H)+

+(81.3+αλ)

cHctgβ

|

43.5H+αλ

(7.95+H)+

+(83.5+αλ)

cHctgβ

|

α

|

|

125

|

36.4H+1.3αλ(7.95+H)+

+(76.4+1.3αλ)cHctgβ

|

39H+1.3αλ

(7.95+H)+

+(79+1.3αλ)cHctgβ

|

41.6H+1.3αλ(7.95+H)

+(81.6+1.3αλ)

cHctgβ

|

44.2H+1.3αλ

(7.95+H)

+(84.2+1.3αλ)

cHctgβ

|

1.3α

|

|

160

|

47.7H+2αλ

(7.95+H)+

+(87.7+2αλ)

cHctgβ

|

51.1H+2αλ

(7.95+H)+

+(91.1+2αλ)

cHctgβ

|

54.6H+2αλ(7.95+H)+

+(94.6+2αλ)

cHctgβ

|

58H+2αλ

(7.95+H)+

+(98+2αλ)

cHctgβ

|

2α

|

|

200

|

74.1H+3.24αλ(7.95+H)

+(114.1+3.24αλ)cHctgβ

|

78.4H+3.24αλ(7.95+H)+

+(118.4+3.24αλ)

cHctgβ

|

82.7H+3.24αλ(7.95+H)

+(122.7+3.24αλ)cHctgβ

|

87H+3.24αλ

(7.95+H)+

+(127+3.24αλ)

cHctgβ

|

3.24α

|

|

250

|

103.6H+5αλ

(7.95+H)+

+(143.6+5αλ)

cHctgβ

|

108.8H+5αλ

(7.95+H)+

+(148.8+5αλ)

cHctgβ

|

113.9H+5αλ(7.95+H)+

+(153.9+5αλ)

cHctgβ

|

119.1H+5αλ

(7.95+H)

+(159.1+5αλ)

cHctgβ

|

5α

|

|

320

|

138.1H+8αλ

(7.95+H)+

+(178.1+8αλ)

cHctgβ

|

145H+8αλ

(7.95+H)+

+(185+8αλ)

cHctgβ

|

151.1H+8αλ(7.95+H)+

+(191.1+8αλ)

cHctgβ

|

158H+8αλ(7.95+H)+

+(198+8αλ)

cHctgβ

|

8α

|

|

400

|

265H+12.6αλ(7.95+H)

+(315.7+12.6αλ)cHctgβ

|

274.4H+12.6αλ(7.95+H)

+(324.4+12.6αλ)

cHctgβ

|

283H+12.6αλ(7.95+H)

+(333+12.6αλ)

cHctgβ

|

291.6H+12.6αλ(7.95+H)

+(341.6+12.6αλ)

cHctgβ

|

12.6α

|

|

500

|

345.2H+19αλ

(7.95+H)

+(420.2+19αλ)

cHctgβ

|

356.4H+19αλ(7.95+H)

+(431.4+19αλ)

cHctgβ

|

367.6H+19αλ(7.95+H)

+(442.6+19αλ)

cHctgβ

|

378.8H+19αλ(7.95+H)

+(453.8+19αλ)

cHctgβ

|

19α

|

|

650

|

438H+28.6αλ

(7.95+H)

+(570+28.6αλ)

cHctgβ

|

451.8H+28.6αλ(7.95+H)

+(583.8+28.6αλ)

cHctgβ

|

465H+28.6αλ(7.95+H)

+(597.6+28.6αλ)cHctgβ

|

479.4H+28.6αλ(7.95+H)

+(611.4+28.6αλ)

cHctgβ

|

28.6α

|

|

800

|

443.3H+40αλ

(7.95+H)

+(612.3+40αλ)

cHctgβ

|

460.5H+40αλ(7.95+H)

+(629.5+40αλ)

cHctgβ

|

477.8H+40αλ(7.95+H)

+(646.8+40αλ)

cHctgβ

|

495H+40αλ(7.95+H)+

+(664+40αλ)

cHctgβ

|

40α

|

|

1000

|

524H+56.3αλ(7.95+H)

+(716.6+56.3αλ)cHctgβ

|

545.3H+56.3αλ(7.95+H)

+(737.3+56.3αλ)

cHctgβ

|

566H+56.3αλ(7.95+H)+

+(758+56.3αλ)

cHctgβ

|

586.7H+56.3αλ(7.95+H)

+(778.7+56.3αλ)

cHctgβ

|

56.25α

|

Table 15

Traction force at the

point 4 at shallow buckets

|

Bucket

width

,

mm ,

mm

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Elevator

productivity, t/h

|

|

100

|

32.1H+0.5αλ(7.95+H)

+(72.1+0.5αλ)

cHctgβ

|

34.3H+0.5αλ(7.95+H)

+(74.3+0.5αλ) cHctgβ

|

36.4H+0.5αλ(7.95+H)

+(76.4+0.5αλ) cHctgβ

|

38.6H+0.5αλ(7.95+H)

+(78.6+0.5αλ) cHctgβ

|

0.5α

|

|

125

|

33.4H+0.66αλ(7.95+H)+(73.4+0.66αλ)

cHctgβ

|

36H+0.66αλ

(7.95+H)

+(76+0.66αλ) cHctgβ

|

37.8H+0.66αλ(7.95+H)

+(77.8+0.66αλ) cHctgβ

|

40.4H+0.66αλ(7.95+H)

+(80.4+0.66αλ) cHctgβ

|

0.66α

|

|

160

|

41.5H+1.17αλ(7.95+H)

