ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука та прогрес

транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2021,

№ 1

(91)

Матеріалознавство

UDC

669.017.16:624.954

Y. I. Hezentsvei1,

D. O. BANNIKOV2*

1Metinvest

Engineering LCC, Yaroslava Mudroho St., 53, Dnipro,

Ukraine, 49038,

tel. +38 (067) 611 57 91,

e-mail

efim.gezentsvey@metinvestholding.com,

ORCID 0000-0003-1190-5465

2*Dep.

«Construction Production and Geodesy», Dnipro National

University

of Railway Transport named after Academician V. Lazaryan,

Lazaryana St., 2, Dnipro, Ukraine, 49010, tel. +38 (063) 400 43 07,

e-mail bdo2020@yahoo.com, ORCID 0000-0002-9019-9679

Use of Fine-Grained

Heat-Strengthened Steels

to Increase the Operation Qualities of

Bunker

Capacities from Thin-Walled Galvanized Profiles

Purpose.

The work is aimed to study

the use efficiency of fine-grained heat-strengthened steels (mainly

10G2FB) for steel bunker capacities.

At the same time, the structural scheme of such a structure using

corrugated steel sheets is considered as the main variant.

Methodology. To

achieve this purpose, a series of numerical calculations was carried

out for a steel bunker capacity of a pyramidal-prismatic type with

overall dimensions in plan view of 6×5.2 m and a total height of 4.5

m. The capacity was designed for complicated working conditions, in

particular, increased loads, including long-term dynamic ones. The

potential possibility of operating the container under conditions of

high or low temperatures was also taken into account. At the same

time, both the traditional structural scheme of a bunker capacity

with horizontal stiffening ribs and the developed structural scheme

based on corrugated steel sheets were analyzed. The calculations were

carried out by the finite element method based on the SCAD for

Windows project complex.

Findings. Based

on the results of the analysis and comparison of the data obtained in

numerical calculations, it was found that the use of fine-grained

heat-strengthened high-strength steels (for example, steel 10G2FB)

for bunker capacities, both the traditional structural scheme with

stiffening ribs and the developed structural scheme based on

corrugated sheets, allows reducing material consumption by about 30%

in both cases. At the same time, due to the good performance of

fine-grained heat-strengthened steel 10G2FB, both at high and at low

temperatures, it can be effectively used for steel bunker capacities

that work in difficult conditions.

Originality. The

possibility and efficiency of the use of fine-grained,

heat-strengthened high-strength steels for the construction of a

steel bunker capacity is estimated. At the same time, such an

estimation was given not only for structures of the traditional

structural scheme with horizontal stiffening ribs, but also for

bunkers with a developed structural scheme based on corrugated

sheets. Practical

value. From a

practical point of view, quantitative parameters of the stress-strain

state were obtained during investigations of various design variants

for a steel bunker capacity. The data are presented in a compact form

that is easy to evaluate and compare. They allow us to state about

the improvement of the operation characteristics of capacities and

the potential reduction of the risks of their failures and accidents

during operation.

Keywords: fine-grained heat-strengthened steel;

thin-walled galvanized profile; finite element method; bunker

capacity

Introduction

In recent decades, a fairly new

and interesting direction in the practice of creating and further

operation of building structures for various purposes is the use of

thin-walled galvanized profiles. Some features of their production

and application in modern conditions of Ukraine are described in the

publication of a master's student of Dnipro National University of

Railway Transport named after Academician V. Lazaryan (DNURT), whose

thesis was devoted to this issue [2].

Thin-walled galvanized profiles

are widely used for steel silo capacitive structures designed mainly

for grain storage. However, various factors often cause failures and

accidents of such structures [3]. The situation is further

complicated by the small thickness of the profiles themselves (not

more than 3 mm), which forces creating packages of several sheets

connected by bolts (Fig. 1).

Fig. 1. Packets of sheets from thin-walled galvanized

profiles for steel silo capacitive structures

Such silo capacities are often

installed at facilities related to transport and storage operations.

These include, for example, railway stations or river and seaports.

In addition to silo capacities,

bunker tanks are also often located at such facilities. They, like

silos, perform the technological functions of accumulation and dosed

distribution of bulk material stored in them over time.

Regarding

bunker tanks, especially those operating under difficult production

conditions and designed for high loads, one of the co-authors of

this article, Professor D. O. Bannikov, has developed a special

design scheme [10]. It is designed to absorb not only static but

also dynamic loads, which are quite

significant in bunker-type tanks.

