Introduction

Biological treatment is one of

the most effective methods of wastewater treatment [3, 4, 6].

Efficiency determination of this treatment at the stage of design or

reconstruction of bioreactors, in which this method of wastewater

treatment is carried out, requires the use of special mathematical

models and calculation methods. Moreover, these theoretical

calculation methods are the main toolkit, since a physical

experiment in the field of biological treatment always requires a

long time and expensive equipment. To date, a significant number of

mathematical models have been developed that allow, with different

approximation degrees, determining the bioreactor efficiency. But

the existing mathematical models (empirical, balance, analytical)

[1–5, 7–17] do not take into account a number of important

parameters affecting the efficiency of bioreactors (their geometric

shapes and design features, movement hydrodynamics activated sludge

and substrate in them, the presence of additional elements, various

modes of operation), or require significant time when implemented on

computers (CFD-models). Therefore, the development of mathematical

models for assessing the efficiency of biological reactors, which

allow taking into account these important factors and quickly

determining the values of the parameters necessary for the designer,

is an important scientific task.

Purpose

This work

provides for the development of a numerical model to assess the

efficiency of wastewater treatment in aerotanks. The task is to

create a multifactorial computer model that makes it possible to

quickly calculate the process of

biological wastewater treatment, taking into account the geometric

shape of the bioreactor.

Methodology

When building a model, we will

take into account the following factors:

-

geometric shapes of aerotank;

– the process of changing the

substrate concentration in aerotanks over time;

– the process of changing the

of activated sludge concentration in aerotanks over time;

– the presence of additional

elements in aero-tanks.

The material balance equations

for the substrate and activated sludge in the reactor based on the

Monod model has the following form:

where

–

activated sludge

measurement coefficient;

–

activated sludge

measurement coefficient;

– time;

– time;

–

averaged concentration

of activated

sludge in the

bioreactor ;

–

averaged concentration

of activated

sludge in the

bioreactor ;

– averaged concentration

of substrate in

the bioreactor;

– averaged concentration

of substrate in

the bioreactor;

– diffusion coefficient; Y –

parameter in the Monod model;

– diffusion coefficient; Y –

parameter in the Monod model;  –

components of the water flow velocity in the bioreactor in the

direction of the x, y axes, respectively;

–

components of the water flow velocity in the bioreactor in the

direction of the x, y axes, respectively;

– components of the diffusion coefficients at the considered plane

point in the x, y

direction.

– components of the diffusion coefficients at the considered plane

point in the x, y

direction.

The averaged

concentration of activated sludge and substrate over the width of

the bioreactor is determined as follows:

Equations

(1) and (2) describe the change in the concentration of activated

sludge and substrate over time in the aeration tank due to movement

and diffusion. Equations (3) – (5) describe the process of

substrate consumption by activated sludge.

The limiting conditions for

modeling equations are as follows:

at the inlet, the boundary

condition is:

,

,

where

– known concentrations of substrate and sludge, respectively;

– known concentrations of substrate and sludge, respectively;

2) boundary

conditions at the exit from the bio-reactor:

;

;

,

,

where

,

, – concentrations in the last computational cell;

– concentrations in the last computational cell;

– concentrations in the previous computation cell;

– concentrations in the previous computation cell;

3) on rigid

surface:

where n

– unit normal to the surface.

The initial

conditions are as follows: at t=0

X=X0,

S=S0.

To solve the hydrodynamics

problem – determining the components field of the flow velocity

vector in the aerotank – a model of potential motion was used [8,

29]:

(6)

(6)

where Р

– velocity potential.

Knowing the potential field,

the values of the components of the flow velocity vector in the

bioreactor are determined by the formulas [8, 9, 14]:

Let us consider the difference

in dependencies, with the help of which the numerical integration of

the modeling equations is carried out. Thus, to calculate the

substrate concentration in the bioreactor, an alternating-triangular

two-step splitting scheme is used [2]. At the first stage of

splitting, the calculated dependence has the form:

(7)

(7)

At the

second step of splitting, the calculated dependence is as follows:

(8)

(8)

where

,

,

.

.

For the

second equation, the difference schemes have the form:

– calculated

dependence at the first step:

(9)

(9)

– calculated

dependence at the second step:

(10)

(10)

where

,

,

.

.

To construct

a local one-dimensional scheme for solving equation (6), we perform

the following transformations. First, let us represent this equation

in the form:

(11)

(11)

where t

– fictitious time.

Further, we

divide equation (11) as follows:

Equation

(12) describes the change in the value of Р

in the direction of the X

axis, and equation (13) describes the change in the Y

direction.