+(81.5+1.17αλ) cHctgβ

|

44.9H+1.17αλ(7.95+H)

+(84.9+1.17αλ) cHctgβ

|

48.4H+1.17αλ(7.95+H)

+(88.4+1.17αλ) cHctgβ

|

51.8H+1.17αλ(7.95+H)

+(91.8+1.17αλ) cHctgβ

|

1.17α

|

|

200

|

61.9H+1.87αλ(7.95+H)

+(101.9+1.87αλ)cHctgβ

|

66.2H+1.87αλ(7.95+H)

+(106.2+1.87αλ)cHctgβ

|

70.5H+1.87αλ(7.95+H)

+(110.5+1.87αλ)cHctgβ

|

74.8H+1.87αλ(7.95+H)

+(114.8+1.87αλ)cHctgβ

|

1.87α

|

|

250

|

79.1H+3.5αλ(7.95+H)+

+(119.1+3.5αλ)cHctgβ

|

84.3H+3.5αλ(7.95+H)+

+(124.3+3.5αλ)cHctgβ

|

89.4H+3.5αλ(7.95+H)+

+(139.4+3.5αλ)cHctgβ

|

94.6H+3.5αλ

(7.95+H)

+(134.6+3.5αλ)cHctgβ

|

3.5α

|

|

320

|

138.1H+5.4αλ(7.95+H)

+(178.1+5.4αλ)cHctgβ

|

145H+5.4αλ

(7.95+H)

+(185+5.4αλ)cHctgβ

|

151.1H+5.4αλ(7.95+H)

+(191.1+5.4αλ)cHctgβ

|

158H+5.4αλ

(7.95+H)+

+(198+5.4αλ)cHctgβ

|

5.4α

|

|

400

|

246.1H+8.4αλ(7.95+H)

+(296.1+8.4αλ)cHctgβ

|

254.8H+8.4αλ(7.95+H)

+(304.8+8.4αλ)cHctgβ

|

263.4H+8.4αλ(7.95+H)