However, to obtain the desired

load-bearing ability, it is often necessary to lay in the hopper

structure thickness of the load-bearing elements not less than 10

mm. This is especially true in the case of operation of such

facilities under adverse and complicated conditions: high loads, low

or high temperatures. It is for these conditions that the use of

fine-grained heat-strengthened high-strength steels of the 10G2FB

type instead of traditional steels of the usual St3 type proved to

be quite efficient. It was tested on the example of blast-furnace

jacket structures and confirmed its high practical efficiency [4].

The choice of steel type is due to the new technological

capabilities of Metinvest Engineering OJSC, which has mastered the

production of such steels with improved mechanical properties and an

expanded range of sheet thicknesses.

10G2FB steel was used during

the design of the steel pyramidal-prismatic bunker of the bypass

track of furnace-charge feeding. The customer of the object is

Pivnichstal PJSC, so the bunker facilities operate at low

temperatures.

The general

description of a design of these bunker constructions, the

theoretical substantiation of possibility and efficiency of use of

steel 10G2FB are presented in the separate publication [15]. The

bunkers are made according to the traditional structural scheme with

horizontal reinforcing stiffening ribs. The calculated economic

effect in the prices of 2019 amounted to about 0.5 million UAH

(almost $ 20,000), and the total weight reduction was about 4 tons

per bunker with dimensions of 6×5.2 m in plan, with a total height

of 4,5 m and a usable volume of 40 m3.

However, as has been repeatedly

noted in the monograph [10], as well as in many other works by

Professor D. O. Bannikov, the traditional structural scheme with

stiffening ribs has certain reserves of load-bearing ability. It is

possible to use them due to the specially developed panel structural

scheme based on corrugated sheets of steel.

Purpose

In regard to the above, the

purpose of our publication is to study the efficiency of

fine-grained heat-strengthened steels (mainly grade 10G2FB) for

steel bunker tanks. Thus, structural scheme of such structure with

the use of corrugated steel sheets variant was considered as the

basic.

Methodology

First of all, it should be

noted that the work of corrugated steel sheets is quite complex. The

current normative document of Ukraine on the design of steel

structures [6] does not pay special attention and does not contain

relevant recommendations for the design of such structural elements.

This issue is partially

addressed in a recently published monograph [1]. However, the

corresponding analytical solutions, even for the simplest cases,

have a whole system of empirical correction factors. Thus, in the

domestic research practice there are actually no full-fledged

theoretical developments that would allow theoretical determining of

the load-bearing ability of corrugated steel sheets.

The situation is further

complicated by such an aspect as the lack of clear recommendations

in the current regulations [5] to determine the loads from the

action of bulk material on the structural elements of the bunker

capacity.

Since the use of corrugated

steel sheets for capacitive structures is the newest direction in

construction, the foreign literature is also quite limited in terms

of the application of analytical approaches. For example, in the

classic monograph [12] there is no information on such topics.

Currently,

in foreign practice there are only partial studies of corrugated

profiles, primarily closed-type profiles [14]. Another part of the

research covers the search for more efficient protective surfaces

for thin-walled profiles [13]. Also, some studies raise the issue of

mounting and manufacturing of structures of thin-walled profiles

[17].

However, even the accumulated

European experience in the calculation and design of corrugated

profiles, presented in the national standards [7, 8], which are

translations of the relevant European standards, is quite limited.

These standards provide only general recommendations for determining

the stress-strain state for some cases, but there are no full

analytical solutions.

Given this

situation, as the main research method the finite element method was

chosen, which has become extremely popular in recent decades and

which is constantly being modernized [20]. Its practical

implementation took place on the basis of SCAD for Windows domestic

project complex [9]. This choice was made

according to the construction orientation of this complex, in

contrast to other developments, such as SolidWorks, CosmosWork,

Nastran or WinMachine, which have a machine-building orientation

[16]. During the research, the experience of school of soil

mechanics of DNURT was also used [18, 19].

As already

mentioned, steel pyramidal-prismatic bunker was the object of the

study. The height of the prismatic part was 0.5 m, and the pyramidal

hopper – 4.0 m. The prismatic part also formed a bunker beam,

through which the capacity rested on the elements of the bunker

trestle. The width of the discharge mouth, as well as its length

were taken equal to 1.2 m, the angle of hopper inclination with such

geometric dimensions was about 60.

Slag scrap,

whose density, according to the initial data, reaches 3 t/m3

and the internal friction angle is 45

is provided as one of the loaded bulk materials. The minimum

coefficient of dynamics, according to the customer data, was 1.3. In

addition, it was necessary to take into account the action of

vibrating feeders, whose operation mode is provided around the

clock. Technological load from the sole weight of bulk material is

set in accordance with the developments presented in the monograph

[10].

