ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2016,

№

3

(63)

транспортне

будівництво

UDC

624.19-022.53:621.643.2-034.14

K. GÓRSKI1*, R. L. IGNATOWICZ2*

1*Institute

of Civil and Geoingeenering, Poznan University

of Life Sciences, ul.

Piątkowska, 94, Poznan, Poland, 60-649,

email

kgorski@up.poznan.pl

2*Dep.

«Metal Structures», Wroclaw University of Technology,

Pl.

Grunwaldzki, 11, Wroclaw, Poland, 50-377,

email

rajmund.ignatowicz@pwr.edu.pl

EFFORT OF STEEL PIPE JACKING IN TERMS

OF

IMPERFECTION PIPES AND

HETEROGENEITY OF GROUND

Purpose. The article presents problem of the

influence of local inhomogeneities of ground on the internal forces

in the steel pipe. Methodology. The authors presented the

differences in the distributions of earth pressures for the pipes.

One of the most common methods is the microtunneling technology. The

examples of numerical analysis by finite element method (FEM) have

been calculated. Findings. The results of numerical analysis

are presented for selected ground conditions and the distribution of

internal forces in the flexible section of the steel pipe is also

shown. Originality and Practical value. The obtained results

clearly show the influence of flexural rigidity of the pipe on the

internal forces, the influence of flexural rigidity and the soil

stiffness on the size of the bending moments in the steel of pipe

jacking. They depend on the interaction of soil – steel pipe.

Keywords: steel pipe; finite element

method; microtunneling; ground

Introduction

Modern

technology construction method of underground pipelines enables

building of sewer pipelines for lengths of over 500 m. It is

possible to make this without disturbing the existing

infrastructure. One of the most common methods is the microtunneling

technology. This technology allows drilling the microtunnel hole by

drilling machine where, after loosening the soil with high-pressure

water, excavated material is transported to the surface of the

ground. The pipe jacking is pressed in place of the removed soil.

This technology and the various methods of calculation are given in

the book [6] and in the article [10]. Microtunnel execution is

preceded by the construction of the starting shaft and receiving

shaft. Before the implementation of microtunnel the full recognition

of geological and engineering on the planned route should be

performed. Unfortunately even that it is not possible to provide all

the possible complications you may encounter during the

implementation of the collector using microtunnelling. Commonly used

methods of static analysis jacking pipes describe the most common

situations without considering exceptional situations such as the

heterogeneity of ground. Such situation is considered by the authors

of the study. The analysis is made for partially realized

microtunnel with a total length of 300 m. The steel pipe has a

diameter of 2 000 mm and thickness of 12 mm. Steel pipe will be

a protective tube for the pipeline made under the river leading to a

large sewage-treatment plant.

Physical

model. In this article an influence

the heterogeneity of soil and a flexural rigidity of the pipe on the

bending moments where presented. In order to solve this problem, it

was divided into two stages. The first stage estimated the force on

the pipe jacking and the second stage included the analysis the

heterogeneity of soil on bending moments. The problem is shown in

Fig. 1.

The loads

acting transversely to the axis of the pipe.

Modern analysis of static tunnels needs to determine static scheme

including the interactions between the soil and pipe jacking. It is

important to choice the characteristics of elastic microtunnel

structures and to determine geotechnical parameters of soil medium.

Microtunnel in selected cross-sections is considered. In order to

perform the analysis the following two distinctive sections were

chosen (Fig. 2).

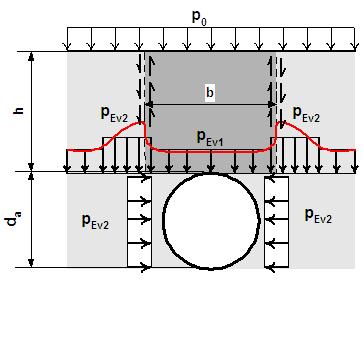

On

the basis of guidelines [1], [5] the load diagram of the steel

pipelines for a microtunnel was adopted which is illustrated in Fig.

3.

Fig. 1. Illustration showing

the reported problem

Fig. 2. The characteristic

sections of computing

According to

various proposals the width of the solid ground was determined. It

was a load on the pipeline. The load induces a state of stress in

the walls of the pipe. It should be noted that the drilling of

microtunnel change the state of stress in the ground. This was

confirmed by the research field and the numerical calculations.

