Introduction

The basis for

ensuring the traffic safety is systems for diagnosing the state of

infrastructure devices, which allow predicting their possible

failures and eliminating emergency situations in a timely

manner. A non-redundant link of electrified lines of railways and

urban electric transport is a contact network (CN), the failures

of which lead to delays of trains, urban electric transport and, as

a consequence, to economic damage [1–12]. An important feature

of the CN is its participation in the current collection, which

causes the appearance of loads requiring the improvement of

interaction models of current collectors with the CN and the

development of a theory of high-current contact to improve the

diagnostic systems [3, 14]. The uniqueness of the CN places high

demands both on the design of its devices and to the methods of

their technical operation [4, 7].

Reliable and

economical operation of the CN is impossible without automated

diagnostic devices that allow detecting the locations of

malfunctions or other aberrations, as well as analysing them to

develop managerial decisions to ensure the

uninterrupted movement of the rolling stock [9, 11–13, 16].

Railway and

industrial companies in many countries strive to eliminate

interruptions in the movement of trains and electric industrial and

urban electric transport through high-quality diagnostics of the CN

and malfunction repair. In this case, the economic aspect associated

with the optimization of the service life of the CN devices and,

first of all, the overhead wire (OW) plays the most important role

[7, 8].

Today, the

triangulation method for determining the height and zigzag of the

OW, the phase measuring method based on the use of light sources,

the method of monitoring the position of the video camera system and

OW wear are known in application. The existing methods are based on

one of two basic principles: contactless measurement or contact one,

when the sensor is installed on the current collector and touches

the overhead wire. Using the contactless systems, measurements can

be made at any movement speed, but the measurement accuracy is

reduced. Contact systems have higher accuracy, but they provide

measurements at low speeds [15, 17].

The optical

method of automatic control involves installation of several optical

systems on the roof of the laboratory car for testing the contact

network (LTCN), which films the catenary suspension with supporting

structures on the move from different points and transfers the

resulting images to a storage unit.

In the

measurement system, specialized high-speed television cameras are

used, and fan-shaped raster pulse laser illuminators are used to

illuminate the overhead wires.

On the German

Railways Network (DBAG), for monitoring small devices, such as bolt

heads or torn wire strands of the carrier cable, the optics

resolution is 1–2 mm, and the flash duration when illuminating the

object should not exceed 45 μs. When measuring the OW wear,

comparison with previous results is not required. A comparison with

the cross-section of the new wire is enough here. The measurement

accuracy of this type is 0.1 mm, and a decrease in the wire

thickness can be detected already at a length of 2–3 cm [15, 17].

In recent

years, qualitatively new diagnostic tools have been developed based

on video measuring systems. Their speed and detection reliability

when diagnosing the CN elements have been increased. Computing power

has been significantly increased, new more advanced photoreceiving

components and image processing algorithms have been developed [9,

13–17]. Therefore, there is a scientific problem of improving

video measuring diagnostics systems to ensure reliable and

economical current collection on electrified lines of railways and

urban electric transport.

Purpose

The main

purpose of the article is a systematic analysis of the state and

development prospects of electric traction networks of electrified

railways and urban electric transport, the development of hardware

and software for improving video measuring diagnostic tools and

expanding the functionality of laboratory cars for testing the

contact network.

Methodology

In our

opinion, in the current situation, it is necessary to solve the

problem of complete replacement of most of the devices of electric

traction networks of railways and urban electric transport by

investing significant funds in modernization. This is evidenced by

the experience of foreign countries. On many railway sections of

transport corridors, as well as in large cities, a new CN is

required, and only in this case safe and economical operation of the

power supply for train traction system and urban electric transport

will be ensured [6, 14].

The problem

of increasing the resolution capability of the quality control

systems of the current collectors and CN’s interaction from the

moving laboratory car was solved using a complex approach. This

approach includes theoretical analysis and experimental research of

the parameters of the control object – overhead wire (OW),

modelling of the control device of the wear of overhead wire and its

functional units, determination of factors influencing the control

error [3, 4, 7, 10]. At the same time, the apparatus of factorial

analysis, the theory of optoelectronic circuits and methods of

statistical information processing were used to determine the

theoretically maximum allowable error in monitoring the wear of the

OW and other components, from the point of view of the operation of

CN.