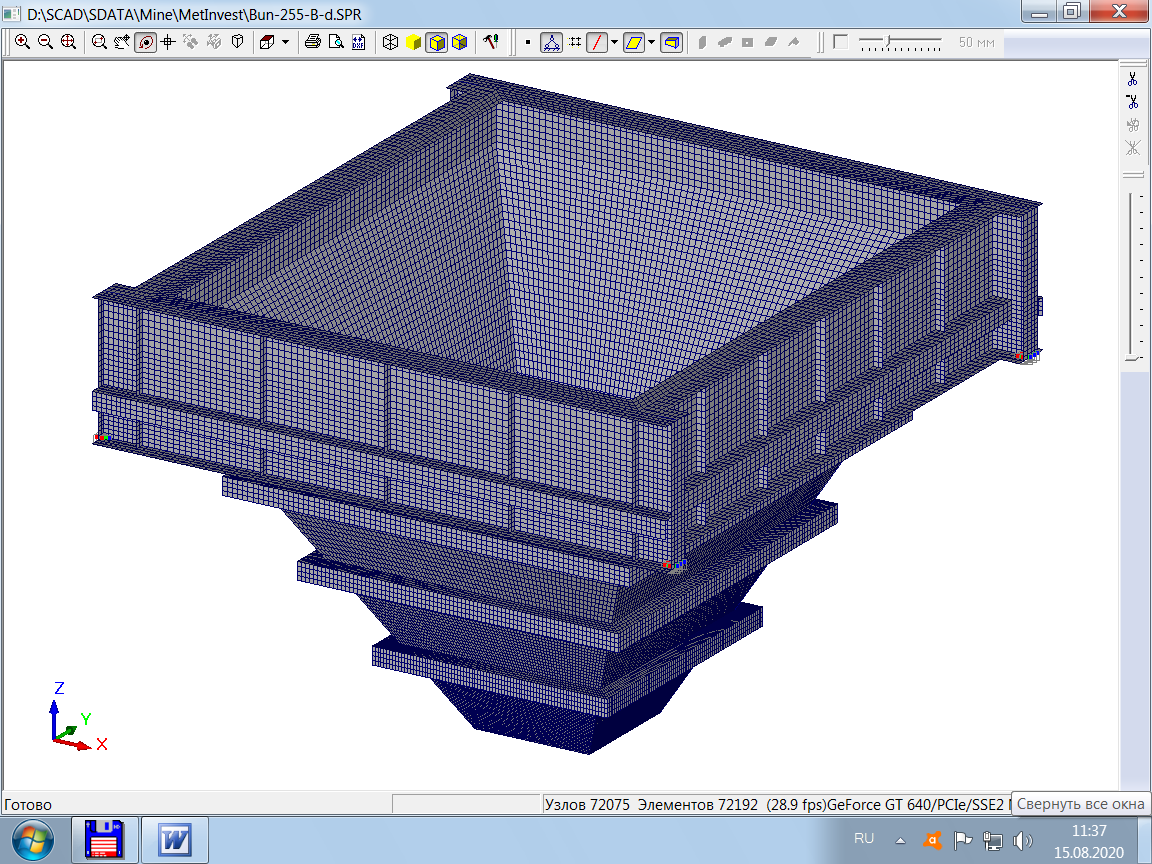

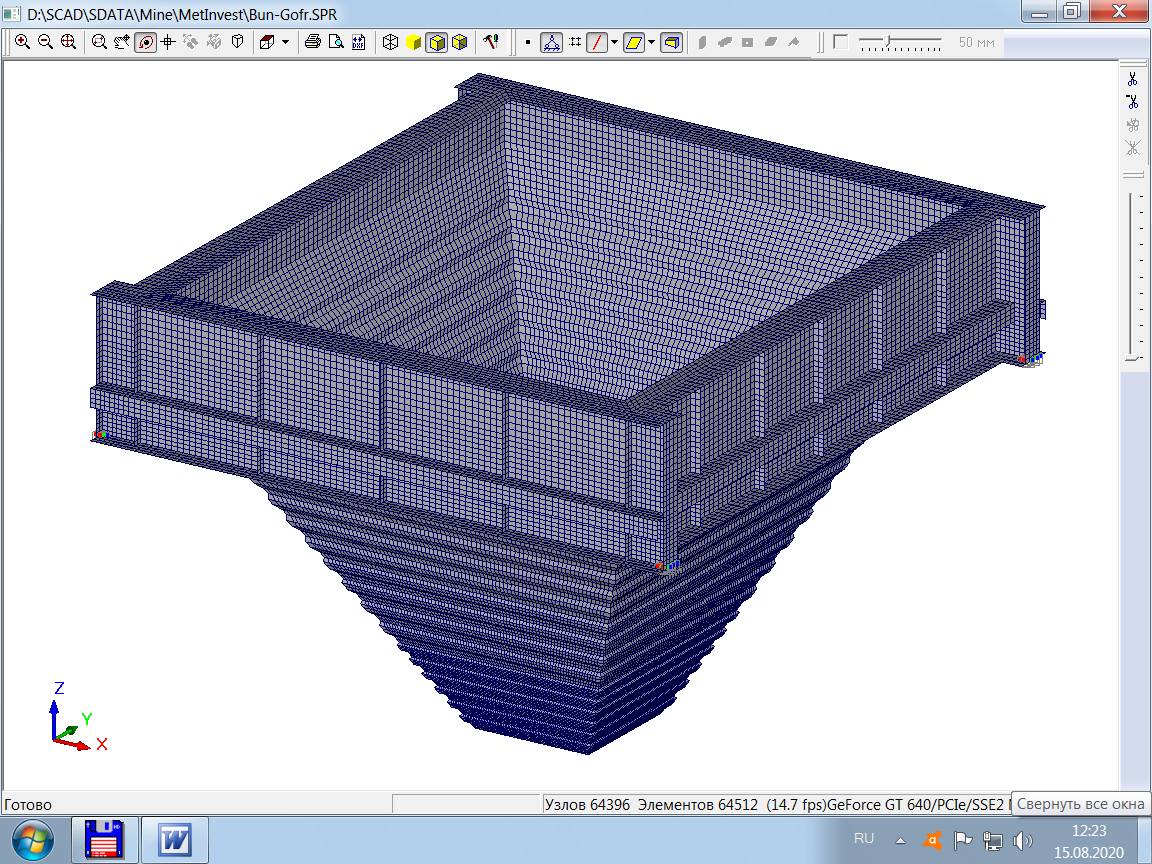

The constructed finite-element

models for research were plate systems (Fig. 2.) The finite element

is an isoparametric shell element from the standard library of the

SCAD for Windows complex. Fastening of bunker capacities is modeled

in such a way to receive the hinged scheme of their operation.

Findings

A separate

issue during the research was to determine the characteristics of

steels, provided for the design of steel bunker capacity. The tests

were conducted by a specialized organization, State

Enterprise Ya. Yu. Osada Scientific

Research Tube Institute (SE SRTI). Both the

chemical composition of steels (Table 1) and their tensile

mechanical characteristics for different temperatures were

determined separately (Table 2).

The chemical

composition was determined by photoelectric spectral analysis on

Spectromax X LMM04 atomic emission spectrometer manufactured by

SPECTRO in Germany. According to the test protocols, the room

temperature was +24 ºC, relative humidity

– 40%.

The mechanical characteristics

were established during the tensile test of standard cylindrical

specimens with a diameter of 10 mm on a test machine type P-5.

a

b

Fig. 2. Finite-element model

of steel hopper capacity:

а

– traditional structural scheme with horizontal stiffening

ribs;

b

– developed

structural scheme with horizontal corrugated elements

Thus, based

on the obtained test results in terms of operation of the bunker

capacity under difficult conditions of high loads, as well as high

and low temperatures, 10G2FB steel grade was the best. It has a

