ISSN

2307-3489 (Print), ISSN 2307-6666 (Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного

університету залізничного транспорту,

2016, № 4

ЗАЛІЗНИЧНА

КОЛІЯ

UDC

625.141.54:625.172

N.

P.

NASTECHIK1,

R. V. MARCUL2*

1Dep.

«Track

and Track Facilities»,

Dnipropetrovsk

National University of Railway Transport named after Academician V.

Lazaryan, Lazaryan St., 2, Dnipro, Ukraine, 49010, tel. +38

(056)

373

15

31,

е–mail

nastechik_mp@mail.ru,

ORCID

0000-0002-4178-6092

2*Dep.

«Track

and Track Facilities»,

Dnipropetrovsk

National University of Railway Transport named after Academician V.

Lazaryan, Lazaryan St., 2, Dnipro, Ukraine, 49010, tel. +38

(056)

373

15

31,

е–mail

guaranga_mr@mail.ru,

ORCID

0000-0002-7630-8963

PROSPECTS

FOR LAYING THE FASTENING

OF THE TYPE СКД65 - Б IN THE CURVESD

TRACK SECTIONS WITH SMALL RADIUS

Purpose.

To

date, according to the order of Ukrzaliznytsia it was decided to

fully transit the main tracks to the concrete sleepers. The reason

for this is the lack of wooden sleepers, their high cost and low

lifetime that in the curved track sections with the radius R≤300 m

is only 5-7 years (this is 5 times less than the lifetime of concrete

sleepers).

After introduction of fastening type СКД65-Б it is possible to

smoothly expand the track from 0 mm to 14 mm, and to narrow from

0 mm to 28 mm with a step 1 mm. At the increased train

load on the track of 75...130 kN in a horizontal plane, which is

characteristic for the curved track sections R≤300 m the

violations in terms of track geometry often take place. It results in

the frequent surfacings, periodicity of which at the fastening type

СКД65-Б is absent for today. Therefore the purpose of the article

is the development of recommendations concerning maintenance of the

track in a plan with the fastening type СКД65-Б. Methodology.

The

methodology of research is based on the comparative estimation of

influence of the track width change dynamics on the periodicity of

surfacing in the plan in the case of the use of fastening type ДО

and СКД65-Б.

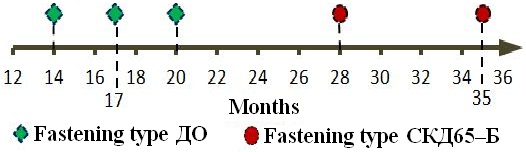

Findings.

With the help of the developed research methodology it was

established that the first implementation of adjusting the track

width at fastening type ДО is necessary to be executed on the 14th

month and at the fastening type СКД65-Б on the 28th

month of operation.

Originality.

It was first described and expressed using the empiric dependence the

process of the track width change, and periodicity of its adjusting

in the case of the fastening type СКД65-Б use. Practical

value.

The developed recommendations will allow in time to execute adjusting

of the track width at fastening type СКД65-Б and ensuring the

safety of train motion at the same time.

Keywords:

fastening

type

СКД65-Б; track width; adjusting of track width; maintenance of

track in plan

Introduction

Increase

in the train speeds, axial loading at the Ukrainian railways

requires increase in the strength and stability of the railway

track. Today, in the vast majority of cases in small radius curves,

especially in the areas of Lviv railway it is operated the track

with wooden sleepers and fastening type ДО.

In

the initial stages of operation the track on wooden sleepers has

little stiffness that provides three-dimensional elasticity of the

track superstructure (hereinafter TS) elements at the simultaneous

perception of both vertical and horizontal dynamic forces from the

rolling stock. During the maintenance work wooden sleeper, unlike

the concrete sleepers, undergoes rapid replacement with the new one

without significant labor costs.

Despite

the advantages, wooden sleepers have several disadvantages that make

economically unprofitable their use. The

reason for this is the lack of wooden sleepers, their high cost and

low lifetime that in the curved track sections with the radius

R≤300 m is only 5-7 years. This is 5 times less than the

lifetime of concrete sleepers

[10].

During

operation of the railway track in the curved sections of small

radius with wooden sleepers and fastening type ДО

the rail thread thrust occurs. It leads to the deviations from the

tolerances

of rail

track width [6,

12].

When the track width exceeds the tolerances it is necessary to carry

out regaging, which largely affects the life of wooden sleepers.

Production

of sleepers of softwood species also results in the fact that in the

short term the metal baseplate, which is the element of the

fastening type ДО,

cuts into the wood fibers [3-6,

10, 12-15].

During production of wooden sleepers their manufacturing technology

based on insufficient seepage is violated. This leads to sleeper

rotting and reduction in its operating lifetime in the track [12].

To

date, according to the order of Ukrzaliznytsia it was decided to

fully transit the main tracks to the concrete sleepers.