+(313.4+8.4αλ)cHctgβ

|

272H+8.4αλ

(7.95+H)+

+(322+8.4αλ)cHctgβ

|

8.4α

|

Table 16

Traction force at the

point 1 at deep buckets

|

Bucket

width

,

mm ,

mm

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Elevator

productivity, t/h

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

100

|

37H+5αλ+

+57cHctgβ

|

39.2H+5αλ+

+59.2cHctgβ

|

41.3H+5αλ+

+61.3cHctgβ

|

43.5H+5αλ+

+63.5cHctgβ

|

α

|

|

125

|

36.4H+6.5αλ+

+56.4cHctgβ

|

39H+6.5αλ+

+59cHctgβ

|

41.6H+6.5αλ+

+61.6cHctgβ

|

44.2H+6.5αλ+

+64.2cHctgβ

|

1.3α

|

|

160

|

47.7H+10αλ+

+67.7cHctgβ

|

51.1H+10αλ+

+71.1cHctgβ

|

54.6H+10αλ+

+74.6cHctgβ

|

58H+10αλ+

+78cHctgβ

|

2α

|

End of

table 16

|

Bucket

width

,

mm ,

mm

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Traction

force at the belt with

,

N ,

N

|

Elevator

productivity, t/h

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

200

|

74.1H+16.2αλ+

+94.1cHctgβ

|

78.4H+16.2αλ+

+98.4cHctgβ

|

82.7H+16.2αλ+

+102.7cHctgβ

|

87H+16.2αλ+

+97cHctgβ

|

3.24α

|

|

250

|

103.6H+25αλ+

+123.6cHctgβ

|

108.8H+25αλ+

+128.8cHctgβ

|

113.9H+25αλ+

+133.9cHctgβ

|

119.1H+25αλ+

+139.1cHctgβ

|

5α

|

|

320

|

138.1H+40αλ+

+158.1cHctgβ

|

145H+40αλ+

+165cHctgβ

|

151.1H+40αλ+

+171.1cHctgβ

|

158H+40αλ+

+178cHctgβ

|

8α

|

Table 17

Traction

force at the point 1 at shallow buckets

|

Bucket

width

,

mm ,

mm

|

Tractive

effort at the belt with

,

N ,

N

|

Tractive

effort at the belt with

,

N ,

N

|

Tractive

effort at the belt with

,

N ,

N

|

Tractive

effort at the belt with

,

N ,

N

|

Elevator

productivity, t/h

|

|

100

|

32.1H+2.5αλ+

+52.1cHctgβ

|

34.3H+2.5αλ+

+54.3cHctgβ

|

36.4H+2.5αλ+

+56.4cHctgβ

|

38.6H+2.5αλ+

+58.6cHctgβ

|

0.5α

|

|

125

|

33.4H+3.3αλ+

+53.4cHctgβ

|

36H+3.3αλ+

+56cHctgβ

|

37.8H+3.3αλ+

+57.8cHctgβ

|

40.4H+3.3αλ+

+60.4cHctgβ

|

0.66α

|

|

160

|

41.5H+5.85αλ+

+61.5cHctgβ

|

44.9H+5.85αλ+

+64.9cHctgβ

|

48.4H+5.85αλ+

+68.4cHctgβ

|

51.8H+5.85αλ+

+71.8cHctgβ

|

1.17α

|

|

200

|

61.9H+9.35αλ+

+81.9cHctgβ

|

66.2H+9.35αλ+

+86.2cHctgβ

|

70.5H+9.35αλ+

+90.5cHctgβ

|

74.8H+9.35αλ+

+94.8cHctgβ

|

1.87α

|

|

250

|

79.1H+17.5αλ+

+99.1cHctgβ

|

84.3H+17.5αλ+

+104.3cHctgβ

|

89.4H+17.5αλ+

+109.4cHctgβ

|

94.6H+17.5αλ+

+114.6cHctgβ

|

3.5α

|

|

320

|

138.1H+27αλ+

+158.1cHctgβ

|

145H+27αλ+

+165cHctgβ

|

151.1H+27αλ+

+171.1cHctgβ

|

158H+27αλ+

+178cHctgβ

|

5.4α

|

|

400

|

246.1H+42αλ+

+271.1cHctgβ

|

254.8H+42αλ+

+279.8cHctgβ

|

263.4H+42αλ+

+288.4cHctgβ

|

272H+42αλ+

+297cHctgβ

|

8.4α

|

Table 18

Tractive

effort on the drive drum at deep buckets

|

Bucket

width

,

mm ,

mm

|

Tractive

effort at the belt with

,

N ,

N

|

Tractive

effort at the belt with

,

N ,

N

|

Tractive

effort at the belt with

,

N ,

N

|

Tractive

effort at the belt with

,

N ,

N

|

Elevator

productivity, t/h

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

100

|

5.9H+αλ(4+1.08H)+

+(30.7+1.08αλ)cHctgβ

|

6.3H+αλ

(4+1.08H)+

+(31.1+1.08αλ)cHctgβ

|

6.6H+αλ

(4+1.08H)+

+(31.4+1.08αλ)cHctgβ

|

7H+αλ

(4+1.08H)+

+(31.8+1.08αλ)cHctgβ

|

α

|

|

125

|

5.82H+1.3αλ(4+1.08H)

+(30.6+1.4αλ)

cHctgβ

|

6.2H+1.3αλ

(4+1.08H)

+(31+1.4αλ)

cHctgβ

|

6.7H+1.3αλ

(4+1.08H)

+(31.5+1.4αλ)

cHctgβ

|

7.1H+1.3αλ

(4+1.08H)+

+(31.9+1.4αλ)

cHctgβ

|

1.3α

|

|

160

|

7.63H+2αλ

(4+1.08H)

+(32.4+2.16αλ)

cHctgβ

|

8.2H+2αλ

(4+1.08H)+

+(33+2.16αλ)

cHctgβ

|

8.7H+2αλ

(4+1.08H)+

+(33.5+2.16αλ)

cHctgβ

|

9.3H+2αλ

(4+1.08H)+

+(34.1+2.16αλ)

cHctgβ

|

2α

|

|

200

|

11.9H+3.24αλ(4+1.08H)

+(36.7+3.5αλ)

cHctgβ

|

12.5H+3.24αλ(4+1.08H)

+(37.3+3.5αλ)

cHctgβ

|

13.2H+3.24αλ(4+1.08H)

+(38

+3.5αλ) cHctgβ

|

13.9H+3.24αλ

(4+1.08H)

+(38.7+3.5αλ)

cHctgβ

|

3.24α

|

|

250

|

16.6H+5αλ

(4+1.08H)+

+(41.4+5.4αλ)

cHctgβ

|

17.4H+5αλ

(4+1.08H)+

+(42.2+5.4αλ)

cHctgβ

|

18.2H+5αλ

(4+1.08H)+

+(43+5.4αλ)

cHctgβ

|

19.1H+5αλ

(4+1.08H)+

+(43.9+5.4αλ)

cHctgβ

|

5α

|

|

320

|

22.1H+8αλ

(4+1.08H)+

+(46.9+8.64αλ)

cHctgβ

|

23.2H+8αλ

(4+1.08H)+

+(48+8.64αλ)

cHctgβ

|

24.2H+8αλ

(4+1.08H)+

+(49+8.64αλ)

cHctgβ

|

25.3H+8αλ

(4+1.08H)+

+(50.1+8.64αλ)

cHctgβ

|

8α

|

|

400

|

42.5H+12.6αλ(4+1.08H)

+(73.5+13.6αλ)

cHctgβ

|

43.9H+12.6αλ(4+1.08H)

+(74.9+13.6αλ)

cHctgβ

|

45.3H+12.6αλ(4+1.08H)

+(76.3+13.6αλ)

cHctgβ

|

46.7H+12.6αλ

(4+1.08H)

+(77.7+13.6αλ)

cHctgβ

|

12.6α

|

|

500

|

55.2H+19αλ

(4+1.08H)+

+(101.7+20.5αλ)

cHctgβ

|

57H+19αλ

(4+1.08H)+

+(103.5+20.5αλ)

cHctgβ

|

58.8H+19αλ

(4+1.08H)

+(105.3+20.5αλ)

cHctgβ

|

60.6H+19αλ

(4+1.08H)

+(107.1+20.5αλ)

cHctgβ

|

19α

|

|

650

|

70.1H+28.6αλ(4+1.08H)

+(167.8+30.9αλ)

cHctgβ

|

72.3H+28.6αλ(4+1.08H)

+(170+30.9αλ)

cHctgβ

|

74.5H+28.6αλ(4+1.08H)

+(172.2+30.9αλ)

cHctgβ

|

76.7H+28.6αλ

(4+1.08H)

+(174.4+30.9αλ)

cHctgβ

|

28.6α

|

|

800

|

70.9H+40αλ

(4+1.08H)