mixed structure of fine ferrite and dispersed carbide and of the

second phase carbonitride, which is achieved by microalloying and

controlled rolling with the addition of

chromium, niobium, vanadium and titanium. These admixtures have a

grinding effect on the original austenitic grain [11]. It also

provides 10G2FB steel with good impact resistance at KCV–15

= 59 J/cm2

and KCU–60

= 39 J/cm2.

Therefore, steel grade 10G2FB was taken as the main for the design

of steel bunker capacity.

As a result of the numerical

calculations, quantitative results were obtained (Table 3), and the

general pictures of the deformed state are shown in Fig. 3 (for ease

of perception, half of the model is presented).

As can be

seen from the results obtained, for the bunker capacity designed

with horizontal corrugated elements, the deformed state is more

uniform. Accordingly, the stress state is also more uniform, with

fewer stress concentrators, which is very important for difficult

operating conditions (especially for low temperatures). Weight

indicators remain almost the same.

Table

1

Chemical composition of tested steels

|

Steel

grade

|

Mass fraction of elements, %

|

|

Carbon (С)

|

Manganese (Mn)

|

Silicon (Si)

|

Sulfur (S)

|

Phosphorus (P)

|

Chromium (Cr)

|

|

St3sp

|

0.16

|

0.50

|

0.20

|

0.004

|

0.009

|

0.04

|

|

09G2S

|

0.09

|

1.64

|

0.55

|

0.004

|

0.009

|

0.03

|

|

10G2FB

|

0.09

|

1.64

|

0.55

|

0.004

|

0.009

|

0.03

|

|

Steel

grade

|

Mass fraction of elements, %

|

|

Nickel (Ni)

|

Copper (Cu)

|

Vanadium (V)

|

Aluminum (Al)

|

Niobium (Nb)

