ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2019,

№ 4 (82)

рухомий

склад і тяга поїздів

рухомий

склад і тяга поїздів

UDC

629.463.62.027.4:625.143.3.033.373

O.

V. Shatunov1*,

A.

O. shvets2*,

O. A. KIRILCHUK3*,

A.

O. shvets4*

1*Dep.

«Cars and Car

Facilities»,

Dnipro National University of Railway

Transport named after

Academician V. Lazaryan, La-zaryan St., 2, Dnipro,

Ukraine, 49010,

tel. +38 (067) 953 60 14, e-mail shatunov220648@gmail.com,

ORCID

0000-0002-1115-0093

2*Dep.

«Theoretical and

Structural Mechanics»,

Dnipro National University of Railway

Transport named after

Academician V. Lazaryan, Lazaryan St., 2, Dnipro,

Ukraine, 49010,

tel. +38 (050) 214 14 19, e-mail angela.shvets69@gmail.com,

ORCID

0000-0002-8469-3902

3*Dep.

«Car and Car Facilities», Dnipro National University of Railway

Transport named after Academician V. Lazaryan,

Lazaryan St., 2,

Dnipro, Ukraine, 49010, tel./fax +38 (056) 776 82 27,

e-mail

o.a.kirilchuk@gmail.com,

ORCID 0000-0002-0565-1692

4*Dep.

«Car and Car Facilities», Dnipro National University of Railway

Transport named after Academician V. Lazaryan,

La-zaryan St., 2,

Dnipro, Ukraine, 49010, tel./fax +38 (095) 235 19 67,

e-mail

angela_Shvets@ua.fm, ORCID 0000-0002-0717-2521

RESEARCH

OF WHEEL-RAIL WEAR due

to

non-SYMMETRICAL

LOADING

OF a FLAT

car

Purpose.

The paper is aimed at determining the

influence of non-symmetrical loading of a flat car on the magnitude

of the wear factor of a wheel-rail pair when changing the operation

parameters that occur in operation.

Methodology.

The dynamic loading of the flat car, model 13-401 with typical

three-piece bogies is studied using a model of spatial oscillations

of a five-car coupling with the help of mathematical and computer

simulation. Theoretical calculations are performed for the most

dangerous sections of the railway track-small and medium radius

curves in the range of permissible speeds. Findings.

The indicators of wear of the rolling stock

wheels and the rails are analysed on the example of flat cars in the

presence of a longitudinal and transverse displacement of the load

mass centre relative to the car symmetry centre. To obtain

information on the effect of permissible deviations of the

arrangement of cargo in the car on the magnitude of the dynamic

loading of the wheel-rail contact, the authors performed theoretical

studies of the spatial variations of the rail carriage and its

interaction with the track. Originality.

To determine the wear of the wheel-rail pair, the effect of

displacement in two directions from the central axis of symmetry of

the load gravity centre was studied, taking into account the value of

the travel speed along the curved sections of the small and medium

radius using a mathematical model of coupling of five freight cars.

Practical value.

As a result of the theoretical studies carried out, the authors

assessed such factors as wear factor,

directional force, and hunting of the wheel set of freight rolling

stock in the event of load gravity centre displacement when moving

along curved sections of the railway track. To establish the possible

cause of intensive wear of the wheels and rails, the following

parameters were analysed: lozenging of front bogie side frames;

hunting of the left side frame of the front bogie; mutual

longitudinal movement of the side frame and axle box of the front

wheel set; mutual hunting of the left side frame of the bogie

relative to the front wheel set.

Keywords:

load; flat

car; lozenging

of bogie side

frames; load

gravity centre

displacement; angle

of wheel set

hunting; travel speed;

wear factor

Introduction

The

intensity of

the wheel-rail

wear is

so far

one of

the most

serious problems

of rail

transport.