Findings

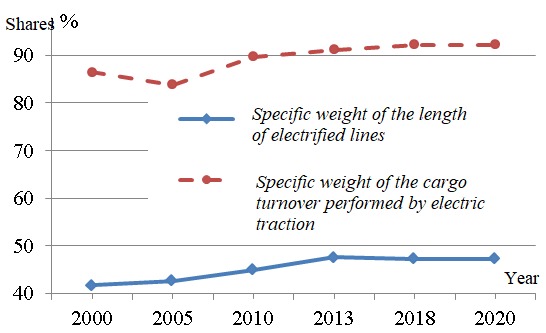

Analysis

of the state and development prospects of electric traction networks

of railways and urban electric transport. At

all stages of the development of railways, electrification was the

leading link in their reconstruction, qualitatively changing the

operational work (Fig. 1). For the period 1994–2011 more than 1700

km of the operational length of railways were electrified, the

polygon of electrified lines was increased by 21%, while the volume

of electric traffic increased to 89.7%. The highest electrification

rates were achieved in 2011–2012 on the sections of the

accelerated movement of passenger trains with an operational length

of 176 km. The specific weight of the length of electrified lines

increased to 47.3%, and the specific weight of electric cargo

turnover was more than 91.2% [1].

The task of

further electrification was planned in the volume of phased

implementation: in total for the period 2013–2020 – about 1 841

km. However, this program failed. At the same time, in recent years,

there has been a tendency for the development of urban electric

transport in large cities.

The rate of

ageing of power supply devices, given the existing funding

shortfall, continues to outstrip the rate of reconstruction. The

length of the electrified lines operated beyond the average period

(40 years) increased from 5012 km (or 52.0%) in 2007 to 6393 km (or

62.3%) in 2012, and in 2020 up to 6820 km (or 67.9%). Today, 73% of

the total number of traction substations of urban electric transport

operate with a service life of more than 40 years, and 43% with

a service life of more than 50 years.

Thus, a complete reconstruction of more

than 80% of the length of the contact network and traction

substations of urban electric transport is required. There is no

global experience in operating a contact network with such

ageing rates. Specific damage to CN, which has served for 40 years

or more, is 2.7 times higher than in the sections with a service

life of 10 years [1, 2].

Fig. 1. Specific

weight of electric traction

in the railway network length and

in the total cargo turnover

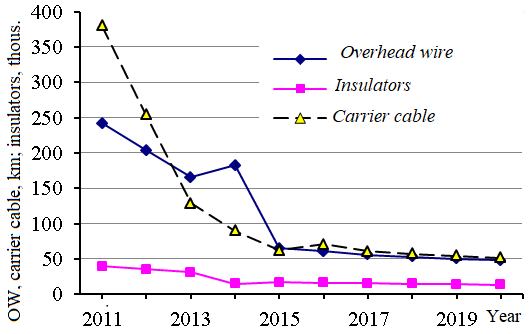

Analysis of

the replacement dynamics of the main CN devices (Fig. 2) shows that

the average values and root-mean-square deviations (shown in

brackets) have the following values: overhead wire – 188 km (80

km); carrier cable – 134 km (79 km); high-voltage insulators –

40 thousand pcs. (17 thousand pieces); supports – 2340 pcs.

(751 pcs.). Thus, the existing rate of replacement of the main

devices of the CN is incommensurate to the rate of their ageing, and

since 2021, it can cause a snowballing growth of failures [2].

Fig. 2. Replacement

dynamics of the main

elements of the CN

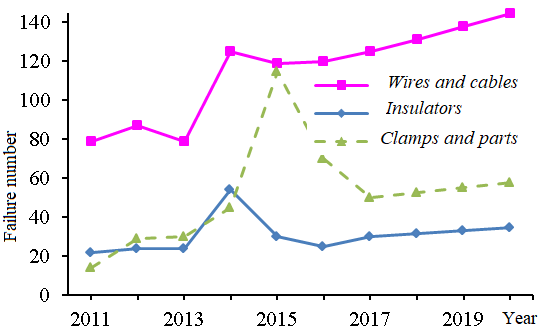

Analysis of

the number of damages at all junctions of the CN of the railways for

different periods shows that the most often fail the overhead wire

and cables, insulators, droppers, clamps and parts. Fig. 3 shows

the failure dynamics of these devices for railways. This is

explained by the fact that structurally all other elements of the CN

are designed to support the OW in the set position. Failures of any

element of the CN often result in OW failure. On the other hand, the

OW is the element of CN that directly interacts with the current

collector. Interaction with the current collector during the current

collection process causes intensive ageing of wires and a large

number of sudden failures caused by malfunctions of the electric

rolling stock.

Fig. 3. Failure

dynamics of the most damageable catenary devices

Over the past

10 years, there has been a tendency for an increase in the number of

CN failures due to mechanical and electromechanical wear of

droppers, as well as clamps and parts. The height depletion of the

support structures, which occurred on a significant part of the

polygon due to multiple track repairs, also became a problem. The

specified problem can be solved only with the overhaul repair of the

CN [2].