|

Titanium (Ti)

|

|

St3sp

|

0.03

|

0.01

|

–

|

0.04

|

–

|

–

|

|

09G2S

|

0.05

|

0.03

|

0.001

|

–

|

–

|

–

|

|

10G2FB

|

0.05

|

0.03

|

0.001

|

0.033

|

0.05

|

0.02

|

Table 2

Mechanical properties of tested steels

|

Steel grade

|

Test temperature,

ºС

|

Yield strength, MPa

|

Strength limit σв,

MPa

|

Relative

elongation, δ5,

%

|

Contraction

ratio,

ψ, %

|

|

σ0,2

|

σТ

|

|

St3sp

|

+20

|

–

|

278

|

418

|

36

|

67

|

|

+600

|

108

|

–

|

155

|

60

|

87

|

|

+800

|

37

|

–

|

55

|

83

|

76

|

|

09G2C

|

+20

|

–

|

343

|

492

|

36

|

74

|

|

+600

|

167

|

–

|

227

|

40

|

85

|

|

+800

|

63

|

–

|

48

|

91

|

77

|

|

10G2FB

|

+20

|

–

|

462

|

584

|

27

|

65

|

|

+600

|

258

|

–

|

285

|

27

|

83

|

|

+800

|

73

|

–

|

84

|

59

|

86

|

Table 3

Quantitative results of numerical analysis

-

|

Indicator

|

Constructive scheme with

horizontal

|

|

stiffening ribs

|

corrugated elements

|

|

St3sp steel

|

10G2FB steel

|

St3sp steel

|

10G2FB steel

|

|

Stability coefficient

|

13.41

|

5.14

|

15.27

|

6.43

|

|

Wall deflection, mm

|

7.27

|

14.24

|

5.15

|

7.35

|

|

Weight, kg

|

15 456

|

11 216

|

15 532

|

11 310

|

It should

also be noted that the presence of a corrugated surface on the

inside of the bunker capacity creates

additional opportunities for special self-lining due to the

retention of bulk material. In the practice of design, this method

of lining the inner surface is created artificially, attaching

special horizontal retaining elements, which in turn increases the

complexity of manufacturing the structure.

Originality and practical

value

This publication evaluates the

possibility and efficiency of using fine-grained high-strength

steels for the construction of steel bunker capacities. And the

similar estimation is given not only for constructions of the

traditional structural scheme with horizontal stiffening ribs, but

also for bunkers with the developed structural scheme on the basis

of corrugated sheets.

From the practical point of

view in the course of the conducted researches of various structural

variants of steel bunker capacity, quantitative indicators of a

stress-strain state are received. The data is presented in a compact

and easy to evaluate and compare form. They suggest an improvement

in the performance of bunkers and a potential reduction in the risk

of their failure and accidents during operation.

Fig. 3. Deformed state

of steel bunker capacity made

of 10G2FB steel:

а

– traditional

structural scheme with horizontal stiffening

ribs;

b

– developed structural scheme with horizontal corrugated elements

Conclusions

Based

on the assessment of the stress-strain state of the steel bunker

capacity, made of steels of different grades, it should be stated

the following:

1. The

use of fine-grained heat-resistant steels of high strength (for

example, 10G2FB steel grade) for bunker capacities of both

traditional structural scheme with stiffening ribs, and developed

structural scheme based on corrugated sheets can reduce the material

consumption of the structure by about 30% in both cases.

2. Due

to good performance at both high and low temperatures, fine-grained

heat-resistant steel grade 10G2FB can be effectively used for steel

bunkers operating under difficult conditions. Such conditions

include working conditions in the northern regions or with hot bulk

materials.

3. It should

be noted the possibility of improving the performance of steel

bunker capacities, in particular durability and reliability, due to

the improved mechanical properties of the steel type used. In

operation, this potentially reduces the possible costs of repairing

and maintaining bunker capacities.

LIST OF REFERENCE LINKS

Баженов В. А., Перельмутер А. В.,

Ворона Ю. В., Отрашевська В. В. Варіаційні

принципи будівельної механіки. Нариси

з історії. Київ : Каравела, 2018. 924 с.

Банніков Д. О. Аварії та відмови

сталевих тонкостінних циліндричних

силосів для зернових культур. Мости

та тунелі : теорія, дослідження, практика.

2019. № 15. С. 6–17.

DOI: 10.15802/bttrp2019/172336

Безсалий В. М., Банніков Д. О.

Ефективність сталевих тонкостінних

оцинкованих профілів для аркових

елементів. Мости та тунелі : теорія,

дослідження, практика. 2019. № 16. С. 20–29.