The

calculated dependencies (Richardson's method) for determining the

unknown value of Р based on

equation (12) have the form:

(14)

(14)

Accordingly,

the calculated dependencies (Richardson's method) for determining

the unknown value of Р based on

equation (13):

(15)

(15)

Since we solve the evolutionary

equation, the calculation by dependencies (14)–(15) ends when the

following condition is met:

where ε

– small number; n

– iteration number.

We calculate the flow velocity

as follows:

For numerical integration of

equations (3)–(4), the Euler method is used.

The algorithm for solving this

problem includes two main stages.

At the first stage, the

following steps are performed:

1) the

velocity potential field P

(x,

y) in the aerotank is calculated;

2) the flow

velocity field u

(x,

y), v

in the aerotank is determined.

The second

stage (calculation at the time step dt)

contains the following steps:

1) the change in the

concentration of activated sludge in the aerotank due to flow

movement and diffusion is calculated;

2) the change in the

concentration of the substrate in the aerotank due to the flow

movement and diffusion is calculated;

3) the change in the

concentration of activated sludge and substrate in each difference

cell based on the Monod model is calculated;

4) the calculation is repeated

at a new time step, starting from item 1.

Based on the constructed

numerical model, the BIO-2K computer program was developed.

Programming is carried out in the FORTRAN algorithmic language.

Findings

Let us

present the results of solving the problem of assessing the

efficiency of the aeration tank using the developed CFD model. The

following scenarios were considered:

scenario no.

1: the aerotank works without additional elements inside the

structure;

scenario no.

2: aerotank has one plate inside the structure;

scenario no.

3: aerotank has two plates inside the structure;

scenario no.

4: aerotank works as a reservoir for the substrate destruction, but

there is no entry and exit of the substrate and activated sludge.

That is, in this scenario, the aerotank is a tank filled with

activated sludge and substrate, and the process of changing their

concentration was studied using the Monod model.

Calculations

were performed with the following initial data:

Sin

= 360 mg/l – the concentration of

the substrate (Biological oxygen demand (complete), which enters the

structure;

bioreactor dimensions 15x5 m;

=

3 495 m3/day

– waste water consumption;

=

3 495 m3/day

– waste water consumption;

mg/l –

concentration of activated sludge that enters the reactor;

mg/l –

concentration of activated sludge that enters the reactor;

μmax

= 1.04 – reproducibility index parameter;

Ks

= 100 mg/l – sludge index

parameter;

Kd

= 0.055 1/day – theb coefficient that takes into account the death

of microorganisms;

Y = 0.55 – parameter

in the Monod model.

Initial

condition: Sin

= 360 mg/l, Xin

= 200 mg/l, is the concentration of the substrate and activated

sludge in the reactor for the time moment t

= 0.