Calculations

have shown that over the past 10 years, there have been changes

in the failure risks, which reflected the growth of ageing, wear and

degradation processes of the CN. The most significant is the risk of

OW failures. The risk of failures of catenary suspension and current

collectors in monetary terms is so great that it requires drastic

solutions in the field of investments both in overhaul repair or

construction of new catenary suspension and current collectors of

electric rolling stock, and in new systems for diagnostics of

current collection.

Analysis of

damage to power supply devices for urban electric transport shows

that the overwhelming amount of damage is accounted for by contact

networks, especially in the sections with a service life of more

than 40 years. Significantly less damage occurs at traction

substations (TS). Damage distribution by the types of devices: CN

– 49.7%; TS – 5.4%; cable lines and trackways –

44.6%.

The ratio

of mathematical expectations and root-mean-square deviations of

damage to the contact network and current collectors as a result of

delays of trams and trolleybuses in percent of the total number of

delays over the past 10 years are as follows: 194.5 and 15.5, which

is 64.3% and 3.4%, respectively.

The need to

expand tram and trolleybus lines and modernize power supply devices

in a resource-saving environment requires new technologies for the

design, construction and operation of infrastructure facilities. For

the first time in Kharkiv, a new generation of traction

substation with dry transformers, 12-pulse rectification circuits,

digital protection and equipment diagnostics was put into operation,

ensuring operation according to condition. It is necessary to create

automated systems for laboratory cars for testing CN of trams

(LTCN–T),

which recognize hidden defects in CN (Fig. 4), as well as

laboratories on the basis of trolley buses or trucks for trolleybus

CN. This task is posed in our country for the first time [7–12].

The modern

LTCN–T include an optical-mechanical unit; laser fast-acting

system for OW diagnostics; video surveillance and information

processing system; additional power supply system; complex control

panel and functional panel; rotation angle sensors, stresses,

lateral displacements, ambient temperature, car movement speed.

Fig. 4. LTCN–T:

а

– appearence; b

– workplace in the car;

c

– operation of the video surveillance system and information

processing synchronously

with the determination of the car

geolocation

LTCN–T

allows controlling the current height position, OW displacement; OW

suspension defects; OW wear; distance travelled; movement speed;

ambient air temperature; CN voltage; GLONASS/GPS coordinates; CN

state with the help of video recording.

The tram

laboratory for a comprehensive assessment of the infrastructure

state, in addition to the LTCN–T

parameters, allows performing measurements of track depression and

alignment, longitudinal track gradient, acceleration on the bogie

and body, track width, rail wear, CN support dimensions, as well as

video monitoring of the rail track, connections of assembling

joints, connection of supply cables, inter-rail connections.

For example,

a specialized video system (Fig. 4, c)

records a video image, the viewer of which is shown on the screen.

The programs work synchronously. This makes it possible to stop the

tape in the places where clarification is needed (for example, a

large zigzag), enter the video program at this place and take a

photo with the necessary comment to analyse, issue to the repair

site and for serviceability.

The use of

LTCN–T allows

obtaining objective data on the CN state, conducting an automated

assessment of the CN state by one or several passes, linking the

measurement results to a place on the map and performing video

surveillance of the CN infrastructure. All the above makes it

possible to create databases on the state of the contact network,

track, cable lines, etc., as well as the conditions for the

transition of their service by state. The solution of the problem

allows improving the assessment quality of the CN state and reducing

the possibility of failures, as well as ensuring energy and resource

saving in the process of passenger transportations.

Video

measuring systems for diagnostics of contact networks. In

recent years, hardware and software have been developed to improve

the system for measuring the OW parameters and other CN components.

A method for increasing the resolution of a stereo television

system and an adaptive lighting system is proposed. It consists in

preliminary image transformation and expansion of the dynamic range

of image measurement. The quality of CN diagnostics in difficult

conditions for video surveillance has been improved. A camera with a

built-in image compression module without loss of its fast action

has been proposed, which allows capturing and transmitting

full-frame images to a computer complex for the application of new

CN diagnosing algorithms [8, 10, 15, 16].

The stereo

television system is based on a specialized fast-acting television

camera of a new generation, and the lighting system can operate both

in continuous and in pulsed mode with a duration of light pulses

from 20 μs. Cameras can be equipped with lenses with automatic iris

control according to the P-iris standard; serial interface; serial

interfaces and high-speed video compression module and frame

grabber.

For the

enterprises of power supply of electrified railways, industrial and

urban electric transport, innovative means of complex diagnostics of

the CN state have been developed. They are laboratory cars, which

provide monitoring of OW wear, the state of high-voltage insulation,

heating of electrical connections, grounding of supports on rail.