+(196+43.2αλ)

cHctgβ

|

73.7H+40αλ

(4+1.08H)

+(198.8+43.2αλ)

cHctgβ

|

76.4H+40αλ

(4+1.08H)

+(201.5+43.2αλ)

cHctgβ

|

79.2H+40αλ

(4+1.08H)

+(204.3+43.2αλ)

cHctgβ

|

40α

|

|

1000

|

83.9H+56.3αλ(4+1.08H)

+(202.9+60.8αλ)

cHctgβ

|

87.2H+56.3αλ(4+1.08H)

+(206.2+60.8αλ)

cHctgβ

|

90.6H+56.3αλ(4+1.08H)

+(209.6+60.8αλ)

cHctgβ

|

93.9H+56.3αλ

(4+1.08H)

+(212.9+60.8αλ)

cHctgβ

|

56.25α

|

Table 19

Tractive effort on the drive drum at shallow

buckets

|

Bucket

width

,

mm ,

mm

|

Tractive

effort at the belt with

,

N ,

N

,

N ,

N

|

Tractive

effort at the belt with

,

N ,

N

,

N ,

N

|

Tractive

effort at the belt with

,

N ,

N

,

N ,

N

|

Tractive

effort at the belt with

,

N ,

N

,

N ,

N

|

Elevator

productivity, t/h

|

|

100

|

5.1H+αλ

(4+1.08H)+

+(30+1.08αλ)

cHctgβ

|

5.5H+αλ

(4+1.08H)+

+(30.3+1.08αλ)cHctgβ

|

5.8H+αλ

(4+1.08H)+

+(30.6+1.08αλ)cHctgβ

|

6.2H+αλ

(4+1.08H)+

+(31+1.08αλ)

cHctgβ

|

0.5α

|

|

125

|

5.3H+1.3αλ(4+1.08H)

+(30.1+1.4αλ)

cHctgβ

|

5.8H+1.3αλ(4+1.08H)

+(30.6+1.4αλ)

cHctgβ

|

6.0H+1.3αλ(4+1.08H)

+(30.8+1.4αλ)

cHctgβ

|

6.5H+1.3αλ(4+1.08H)

+(31.3+1.4αλ)

cHctgβ

|

0.66α

|

|

160

|

6.6H+2αλ

(4+1.08H)+

+(31.4+2.16αλ)cHctgβ

|

7.2H+2αλ

(4+1.08H)+

+(32+2.16αλ)

cHctgβ

|

7.7H+2αλ

(4+1.08H)+

+(32.5+2.16αλ)cHctgβ

|

8.3H+2αλ

(4+1.08H)+

+(33.1+2.16αλ)cHctgβ

|

1.17α

|

|

200

|

9.9H+3.24αλ(4+1.08H)

+(34.7+3.5αλ)

cHctgβ

|

10.6H+3.24αλ(4+1.08H)

+(35.4+3.5αλ)

cHctgβ

|

11.3H+3.24αλ(4+1.08H)

+(36.1+3.5αλ)

cHctgβ

|

12H+3.24αλ

(4+1.08H)+

+(36.8+3.5αλ)

cHctgβ

|

1.87α

|

|

250

|

12.7H+5αλ

(4+1.08H)+

+(37.5+5.4αλ)

cHctgβ

|

13.5H+5αλ

(4+1.08H)+

+(38.3+5.4αλ)

cHctgβ

|

14.3H+5αλ

(4+1.08H)+

+(39.1+5.4αλ)

cHctgβ

|

15.1H+5αλ

(4+1.08H)+

+(39.9+5.4αλ)

cHctgβ

|

3.5α

|

|

320

|

22.1H+8αλ

(4+1.08H)+

+(46.9+8.6αλ)

cHctgβ

|

23.2H+8αλ

(4+1.08H)+

+(48+8.6αλ)

cHctgβ

|

24.2H+8αλ

(4+1.08H)+

+(49+8.6αλ)

cHctgβ

|

25.3H+8αλ

(4+1.08H)+

+(50.1+8.6αλ)

cHctgβ

|

5.4α

|

|

400

|

39.4H+12.6αλ(4+1.08H)

+(70.4+13.6αλ)

cHctgβ

|

40.8H+12.6αλ(4+1.08H)

+(71.8+13.6αλ)

cHctgβ

|

42.1H+12.6αλ(4+1.08H)

+(73.1+13.6αλ)

cHctgβ

|

43.5H+12.6αλ(4+1.08H)

+(74.5+13.6αλ)

cHctgβ

|

8.4α

|

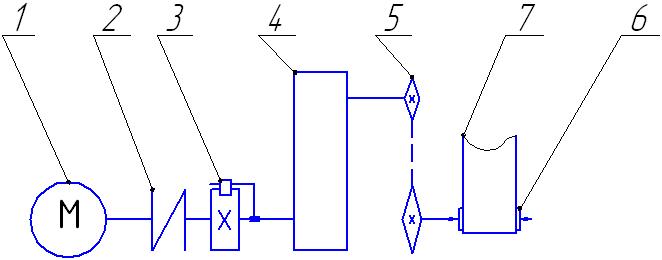

Estimated kinematic scheme of

the elevator’s drive is shown in the Fig. 2.

Fig. 2. Scheme of bucket elevator drive:

1

– engine; 2

– elastic clutch; 3

– locking device (ratchet);

4

– reducing gear; 5

– chain transmission; 6

– drive drum;

7

– belt

Efficiency coefficient of the

drive is determined by the formula:

, (20)

, (20)

where

– efficiency coefficient of reducing gear;

– efficiency coefficient of reducing gear;

– efficiency coefficient of chain transmission;

– efficiency coefficient of chain transmission;

– efficiency coefficient of clutch.