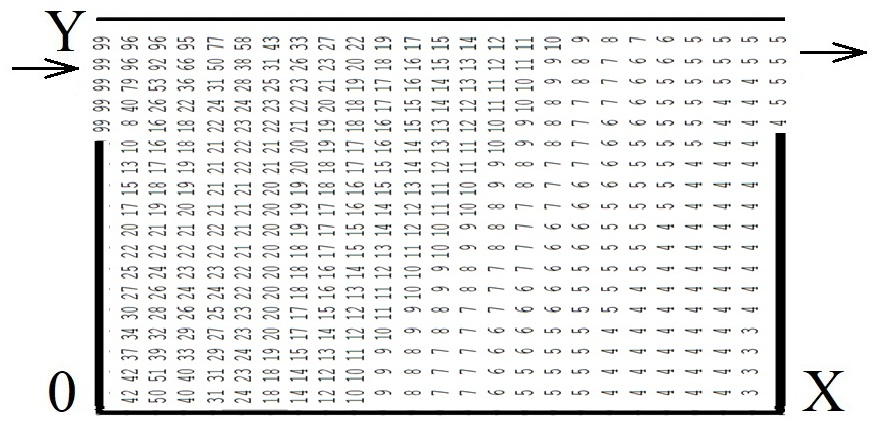

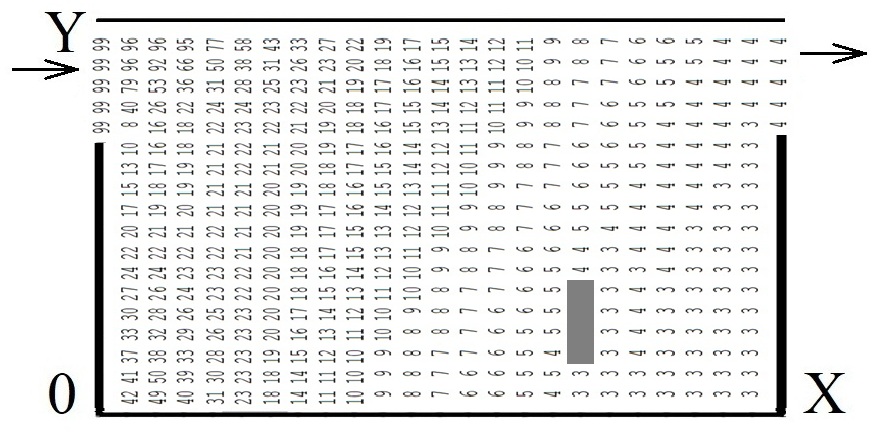

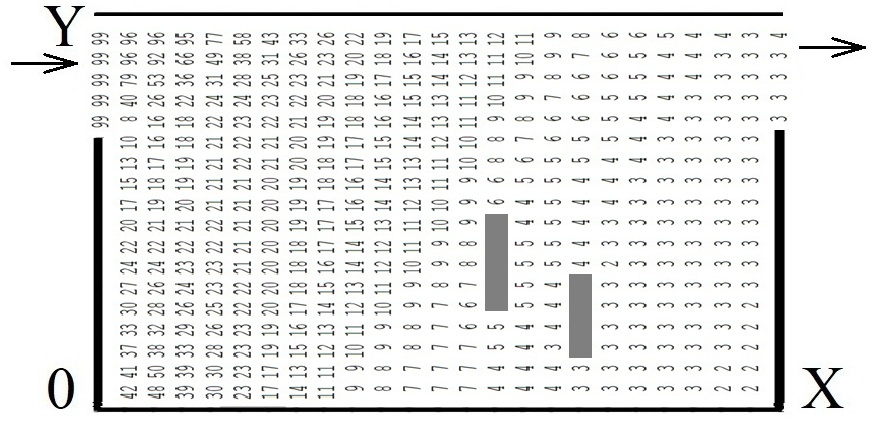

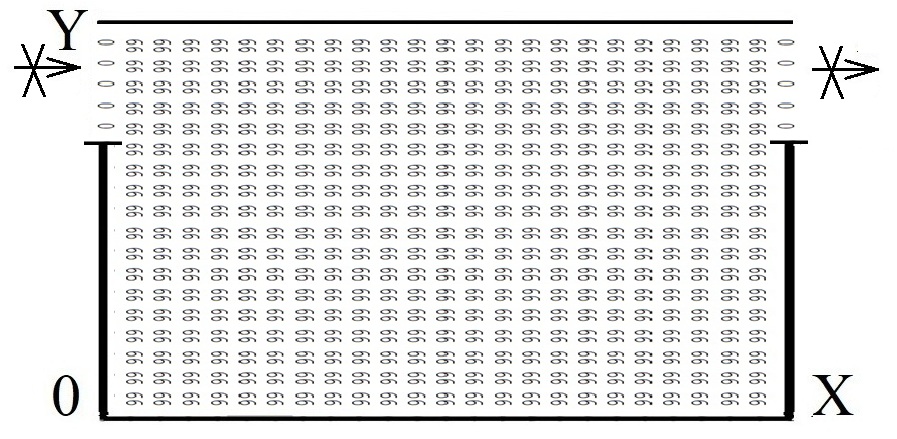

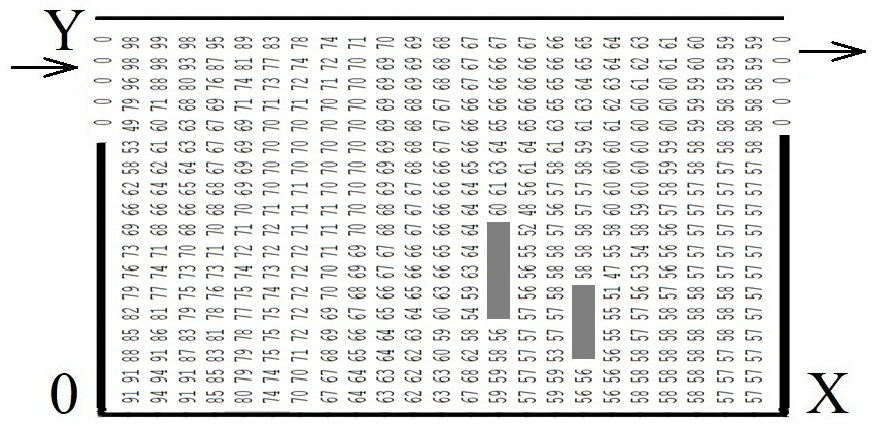

Figures 1–4

show how the substrate concentration at the reactor outlet changes

for the scenarios under consideration. The concentration is averaged

over the aerotank width for the time moment t

= 1.5 (dimensionless time). Each number in the Figures shows the

substrate concentration as a percentage of the maximum concentration

(this is the concentration at the entrance to the reactor Sin

= 360 mg/l).