An automated

video-measuring system for monitoring the CN supports grounding and

its other equipment, as well as elements of the track facilities

located in the visibility zone of specialized cameras, which ensure

the system's operability at any time of the day at speeds up to 160

km/h, is proposed: discretization of image lines along the track

length from 0.5 mm; the value of the electronic shutter at a speed

of 160 km/h is not more than 22 μs; the

number of pixels in a line is at least 1000. An air curtain

subsystem is implemented to protect the cameras.

Development

of new diagnostic tools for the contact network and improving the

efficiency of existing ones is a priority area of activity of

DAK-Energetika LLC, which carries out the entire range of works,

including research, design, manufacture, installation,

commissioning, warranty and service.

The

manufactured measuring equipment is included in the State Register

of Measuring Instruments

and Register of Measuring Instruments, Test Equipment and Methods of

Measurements Used in Ukrainian Railway

OJSC, and is

metrologically certified and protected by patents.

Improvement

of WEAR laser fast-acting system for measuring the parameters of the

contact wire. The Aptima MT9M413C36STC

video sensor used in the WEAR system has a 100-bit output data bus

that transmits a block of 10-bit brightness readings of 10

neighbouring pixels of the current line per one cycle of the

operating frequency fг.

Each line of the image has a size of 1280 pixels and is transmitted

in a block consisting of 128 fг

cycles. For contactless measuring of the

profile of the worn out OW part, measuring the position of the OW

relative to the current collector axis, detecting OW overturns and

lateral slopes of the OW clips (dropper, pull-off, etc.), LTCN

is equipped with WEAR

fast-acting laser diagnostic OW system.

This

diagnostic system belongs to the group of systems that measure OW

wear by its profile, their operating principle is indicated in [8,

10, 13].

The measuring

system consists of 8 laser fan-shaped emitters, in which the

collimated laser beam is converted into a flat fan out light beam

0.3–0.6 mm thick using a spreading system, and 4 matrix

television cameras. When the fan beam of light strikes the OW, a

visible line of its intersection with the plane is formed on the

wire surface, in which the correct beam lies. It is this

intersection line that is distinguished by the processing system

from the resulting image of the current frame of the television

camera. In this case, the shape of the fixed line weakly depends on

the OW inclination and is mainly determined by its wear. The program

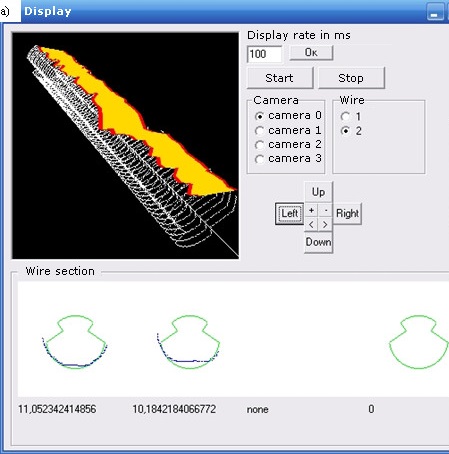

provides the ability to display a 3-D OW model with imposed measured

wear for the selected camera (Fig. 5).

The use of

LED illumination, which effectively illuminates the entire surface

of the lower part of the overhead wire and clamps, together with the

possibility of obtaining a full frame of the image at the input of

the information-computing complex, can significantly increase the

informativeness of the WEAR system. Thus, many unclear situations

caused by the insufficient informativeness of the measuring system

can be resolved in real time by visual or programmatic assessment of

the received frames corresponding to the CN section that causes

questions.

b

Fig. 5.

Reconstructed 3-D model of the worn-out section

of the OW (a)

and a photograph of this place (b)

The second

important aspect of the WEAR system modernization is the need to

obtain full-frame illuminated images of the CN elements at a high

speed for continuous scanning of objects of interest.

Based on the optical characteristics of

the lenses, the frame resolution and the distance at which the

cameras are located relative to the measured objects, the field

of view along the OW is Ɩ

= 37 mm. The maximum speed at which the WEAR system operates is ʋ =

72 km/h. The maximum time Ƭ

of receiving one frame, at which continuous scanning of the CN

is provided, is determined by the expression Ƭ

= c ∙

(Ɩ / ʋ),

where c =

0.0036 is the reduction coefficient of values to the SI system.

With the

given values Ɩ

and ʋ Ƭ

= 0.00185 s, which corresponds to the frequency of obtaining frames

ƒ = 541 fps.

The required

bandwidth of the channel C

for transmitting only an uncompressed image for a frame with a

resolution r

and a bitness of

one pixel n

is determined by the following expression: C

= r ∙ n ∙ ƒ.

With r

= 1 280 ∙ 128

and n

= 10

С

= 846 Mb/s.