During the drill microtunnel occurs reduction of the load ground on

the pipeline. This is a consequence of loosening the soil in the

area of vaults and transfer loads to the ground on both sides of the

pipe. This phenomenon was studied among others by Terzaghi and

Houskawa based on the theory of the silo. The necessary condition to

reduce the load is large vertical deformation in the key course.

Using appropriate technological solutions in the implementation of

microtunneling seeks to reduce the vertical movements to a minimum,

which results in that only a small portion of the angle of internal

friction is mobilized in the plane of shear. It is known that

already at 10% of the value of the vertical movement is mobilized

half of the angle of friction. This phenomenon allowing appoint an

increased load on the ground in areas of the lateral pipe. According

to silo theory (Terzaghi)

was accepted. The results of calculating the width of the ground

solids of different proposals was illustrated in Fig. 4. The values

of the vertical and horizontal loads were calculated according to

the following relationships.

was accepted. The results of calculating the width of the ground

solids of different proposals was illustrated in Fig. 4. The values

of the vertical and horizontal loads were calculated according to

the following relationships.

Vertical

load acting on the ground pipe

(1)

(1)

Fig. 3. The load diagram

of

the pipelines microtunnel by [5, 1]

Where:

– volume weight of soil overburden conductor;

– reduction factor taking into account the stress distribution

after completing of microtunnel; h

– thickness of the soil on the pipeline.

The

reduction factor

from the expression was determined:

(2)

(2)

where

K1 –

coefficient of earth pressure on the wall of the silo, K11,0;

The

horizontal earth pressure at the height of the key course of the

pipe was calculated by the following expression:

(3)

(3)

Where

(4)

(4)

and

t is the

wall thickness of the pipe, rm

– radius in the middle of the wall

thickness, Ep

is the modulus of elasticity of the pipe material, Es

– the modulus of elasticity of soil.

A common

approach are the guidelines contained in the ATV 161 E [1], so for

numerical analysis the width of the ground solid

b = (3)0.5

× da

was assumed. The load on the Terzaghi assumptions is shown below

(Fig. 5). In the

analysis the distributions of internal forces for the various static

diagrams were compared. The loads for different schemes are

shown below (Fig.6, 7).

Fig. 4. Comparison of the

calculated b by different authors

Fig. 5. The load a

underground pipe with solid ground

Fig.

6. The loads on a underground pipe by Hevett, Schultze,

Volkov

Fig. 7. The loads on a

underground pipe by Bugajeva, Buzgryla, Pytkowski

Fig. 8. The bending

moment in cross-section

from the ground pressure and weight

of the pipe by:

a

− Hevett, b

− Schulze, Volkov, c

− Bugajeva, d

− Buzgryla, Pytkowski

|

Findings

Internal

force diagrams for different schemes are shown below (Fig.8). The

results were compared to the values calculated according to [1],

which is presented in Table 1.