To

date, according to the order of Ukrzaliznytsia there is a tendency

to transition to the concrete sleepers in curves of small radius, in

connection with the increased speed of trains, axial loads and

freight traffic on the railway. At the same time the increase in

strength and stability of railway track is required.

With

the fastening type СКД65-Б

(Fig.

1) [1,

7],

there is a possibility to use the concrete sleepers in curved track

sections of small radius without construction modification of the

sleeper type of Ш1-1.

The use of concrete sleepers and fastening type СКД65-Б

makes it possible to avoid many of the problems arising in the

railway track on wooden sleepers with the fastening type ДО.

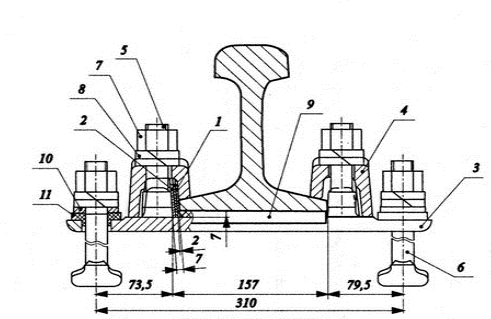

Fig.

1. The СКД65-Б type of fastening

1

-

аdjusting card,

2 mm width (two items);

2

- аdjusting card, 3 mm width (one item);

3

- plate 2КБЛ65;

4

-

terminal ПКЛ;

5

-

terminal bolt;

6

-

insert bolt; 7

-

screw nut;

8:

double coil washer; 9

-

plate ПРБ-4;

10

-

plain washer ШП-1.1;

11

-

insulating sleeve

At

the fastening type СКД65-Б it is allowed to build into the

curves of radius between 450 m to 200 m

concrete sleepers with distribution diagram of sleeper laying 1.840

units/km. At this the fastening СКД65-Б

ensures

a smooth transition of width in the transition curves for expansion

from 0 mm to 14 mm and narrowing from 0 mm to 28 mm. In a circular

curve using the fastening type СКД65-Б

one

can set the pattern 1534 mm using the concrete sleepers of type Ш1-1

according to the works [1,

7, 16].

At

the increased train load on the track of 75...130 kN in a

horizontal plane, which is characteristic for the curved track

sections R≤300 m the violations in terms of track geometry

often take place [9].

It results in the frequent surfacings, the periodicity of which at

the fastening type СКД65-Б is absent for today. Therefore the

purpose of the article is the development of recommendations

concerning maintenance of the track in a plan with the fastening

type СКД65-Б.

Purpose

Therefore

the purpose of the article is the development of methods and

recommendations concerning maintenance of the track in a plan with

the fastening type СКД65-Б.

Methodology

The

methodology of research is based on the comparative estimation of

influence of the track width change dynamics on the periodicity of

surfacing in the plan and adjusting of its width at the fastening

type ДО and СКД65-Б.

In

2015, on one of the Ukrainian railways two curved track sections

with the radius of 350 m were chosen. At the one track section was

laid the track panel (further TP) with wooden sleepers and fastening

ДО,

and the second TP with the concrete sleepers and fastening СКД65-Б.

The width measurements were executed after laying of two TP for five

months, every 10 meters along the length of the curve.

When

performing the measurements on each of the sections there were

studied various additional factors, the probability of which can

affect the process of changing the width of the rail track.

At

TP with wooden sleepers it was observed the influence of such

factors as side wear of the outer railway line, sloping caused by

indentation of metal baseplate into the wooden sleeper. At TP with

concrete sleepers it was mainly observed the change of track width

due to the side wear of the outer railway line.

Using

the obtained statistics there were determined the average values of

track width change at the type fastening ДО

and

СКД65-Б

in the curve with radius of 350 m over five months, which are

presented in the Table 1.