Test

results of the WEAR system. The

automated system for measuring the wear of the

overhead wire installed on the LTCN

was tested along the 1 and 2 station track in variable cloud

conditions at a temperature of +28°C. A double contact wire

MF-100 is suspended within the test section. Automated measurements

were carried out at a measuring car speed of 37 km/h.

Manual wear

measurements were taken between the 69th and 71st supports along the

first station track. For accurate synchronization of measurements,

manual measurements were carried out next to the dropper and

pull-off clips, since such places can be easily identified using the

measurement data from the WEAR system. The measurements results are

given in Table 1.

It was found

that at the points being checked, the difference between the

automated measurements of the WEAR system and manual measurements of

the residual height does not exceed 0.26 mm.

Table

1

Results

of manual and automated

measurements

of OW wear along the

first station track

|

Distance

from support, cm

|

Manual

measurements,

mm

|

Wear

system measurement,

mm

|

Error,

mm

|

|

left

|

right

|

left

|

right

|

left

|

right

|

|

0

|

10.47

|

8.1

|

10.3

|

8.35

|

0.17

|

–0.25

|

|

075

|

9.57

|

9.49

|

9.5

|

9.29

|

0.07

|

0.2

|

|

150

|

10.13

|

9.57

|

10.16

|

9.54

|

–0.03

|

0.03

|

|

850

|

9.45

|

8.92

|

9.8

|

8.9

|

–0.35

|

0.02

|

|

1

875

|

9.36

|

9.1

|

9.3

|

8.98

|

0.06

|

0.12

|

|

2

875

|

8.5

|

9.38

|

8.65

|

9.05

|

–0.15

|

0.23

|

|

3

745

|

8.17

|

8.75

|

8.25

|

8.9

|

–0.08

|

–0.15

|

|

4

025

|

9.8

|

8.71

|

9.5

|

8.76

|

0.2

|

–0.05

|

|

4

085

|

9.24

|

8.71

|

9.7

|

8.7

|

–0.26

|

0.01

|

|

4

875

|

9

|

8.93

|

9.12

|

8.93

|

–0.12

|

0.11

|

|

5

850

|

9.8

|

9.35

|

9.5

|

9.2

|

0.24

|

0.23

|

|

6

000

|

9.37

|

9.67

|

9.2

|

9.5

|

0.16

|

0.26

|

|

6

075

|

9.2

|

9.76

|

9

|

9.61

|

0.25

|

0.15

|

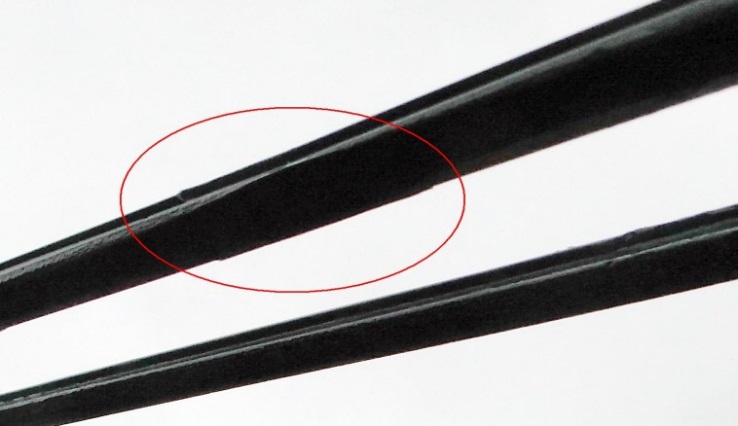

During the

test drive on the second station track, several places were found

where, due to lateral wear of the overhead wire, the wear area

reached the clamp itself, as a result of which the bite wear began

(Fig. 5).

The

difference between manual and automatic measurements (Table 2) does

not exceed 0.33 mm in the residual wire height, except for the

reference

point at the

mark of 4 473 cm (right wire), where there is strong lateral

wear of the wire and an error could be made during manual

measurements.