The

presented results of calculations have shown that there are large

differences in the values of the internal forces determined on the

basis of proposals from different authors and they cannot be

directly compared. Differences result directly from the assumptions

regarding the scope and distribution of elastic supports describing

the interaction of soil – pipe. The consequence of these

assumptions is the distribution of soil along the perimeter of the

steel tube, which also generates different distributions of internal

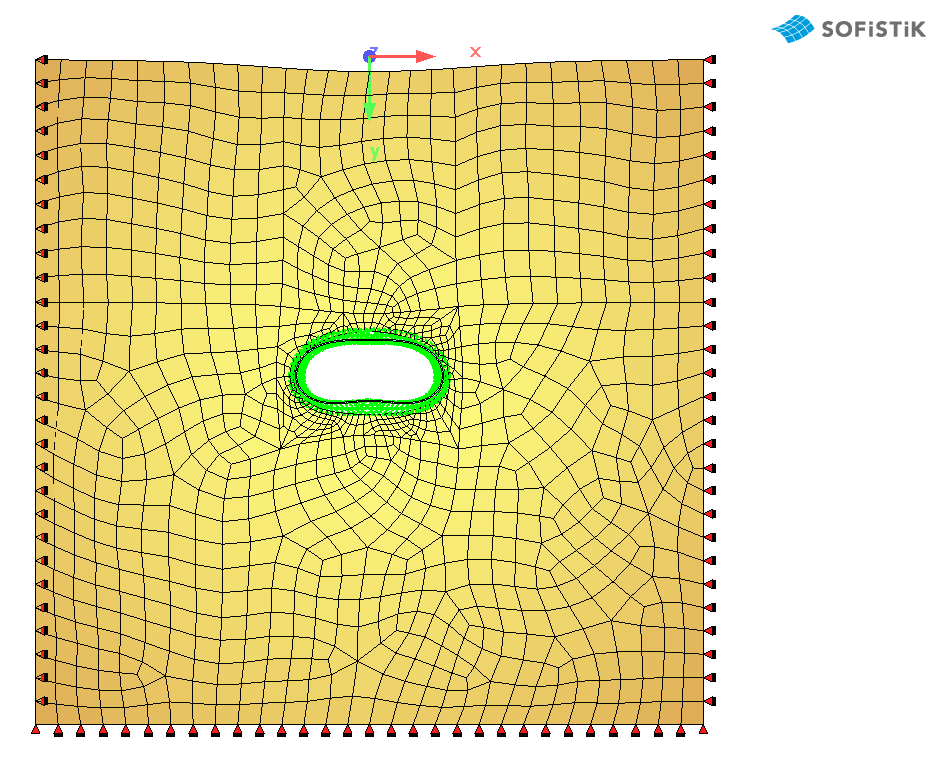

forces. In order to verify the above conclusions, numerical analysis

using finite element modeling system and geotechnical calculations

Sofistik -Talpa [16] were performed. Numerical model was made in the

plane strain. The calculations were made in several stages the state

of stress and strain as the initial condition for the next stage of

the calculation. The model of Coulomb – Mohr’s with

non-associated flow rule in plasticity was calculated. For the

analysis, the following parameters were taken: angle of internal

friction of soil

= 31o,

cohesion cu

= 0 kPa, the volume density of soil

= 18,5 kN/m3.

In the contact zone of the soil – pipe, special contact elements

were used which were assigned a variable

coefficient

of friction. Contact elements do not carry the tensile forces. In

order to take account of the effect of a breach in the soil zone

drilling area, the model is divided into various material

parameters. It allowed to map the loosening of the soil and its

effect on the internal forces in the cross section of the pipe.

Table

1

The

bending moments in the pipe jacking

|

Bending moments

|

ATV 161

|

Hevett

|

Schulze, Volkov

|

Bugajeva

|

Buzgryla, Pytkowski

|

|

|

kNm

|

kNm

|

kNm

|

kNm

|

kNm

|

|

ME1- key course

|

-16,61

|

-13,50

|

7,20

|

-5,10

|

-10,30

|

|

ME2- side wall

|

17,38

|

11,70

|

0

|

0

|

-12,20

|

|

ME3- invert

|

-17,52

|

-9,95

|

2,21

|

-0,63

|

-2,37

|

|

Legend

|

|

Fig. 9. An example of a

numerical (FEM) model

of the interaction of soil – pipe

In

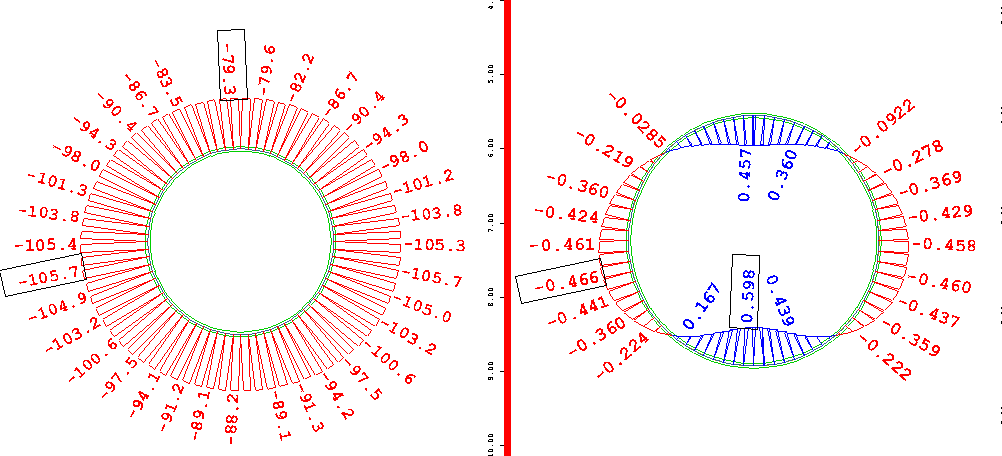

Fig. 10 one can see that the internal forces are significantly

different from the values determined by guidelines [1]. We can

conclude that the graph of internal forces has a similar

distribution as in the proposal Hevetta. In the case of the analysis

the flexural rigidity of the pipe is very important. In order to

grasp this fact, numerical analysis controlling two parameters was

made. First parameter was the change of modulus of elasticity in the

zone of potential loosening of the soil and secend parameter was the

change in the flexural rigidity of pipe. For the analysis of the

interaction pipe – soil has been introduced a replacing flexural

rigidity of the pipe as a function of strain. Vertical displacement

of the pipe was calculated by the theory of second order. It was

shown in the Fig. 13.