Fig.

1. Substrate concentration in the bioreactor

(no plates,

scenario no. 1)

Fig.

2. Substrate concentration

in the

bioreactor

(one

plate, scenario

no. 2)

Fig.

3. Substrate concentration in the bioreactor

(two plates,

scenario no. 3)

Fig.

4. Substrate concentration

in the

bioreactor, t

= 1.5 (no flow

in the reactor,

scenario no. 4)

As can be seen from the above

figures, the field of substrate concentration inside the reactor can

be divided into two zones. The first zone corresponds to the

concentration range from 99 to 10% and occupies approximately the

first half of the reactor. The second zone corresponds to the

substrate concentration in the range of 10–3% (output from the

reactor). The border between the zones looks like a «slanting»

line. The second zone even has a «sparse» view. A significant

concentration of the substrate in the first zone is caused by its

constant ingress into the structure through the inlet.

Fig. 5 shows

the field of activated sludge concentration in the structure (each

number is the activated sludge concentration in percent of the

maximum concentration value at a given time, for this time – Xmax

= 620.76 mg/l). This concentration gradually decreases from the

inlet (where the active sludge enters the reactor) to the outlet.

Thus, Table

1 shows the average value of the substrate concentration at the

outlet from the reactor for the time t

=1.5 for each scenario.

As you can see from Table 1,

the plates in the strcture affect the efficiency of water

purification in the bioreactor. The most active process of water

purification takes place if there is no movement in the reactor

(scenario no. 4), i.e., if there is no new portions of the substrate

entering the reactor. Thus, it can be concluded that the quality

control of wastewater treatment in biological reactors is possible

through the use of additional elements in the structure – plates.

Fig.

5. Activated sludge concentration in the bioreactor, t

= 1.5 (two plates, scenario no. 3)

Table 1

Average

value of substrate concentration

at the bioreactor outlet

|

Scenario

|

Scenario

no. 1

|

Scenario

no. 2

|

Scenario

no. № 3

|

Scenario

no. 4

|

|

Concentration

|

19.95

mg/l

|

17.37

mg/l

|

14.71

mg/l

|

1.63

mg/l

|

It is also important to compare

the dynamics of the water purification rate in the reactor if there

is no movement (scenario no. 4) and when there is movement (scenario

no. 1). Biological reactors in scenarios no. 1 and no. 4 have the

same geometry, so this comparison is logical. Table 2 shows the

results of calculations for these reactors.

Table 2

Average

value of substrate concentration

at the bioreactor outlet

|

Time

(dimensionless)

|

Scenario

no. 4

|

Scenario

no. 1

|

|

0.6

|

148.32

mg/l

|

133.81

mg/l

|

|

0.96

|

44.71

mg/l

|

55.38

mg/l

|

|

1.2

|

12.25

mg/l

|

32.76

mg/l

|

|

1.4

|

2.89

mg/l

|

22.66

mg/l

|

|

1.5

|

1.63

mg/l

|

19.95

mg/l

|

Data

analysis of Table 2 shows that approximately from the moment of time

t = 0.96,

the deceleration of the water purification process starts in the

reactor, where the movement takes place, (scenario no. 1). By the

time moment t

= 1.5, the substrate concentration at the outlet from the reactor,

where there is movement, is significantly different from the

concentration for the reactor, where there is no movement.

Note that the time for

calculating each scenario was 5 s.

Originality

and practical value

A new numerical 2D model is

proposed to assess the operation efficiency of the aerotank. A

feature of the model is the ability to assess the operation of the

aerotank, taking into account its geometric shape and location of

additional plates in the structure. The simulated equations reflect

the fundamental law of continuum mechanics – the law of mass

conservation.

The developed numerical model

makes it possible to determine the concentration field of the

substrate and activated sludge in the bioreactor. The model can be

useful when performing calculations in the case of designing

biological treatment facilities or when reconstructing existing

bioreactors.

Conclusions

In the article, a new numerical

model has been developed that allows one to determine the aerotank

operation efficiency, taking into account its geometric shape. The

results of computational experiments show that the use of additional

elements in the aerotank improves the efficiency of water

purification.

In the future, this scientific

direction should be developed in the field of development of

numerical models for evaluating the aerotank operation efficiency

based on the Navier-Stokes equation.

list of reference links

Беляев

Н. Н., Нагорная Е. К. Математическое

моделирование массопереноса в

отстойниках систем водоотведения

: монография.