Table

2

Results

of manual and automated measurements

of OW

wear along the second station track

|

Distance

from support, cm

|

Manual

measurements,

mm

|

Wear

system measurement,

mm

|

Error,

mm

|

|

left

|

right

|

left

|

right

|

left

|

right

|

|

0

|

11.5

|

11.5

|

11.4

|

11.3

|

0.1

|

0.2

|

|

25

|

9.25

|

10.4

|

9.11

|

10.43

|

0.14

|

–0.03

|

|

1

075

|

9.27

|

11.2

|

9.04

|

10.63

|

0.23

|

0.57

|

|

1

174

|

9.27

|

11.75

|

9.35

|

11.7

|

–0.08

|

0.05

|

|

1

211

|

9.38

|

11.65

|

9.19

|

11.63

|

0.19

|

0.02

|

|

1

982

|

9.75

|

10.95

|

9.78

|

10.88

|

–0.03

|

0.07

|

|

2

767

|

9.45

|

10.12

|

9.89

|

9.855

|

–0.24

|

0.265

|

|

2

839

|

10.1

|

10.15

|

10.03

|

10.01

|

0.07

|

0.14

|

|

3

557

|

10.45

|

11.55

|

10.37

|

11.7

|

0.08

|

–0.15

|

|

4

390

|

11

|

11.15

|

10.73

|

10.94

|

0.27

|

0.21

|

|

4

408

|

9.32

|

11.25

|

8.9

|

11.05

|

0.32

|

0.2

|

|

4

420

|

11

|

11.05

|

10.7

|

10.75

|

0.3

|

0.3

|

|

4

446

|

11.65

|

11.15

|

11.32

|

10.85

|

0.33

|

0.3

|

|

4

473

|

11.27

|

11.16

|

11.1

|

10.35

|

0.17

|

0.81

|

Originality

and practical value

The

theoretical maximum permissible, from the point of view of the

contact network operation, wear control error of the overhead wire

and other components of the electric traction network has been

determined. A method for increasing the resolution capability of a

stereo television system and an adaptive lighting system is

proposed, which consists in preliminary image transformation and

expansion of the dynamic range of image measurement.

The quality

of diagnostics of the contact network in difficult conditions for

video surveillance has been improved. A camera with a built-in image

compression module without loss of its performance has been

proposed, which allows capturing and transmitting full-frame images

to a computer complex for the application of new diagnostic

algorithms for the components of the contact network of electrified

railways and urban electric transport.

Conclusions

To reduce the

wear of the overhead wire and current collector plates, to ensure

reliable and economical current collection in the process of

transportation by electric transport, high-quality diagnostics of

the electric traction network is required. The proposed video system

has the following speed characteristics: obtaining a JPEG image with

a compression ratio of k>

= 10 and a resolution of 1 280 x 128 at a speed of 976 fps. In this

case, the required maximum speed of compressed data transfer does

not exceed 85 Mb/s. The system is equipped with fast-acting LED

backlighting, which makes it possible to obtain a continuous

illuminated image of the CN elements in real time. Thus, the

improvement of the WEAR laser fast-acting system can significantly

increase the reliability and reduce the detection time of emerging

OW malfunctions and other CN components.

LIST OF

REFERENCE LINKS

Аналіз

роботи господарства електрифікації

та електропостачання в 2011 році.

Київ : «Укрзалізниця»,

Головне Управління Електрифікації та

Електропостачання, 2012. 323 с.

Аналіз

роботи господарства електропостачання

в 2015 році. Київ :

ПАТ «Українська залізниця»,

Департамент Електропостачання, 2016. 148

с.

Вологин

В. А. Взаимодействие

токоприемников и контактной сети.

Москва : Интекст, 2006. 256 с.

Доманський В. Т.,

Переверзєв К. В. Концепція технічного

обслуговування пристроїв електропостачання

залізниць за станом на базі їх діагностики

і моніторингу. Українська

залізниця. 2019. №

3 (69).

С. 9–13.

Доманський І. В.

Основи енергоефективності

електричних систем з тяговими

навантаженнями :

монографія. НТУ «ХПІ».

Харків : вид-во ТОВ «Центр

інформації транспорту України», 2016.

224 с.

Корниенко

В. В., Котельников А. В., Доманский В. Т.

Электрификация железных дорог. Мировые

тенденции и перспективы (Аналитический

обзор) : монография. Киев : Транспорт

Украины, 2004. 196 с.

Переверзев К. В.

Современные методы и средства диагностики

контактных сетей электрифицированных

железных дорог. Українська залізниця.

2019. № 6 (72). С. 23–27.

Столбов П. В.

Высокоскоростная специализированная

матричная камера с расширенным

динамическим диапазоном и сжатием

изображения. Материалы 14-ой международной

конференции «Телевидение : передача и

обработка изображений» (Санкт-Петербург,

27–28 июня 2017 г.). Санкт-Петербург, 2017. С.

54–57.

Хворост

М. В., Доманський І. В.,

Васенко В. О. Ресурсозберігаючі

технології експлуатації контактної

мережі за станом для міського

електротранспорту. Світлотехніка

та електроенергетика.

2020. Вип. 58, № 02. С. 3–9. DOI:

10.33042/2079-424X-2020-2-58-3-9

Шевяков С. М.,

Сиротинин В. И., Сафин В. Г,

Воронин А. В. Видеоизмерительные

системы диагностики контактной сети.

Евразия Вести. 2017. № 11.

С. 23.

Demydov

O., Liubarskyi B., Domanskyi

V, Glebova

M., Iakunin D., Tyshchenko A.