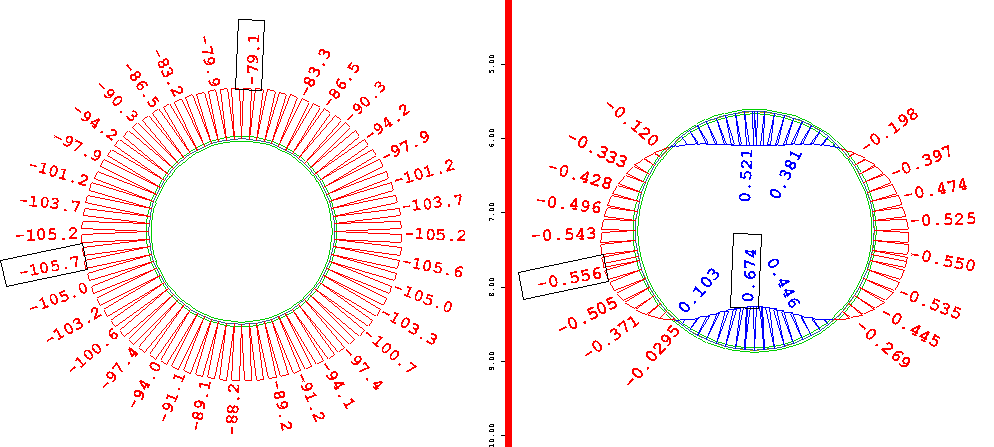

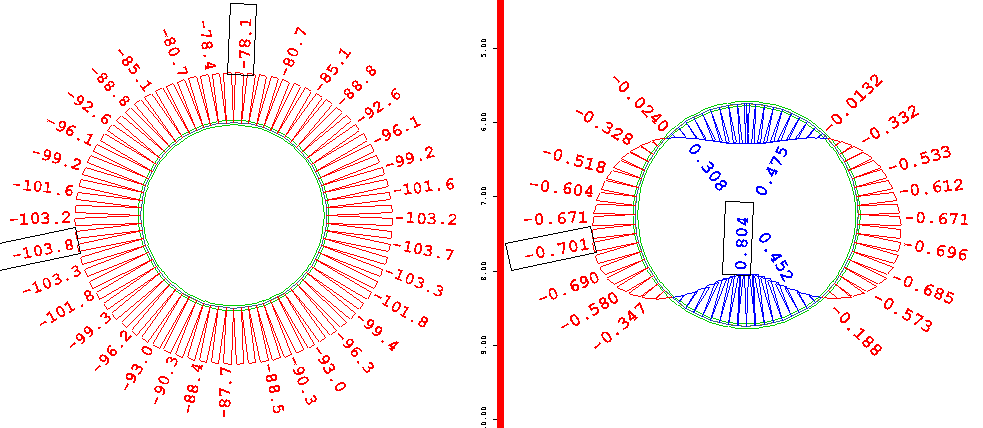

Fig. 10. Internal force

diagrams without loosening of the soil in the area around the pipe,

(E = 100 kPa). Steel pipe Dz = 2500 mm, t = 25 mm

Fig. 11. Internal forces

diagrams without loosening the soil in the area around the pipe,

(E

= 50 kPa). Steel pipe Dz = 2 500 mm, t = 25 mm

Fig. 12. Internal forces diagrams without loosening the

soil in the area around the pipe, (E = 25 kPa).