The analysis of publications and studies

related to this issue has shown that increased wear of rails and

rolling stock can be caused by several reasons associated with both

the state of the carriage chassis and the state of the rail track in

curved sections [5, 8, 9, 16].

Wear of wheels and rails depends

on physical and mechanical processes occurring in the area of their

contact. The nature of these processes and their intensity depend to

a large extent on external influences on the surface of the contact

point, in particular, on the interaction forces of the contacting

bodies and their relative displacements. Therefore, one of the

possible ways to solve the problem of reducing the intensity of wear

of the wheel flanges and rail head side surfaces is to establish

conditions for reducing external impacts on the contacting bodies,

or reducing the dynamic loading of the contact point. Of particular

importance are the reciprocal movements of the contacting bodies, as

the wear is associated with the work of friction (pseudo-slipping

forces) in the contact area. Therefore, the solution to this problem

is to minimize the forces of interaction and mutual displacement of

the wheel-rail pair in the points of contact.

Determination of the wear index

is connected with the task of studying spatial oscillations and the

interaction of rail carriage and track. For solving this problem the

Dnpro National University of Railway Transport named after

Academician V. Lazaryan developed the mathematical models that make

it possible to determine the necessary values of forces and

displacements, and to obtain the wear indicator as the resultant

value [2-4, 12, 15]. With these models, it is possible to obtain

solutions for various types of wheel-rail contact, to take into

account the rigidity of the structural elements and the various

deviations from the initial configuration of the system, such as the

misalignment of the wheel set axles in the bogie, the difference in

the wheel radii of one wheel set, of different wheel sets in a bogie

and different bogies, rail gradient and wheel profile of various

types, change in the cross gap of the wheel set and rail track, the

change of longitudinal and cross clearance between the axle-boxes

and side frames, the displacement of the body mass center relative

to the car symmetry, etc. [5, 13, 17-19, 20-22].

Purpose

The purpose of this study is to

determine the influence of non-symmetrical loading of a flat car on

the magnitude of the wear factor of a wheel-rail pair when changing

the operation parameters.