Table

1

Mean

values of track width for each month

-

|

Fastening

type in the curve

|

Mean

value of the track width,

mm

|

|

November

|

December

|

January

|

February

|

March

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

ДО

|

1529.35

|

1529.76

|

1530.35

|

1531.06

|

1531.71

|

|

СКД65-Б

|

1531

|

1531.24

|

1531.47

|

1531.71

|

1531.94

|

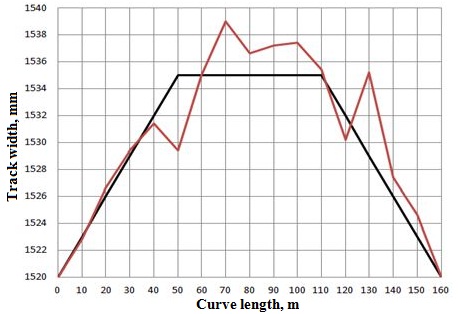

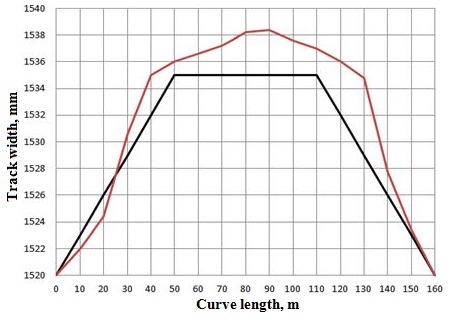

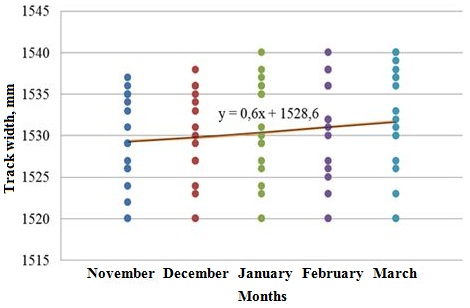

Mean values

of the track width change at the two track sections with the

fastening type ДО

and

СКД65-Б

during five months of operation are shown in the Fig. 2-3.

Fig.

2. Change of track width at fastening of

type

ДО

for five months

According to

the two-factor dispersion analysis [8] taking into account the above

mentioned impacts, it was established the criterion of influence «F»

on the track width change:

Observation

results of the track width change at the track sections with the

fastening type ДО

and

СКД65-Б,

depending on the time parameter, presented as coordinate pair ''х''

and

''у''

were approximated [8] (Fig. 4-5 ).

Fig.

3.

Change

of track width at fastening of

type

СКД65-Б

for five months

According to

the approximation results in the Fig. 4-5 one can clearly see that

the change of the track width with the fastening type ДО

and

СКД65-Б

is linear, which can be described by the function:

where

- are

the constant parameters.

- are

the constant parameters.

Function

parameters (1) using the method of least squares [8] can be

described by the following set of equations:

where

- are

the measured coordinates of the

- are

the measured coordinates of the

-th

point;

n- is

the

number of points with measured

coordinates.

-th

point;

n- is

the

number of points with measured

coordinates.

Fig.

4. Change of track width at fastening of type ДО

Fig.

5.

Change

of track width at fastening of type СКД65-Б

Recommendations

concerning the frequency of track width adjustment

On the basis

of the work [11] the state of track upon the condition of its

expansion according to the tape of track measurement car is

evaluated in points. According to our case for the studied track

sections with radius

,

the track state according to the width based on evaluation scores

will be fined:

,

the track state according to the width based on evaluation scores

will be fined:

According to

the obtained function (1) it was determined the time, when the track

regaging (with the fastening type ДО)

and track width adjusting (with the fastening type СКД65-Б)

should be carried out. For clarity the frequency diagram of track

width adjustment in the curve radius of 350 m with two types of

fastening was constructed (Fig. 6).

Fig.

6. Frequency of adjusting the track width of

in

the curve of R=350 m at fastenings

of

type ДО

and

СКД65-Б

This

diagram shows that after the first track width adjustment at the

section with fastening type ДО,

the next adjustment is carried out every three months and at the

curve with fastening type СКД65-Б

every 7 months.

According to

the papers [7, 8] at the TP with wooden sleepers the spike fastening

holes already broken after the third regaging this almost eliminates

a tight pressing of rail to the rail seat using the spikes.

The proposed

methodology of periodicity of the track width adjusting upon the

condition of its widening at the fastening type ДО

and

СКД65-Б was

based not on the complete elimination of widening but on the

bringing to the appropriate state of retreat from the existing

state, where the evaluation in points, at which the section will be

fined that was the part of the range "good".

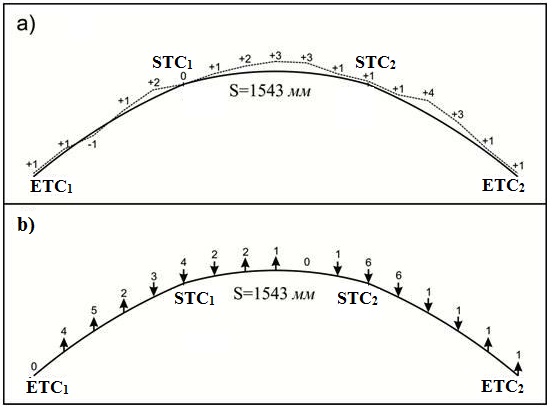

Based on the

above mentioned data, and methodology track maintenance upon the

condition of its widening, it is proposed to adjust the width of the

track when using the intermediate rail fastening of type ДО

and

СКД65-Б under

the schemes presented in the Figures 7-8.

Fig.7.

Adjusting of track width in the studied curve with fastening of type

ДО

Fig. 8.