Determination of optimal parameters of the

pulse width modulation of the 4qs transducer for electriс

rolling stock. Eastern-European Journal

of Enterprise Technologies. 2018. Vol.

5. Iss. 5 (95). P. 29–38. DOI:

10.15587/1729-4061.2018.143789

Domanskyi I.,

Kozlova О. Development prospects of external power supply

electrical networks of traction substations. Series

: Engineering Science and Architecture. 2020.

Vol. 1. Iss. 154. P. 8–15.

DOI:

10.33042/2522-1809-2020-1-154-8-15

Information

technology – digital compression and coding of continuous-tone

still images – Requirements and guidelines. URL:

https://www.w3.org/graphics/jpeg/itu-t81.pdf (дата

звернення: 05.01.2021)

Kiessling F.,

Puschmann R., Schmieder A., Schneider E. Contact

Lines for Electric Railways : Planning, De-sign, Implementation,

Maintenance, 3rd Edition. Wiley

Publishers, 2017. 994 p.

Sarnes B.

Измерительная система для определения

положения и износа контактного провода.

Elektrische Bahnen.

2001. №

12.

C. 490–495.

Schmidt H.,

Schmieder A. Current

collection for high-speed transport.

Elektrische Bahnen. 2005.

№ 4.

P. 231–236.

Sohei

Y., Toshihide

K., Hiroshi

Y. Utilization

of Data

Obtained Using

Power Equipment

Monitoring

System Equipped

to Series

E235 Rolling

Stock. JR

EAST

Technical

Review.

2016. № 34. P.

33–36.

І. В.

Доманський1*,

В. О. ВАСЕНКО2

1*Каф.

«Електричний транспорт», Харківський

національний університет

міського

господарства імені О. М. Бекетова, вул.

Маршала Бажанова, 17,

Харків, Україна,

61002, тел. +38 (056) 736 24 80,

ел. пошта

ilya.domanskiy@gmail.com, ORCID 0000-0001-8819-410X

2Комунальне

підприємство «Міськелектротранссервіс»,

вул. Актюбінська, 24,

Харків,

Україна, 61001, тел. +38 (057)

737 96 58,

ел. пошта vladvasenko2021@gmail.com,

ORCID 0000-0001-8613-973X

Удосконалення

відеовимірювальних

систем діагностики

електротягової мережі

Мета.

Основною метою статті є системний аналіз

стану електротягових мереж, а також

методів комплексної діагностики

контактної мережі (КМ) з рухомого

вагона-лабораторії для підвищення

роздільної здатності систем контролю

якості взаємодії контактної мережі і

струмоприймачів. Методика.

Поставлену задачу вирішено шляхом

теоретичного аналізу та експериментальних

досліджень параметрів струмозняття,

узагальненої моделі пристрою контролю

зносу контактного проводу (КП) та його

функціональних вузлів із метою визначення

факторів, що впливають на похибку

контролю, а також розробки методів, що

знижують зазначену похибку. При цьому

використано апарат факторного аналізу,

теорію оптико-електронних схем і

методи статистичної обробки інформації.

Результати.

Запропоновано інноваційні підходи та

якісно нові діагностичні засоби, що

дозволяють розширити функціональні

можливості вагонів-лабораторій

випробування контактної мережі для

підприємств електропостачання

електрифікованих залізниць, промислового

й міського електротранспорту.

Розроблено апаратні та програмні засоби

для вдосконалення системи вимірювання

параметрів контактного проводу та інших

компонентів контактної мережі. Наукова

новизна. Визначене

теоретичну максимально допустиму, із

точки зору експлуатації контактної

мережі, похибку контролю зносу контактного

проводу та інших компонентів електротягової

мережі. Запропоновано метод підвищення

роздільної здатності стереотелевізійної

системи й адаптивної системи освітлення,

що полягає в попередній трансформації

зображення й розширенні динамічного

діапазону вимірювання зображення.

Запропоновано шляхи впровадження

високошвидкісного алгоритму стиснення

реального часу й застосування

світлодіодного підсвічування. Практична

значимість. Підвищено

якість діагностики контактної мережі

в складних для відеоспостереження

умовах. Запропоновано камеру із вбудованим

модулем стиснення зображення без втрати

її швидкодії, що дозволяє захоплювати

й передавати в обчислювальний комплекс

повнокадрові зображення для застосування

нових алгоритмів діагностики компонентів

контактної мережі. Запропоновано

модернізовані відеовимірювальні системи

вимірювання зносу контактного проводу,

контролю заземлення опор контактної

мережі, а також елементів колійного

господарства, розташованого в зоні

видимості спеціалізованих камер, які

забезпечують працездатність систем у

будь-який час доби на швидкостях до 160

км/год. Для захисту камер реалізовано

підсистему повітряної завіси.