– efficiency coefficient of clutch.

Thus,

.

.

Engine power

is determined by

the formula:

. (21)

. (21)

Calculated

power of the engine is determined

by the formula:

, (22)

, (22)

where

– is

the safety factor.

– is

the safety factor.

Since

and

and

then using the formulas (21) and (22) we obtain the following:

then using the formulas (21) and (22) we obtain the following:

. (23)

. (23)

Dependence

of the calculated engine power on the

values of design

performance,

bucket type, number of

insert plies of the belt,

speed of the belt movement

and lifting height of cargo calculated

using the formula (23) taking into account

data from the Tables

18-19 are summarized in the Tables

20-21:

Table

20

Calculated

power of engine at deep buckets

|

Bucket

width

,

mm ,

mm

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Elevator

productivity, t/h

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

100

|

v

[5.9H+αλ

(4+1.08H)+

+(30.7+1.08αλ)cHctgβ]

|

v

[6.3H+αλ

(4+1.08H)+

+(31.1+1.08αλ)cHctgβ]

|

v

[6.6H+αλ

(4+1.08H)+

+(31.4+1.08αλ)cHctgβ]

|

v[7H+αλ

(4+1.08H)+

+(31.8+1.08αλ)

cHctgβ]

|

α

|

|

125

|

[5.82H+1.3αλ(4+1.08H)

+(30.6+1.4αλ)cHctgβ]v

|

[6.2H+1.3αλ

(4+1.08H)

+(31+1.4αλ)

cHctgβ]v

|

[6.7H+1.3αλ

(4+1.08H)

+(31.5+1.4αλ)

cHctgβ]v

|

[7.1H+1.3αλ(4+1.08H)+

+(31.9+1.4αλ)cHctgβ]v

|

1.3α

|

|

160

|

v[7.63H+2αλ

(4+1.08H)

+(32.4+2.16αλ)

cHctgβ]

|

[8.2H+2αλ

(4+1.08H)+

+(33+2.16αλ)

cHctgβ]v

|

[8.7H+2αλ

(4+1.08H)+

+(33.5+2.16αλ)cHctgβ]v

|

v[9.3H+2αλ

(4+1.08H)+

+(34.1+2.16αλ)

cHctgβ]

|

2α

|

|

200

|

[11.9H+3.2αλ(4+1.08H)

+(36.7+3.5αλ)

cHctgβ]v

|

[12.5H+3.2αλ(4+1.08H)

+(37.3+3.5αλ)

cHctgβ]v

|

[13.2H+3.2αλ(4+1.08H)

+(38

+3.5αλ) cHctgβ]v

|

[13.9H+3.2αλ(4+1.08H)

+(38.7+3.5αλ)

cHctgβ]v

|

3.24α

|

|

250

|

[16.6H+5αλ

(4+1.08H)+

+(41.4+5.4αλ)

cHctgβ]v

|

[17.4H+5αλ

(4+1.08H)+

+(42.2+5.4αλ)

cHctgβ]v

|

[18.2H+5αλ(4+1.08H)+

+(43+5.4αλ)cHctgβ]v

|

[19.1H+5αλ

(4+1.08H)+

+(43.9+5.4αλ)

cHctgβ]v

|

5α

|

|

320

|

[22.1H+8αλ

(4+1.08H)+

+(46.9+8.64αλ)cHctgβ]v

|

[23.2H+8αλ

(4+1.08H)+

+(48+8.64αλ)

cHctgβ]v

|

[24.2H+8αλ

(4+1.08H)+

+(49+8.64αλ)cHctgβ]v

|

[25.3H+8αλ

(4+1.08H)+

+(50.1+8.64αλ)cHctgβ]v

|

8α

|

|

400

|

[42.5H+12.6αλ(4+1.08H)

+(73.5+13.6αλ)

cHctgβ]v

|

[43.9H+12.6αλ(4+1.08H)

+(74.9+13.6αλ)

cHctgβ]v

|

[45.3H+12.6αλ(4+1.08H)

+(76.3+13.6αλ)

cHctgβ]v

|

[46.7H+12.6αλ(4+1.08H)

+(77.7+13.6αλ)

cHctgβ]v

|

12.6α

|

|

500

|

[55,2H+19αλ

(4+1,08H)+

+(101,7+20,5αλ)cHctgβ]v

|

v[57H+19αλ

(4+1,08H)+

+(103,5+20,5αλ)

cHctgβ]

|

v[58,8H+19αλ

(4+1,08H)

+(105,3+20,5αλ)

cHctgβ]

|

v[60,6H+19αλ

(4+1,08H)

+(107,1+20,5αλ)

cHctgβ]

|

19α

|

|

650

|

[70,1H+28,6αλ(4+1,08H)

+(167,8+30,9αλ)cHctgβ]v

|

[72,3H+28,6αλ(4+1,08H)

+(170+30,9αλ)

cHctgβ]v

|

[74,5H+28,6αλ(4+1,08H)

+(172,2+30,9αλ)cHctgβ]v

|

[76,7H+28,6αλ(4+1,08H)

+(174,4+30,9αλ)cHctgβ]v

|

28,6α

|

|

800

|

[70,9H+40αλ

(4+1,08H)