Adjusting of track width in the

studied

curve with fastening of type СКД65-Б

The Figures

7a and 8a show the existing condition dashed line of the track width

in curves with the dashed line, and the project condition with the

solid line. The numbers show by how many millimeters the existing

track width is greater (+) or less (-) than the project one. The

arrows up or down in the Figures 7b and 8b show how it is necessary

to expand or narrow the track (in mm) during operation of the

railway track with the fastening type ДО

and

СКД65-Б.

Technical

and economic efficiency of the proposed recommendations

A separate

challenge was to determine the technical and economic efficiency

from laying the railway track construction with concrete sleepers in

curves of small radius with fastening type СКД65-Б,

as compared to the railway track with wooden sleepers and fastening

of type ДО.

During the

studies it was used a methodology, which allows to analyze the

cost-effectiveness of TS variant throughout the repair interval of

operation [2]. This methodology is based on the analysis of total

reduced costs:

where

Кі

– are

the capital investments

for

laying of і-th

variant of track design,UAH/km (the cost for capital

repairs of the track);

Еti

–

is the

annual operating costs of the i-th variant,

UAH/km

per year;

Сі

– is

the simultaneous

costs (for

complex and recreational medium and other repairs) on the i-th in

each year tі,

UAH/km;

tі

– is

the year, in which the costs are determined;

tкр

– is

the lifetime

of the

most

long-term variant

of the track construction;

ηt

– is

the cost reduction coefficient of (discount coefficient).

The cost

reduction coefficient is determined by the following formula:

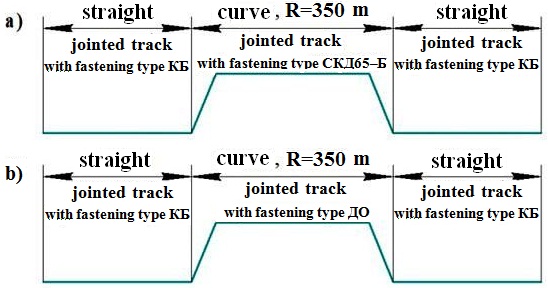

The

calculation methodology was based on the calculation of one

kilometer of track consisting of curves and straight sections.

During calculations the most optimal variants of the track

construction from the following ones were accepted (Fig. 9):

Fig.

9 Possible variants of track construction replacement

а)

variant

1; b)

variant

2

Labor costs

are determined by the expression:

where

- is

the hourly tariff rate corresponding to the fourth category;

- is

the hourly tariff rate corresponding to the fourth category;

- is

the

total number of elements

that are

changed

at different current repairs and maintenance;

- is

the

total number of elements

that are

changed

at different current repairs and maintenance;

-

is

the time required for replacement of the і- th element og

TS.

-

is

the time required for replacement of the і- th element og

TS.

The

cost of materials is determined by the expression:

where

is

and cost of the і-th

element of the TS.

is

and cost of the і-th

element of the TS.

Chart of the

total reduced costs that makes it possible to determine the payback

period of laying the track construction with the fastening type

СКД65-Б

as

compared to the construction of the track with the fastening type ДО

is

shown in the Fig. 10.

Fig.

10 Chart of the total reduced maintenance costs of railway track

with fastening of

type

ДО and СКД65-Б

From the

graph of total reduced costs (Fig. 10) it was established that the

savings for 1 km railway track when laying the concrete sleepers in

the curve of radius 350 m with the fastening type СКД65-Б

is

31.5%. This is mainly due to the reduction of the time required to

perform the works at the current maintenance and material savings of

TS.

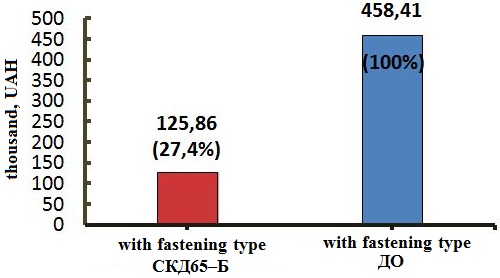

At the

current maintenance of one kilometer of railway track with

intermediate rail fastening of the type СКД65-Б

the annual saving is 72.6% of the costs for existing regulations of

maintenance (wooden sleepers, fastening type ДО),

which is shown in the Fig. 11.

Fig.

11 The economic effect of the current maintenance of 1 km of railway

track

When laying

the concrete sleepers in curves with radius less than 350 m with the

fastening of the type СКД65-Б

according to the above mentioned studies it is reduced the number

regagings and adjustings of the rail track width.

Thus, the

number of regagings for the entire turnaround time (27 years, 800

mln. tons gross) is approximately:

Findings

Using the

above mentioned studies it was found that the frequency of rail

track width adjustment in the curve with radius of 350 m at the

intermediate rail fastening СКД65-Б

is twofold reduced as opposed to the fastening type ДО.

The railway track width adjustment with the fastening type ДО

is required on the 14th month and with the fastening of СКД65-Б

type on the 28th month of the railway track operation.