Steel

pipe Dz = 2500 mm, t = 25 mm

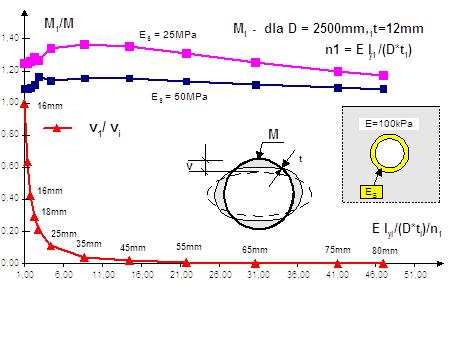

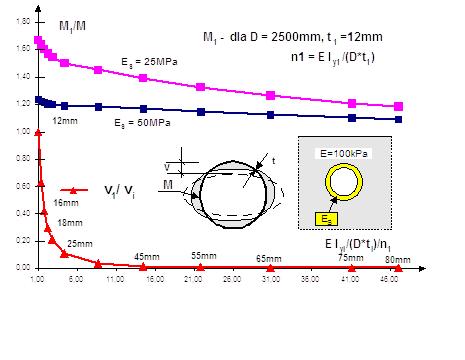

Fig. 13. The replacing flexural rigidity the pipe

Fig. 14. The increment of the

bending moment M in key course as a function

of a

flexural rigidity the steel pipe and soil stiffness

Fig. 15. The increment of the bending moment M

in side wall as a function

of a flexural rigidity the steel pipe

and soil stiffness

The obtained results clearly

show the influence of flexural rigidity of the pipe on the internal

forces. The bending moments in the steel pipe with the wall

thickness between 12 mm – 35 mm are quite different. They are much

smaller than the value calculated on the basis of the guidelines

[1]. The formulas for the bending moments in [1] are independent of

the deformability pipe.

Conclusions

The obtained

results showed the influence of flexural rigidity and the soil

stiffness on the size of the bending moments in the steel of pipe

jacking. They depend on the interaction of soil – steel pipe. On

the basis of Fig.14 with the modulus of elasticity of the soil Es

= 50 MPa, the increase of the bending moment in the key course of

the pipe is practically not variable independently of the wall

thickness of the steel pipe. A similar example was found for bending

moments in the side wall tunnel (Fig. 15). The construction steel

pipe jacking behaves quite different, when the modulus of soil Es

is smaller (Es

= 25 MPa). The increase of the bending moment in the key course

according to the rigidity of the tube can be up to 15% (Fig. 14). In

the case of the increase of the bending moment side wall, it may be

as high as 41.5% (Fig. 15).

LIST OF REFERENCE LINKS

ATV 161 E. Structural calculation

driven pipes :

German ATV Standards Wastewater-Waste. – Hennef : GFA, 1990.

Brzoska, Z. Statyka i stateczność

konstrukcji prętowych i cienkościennych

/ Z.

Brzoska. – War-szawa : PWN, 1961.

Buckling of steel shells

– European Design Recommendations

/ Edited by J. Michael Rotter and Herbert

Schmidt. –

2013.

– 408 р.

Hornung, K. Statik eruberddeckter

Rohde / K. Ho-rnung, D. Kitel. – Berlin

: Bauverlag GMBH, 1989.

Glinicki, S. Budownictwo podziemne / S. Gli-nicki. –

Politechnika Białostocka, 1994.

Madryas, C. Konstrukcje przewodów

kanaliza-cyjnych / C. Madryas, A. Kolonko, L. Wysocki.

– Wrocław : Oficyna Wydawnicza

Politechniki Wrocławskiej, 2002. – 377 p.

Mendera, Z., Interakcyjne kryteria

stateczności płyt i powłok metalowych w złożonych stanach

naprężenia / Z. Mendera // Inżynieria i Budo-wnictwo. – 1993.

– №. 2.

– P. 50–53.

Mendera, Z. Stateczność stalowych

powłok walcowych ściskanych podłużnie / Z.

Mendera // Inżynieria i Budownictwo. –

2000. – №.

4/5. – P.

240–243.

Murzewski, J. Stalowe belki

powłokowe / J. Mur-zewski, J. Siepak.

– Kraków : Politechnika Krakowska, 1978.

Kuliczkowski,

A. Projektowanie konstrukcji prze-wodów kanalizacyjnych. –

Kielce : Politechnika Świętokrzyska, 1993. – W.

I, №.

222. – 290 p.

PN-EN 1991-1-3:2005.

Eurokod 1.

Oddziaływania na konstrukcje. Część 1–3

: Oddziaływania ogólne.

Obciążenie śniegiem.

PN-EN 1993-1-5.

Projektowanie konstrukcji stalowych. Część 1-5

: Blachownice, PKN. –

Warszawa, 2008.

PN-EN 1993-1-1.

Projektowanie konstrukcji stalowych. Część 1-1

: Reguły ogólne i reguły dla budynków,

PKN. –

Warszawa, 2008.