Днепропетровск : Новая идеология, 2012.

112 с.

Беляев

Н. Н., Козачина В. А.

Математическое моделирование

массопереноса в горизонтальных

отстойниках :

монография. Днепропетровск : Акцент

ПП, 2015. 115 с.

Василенко

О. А., Грабовський П. О., Ларкіна Г. М.,

Поліщук О. В., Прогульний В. Й. Реконструкція

і інтенсифікація споруд водопостачання

та водовідведення :

навч. посіб. Київ : ІВНВКП «Укргеліотек»,

2010. 272 с.

Карелин

Я. А., Жуков Д. Д., Журов В. Н., Репин Б. Н.

Очистка производственных

сточных вод в

аеротенках. Москва :

Стройиздат, 1973, 223 с.

Ласков

Ю. М., Воронов Ю. В., Калицун В. И. Примеры

расчетов канализационных сооружений.

Москва : Высшая

школа, 1981. 237 с.

Олійник О. Я, Айрапетян

Т. С. Моделювання очисних стічних вод

від органічних забруднень в

біореакторах-аеротенках зі зваженим

(вільно плаваючим) і закріпленим

біоценозом. Доповідь

НАН України. 2015. № 5.

С. 55–60. DOI: 10/15407/dopovidi2015.05.055

Alharbi

A. O. M. The biological treatment of wastewater : mathematical

models. Bulletin of the Australian

Mathematical Society.

2016. Vol. 94. Іss. 2. P. 347–348.

DOI: https://doi.org/10.1017/S0004972716000411

Amaral A., Gillot S.,

Garrido-Baserba M., Filali A., Karpinska A. M., Plósz B. G., …

Rosso D. Modelling gas-liquid mass transfer in wastewater treatment

: when current knowledge needs to encounter engineering practice

and vice-versa. Water Science &

Technology.

2019. Vol. 80.

Iss. 4. P. 607–619. DOI: 10.2166/wst.2019.253

Babaei A.,

Azadi R., Jaafarzadeh N., Alavi N. Application and Kinetic

Evaluation of upflow Anaerobic biofilm Reactor for Nitrogen Removal

from Wastewater. Iranian Journal of

Environmental Health Science and Engineering.

2013. Vol. 10. Iss. 1. P. 1–8. DOI:

10.1186/1735-2746-10-20

Bomba A., Klymiuk Y.,

Prysiazhniuk I., Prysiazhniuk O., Safonyk A.

Mathematical modeling of wastewater treatment from multicomponent

pollution by through microporous filling.

AIP Conference Proceedings.

2016. Vol. 1773.

P. 040003-1–040003-11. DOI: 10.1063/1.4964966

Dapelo D.,

Bridgeman G. A CFD strategy to retrofit an anaerobic digester

to improve mixing performance in wastewater treatment. Water

Science & Technology. 2020. Vol.

81. Iss. 8. P. 1646–1657.

DOI: 10.2166/wst.2020.086

Gao

H., Stenstrom M. K. Development and applications in CFD modeling

for secondary settling tanks over the last three decades : A

review. Water Environment Research.

2019. Vol. 92. Iss. 6. P. 796–820.

DOI: 10.1002/wer.1279

Gao

H., Stenstrom M. K. Influence of Model Parameters and Inlet

Turbulence Boundary Specification Methods in Secondary Settling

Tanks : Computational Fluid Dynamics Study. Journal

of Environmental Engineering.

2020. Vol. 146. Iss. 5. P. 04020028-1–04020028-12. DOI:

10.1061/(ASCE)EE.1943-7870.0001689

Gao

H., Stenstrom M. K. Computational Fluid Dynamics Analysis for

Improving Secondary Settling Tank Performance. Conference

: World Environmental and Water Resources Congress 2020.

2020. P. 212–224. DOI: 10.1061/9780784482988.021

Griborio

A. Secondary Clarifier Modeling : A

Multi-Process Approach. Dissertation

and Theses. University of New Orleans

: USA, 2004. 440 p.

Mocanu

C. R., Mihaillescu R. Numerical Simulation Wastewater Treatment

Aeration Processes. U. P. B. Sci.

Bull., Series D. 2012. Vol. 74. Iss.

2. P. 191–198.

Pereda

M., Zamarreno J. M. Agent – based modeling of an activated sludge

process in batch reactor. 19th

Mediterrian Conference on Control and Automation Aquis.

2011. P. 1128–1133. DOI: 10.1109/med.2011.5983027

М. М. БІЛЯЄВ1*,

М. В. ЛЕМЕШ2*,

В. В. БІЛЯЄВА3*,

П. Б. МАШИХІНА4*,

З. М. Якубовська5*

1*Каф.