Originality

and

practical

value

For the first

time it was comprehensively studied, described and expressed by the

empirical dependence the process of changing the track width and the

frequency of its adjustment in the case of fastening type

СКД65-Б.

Presented

preliminary studies and recommendations make it possible to perform

rail track width adjustment with the fastening of type СКД65-Б

in time. This will partly prevent and eliminate further development

defects of the rail track in plan occurring during its operation

with simultaneous ensuring the safety of train motion.

Conclusions

The work

represents the studies, which are based on comparative assessment of

the influence of the track width change on the periodicity of

correction and adjusting its width at the fastening of type ДО,

and СКД65-Б.

It was chosen two curved sections of track with curve radius of 350

m. On the one section was laid the TP on wooden sleepers with the

fastening type ДО,

on the second section was the TP on concrete sleepers with the

fastening type СКД65-Б.

The track

width change at the above mentioned railway sections was

investigated within five months of operation. Using the above

mentioned data of the field tests it was for the first time

established the frequency of rail track width adjustment with the

fastening of СКД65-Б type

during operation.

The first

adjustment of track width in the curve radius of 350 m with the

fastening of type СКД65-Б

should be performed at the 28th month of operation (then every 7

months), and with the fastening of type ДО

on wooden sleepers on the 14th month (then every 3 months).

Using the

technical and economic calculations it was established that, unlike

the track structures on wooden sleepers with the fastening type ДО,

in case of laying the concrete sleepers with the fastening type

СКД65-Б the economy for 1 km of railway track for the entire repair interval

is 31.5%. At the current maintenance for 1 km of railway track the

annual economy is 72.6%.

It was

established possible number of the track for width adjustment for

the entire turnaround time (800 mln. tn. gross) with concrete

sleepers and the fastening type СКД65-Б decreased in 59 times.

LIST

OF REFERENCE LINKS

Губар,

О. В. Конструкція скріплення типу

СКД65-Б, можливості його застосування

та визначення ділянки відводу розширення

в межах перехідної кривої / О. В. Губар,

М. П. Настечик // Проблеми та перспективи

розвитку залізн. трансп. : тези доп. 69

Міжнар. наук.-практ. конф. / Дніпропетр.

нац. ун-т залізн. трансп. – Дніпропетровськ,

2009. – С. 155.

Даніленко,

Е. І. Залізнична колія : підруч. для вищ.

навч. закл. : у 2 т. / Е. І. Даніленко. –

Киів : Інпрес, 2010. – Т. 1. – 528 с.

Каменский,

В. Б. Содержание железнодорожного

пути в кривых / В. Б. Каменский, Э. Я. Шац.

– Москва : Транспорт, 1987. – 189 с.

Лысюк,

В. С. Износ деревянных шпал и борьба с

ним / В. С. Лысюк // Тр. ЦНИИ МПС. –

Москва : Транспорт, 1971. – Вып. 445. – С.

3–220.

Лысюк,

В. С. Экспериментальные исследования

сопротивления рельсовой нити распору

в условиях обращения тяжеловесных

поездов / В. С. Лысюк, А. В. Переслечин,

Е. В. Суворов

// Скорости движения поездов в кривых

: сб.

науч. тр. /

ВНИИЖТ. –

Москва : Транспорт, 1988. – С. 50–60.

Пат.

31032 Україна, МПК7

Е 01 В 9/44 Рейкове скріплення / О. В. Губар

М. П. Настечик, П. В. Рагулін, В. В. Рибкін,

К. В. Корноухова, В. О. Яковлев.

–№ 200712086 ; заявл. 01.11.2007 ; опубл.

25.03.2008, Бюл. № 6. – 3 с.

Рибкін,

В. В. Надійність залізничної колії :

навч. посіб. / В. В. Рибкін, І. О.

Бондаренко, Д. М. Курган. – Дніпропетровськ

: ДНУЗТ, 2013. – 154 с.

Рибкін,

В. В. Оцінка впливу величини

бічної-горизонтальної сили, що

передається на вузол проміжного

рейкового скріплення типу КБ та

КПП-5

/ В. В. Рибкін, І. О. Бондаренко, Р. В. Маркуль

/ Проблеми взаємодії колії та рухомого

складу : пр. Міжнар. наук.-практ. конф.,

присв. 100-річчю проф. М. А. Фрішмана /

Дніпропетр. нац. ун-т залізн. трансп. –

Дніпропетровськ, 2013. – С. 38–39.

Рыбкин,

В. В. Исследование вопросов внедрения

конструкции бесстыкового пути на

железобетонных шпалах в кривых радиусом

R≤350 м

/ В. В. Рыбкин, Н. П. Настечик,

Р. В. Маркуль

// Тр. X-ой науч.-техн. конф. с междунар.

участием / Моск. гос. ун-т путей сообщ.

– Москва, 2013.

– С. 198–201.