+(196+43,2αλ)

cHctgβ]v

|

[73,7H+40αλ

(4+1,08H)

+(198,8+43,2αλ)cHctgβ]v

|

[76,4H+40αλ

(4+1,08H)

+(201,5+43,2αλ)cHctgβ]v

|

[79,2H+40αλ

(4+1,08H)

+(204,3+43,2αλ)cHctgβ]v

|

40α

|

|

1000

|

[83,9H+56,3αλ(4+1,08H)

+(202,9+60,8αλ)cHctgβ]v

|

[87,2H+56,3αλ(4+1,08H)

+(206,2+60,8αλ)cHctgβ]v

|

[90,6H+56,3αλ(4+1,08H)

+(209,6+60,8αλ)cHctgβ]v

|

[93,9H+56,3αλ(4+1,08H)

+(212,9+60,8αλ)cHctgβ]v

|

56,25α

|

Table 21

Calculated

power of engine at shallow buckets

|

Bucket

width

,

mm ,

mm

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Elevator

productivity, t/h

|

|

100

|

[5,1H+αλ

(4+1,08H)+

+(30+1,08αλ)

cHctgβ]v

|

v[5,5H+αλ

(4+1,08H)+

+(30,3+1,08αλ)

cHctgβ]

|

v[5,8H+αλ

(4+1,08H)+

+(30,6+1,08αλ)

cHctgβ]

|

v[6,2H+αλ

(4+1,08H)+

+(31+1,08αλ)

cHctgβ]

|

0,5α

|

|

125

|

[5,3H+1,3αλ(4+1,08H)+

+(30,1+1,4αλ)

cHctgβ]v

|

[5,8H+1,3αλ(4+1,08H)+

+(30,6+1,4αλ)

cHctgβ]v

|

[6,0H+1,3αλ(4+1,08H)+

+(30,8+1,4αλ)

cHctgβ]v

|

[6,5H+1,3αλ(4+1,08H)+

+(31,3+1,4αλ)

cHctgβ]v

|

0,66α

|

|

160

|

[6,6H+2αλ

(4+1,08H)+

+(31,4+2,16αλ)cHctgβ]v

|

[7,2H+2αλ

(4+1,08H)+

+(32+2,16αλ)

cHctgβ]v

|

[7,7H+2αλ

(4+1,08H)+

+(32,5+2,16αλ)cHctgβ]v

|

[8,3H+2αλ

(4+1,08H)+

+(33,1+2,16αλ)cHctgβ]v

|

1,17α

|

|

200

|

[9,9H+3,24αλ

(4+1,08H)

+(34,7+3,5αλ)

cHctgβ]v

|

[10,6H+3,2αλ(4+1,08H)

+(35,4+3,5αλ)

cHctgβ]v

|

[11,3H+3,2αλ(4+1,08H)

+(36,1+3,5αλ)

cHctgβ]v

|

[12H+3,24αλ(4+1,08H)

+(36,8+3,5αλ)

cHctgβ]v

|

1,87α

|

End of

table 21

|

Bucket

width

,

mm ,

mm

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Elevator

productivity, t/h

|

|

250

|

[12,7H+5αλ(4+1,08H)+

+(37,5+5,4αλ)

cHctgβ]v

|

[13,5H+5αλ

(4+1,08H)+

+(38,3+5,4αλ)

cHctgβ]v

|

[14,3H+5αλ

(4+1,08H)+

+(39,1+5,4αλ)

cHctgβ]v

|

[15,1H+5αλ

(4+1,08H)+

+(39,9+5,4αλ)

cHctgβ]v

|

3,5α

|

|

320

|

[22,1H+8αλ

(4+1,08H)+

+(46,9+8,6αλ)

cHctgβ]v

|

[23,2H+8αλ

(4+1,08H)+

+(48+8,6αλ)

cHctgβ]v

|

[24,2H+8αλ

(4+1,08H)+

+(49+8,6αλ)

cHctgβ]v

|

[25,3H+8αλ

(4+1,08H)+

+(50,1+8,6αλ)

cHctgβ]v

|

5,4α

|

|

400

|

[39,4H+12,6αλ(4+1,08H)

+(70,4+13,6αλ)

cHctgβ]v

|

[40,8H+12,6αλ(4+1,08H)

+(71,8+13,6αλ)

cHctgβ]v

|

[42,1H+12,6αλ(4+1,08H)

+(73,1+13,6αλ)

cHctgβ]v

|

[43,5H+12,6αλ(4+1,08H)

+(74,5+13,6αλ)

cHctgβ]v

|

8,4α

|

Findings

Let us

analyze the influence of design parameters of inclined bucket

elevator for transportation of fine coal on the power of required

drive. Taking into account the physical and mechanical properties of

fine coal according to the recommendations presented in the work [9]

it was selected the belt elevator with spaced deep buckets and

centrifugal discharge. The speed of belt movement is

m/s;

fill factor of the bucket

m/s;

fill factor of the bucket ;

t/m3

–density of

fine coal; lift height of the cargo

;

t/m3

–density of

fine coal; lift height of the cargo

m; inclination angle of elevator to the

horizontal

m; inclination angle of elevator to the

horizontal

.

.