«Гідравліка і водопостачання»,

Дніпровський національний університет

залізничного транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2,

Дніпро,

Україна, 49010, тел. +38 (056) 273 15 09,

ел. пошта

water.supply.treatment@gmail.com, ORCID 0000-0002-1230-8040

2*Каф.

«Гідравліка і водопостачання»,

Дніпровський національний

університет

залізничного транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38 (056) 273 15 09, ел. пошта

water.supply.treatment@gmail.com,

ORCID 0000-0002-1531-7882

3*Каф.

«Аерогідромеханіка та енергомасоперенос»,

Дніпровський національний університет

імені Олеся Гончара,

пр. Гагаріна, 72, Дніпро, Україна,

49000, тел. +38 (056) 374

98 22,

ел. пошта water.supply.treatment@gmail.com,

ORCID 0000-0003-2399-3124

4*Каф.

«Гідравліка і водопостачання»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010,

тел. +38 (056) 273 15 09, ел. пошта

gidro_eko@ukr.net, ORCID 0000-0003-3057-9204

5*Каф.

«Фізика», Український

державний хіміко-технологічний

університет, пр. Гагаріна, 8,

Дніпро,

Україна, 49005, тел. +38 (056) 753 56 38, ел. пошта

physics@udhtu.edu.ua,

ORCID 0000-0002-9893-3479

КОМП’ЮТЕРНЕ

МОДЕЛЮВАННЯ ПРОЦЕСІВ

БІОЛОГІЧНОГО

ОЧИЩЕННЯ СТІЧНИХ ВОД

В

АЕРОТЕНКАХ ІЗ ПЛАСТИНАМИ

Мета.

Визначення ефективності роботи

аеротенків на етапі проєктування або

реконструкції біореакторів, у яких

здійснюється біологічне очищення

стічних вод, вимагає використання

спеціальних математичних моделей і

методів розрахунку. Основною метою

статті є розробка CFD-моделі для оцінки

ефективності роботи аеротенка. Методика.

Для комп’ютерного

розрахунку процесу біологічного

очищення стічних вод в аеротенку, з

урахуванням гідродинаміки, розроблена

чисельна модель. В основу моделі

покладено двовимірні рівняння збереження

маси для субстрату та активного мулу

та рівняння для потенціалу швидкості.

Процес біологічного перетворення

субстрату розраховано на базі моделі

Monod. Для чисельного інтегрування рівнянь

масопереносу активного мулу та субстрату

використано поперемінно-трикутну

різницеву схему розщеплення. При цьому

базові рівняння розщеплено на два

рівняння більш спрощеного вигляду.

Для чисельного інтегрування рівняння

для потенціалу швидкості здійснено

його розщеплення на два одновимірних

рівняння. Далі кожне рівняння розв’язано

за явною схемою. Для чисельного

інтегрування рівнянь, що описують

процес трансформації субстрату на базі

моделі Monod, використано метод Ейлера.

Результати.

Здійснено програмну реалізацію

побудованої чисельної моделі. Наведено

результати обчислювального експерименту

з дослідження процесу очищення стічних

вод в аеротенку за рахунок використання

додаткових елементів у споруді–пластин.

Це дозволяє зробити висновки, що

управління якістю очищення стічних

вод в аеротенках можливе за допомогою

застосування пластин. Наукова

новизна.

Розроблено багатофакторну CFD-модель,

що дозволяє швидко оцінити ефективність

роботи аеротенка. Особливістю моделі

є можливість оцінки роботи аеротенка

з урахуванням його геометричної форми

та розташування в споруді додаткових

пластин. Практична

значимість. Побудована

чисельна модель може

бути використана під час проведення

розрахунків у випадку проєктування

споруд аеротенків або під час визначення

ефективності очищення стічних вод за

нових умов експлуатації.

Ключові слова: очищення

води; чисельне моделювання; аеротенк;

модель Monod; CFD-моделі; біологічне очищення;

стічні води; активний мул; концентрація

забруднювальних речовин

Н. Н. БЕЛЯеВ1*,

М. В. ЛЕМЕШ2*,

В. В. БЕЛЯеВА3*,

П. Б. МАШИХиНА4*,

З. Н. ЯкубовскаЯ5*

1*Каф.

«Гидравлика и водоснабжение», Днипровский

национальный университет

железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2,

Днипро, Украина, 49010, тел.

+38 (056) 273 15 09,

эл. почта

water.supply.treatment@gmail.com, ORCID 0000-0002-1230-8040

2*Каф.

«Гидравлика и водоснабжение», Днипровский

национальный университет

железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2,

Днипро, Украина, 49010, тел.