Технічні

вказівки щодо оцінки стану рейкової

колії за показниками колієвимірювальних

вагонів та забезпечення безпеки руху

поїздів при відступах від норм утримання

рейкової колії : затв. наказом Укрзалізниці

№ 033 Ц від 01.02.2012. – Киів : М-во

інфраструктури України, 2012. – 48 с.

Фришман,

М. А. Как работает путь под поездами /

М. А. Фришман. – 4-е изд., перераб. и доп.

– Москва : Транспорт, 1987.

– 189 с.

Яхов,

О. П. Особенности перешивки колеи на

старогодных шпалах при проведении

унификации ширины колеи / М. С. Яхов, О.

П. Ершков // Тр. ВНИИЖТа.

– Москва, 1960. – Вып.

192

: Ершков

О. П.

Расчеты железнодорожного пути в кривых

и нормы его устройства / О. П. Ершков,

Л. П. Мелентьев, М. С. Яхов. – С. 146–149.

Ahlf,

R. Matching M/W practice to require use of track / R. Ahlf // J. RT

& S (Railway Track & Structures). – New York, 2016. –

Vol. 10. – P. 2–3.

Baluch,

H. Diagnostyka nawierzchni kolejowej / H. Baluch. – Warszawa :

Wydawnictwa komunikacji i lacznosgi, 1978. – 415 p.

Lichtberger,

B. Track Compendium. Formation, Permanent Way, Maintenance,

Economic / B. Lichtberger. – Hamburg : Eurailpress, 2005. –

634 p.

Rybkin,

V.

V.

Stability

issues

of

the

continuous

welded

rail

track

on

the

concrete

sleepers

on

the

curves

with

radius

R≤300

m.

/ V.

V.

Rybkin

N.

P.

Nastechik,

R. V. Markul

//

Sciences

in

Cold

and

Arid

Region.

–

2013.

–

Vol.

5.

–

Iss.

5. –

P. 654–658. doi: 10.3724/SP.J.1226.2013.00654.

М.

П. НАСТЕЧИК1,

Р. В. МАРКУЛЬ2*

1Каф.

«Колія

та колійне господарство», Дніпропетровський

національний університет залізничного

транспорту імені академіка В. Лазаряна,

вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (056) 373 15 31, ел. пошта nastechik_mp@mail.ru, ORCID

0000-0002-4178-6092

2*Каф.

«Колія

та колійне господарство», Дніпропетровський

національний університет залізничного

транспорту імені академіка В. Лазаряна,

вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (056) 373 15 31, ел. пошта guaranga_mr@mail.ru,

ORCID

0000-0002-7630-8963

ПЕРСПЕКТИВИ

УКЛАДАННЯ СКРІПЛЕННЯ ТИПУ

СКД 65-Б В

КРИВИХ ДІЛЯНКАХ КОЛІЇ МАЛОГО РАДІУСА

Мета.

На

сьогоднішній день згідно наказу

Укрзалізниці прийнято рішення щодо

повного переходу головних колій на

залізобетонні шпали. Причиною цього є

дефіцит дерев'яних шпал, їх висока

вартість та низький термін служби, що

в кривих ділянках колії радіусом R≤300 м

складає всього 5–7 років (це у 5 разів

менше строку служби залізобетонних

шпал). Із впровадженням скріплення типу

СКД65-Б з’явилась можливість плавно

розширювати колію від 0 мм до 14 мм

та звузити – від 0 мм до 28 мм із

кроком 1 мм. При збільшеному поїзному

навантаженні на колію 75…130 кН в

горизонтальній площині, що характерно

для кривих ділянок колії R≤300 м,

часто відбуваються порушення геометрії

колії у плані. Це призводить до частих

виправок, періодичність проведення

яких при скріпленні типу СКД65-Б на

сьогоднішній день відсутня. Тому метою

статті є розробка рекомендацій щодо

утримання рейкової колії у плані зі

скріпленням типу СКД65-Б. Методика.

В

основі методики проведення досліджень

лежить порівняльна оцінка впливу

динаміки зміни ширини рейкової колії

на періодичність виконання виправки

її в плані у випадку використання

скріплення типу ДО та СКД65-Б. Результати.

За допомогою розробленої методики

досліджень було встановлено, що перше

регулювання ширини рейкової колії при

скріпленні типу ДО необхідно виконувати

уже на 14-ий місяць, а при скріпленні

типу СКД65-Б – на 28-ий місяць експлуатації.

Наукова

новизна. Вперше

було описано та виражено емпіричною

залежністю процес зміни ширини рейкової

колії та періодичність виконання її

регулювання у випадку використання

скріплення типуСКД65-Б.

Практична

значимість. Розроблені

авторами рекомендації дозволять вчасно

виконувати регулювання ширини рейкової

колії при скріпленні типу СКД65-Б і

одночасно забезпечують безпеку руху

поїздів.