Under these

conditions the

coefficient are:

(t m/l h);

(t m/l h);

. (N/m)

. (N/m)

At this

the dependence

of calculated

power of electric

engine of the elevator’s

bucket on the design performance is

given in the

Table 22:

Table

22

Calculated

power of the engine at deep buckets

|

Bucket

width

,

mm ,

mm

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Elevator

productivity, t/h

|

|

100

|

520

|

533

|

543

|

555

|

4.61

|

|

125

|

614

|

627

|

651

|

670

|

6

|

|

160

|

899

|

918

|

934

|

953

|

9.22

|

|

200

|

1438

|

1457

|

1480

|

1502

|

14.9

|

|

250

|

2158

|

2184

|

2210

|

2239

|

23.1

|

|

320

|

3306

|

3341

|

3373

|

3409

|

36.9

|

|

400

|

5452.5

|

5493

|

5538

|

5588

|

58.1

|

End of table 22

|

Bucket

width

,

mm ,

mm

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Engine

power at the belt with

,

W ,

W

|

Elevator

productivity, t/h

|

|

500

|

7935

|

7988

|

8045

|

8109

|

87.6

|

|

650

|

11533

|

11603

|

11673

|

11746

|

131.8

|

|

800

|

15251

|

15341

|

15430

|

15519

|

184.4

|

|

1000

|

20939

|

21039

|

21144

|

21261

|

259.3

|

Taking into

account standard values

of power of

three-phase asynchronous squirrel cage

motors of 4A

series with

synchronous frequency of rotation 1000 rev/min for

the drive of

inclined elevator for

transportation of fine coal

it was compiled the table

of correspondence of design performance

and the required engine power.

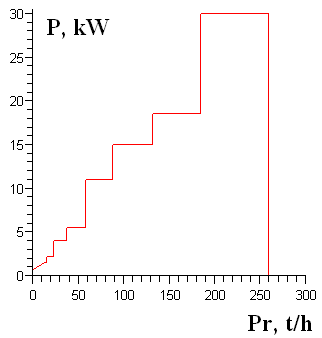

Analyzing results of

calculations presented in the Table 23 it can be concluded that the

dependence of elevator drive power on its design performance (at

fixed lift height, type of cargo, the angle of inclination to

horizontal) in general is a piecewise constant monotonically

increasing function. At this the productivity values given in the

last column of the Table 23 should be considered as such, in which

the power value varies and is equal to the appropriate value given

in the second column of the Table 23. But to the value of 4.61 t/h

the power is 0.75 kW due to the minimum of such power in the engines

of such class. According to calculations it was plotted the

dependence of inclined elevator drive for fine coal transportation

on the value of design productivity (Fig. 3).

To determine

the graphic dependence of elevator drive power on its inclination

angle we take the initial data: transported material – fine coal;

productivity

t/h lift height

t/h lift height

m; speed of the belt movement

m; speed of the belt movement

m/sec.

m/sec.

Taking into

account the fact that

and

and

t/h for calculation of drive power the dependency in the 5th line

and first column will be used (Tab. 20).

t/h for calculation of drive power the dependency in the 5th line

and first column will be used (Tab. 20).

Substituting the initial data

for calculation into resulting dependence we obtain:

. (24)

. (24)

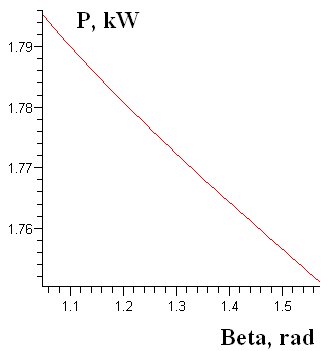

Graphic

dependence of value of elevator drive power when transporting fine

coal with design productivity

t/h on the angle of its inclination within

t/h on the angle of its inclination within

is presented in the Fig. 4.

is presented in the Fig. 4.

Table 23

Engine power at shallow buckets

|

Bucket

width

,

mm ,

mm

|

Engine

power

,

kW ,

kW

|

Engine

type

|

Elevator

productivity, t/h

|

|

100

125

160

200

250

320

400

500

650

800

1000

|

0.75

0.75

1.1

1.5

2.2

4.0

5.5

11.0

15.0

18.5

30

|

4А80А6У3

4А80А6У3

4А80В6У3

4А90L6У3

4А100L6У3

4А112MВ6У3

4А132S6У3

4А160S6У3

4А160M6У3

4А180M6У3

4А200M6У3

|

4.61

6

9.22

14.9

23.1

36.9

58.1

87.6

131.8

184.4

259.3

|

Fig. 3. Dependence of elevator drive power

on the productivity

Fig. 4. Dependence of

elevator drive power

on

the angle of inclination

Originality and practical

value

It was plotted the analytical

dependence of elevator drive power on its design parameters (type

and characteristics of the cargo, lifting height, inclination angle,

productivity), which takes into account the standard sizes and types

of buckets and belts.

Using this dependence makes it

possible rapid determination of the approximate value of drive power

of inclined elevators with deep and shallow buckets and performing

high-quality selection of its key elements at the specific design

characteristics.

Based on the proposed

dependences it was plotted graphic dependence of power influence of

required inclined elevator’s drive on design productivity at the

fixed lift height, inclination angle, and the type of cargo. It was

also presented the graphic dependence of drive power on the

inclination angle of elevator at the other fixed design parameters.