Methodology

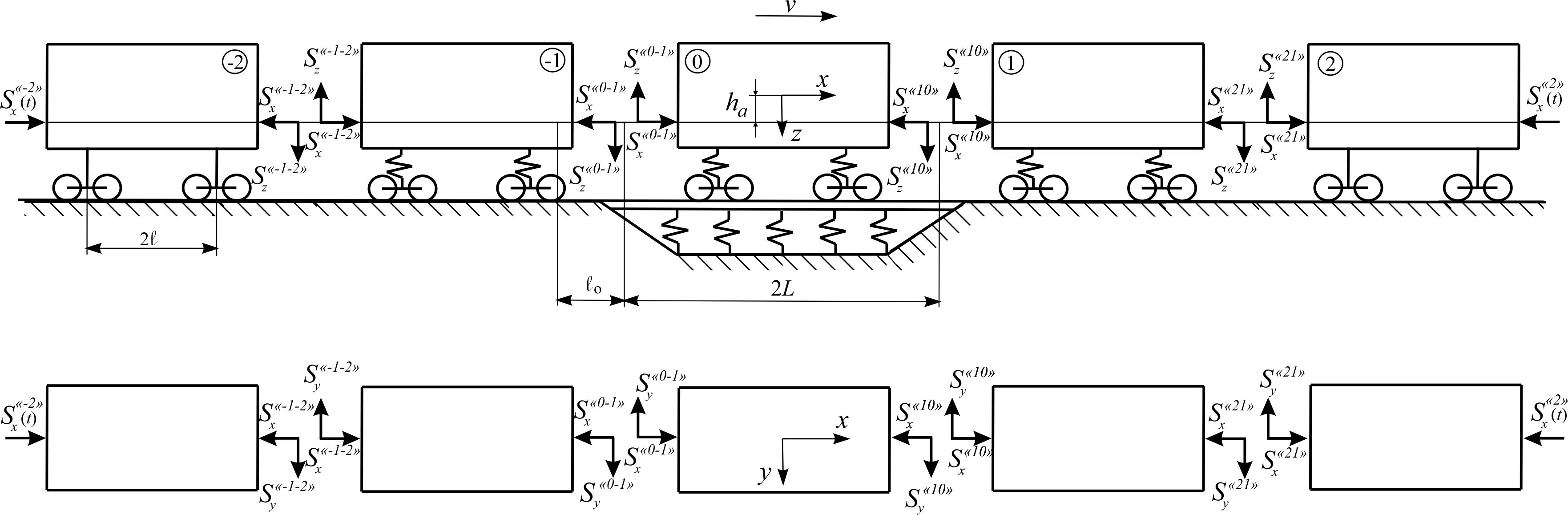

Theoretical

studies of the dynamic loading of the wheel-rail contact during the

movement of 13-401 model flat car with typical bogies 18-100 in the

speed range

km/h in the small and middle radius curves

were performed using the model of spatial oscillations of a five-car

coupling (Fig. 1) [2-4, 6, 10, 21].

km/h in the small and middle radius curves

were performed using the model of spatial oscillations of a five-car

coupling (Fig. 1) [2-4, 6, 10, 21].