Ключові

слова:

скріплення типу СКД65-Б; ширина колії;

регулювання ширини колії, утримання

колії у план

іН.

П. НАСТЕЧИК1,

Р. В. МАРКУЛЬ2*

1Каф.

«Путь и путевое хозяйство», Днепропетровский

национальный

университет

железнодорожного

транспорта

имени

академика

В.

Лазаряна,

ул.

Лазаряна,

2,

Днипро,

Украина,

49010,

тел.

+38

(056)

373

15

31,

эл. почта

nastechik_mp@mail.ru,

ORCID

0000-0002-4178-6092

2*Каф.

«Путь и путевое хозяйство», Днепропетровский

национальный

университет

железнодорожного

транспорта

имени

академика

В.

Лазаряна,

ул.

Лазаряна,

2,

Днипро,

Украина,

49010,

тел.

+38

(056)

373

15

31,

эл. почта

guaranga_mr@mail.ru,

ORCID

0000-0002-7630-8963

ПЕРСПЕКТИВЫ

УКЛАДКИ

СКРЕПЛЕНИЯ ТИПА СКД 65-Б

В

КРИВЫХ УЧАСТКАХ ПУТИ МАЛОГО РАДИУСА

Цель.

На

сегодняшний день согласно приказу

Укрзализныци принято решение о полном

переходе главных путей на железобетонные

шпалы. Причиной этого является дефицит

деревянных шпал, их высокая стоимость

и низкий срок службы, который

в

кривых участках пути радиусом R≤300 м

составляет всего 5–7 лет (что в 5 раз

меньше срока службы железобетонных

шпал).

С

внедрением скрепления типа СКД65-Б

появилась возможность плавно расширять

колею от 0 мм до 14 мм и сузить – от

0 мм до 28 мм с шагом 1 мм. При

увеличенной поездной нагрузке на путь

75...130 кН в горизонтальной плоскости,

что характерно для кривых участков

пути R≤300 м, часто происходят нарушения

геометрии пути в плане. Это приводит к

частым выправкам, периодичность

проведения которых при скреплении типа

СКД65-Б на сегодняшний день отсутствует.

Поэтому целью статьи является разработка

рекомендаций по содержанию рельсовой

колеи в плане со связыванием типа

СКД65-Б. Методика.

В основе методики проведения исследований

лежит сравнительная оценка влияния

динамики изменения ширины рельсовой

колеи на периодичность выполнения

выправки ее в плане в случае использования

скрепления типа ДО и СКД65-Б.

Результаты.

С помощью разработанной методики

исследований было установлено, что

первое регулирование ширины рельсовой

колеи при скреплении типа ДО необходимо

выполнять

уже

на

14-ый месяц,

а при скреплении типа СКД65-Б – на

двадцать восьмой месяц эксплуатации.

Научная

новизна.

Впервые было описано и выражено

эмпирической зависимостью процесс

изменения ширины рельсовой колеи и

периодичность выполнения ее регулирования

в случае использования скрепления типа

СКД65-Б. Практическая

значимость.

Разработанные авторами рекомендации

позволят своевременно выполнять

регулировку ширины рельсовой колеи

при скреплении типа СКД65-Б и одновременно

обеспечивают безопасность движения

поездов.

Ключевые

слова:

скрепление типа СКД65-Б;

ширина колеи;

регулирование

ширины колеи;

содержание пути в плане

REFERENCES

Hubar

O.V.,

Nastechyk

M.P.

Konstruktsiia

skriplennia typu SKD65-B, mozhlyvosti yoho zastosuvannia ta

vyznachennia dilianky vidvodu rozshyrennia v mezhakh perekhidnoi

kryvoi [Fastening

construction

СКД65-Б, possibilities of its

application and determination of area of taking of expansion within

the limits of transitional curve].

Tezy

dopovidei

69 Mizhnarodnoi

naukovo-praktychnoi

konferentsii

«Problemy

ta perspektyvy rozvytku zaliznychnoho

transportu»

[Proc.

of the 69 Int.

Scientific

and

Practical Conf.

«Problems

and prospects

of railway transport development»].

Dnipropetrovsk,

2009, p.

155.

Danilenko

E.I. Zaliznychna

koliia.

Tom 1

[Railway track. Vol. 1]. Kyiv, Inpres Publ., 2010. 528 р

Kamensky

V.B., Shats E.Ya. Soderzhaniye zheleznodorozhnogo puti v krivykh

[Maintenance of railway track in curves]. Moscow, Transport Publ.,

1987. 189 p.

Lysyuk

V.S Iznos derevyannykh shpal i borba s nim [Wear of wooden sleepers

and preventing it]. Trudy

TsNII MPS [Proc.

of the Central Research Institute of Communication Lines Ministry],

1971, vol. 445, pp. 3-220.