+38 (056) 273 15 09,

эл. почта

water.supply.treatment@gmail.com, ORCID 0000-0002-1531-7882

3*Каф.

«Аэрогидромеханика и энергомассоперенос»,

Днипровский национальный

университет имени Олеся Гончара,

пр. Гагарина, 72, Днипро,

Украина, 49000,

тел. +38 (056) 374

98 22, эл. почта

water.supply.treatment@gmail.com,

ORCID 0000-0003-2399-3124

4*Каф.

«Гидравлика и водоснабжение», Днипровский

национальный университет

железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2,

Днипро, Украина, 49010, тел.

+38 (056) 273 15 09, эл. почта gidro_eko@ukr.net,

ORCID

0000-0003-3057-9204

5*Каф.

«Физика»,

Украинский государственный

химико-технологический

университет,

пр. Гагарина, 8, Днипро, Украина, 49005,

тел. +38 (056) 753 56 38,

эл. почта physics@udhtu.edu.ua,

ORCID 0000-0002-9893-3479

КОМПЬЮТЕРНОЕ МОДЕЛИРОВАНИЕ

ПРОЦЕССОВ

БИОЛОГИЧЕСКОЙ ОЧИСТКИ СТОЧНЫХ

ВОД

В АЭРОТЕНКАХ С ПЛАСТИНАМИ

Цель. Определение

эффективности работы аэротенка на

этапе проектирования или реконструкции

биореакторов, в которых осуществляется

биологическая очистка сточных вод,

требует использования специальных

математических моделей и методов

расчета. Основной целью статьи является

разработка CFD-модели для оценки

эффективности работы аэротенков.

Методика. Для

компьютерного расчета процесса

биологической очистки сточных вод в

аэротенках, с учётом гидродинамики,

разработана численная модель. В основу

модели заложены двухуровневые уравнения

сохранения массы для субстрата и

активного ила и уравнение для потенциала

скорости. Процесс биологического

преобразования субстрата рассчитан

на базе модели Monod. Для численного

интегрирования уравнений массопереноса

активного ила и субстрата использована

попеременно–треугольная разностная

схема расщепления. При этом базовые

уравнения разделены на два уравнения

более упрощенного вида. Для численного

интегрирования уравнения для потенциала

скорости осуществлено его расщепление

на два одномерных уравнения. Далее

каждое уравнение решено по явной схеме.

Для численного интегрирования уравнений,

описывающих процесс трансформации

субстрата на базе модели Monod, использован

метод Эйлера. Результаты.

Осуществлена программная реализация

построенной численной модели. Приведены

результаты вычислительного эксперимента

по исследованию процесса очистки

сточных вод в аэротенке за счет

использования дополнительных элементов

в сооружении – пластин. Это проводит

к выводу, что управление качеством

очистки сточных вод в аэротенках

возможно с помощью применения пластин.

Научная новизна.

Разработана многофакторная CFD-модель,

позволяющая быстро оценить эффективность

работы аэротенка. Особенностью модели

является возможность оценки работы

аэротенка с учетом его геометрической

формы и расположения в сооружении

дополнительных пластин. Практическая

значимость. Построенная

численная модель может быть использована

при проведении расчетов в случае

проектирования сооружений аэротенков

или при определении эффективности

очистки сточных вод в новых условиях

эксплуатации.

Ключевые слова: очистка

воды; численное моделирование; аэротенк;

модель Monod; CFD-модели; биологическая

очистка; сточные воды; активный ил;

концентрация загрязняющих веществ

REFERENCES

Biliaiev,

N. N., & Nagornaya, E. K. (2012). Matematicheskoye

modelirovaniye massoperenosa v otstoynikakh sistem vodootvedeniya:

monografiya. Dnepropetrovsk: Novaya ideologiya. (in Russian)

Biliaiev,

N. N., & Kozachina, V. A. (2015). Modelirovaniye

massoperenosa v gorizontalnykh otstoynikakh:

monografiya. Dnepropetrovsk: Aktsent PP. (in Russian)

Vasylenko,

O. A., Hrabovskyi, P. O., Larkina, H. M., Polishchuk, O. V., &

Prohulnyi, V. Y. (2010). Rekonstruktsiia

i intensyfikatsiia sporud vodopostachannia ta vodovidvedennia:

navchalnyi posibnyk.

Kyiv: IVNVKP «Ukrheliotek». (in Ukrainian)

Karelin,

Ya. A., Zhukov,

D. D., Zhurov,

V. N., & Repin,

B. N. (1973). Ochistka

proizvodstvennyh

stochnyh

vod

v

aerotenkah.