Fig. 1. Design

diagram of the five-freight-car coupling

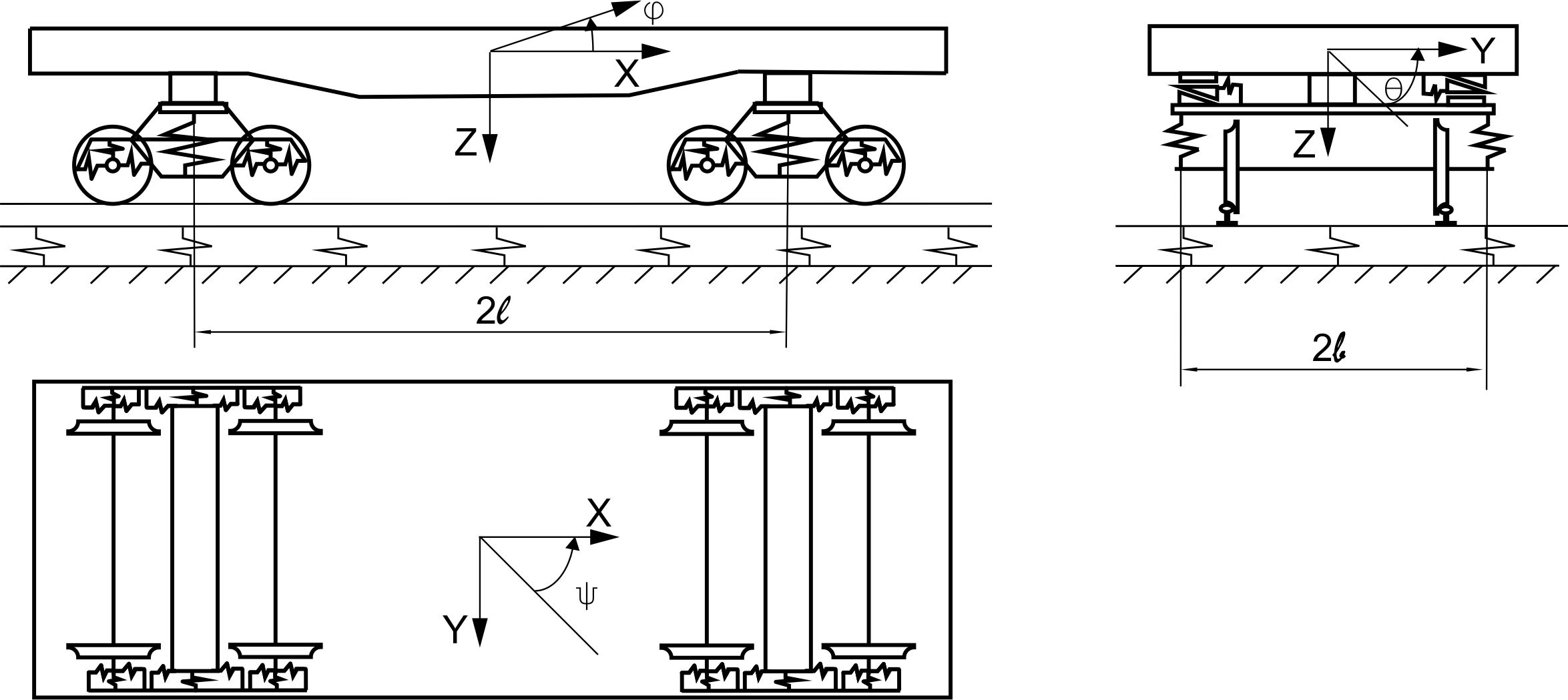

The flat car is considered as a

mechanical system (Fig. 2), which consists of 12 solids (load, car

frame, two bolsters, four bogie side frames, four wheel sets).

Fig. 2. Design

diagram of the 4-axle flat car

In our

research we studied the effect of the load mass center shift on the

flat car frame in the longitudinal

and transverse directions

and transverse directions

,

as well as in both directions

simultaneously. Preliminary theoretical studies have shown that in

the presence of a transverse or simultaneous transverse and

longitudinal displacement of the load mass center over

,

as well as in both directions

simultaneously. Preliminary theoretical studies have shown that in

the presence of a transverse or simultaneous transverse and

longitudinal displacement of the load mass center over

m there is a sharp decrease in the

derailment coefficient and a high probability of rolling stock

derailment [21].

m there is a sharp decrease in the

derailment coefficient and a high probability of rolling stock

derailment [21].

In

order to

determine the

effect of

only the

load mass

centre

displacement on

the factor

of wheel

and rail

wear, the

displacement in

the transverse

and simultaneous

transverse and

longitudinal

directions is

considered

within the

limits

m and

m and .

The stationary movement of a

five-freight-car coupling in the right curve is studied.

Consequently, the left wheel of the first wheel set climbs the outer

rail. The carriage chassis, the wheel rolling surface and the rail

head profile are provided in a normal technical condition.

.

The stationary movement of a

five-freight-car coupling in the right curve is studied.

Consequently, the left wheel of the first wheel set climbs the outer

rail. The carriage chassis, the wheel rolling surface and the rail

head profile are provided in a normal technical condition.