Ключові

слова: системи діагностики;

контактна мережа (КМ); знос контактного

проводу (КП); оптичні методи вимірювань

REFERENCES

Analiz

roboty hospodarstva elektryfikatsiyi ta elektropostachannya v 2011

rotsi. (2012). Kiev: «Ukrzaliznytsya»,

Holovne Upravlinnya Elektryfikatsiyi ta Elektropostachannya. (in

Ukrainian)

Analiz

roboty hospodarstva elektropostachannya v 2015 rotsi.

(2016). Kiev: PAT «Ukrayins'ka zaliznytsya», Departament

Elektropostachannya. (in Ukrainian)

Vologin,

V. A. (2006). Vzaimodeystvie

tokopriemnikov i kontaktnoy seti.

Mosсow:

Intekst. (in Russian)

Domanskyy,

V. T., & Pereverzyev, K. V. (2019). Kontseptsiya tekhnichnoho

obsluhovuvannya prystroyiv elektropostachannya zaliznyts za stanom

na bazi yikh diahnostyky i monitorynhu. Ukrainian

Railway, 3(69),

9-13. (in Ukrainian)

Domanskyy,

I. V. (2016). Osnovy enerhoefektyvnosti

elektrychnykh system z tyahovymy navantazhennyamy:

monohrafiya. NTU «KhPI». Kharkiv: vydavnytstvo TOV «Tsentr

informatsiyi transportu Ukrayiny». (in Ukrainian)

Kornienko, V. V.,

Kotelnikov, A. V., & Domanskiy, V. T.

(2004). Elektrifikatsiya zheleznykh

dorog. Mirovye tendentsii i perspektivy (Analiticheskiy obzor):

monografiya. Kiev : Transport Ukrainy. (in Russian)

Pereverzev, K. V.

(2019). Sovremennye metody i sredstva diagnostiki kontaktnykh setey

elektrifitsirovannykh zheleznykh dorog. Ukrainian

Railway, 6(72),

23-27. (in Russian)

Stolbov,

P. V. (2017). Vysokoskorostnaya spetsializirovannaya

matrichnaya kamera s rasshirennym dinamicheskim diapazonom i

szhatiem izobrazheniya. Materialy 14-oy mezhdunarodnoy konferentsii

«Television: images broadcasting &

processing» (pp. 54-57).

St. Petersburg, Russia. (in Russian)

Khvorost,

M., Domanskiy, I., & Vasenko, V. (2020). Resource-saving

technologies of operation of a contact network on the state for city

electric transport. Lighting

Engineering & Power Engineering, 2(58),

3-9.

DOI: 10.33042/2079-424X-2020-2-58-3-9.

(in Ukrainian)

Shevyakov,

S. M., Sirotinin, V. I., Safin, V. G., & Voronin, A. V. (2017).

Videoizmeritelnye sistemy diagnostiki kontaktnoy seti. Yevraziya

Vesti, 11, 23. (in Russian)

Demydov,

О., Liubarskyi, B., Domanskyi, V., Glebova, M., Iakunin, D., &

Tyshchenko, A. (2018). Determination of optimal parameters of the

pulse width modulation of the 4qs transducer for electriс rolling

stock. Eastern-European Journal of

Enterprise Technologies, 5(5(95)),

29-38. DOI: 10.15587/1729-4061.2018.143789

(in English)

Domanskyi,

I., & Kozlova, О. (2020). Development prospects of external

power supply electrical networks of traction substations. Series:

Engineering Science and Architecture, 1(154),

8-15.

DOI:

10.33042/2522-1809-2020-1-154-8-15

(in English)

Information

technology-digital compression and coding of continuous-tone still

images-Requirements and guidelines. Retrieved from

https://www.w3.org/graphics/jpeg/itu-t81.pdf (in English)

Kiessling,

F., Puschmann, R., Schmieder, A., & Schneider, E. (2017).

Contact Lines for Electric

Railways:Planning, Design, Implementation, Maintenance, 3rd Edition.

Wiley Publishers. (in English)

Sarnes, B.

(2001). Izmeritelnaya sistema dlya opredeleniya polozheniya i iznosa

kontaktnogo provoda. Elektrische

Bahnen, 12,

490-495. (in Russian)

Schmidt, H.,

& Schmieder A. (2005). Current collection for high-speed

transport. Elektrische Bahnen,

4,

231-236. (in English)

Sohei,

Y., Toshihide,

K., &

Hiroshi, Y.

(2016). Utilization

of Data

Obtained Using

Power Equipment

Monitoring

System Equipped

to Series

E235 Rolling

Stock. JR

EAST

Technical

Review,

34,

33-36.

(in English)

Received:

Oct. 02, 2020

Accepted:

Feb. 02, 2021