DOI: 10.15802/bttrp2019/189428

Гезенцвей Е. И. Технологичность

применения мелкозернистых термоупрочненных

сталей в конструкциях кожухов доменных

печей. Промислове будівництво та

інженерні споруди. 2016. № 3. С. 43–47.

ДБН В.2.2-8-98. Підприємства,

будівлі і споруди по зберіганню та

переробці зерна. [Чинний від

1998-01-07]. Вид. офіц. Київ : Держбуд, 1998.

41 с.

ДБН В.2.6-198:2014. Сталеві конструкції.

Норми проектування. [Чинний від

2015-01-01]. Вид. офіц. Київ : Мінрегіон, 2014.

205 с.

ДСТУ-Н Б EN 1993-1-3:2012. Національний

стандарт України. Єврокод 3. Проектування

сталевих конструкцій. Частина 1-3.

Загальні правила. Додаткові правила

для холодноформованих елементів і

профільованих листів. (EN 1993-1-3:2005, IDT).

[Чинний від 2014-01-07]. Вид. офіц. Київ :

Мінрегіонбуд та ЖКГ України, 2012. 14 с.

ДСТУ-Н Б EN 1993-4-1:2012. Національний

стандарт України. Єврокод 3: Проектування

сталевих конструкцій. Частина 4-1:

Силоси, (EN 1993-4-1:2007, IDT).

[Чинний від 2021-01-01]. Вид. офіц. Київ :

Мінрегіонбуд та ЖКГ України, 2017. 64 с.

Карпиловский В. С., Криксунов

Э. З., Маляренко А. А., Фиалко С. Ю.,

Перельмутер А. В., Пе-рельмутер М. А.

SCAD Office. Версия 21. Вычислительный

комплекс SCAD++. Москва : СКАД СОФТ,

2015. 848 с.

Качуренко В. В., Банников Д. О.

Конструктивные решения стальных

емкостей для сыпучих материалов :

монография. Днепропетровск : Новая

идеология, 2016. 168 с.

Малинов Л. С., Бурова Д. В., Малышева

Е. И. Способы повышения свойств стали

10Г2ФБ, обеспечивающие ее применение

по новому назначению и энергосбережение.

Новые материалы и технологии в

металлургии и машиностроении. 2017. №

2. С. 72–74.

Edwin H.,

Gaylord Jr., Gaylord Сh. N.,

Stallmeyer J. E.

Structural Engineering Handbook. McGraw-Hill,

1997. 1368 p.

Gronostajski

Z., Kaczyński

P., Polak

S., Bartczak

B. Energy absorption of thin-walled profiles

made of AZ31 magnesium alloy. Thin-Walled

Structures. 2018. Vol.

122. P. 491–500.

DOI: 10.1016/j.tws.2017.10.035

He

K., Chen

Yu., Wan

J. Web crippling behavior of grouted galvanized

rectangular steel tube. Thin-Walled

Structures. 2018. Vol. 122. P.

300–313. DOI: 10.1016/j.tws.2017.09.032

Hezentsvei Yu., Bannikov D. Effectiveness

Evaluation of Steel Strength Improvement for Pyramidal-Prismatic

Bunkers. Eureka :

Physics and Engineering. 2020. № 2

(27). P. 30–38.

DOI: 10.21303/2461-4262.2020.001146

Neduzha L. O., Shvets A. O.

Application

of APM WinMachine software for design and calculations in

mechanical engineering.

Наука та прогрес транспорту.

2016. № 2 (62).

P. 129–147.

DOI: 10.15802/stp2016/67328

Piekarczuk

A., Więch

Pr., Cybulski

R. Experimental method to evaluate the

load-carrying capacity of double corrugated sheet profiles.

Thin-Walled Structures.

2019. Vol.

144. URL:

https://www.sciencedirect.com/science/article/abs/pii/S0263823119302368.

DOI: 10.1016/j.tws.2019.106283

Tiutkin O., Miroshnyk

V., Radkevych A., Alkhdour A.

Nonuniform Stress State of a Hoisting Shaft Lining as a Result of

Disturbance of the Ground Freezing Technology.

E3S Web of Conferences. 2019. Vol.

109.

P. 1–6. DOI:

10.1051/e3sconf/201910900099

Tiutkin O., Petrosian N.,

Radkevych A., Alkhdour A.

Regularities of Stress State of Unsupported Working

Occurring in a Layered Massif. E3S Web

of Conferences. 2019. Vol. 109.

P. 1–7.

DOI: 10.1051/e3sconf/201910900100

Zhang

Y., Ge

W., Zhang

Y., Zhao

Z. Topology

optimization method with direct coupled finite element–element-free

Galerkin method. Advances

in

Engineering

Software.

2018. Vol. 115. P.

217–229.