Lysyuk

V.S., Pereslechin A.V., Suvorov Ye.V. Eksperimentalnyye

issledovaniya soprotivleniya relsovoy niti rasporu v usloviyakh

obrashcheniya tyazhelovesnykh poezdov [Experimental research of

resistance of the rail thread spacers under conditions of heavy

trains]. Skorosti

dvizheniya poyezdov v krivykh

[Rates of movement of trains in curves]. Moscow, 1988, pp. 50-60.

Hubar

O.V., Nastechyk M.P., Rahulin P.V., Rybkin V.V., Kornoukhova K.V.,

Yakovlev V.O. Reikove

skriplennia

[Rail

fastening].

Patent

UA,

no.

200712086,

2007.

Rybkin

V.V.,

Bondarenko

I.O., Kurhan D.M. Nadiinist zaliznychnoi kolii [Reliability

railway

line].

Dnipropetrovsk, DNURT Publ.,

2013.

154

p.

Rybkin

V.V., Bondarenko I.O., Markul R.V. Otsinka vplyvu velychyny

bichnoi-horyzontalnoi syly, shcho peredaietsia na vuzol promizhnoho

reikovoho skriplennia typu KB ta KPP-5 [Evaluation of the influence

of the horizontal lateral-force transferred to the intermediate

node of the fastening type КБ

and

КПП-5].

pratsi Mizhnarodnoi naukovo-praktychnoi konferentsii, prysviachenoi

100-richchiu profesora M. A. Frishmana «Problemy vzaiemodii kolii

ta rukhomoho skladu» [Proceedings of Int. Scientific-Practical

Conf. "Problems of interaction between the track and rolling

stock", dedicated to the 100th anniversary

of

Professor M. A. Frishman]. Dnipropetrovsk, 2013, pp. 38-39.

Rybkin

V.V.,

Nastechik

N.P.

Markul

R.V.

Issledovaniye

voprosov

vnedreniya

konstruktsii

besstykovogo

puti

na

zhelezobetonnykh

shpalakh

v krivykh radiusom R≤350 m

[Study on

the

introduction of

design

welded

rails

on

concrete sleepers

in

a

curve

with a radius

of

less than 300 m].

Trudy

X-oy nauchno-tekhnicheskoy konferentsii s mezhdunarodnym uchastiyem

[Proc.

of the

X-th

Scientific

Conference

with

international participation].

Moscow,

2013,

pp.

198-201.

Tekhnichni

vkazivky shchodo otsinky stanu reikovoi kolii za pokaznykamy

koliievymiriuvalnykh vahoniv ta zabezpechennia bezpeky rukhu poizdiv

pry vidstupakh vid norm utrymannia reikovoi kolii

[Technical

guidelines

for

assessment

of

rail

track

by

track

measuring

performance

cars

and

ensuring

traffic

safety

in

deviation

from the norms

of

rail

track

maintenance].

Kyiv,

M-vo infrastruktury Ukrainy Publ., 2012. 48

p.

Frishman

M.A. Kak

rabotayet put pod poyezdami

[How works the under trains]. Moscow, Transport Publ., 1987. 189 p.

Yakhov

M.S., Yershkov O.P, Melentyev L.P. Osobennosti pereshivki kolei na

starogodnykh shpalakh pri provedenii unifikatsii shirini kolei

[Peculiarities of regaging the track on the used sleepers during the

unification of track width]. Raschety

zheleznodorozhnogo puti v krivykh i normy yego ustroystva

[Calculations of railway track in curves and norms of its devices].

Moscow, Transport Publ., 1960. pp. 146-149.

Ahlf

R. Matching M/W practice to require use of track. Journal

RT & S (Railway Track & Structures),

2016, vol. 10, pp. 2-3.

Baluch

H. Diagnostyka nawierzchni kolejowej. Warszawa, Wydawnictwa

komunikacji i lacznosgi Publ., 1978. 415 p.

Lichtberger

B. Track Compendium. Formation, Permanent Way, Maintenance,

Economic. Hamburg, Eurailpress Publ., 2005. 634 p.

Rybkin

V.V.,

Nastechik N.P.,

Markul

R.V.

Stability

issues

of

the

continuous

welded

rail

track

on

the

concrete

sleepers

on

the

curves

with

radius

R≤300

m.

Sciences

in

Cold

and

Arid

Region,

2013, vol.

5,

issue 5, pp. 654-658. doi: 10.3724/SP.J.1226.2013.00654.

.

Prof.

V. D. Petrenko, Sc.

Tech. (Ukraine);

Head of Dnipropetrovsk track distance (FC-9): Regional branch of

«Prydniprovsk

Railways»

O. O. Saldyha (Ukraine)

recommended this article to be published

Accessed:

Feb. 05, 2016

Received:

June

02,

2016

©

N.

P.

Nastechik,

R.

V. Marcul

2016