PN-EN 1993-1-6.

Projektowanie konstrukcji stalowych. Część 1-6

: Wytrzymałość i state-czność

konstrukcji powłokowych, PKN. –

War-szawa, 2008.

Samuelson,

L. A.

Shell stability

handbook / L.

A. Samuelson,

S. F. Eggwertz. – London ;

New York : Elsevier, 1992. – 303 p.

Sofistik v 2014, Licencja:

Rajmund Ignatowicz.

Timoszenko,

S. P. Ustojcziwost’ uprugich system / S. P. Timoszenko. – Moskwa

: GITTL, 1955. – 568 p.

К. Горскі1*, Р.

Л. Ігнатович2*

1*Каф.

«Цивільна та інженерна геологія»,

Познаньський університет

природничих

наук, вул. Піатковська, 94, Познань,

Польща, 60-649,

ел. пошта kgorski@up.poznan.pl

2*Каф.

«Металеві конструкції», Вроцлавський

технологічний

університет, Грюнвальдська

пл., 11, Вроцлав, Польща,

50-377,

ел. пошта rajmund.ignatowicz@pwr.edu.pl

НАПРУГА СТАЛЕВОЇ ТРУБИ,

ПРОКЛАДЕНОЇ

В УМОВАХ НЕДОСКОНАЛОСТІ

ТРУБ ТА

НЕОДНОРІДНОСТІ ГРУНТУ

Мета.

У дослідженні необхідно вивчити питання

впливу локальних неоднорідностей

ґрунту на внутрішні сили в сталевій

трубі. Методика.

Автори представили відмінності в

розподілі ґрунтового тиску на труби.

Одним із найбільш поширених методів є

технологія мікротунелювання. Приклади

чисельного аналізу були розраховані

методом скінченних елементів (МСЕ).

Результати.

Встановлені дані чисельного аналізу

представлені для обраних ґрунтових

умов. Був також показаний розподіл

внутрішніх сил у гнучкій секції сталевої

труби. Наукова новизна

та практична значимість.

Отримані результати чітко показують

вплив згинальної жорсткості труби на

внутрішні сили, на величину згинальних

моментів у сталі вдавлених труб. Вони

залежать від взаємодії грунт–сталева

труба.

Ключові слова: сталеві труби;

метод кінцевих елементів; мікротунелювання;

грунт

К. Горски1*, Р. Л. Игнатович2*

1*Каф.

«Гражданская и инженерная геология»,

Познаньский университет

естественных

наук, ул. Пиатковска, 94, Познань,

Польша, 60-649,

эл. почта kgorski@up.poznan.pl

2*Каф.

«Металлические конструкции», Вроцлавский

технологический

университет, Грюнвальдская

пл., 11, Вроцлав, Польша, 50-377,

эл. почта

rajmund.ignatowicz@pwr.edu.pl

НАПРЯЖЕНИЕ СТАЛЬНОЙ ТРУБЫ,

ПРОЛОЖЕННОЙ В УСЛОВИЯХ

НЕСОВЕРШЕНСТВА

ТРУБ

И НЕОДНОРОДНОСТИ ГРУНТА

Цель. В

исследовании необходимо изучить вопросы

влияния локальных неоднородностей

грунта на внутренние силы в стальной

трубе. Методика.

Авторы представили различия в

распределении грунтового давления на

трубы. Одним из наиболее

распространенных методов является

технология микротоннелирования. Примеры

численного анализа были рассчитаны

методом конечных элементов (МКЭ).

Результаты.

Установленные данные численного анализа

представлены для выбранных грунтовых

условий. Также показано распределение

внутренних сил в гибкой секции стальной

трубы. Научная новизна

и практическое значение. Полученные

результаты четко показывают влияние

изгибной жесткости трубы на внутренние

силы, на величину изгибающих моментов

в стали вдавленных труб. Они зависят

от взаимодействия почва–стальная

труба.

Ключевые слова: стальные

трубы; метод конечных элементов;

микротоннелирование; грунт

Prof. V. D. Petrenko, D. Sc.

(Tech.) (Ukraine) recommended this article to be published

Accessed: Feb., 29.

2016

Received: May, 31.

2016

was accepted. The results of calculating the width of the ground

solids of different proposals was illustrated in Fig. 4. The values

of the vertical and horizontal loads were calculated according to

the following relationships.

(1)

(2)

(3)

(4)