DOI: 10.1016/j.advengsoft.2017.09.012

Ю. І. ГЕЗЕНЦВЕЙ1,

Д. О. БАННІКОВ2*

1ВАТ

«Метінвест Інжиніринг», вул. Ярослава

Мудрого, 53, Дніпро,

Україна, 49038, тел.

+38 (067) 611 57 91,

ел. пошта

efim.gezentsvey@metinvestholding.com,

ORCID 0000-0003-1190-5465

2*Каф. «Будівельне

виробництво та геодезія», Дніпровський

національний

університет залізничного

транспорту імені академіка В. Лазаряна,

вул. Лазаряна, 2, Дніпро, Україна, 49010,

тел. +38 (063) 400 43 07,

ел. пошта bdo2020@yahoo.com,

ORCID 0000-0002-9019-9679

Застосування дрібнозернистих

термозміцнених сталей

для підвищення

експлуатаційних якостей бункерних

ємностей із тонкостінних оцинкованих

профілів

Мета.

У роботі передбачено дослідити

ефективність застосування дрібнозернистих

термозміцнених сталей (переважно марки

10Г2ФБ) для сталевих бункерних ємностей.

При цьому як основний варіант розглянуто

конструктивну схему такої споруди з

використанням сталевих гофрованих

листів. Методика.

Для досягнення поставленої мети

проведено серію чисельних розрахунків

сталевої бункерної ємності

пірамідально-призматичного типу з

габаритними розмірами в плані 6×5,2 м й

загальною висотою 4,5 м. Ємність

спроектовано для ускладнених умов

роботи, зокрема підвищених навантажень,

у тому числі й тривалих динамічних.

Також до уваги взято потенційну

можливість експлуатації ємності за

умов підвищених або понижених температур.

При цьому проаналізовано як традиційну

конструктивну схему бункерної ємності

з горизонтальними ребрами жорсткості,

так і розроблену конструктивну схему

на основі сталевих гофрованих листів.

Обчислення проведено методом скінченних

елементів на базі проектного комплексу

SCAD for Windows. Результати.

На підставі аналізу та зіставлення

отриманих під час чисельних розрахунків

даних установлено, що застосування

дрібнозернистих термозміцнених сталей

високої міцності (на прикладі сталі

марки 10Г2ФБ) для

бункерних ємностей як традиційної

конструктивної схеми з ребрами

жорсткості, так і розробленої

конструктивної схеми на основі гофрованих

листів дозволяє знизити матеріалоємність

споруди приблизно на 30 % в обох випадках.

При цьому завдяки

хорошим показникам роботи як

за підвищених, так і за понижених

температур

дрібнозерниста термозміцнена сталь

марки 10Г2ФБ може

бути ефективно застосована для

сталевих бункерних ємностей, які

працюють в ускладнених умовах. Наукова

новизна. Оцінено

можливість та ефективність застосування

дрібнозернистих термозміцнених сталей

високої міцності для конструкції

сталевої бункерної ємності. Причому

подібну оцінку надано не тільки для

споруд традиційної конструктивної

схеми з горизонтальними ребрами

жорсткості, а й для бункерів із розробленою

конструктивною схемою на основі

гофрованих листів. Практична

значимість. Із практичної

точки зору в ході проведених досліджень

різноманітних конструктивних варіантів

сталевої бункерної ємності отримано

кількісні показники напружено-деформованого

стану. Дані представлено в компактній

та зручній для оцінки й зіставлення

формі. Вони дозволяють стверджувати

про поліпшення експлуатаційних

характеристик ємностей і потенційне

зниження ризиків їх відмов та аварій

під час експлуатації.

Ключові слова: дрібнозерниста

термозміцнена сталь; тонкостінний

оцинкований профіль; метод скінченних

елементів; бункерна ємність

REFERENCES

Bazhenov, V. A., Perelmuter, A. V.,

Vorona, Yu. V., & Otrashevska, V. V. (2018). Variatsiini

pryntsypy budivelnoi mekhaniky. Narysy z istorii.

Kiev: Karavela. (in Ukrainian)

Bannikov, D. O. (2019). Accidents

and failures of steel thin-walled cilindric silos for grain

cultures. Bridges and Tunnels: Theory,

Research, Practice, 15, 6-17. DOI:

10.15802/bttrp2019/172336 (in Ukrainian)

Bezsalyi, V. M., & Bannikov, D.

O. (2019). Efficiency of thin-walled galvanized profiles for arch

elements. Bridges and Tunnels: Theory,

Research, Practice, 16, 20-29. DOI:

10.15802/bttrp2019/189428 (in Ukrainian)

Gezentsvey, Ye. I. (2016).