Findings

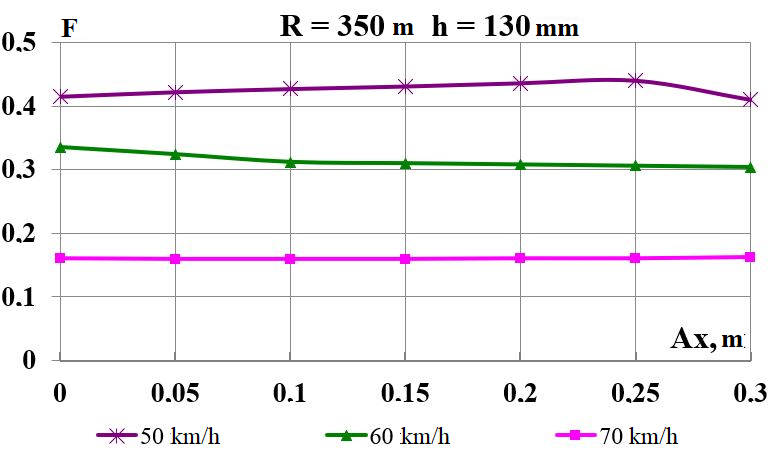

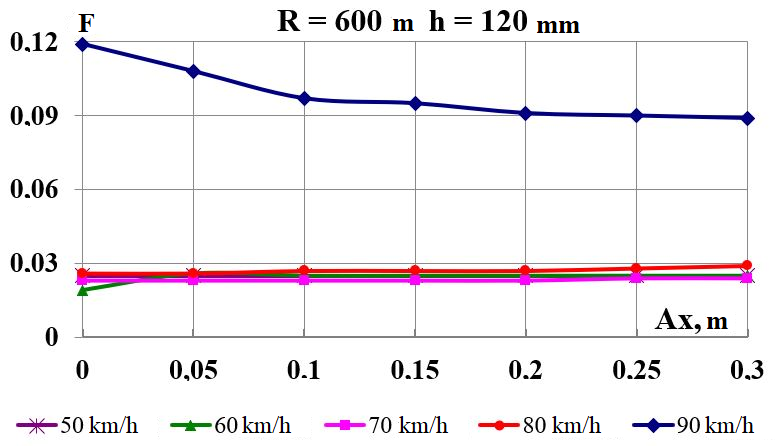

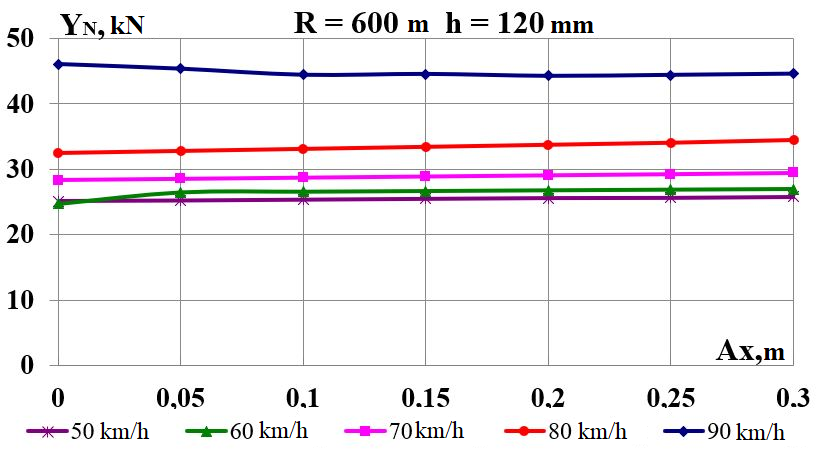

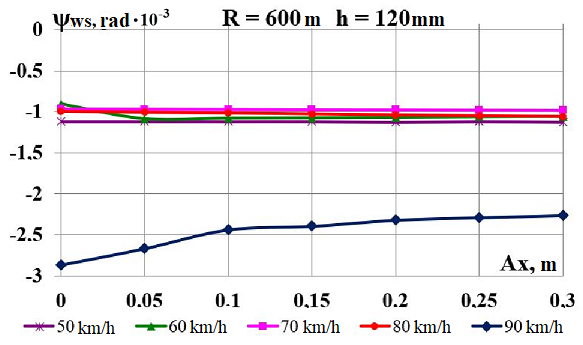

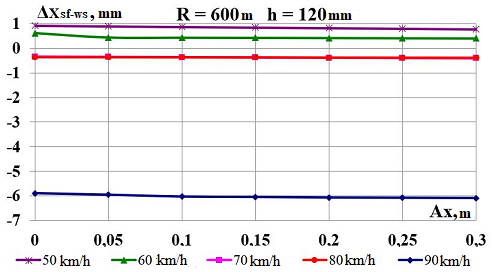

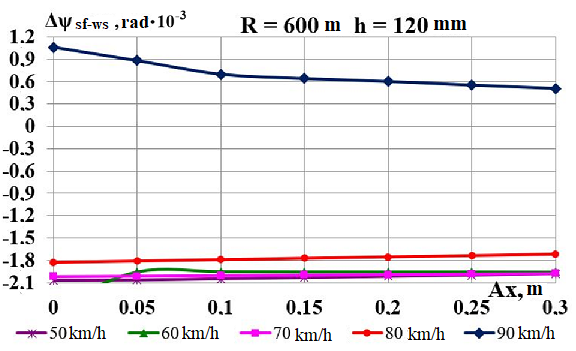

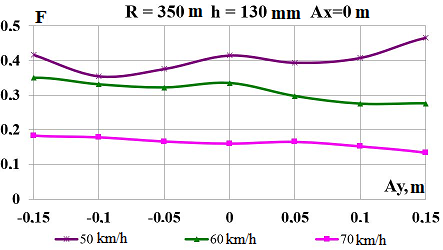

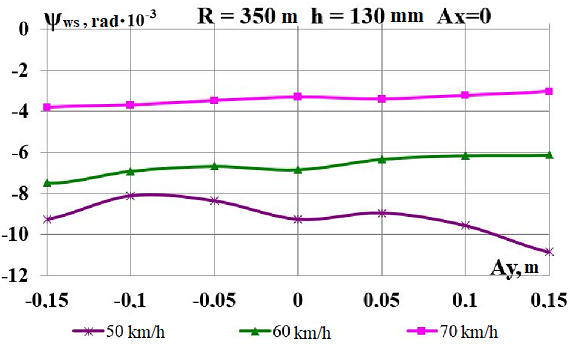

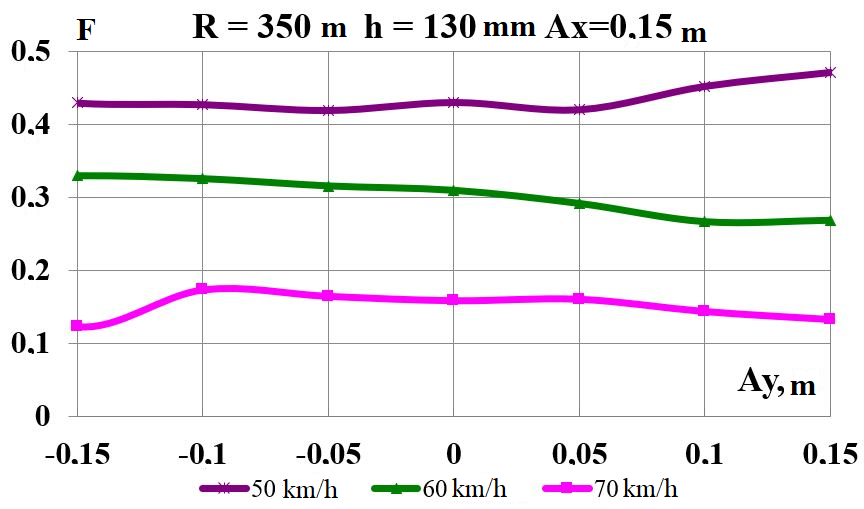

The graphs of

variance of the studied parameters during the movement in the curve

sections of the track

and 350 m are shown in Fig. 3-8. The

displacement in the longitudinal direction (Fig. 3, 4) is considered

in the range from 0 to

and 350 m are shown in Fig. 3-8. The

displacement in the longitudinal direction (Fig. 3, 4) is considered

in the range from 0 to

.

For a detailed analysis of the physical processes occurring during

the sliding of the wheel flange on the rail side face, it is

necessary to investigate the corresponding dependences of the

directional force and the striking angle of the wheel set [5].

.

For a detailed analysis of the physical processes occurring during

the sliding of the wheel flange on the rail side face, it is

necessary to investigate the corresponding dependences of the

directional force and the striking angle of the wheel set [5].

As

can be

seen from

Fig. 3 (a,

b),

increase of

the longitudinal

displacement of

the load

mass center

has almost

no effect

on the

wear factor.