Conclusions

For inclined belt bucket

elevators it was plotted analytical dependence of the drive power

value on its design parameters. This makes it possible to obtain the

required drive power value taking into account the type and physical

and mechanical properties of the cargo, the value of lift height,

inclination angle, design productivity and working conditions,

involving only one calculation formula. As an example of involving

the obtained results it was considered the process of plotting the

dependence of drive power on the design productivity of elevator for

fine coal transportation. For such elevator it was plotted the

parametric and graphic dependence of drive power on design

productivity and inclination angle of elevator taking into account

the standard parameters of buckets and properties of electric

engines. It was established that the function of varying the value

of elevator power on the design productivity (at fixed lifting

height, type of cargo¸ inclination angle) is piecewise and

monotonically increasing, and the dependence of elevator power value

on its inclination angle (at fixed design productivity, lift height,

load type, the speed of belt movement) is non-linear and

monotonically decreasing.

LIST OF REFERENCE LINKS

Александров,

М. П. Подъемно-транспортные

машины : учебник

/ М. П.

Александров. – Москва

: Высш. шк., 2000. – 522 с.

Богомаз,

В. М. Аналіз впливу проектних характеристик

елеватору на параметри його приводу

/ В. М. Богомаз // Наука та прогрес

транспорту. – 2015. – № 3 (57). – С.

162–175. doi:

10.15802/stp2015/46076.

Богомаз,

В. М. Дослідження впливу проектної

продуктивності елеватору на потужність

його приводу / В. М. Богомаз, К. Ц.

Главацький, О. А. Мазур // Наука та

прогрес транспорту. – 2015. – № 2 (56). –

С. 189–206. doi: 10.15802/stp2015/42178.

Богомаз,

В. М. Дослідження залежності

потужності приводу стрічкового конвеєру

від його проектних параметрів / В.

М. Богомаз // Наука та

прогрес транспорту. – 2016. – № 1 (61). –

С. 131–146. doi: 10.15802/stp2016/61024.

Зенков,

Р. Л. Машины непрерывного

транспорта : учебник

/ Р. Л. Зенков, И. И. Ивашков, Л. Н.

Колобов. – Москва : Машиностроение,

1987. – 432 с.

Іванченко,

Ф. К. Підйомно-транспортні машини :

підручник / Ф. К. Іванченко. – Київ :

Вища шк., 1993. – 413 с.

Катрюк,

И. С. Машины непрерывного

транспорта. Конструкции, проектирование

и эксплуатация : учеб.

пособие / И.

С. Катрюк, Е. В.

Мусияченко. – Красноярск :

ИПЦ КГТУ, 2006. – 266 с.

Кузьмин,

А. В. Справочник по расчетам механизмов

подъемно-транспортных

машин : учеб. пособие. – Минск

: Высш. шк., 1983. – 350 с.

Підйомно-транспортні

машини: розрахунки підіймальних і

транспортувальних машин : підручник

/ В. С. Бондарєв, О. І. Дубинець, М. П.

Колісник [та ін.].

– Київ : Вища шк., 2009. – 734 с.

Ракша,

С. В. Аналіз впливу пружних деформацій

несучого каната на зусилля в тяговому

канаті підвісної дороги / С. В. Ракша,

Ю. К. Горячов, О. С. Куроп’ятник // Наука

та прогрес транспорту. – 2013. – № 6 (48).

– С. 110–119. doi:

10.15802/stp2013/19686.

Расчет

и проектирование транспортных средств

непрерывного действия :

науч. пособие для вузов / А. И. Барышев,

В. А. Будишевский, А. А. Сулима, А. М.

Ткачук. – Донецк : Норд-Пресс, 2005. – 689

с.

Ромакин,

Н. Е. Машины непрерывного транспорта

: учеб. пособие / Н. Е. Ромакин.

– Москва : Издательский дом «Академия»,

2008. – 432 с.

Askari,

H. Nonlinear Oscillations Analysis of the Elevator Cable in a Drum

Drive Elevator System / H. Askari, D. Younesian, Z. Saadatnia

// Advances in Applied Mathematics and

Mechanics. – 2015.

– Vol. 7. – Iss. 01. – P. 43–57.

doi: 10.4208/aamm.2013.m225.

Failure

Analysis on Conveyer Chain Links of a Central Bucket Elevator /

J. Yin, O. Muvengei, J. Kihiu, K. Njoroge / J. of Mechanical and

Civil Engineering. – 2016.

– Vol. 13. –

Iss. 04. – P. 56–63.

doi: 10.9790/1684-1304075663.

Li,

S. C. Study on Elevator Drive System Dynamics Simulation of Rail

Transport Conveyer / S. C. Li, X. J. Wang // Applied Mechanics and

Materials. –

2014. – Vol.

511–512. –

P. 619–622.

doi:

10.4028/www.scientific.net/amm.511-512.619.

В. М. Богомаз1*,

М. В. БОРЕНКО2*,

С. В. ПАЦАНОВСЬКИЙ3*,

О. О. ТКАЧОВ4*

1*Каф.

«Військова підготовка спеціалістів

Державної спеціальної служби транспорту»,

Дніпропетровський

національний

університет залізничного транспорту

імені академіка В. Лазаряна, вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (056) 373 19 09, ел. пошта wbogomas@i.ua, ORCID

0000-0001-5913-2671

2*Каф.

«Військова підготовка спеціалістів

Державної спеціальної служби транспорту»,

Дніпропетровський

національний

університет залізничного транспорту

імені академіка В. Лазаряна, вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (056) 373 19 09, ел. пошта bmw1961@ukr.net, ORCID

0000-0001-9578-3906

3*Каф.

«Військова підготовка спеціалістів

Державної спеціальної служби транспорту»,

Дніпропетровський

національний

університет залізничного транспорту

імені академіка В. Лазаряна, вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (056) 373 19 09, ел. пошта psven68@i.ua, ORCID

0000-0002-1628-3733