Moscow:

Stroiyzdat. (in

Russian)

Laskov,

Yu. M., Voronov, Yu. V., & Kalicun, V. I. (1981). Primery

raschetov kanalizacionnyh sooruzhenij.

Moscow: Vysshaya Shkola.

(in Russian)

Oleynik,

A. Y., & Airapetyan, T. S. (2015). The modeling of the

clearance of waste waters from organic pollutions in

bioreactors-aerotanks with suspended (free flow) and fixed

biocenoses. Reports of the National

Academy of Sciences of Ukraine, 5,

55-60. DOI: 10.15407/dopovidi2015.05.055 (in

Ukrainian)

Alharbi, A. O. M. (2016). The

biological treatment of wastewater: mathematical models. Bulletin

of the Australian Mathematical Society, 94(2),

347-348. DOI: 10.1017/s0004972716000411 (in

English)

Amaral,

A., Gillot, S., Garrido-Baserba, M., Filali, A., Karpinska, A. M.,

Plósz, B. G., … & Rosso, D. (2019). Modelling gas-liquid

mass transfer in wastewater treatment: when current knowledge needs

to encounter engineering practice and vice-versa. Water

Science & Technology,

80(4),

607-619. DOI: 10.2166/wst.2019.253

(in English)

Babaei,

A., Azadi, R., Jaafarzadeh, N., & Alavi, N. (2013). Application

and Kinetic Evaluation of upflow Anaerobic biofilm Reactor for

Nitrogen Removal from Wastewater. Iranian

Journal of Environmental Health Science and Engineering, 10(1),

1-8. DOI:

10.1186/1735-2746-10-20 (in English)

Bomba,

A., Klymiuk, Y., Prysiazhniuk, I., Prysiazhniuk, O., & Safonyk,

A. (2016). Mathematical modeling of wastewater treatment from

multicomponent pollution by through microporous filling. AIP

Conference Proceedings, 1773,

040003-1-040003-11. DOI: 10.1063/1.4964966 (in

English)

Dapelo, D.,

& Bridgeman, G. (2020). A CFD strategy to retrofit an

anaerobic digester to improve mixing performance in wastewater

treatment. Water Science &

Technology, 81(8), 1646-1657.

DOI: 10.2166/wst.2020.086

(in English)

Gao,

H., & Stenstrom, M. K. (2019). Development and applications in

CFD modeling for secondary settling tanks over the last three

decades: A review. Water Environment

Research, 92(6),

796-820

DOI: 10.1002/wer.1279

(in English)

Gao,

H., & Stenstrom, M. K. (2020). Influence of Model Parameters

and Inlet Turbulence Boundary Specification Methods in Secondary

Settling Tanks: Computational Fluid Dynamics Study. Journal

of Environmental Engineering,

146(5), 04020028-1-04020028-12.

DOI: 10.1061/(ASCE)EE.1943-7870.0001689

(in English)

Gao, H.,

& Stenstrom, M. K. (2020). Computational Fluid Dynamics

Analysis for Improving Secondary Settling Tank Performance.

Conference: World Environmental and

Water Resources Congress 2020,

212-224.

DOI: 10.1061/9780784482988.021

(in English)

Griborio,

A. (2004). Secondary Clarifier

Modeling: A Multi-Process Approach. Dissertation and Theses.

USA, University of New Orleans Publ. (in English)

Mocanu,

C. R., & Mihaillescu, R. (2012). Numerical Simulation

Wastewater Treatment Aeration Processes.U.

P. B. Sci. Bull., Series D, 74(2),

191-198. (in English)

Pereda,

M., & Zamarreno, J. M. (2011). Agent–based modeling of an

activated sludge process in batch reactor. 19th

Mediterrian Conference on Control and Automation Aquis, 1128-1133.

DOI: 10.1109/med.2011.5983027

(in English)

Received:

05.06.2020

Accepted:

07.10.2020

–

activated sludge

measurement coefficient;

– time;

–

averaged concentration

of activated

sludge in the

bioreactor ;

– averaged concentration

of substrate in

the bioreactor;

– diffusion coefficient; Y –

parameter in the Monod model;

–

components of the water flow velocity in the bioreactor in the

direction of the x, y axes, respectively;

– components of the diffusion coefficients at the considered plane

point in the x, y

direction.

,

– known concentrations of substrate and sludge, respectively;

;

,

,

– concentrations in the last computational cell;

– concentrations in the previous computation cell;

(6)

(7)

(8)

,

.

(9)

(10)

,

.

(11)

(14)

(15)

=

3 495 m3/day

– waste water consumption;

mg/l –

concentration of activated sludge that enters the reactor;