Tekhnologichnost primeneniya melkozernistykh termouprochnennykh

staley v konstruktsiyakh kozhukhov domennykh pechey. Promyslove

budivnytstvo ta inzhenerni sporudy, 3,

43-47 (in Russian)

Pidpryiemstva,

budivli i sporudy po zberihanniu ta pererobtsi zerna, 41 DBN

V.2.2-8-98 (1998). (in Ukrainian)

Stalevi

konstruktsii. Normy proektuvannia, 205 DBN В.2.6-198:2014 (2014).

(in Ukrainian)

Natsionalnyi standart Ukrainy.

Yevrokod 3. Proektuvannia stalevykh konstruktsii. Chastyna 1-3.

Zahalni pravyla. Dodatkovi pravyla dlia kholodnoformovanykh

elementiv i profilovanykh lystiv. (EN 1993-1-3:2005, IDT) 14

DSTU-N B EN 1993-1-3:2012 (2014).

(in Ukrainian)

Natsionalnyi standart Ukrainy.

Yevrokod 3: Proektuvannia stalevykh konstruktsii. Chastyna 4-1:

Sylosy, (EN 1993-4-1:2007, IDT) 64 DSTU-N B EN 1993-4-1:2012

(2021). (in Ukrainian)

Karpilovskyy, V. S., Kryksunov, E.

Z., Maliarenko, A. A., Fialko, S. Yu., Perelmuter, A. V., &

Perelmuter, M. A. (2015). SCAD

Office. Version 21. Computing complex SCAD++.

Moskow: SCAD SOFT. (in Russian)

Kachurenko, V. V., &

Bannikov D. O. (2016). Structural

decisions of steel capacities for granular materials:

monograph. Dnepropetrovsk: Novaya ideologiya. (in Russian)

Malinov, L., Burova, D., &

Malysheva, I. (2017). A method for improving the properties of

steel 10G2FB, providing its application for a new purpose and

energy saving. New Materials and

Technologies in Metallurgy and Mechanical Engineering,

2,

72-74. (in Russian)

Edwin, H.,

Gaylord, Jr., Gaylord,

Сh. N., & Stallmeyer, J.

E. (1997). Structural

Engineering Handbook. McGraw-Hill. (in

English)

Gronostajski,

Z., Kaczyński,

P., Polak,

S., & Bartczak,

B. (2018). Energy

absorption of thin-walled profiles made of AZ31 magnesium alloy.

Thin-Walled Structures, 122,

491-500. DOI: 10.1016/j.tws.2017.10.035

(in English)

He,

K., Chen,

Yu., & Wan,

J. (2018). Web

crippling behavior of grouted galvanized rectangular steel tube.

Thin-Walled Structures, 122,

300-313. DOI: 10.1016/j.tws.2017.09.032

(in English)

Hezentsvei, Yu., &

Bannikov, D. (2020). Effectiveness

Evaluation of Steel Strength Improvement for Pyramidal-Prismatic

Bunkers. Eureka: Physics and Engineering,

2(27), 30-38.

DOI: 10.21303/2461-4262.2020.001146

(in English)

Neduzha, L. O., & Shvets, A. O.

(2016). Application

of APM WinMachine software for design and calculations in

mechanical engineering.

Science and Transport Progress,

2(62), 129-147.

DOI: 10.15802/stp2016/67328

(in English)

Piekarczuk, A., Więch, P., & Cybulski, R. (2019).

Experimental method to evaluate the load-carrying capacity of

double corrugated sheet profiles. Thin-Walled Structures, 144.

Retrieved from

https://www.sciencedirect.com/science/article/abs/pii/S0263823119302368.

DOI: 10.1016/j.tws.2019.106283

(in English)

Tiutkin, O.,

Miroshnyk, V.,

Radkevych, A.,

& Alkhdour, A. (2019).

Nonuniform Stress State of a Hoisting Shaft Lining as a

Result of Disturbance of the Ground Freezing Technology.

E3S Web of Conferences, 109,

1-6. DOI:

10.1051/e3sconf/201910900099

(in English)

Tiutkin, O.,

Petrosian, N.,

Radkevych, A.,

& Alkhdour, A.

(2019). Regularities of Stress State of Unsupported Working

Occurring in a Layered Massif. E3S Web

of Conferences, 109, 1-7.

DOI: 10.1051/e3sconf/201910900100

(in English)

Zhang, Y., Ge, W., Zhang, Y., &

Zhao, Z. (2018). Topology optimization method with direct coupled

finite element–element-free Galerkin method. Advances

in Engineering Software, 115,

217-229. DOI: 10.1016/j.advengsoft.2017.09.012

(in English)

Received:

Oct. 01, 2020

Accepted:

Feb. 01, 2021

Creative

Commons Attribution 4.0 International

doi:

10.15802/stp2021/227198

© Y.

I. Hezentsvei, D. O. Bannikov,

2021