This indicator

is significantly

influenced by

the travel

speed. In

curves

m, the

wear factor

F with

an increase

in speed

from 50 to

70 km/h

decreases by

2.7 times. The

wear factor

in the

curves of

the small

radius is

greater than

the

corresponding

values in

the curves

of the

average radius

by 16.8÷6.7

times in

the speed

range

m, the

wear factor

F with

an increase

in speed

from 50 to

70 km/h

decreases by

2.7 times. The

wear factor

in the

curves of

the small

radius is

greater than

the

corresponding

values in

the curves

of the

average radius

by 16.8÷6.7

times in

the speed

range

km/h.

This can

be explained

by the

higher levels

of the

directional

forces

km/h.

This can

be explained

by the

higher levels

of the

directional

forces

(Fig. 3, c,

d)

and the

hunting angles

(Fig. 3, c,

d)

and the

hunting angles

(Fig. 3, e,

f) in

the curves

(Fig. 3, e,

f) in

the curves

m. At

a speed of 90 km/h, the index

m. At

a speed of 90 km/h, the index

in case of increasing the longitudinal

displacement in the curve

in case of increasing the longitudinal

displacement in the curve

m from 0 up to 0.3 m is significantly

differs from the speed interval

m from 0 up to 0.3 m is significantly

differs from the speed interval

km/h and exceeds the corresponding values

by an average of 29.5%. In addition, the hunting angles

km/h and exceeds the corresponding values

by an average of 29.5%. In addition, the hunting angles

in both curves have a sign «–»,

that is, the wheel sets rotate in the track plane against the

direction of the curve in accordance with the accepted rule of the

signs (Fig. 2).

in both curves have a sign «–»,

that is, the wheel sets rotate in the track plane against the

direction of the curve in accordance with the accepted rule of the

signs (Fig. 2).

а

b

c

d

e

f

Fig.

3. Graphs of dependence on load displacement

in the longitudinal

direction:

a,

b

– wear factor; c,

d

– directional force acting from the rail side on the wheel;

e,

f

– hunting of the wheel set

The disadvantages of the

three-piece bogie of 18-100 model include the possibility of side

frames lozenging under the action of the longitudinal components of

the frictional forces on the wheel-rail contacts, which causes loss

of the bogie frame geometry and the appearance of distortions of the

wheel set axle therein. In addition, the design of the side frame

box opening and the axle box presupposes the presence of

longitudinal and transverse gaps between the box housing lug and the

box opening guides, through which the nature of their contact can

also change. This phenomenon negatively affects the dynamics of the

car and, as a result, leads to intensive wear of the wheel

flanges [1, 7, 9, 14, 23].

In addition, the mutual

longitudinal lozenging of side frames are particularly harmful when

moving along curved track sections, as they cause the turns of the

wheel sets in the track plane against the direction of the curve.

This, in turn, increases the striking angles of the wheel flanges on

the rails, resulting in their mutual wear, since this reduces the

contact area of the flange with the rail side face and, accordingly,

increases the specific pressure on it, which determines their wear.

To

determine the

probable cause

of the

intense wear

of the

wheels and

rails during

the movement

in the

curves

m, let

us consider

the following

parameters:

lozenging of side

frames of

the front

bogie; hunting

of the left side frame of the front bogie;

mutual longitudinal displacement of side

frame and axle box of the front wheel set;

mutual hunting of the bogie left side

frame relative to the front wheel set

(Fig.4).

m, let

us consider

the following

parameters:

lozenging of side

frames of

the front

bogie; hunting

of the left side frame of the front bogie;

mutual longitudinal displacement of side

frame and axle box of the front wheel set;

mutual hunting of the bogie left side

frame relative to the front wheel set

(Fig.4).

a

b

c

d

Fig.

4. Graphs of dependence on load displacement in the

longitudinal direction:

а

–

lozenging

of side frames of the front bogie;

b

–

hunting

of the left side frame of the front bogie;

c

–

mutual

longitudinal displacement of side frame and axle box of the front

wheel set;

d

–

mutual

hunting of the bogie left side frame relative to the front wheel set

a

b

c

d

e

f

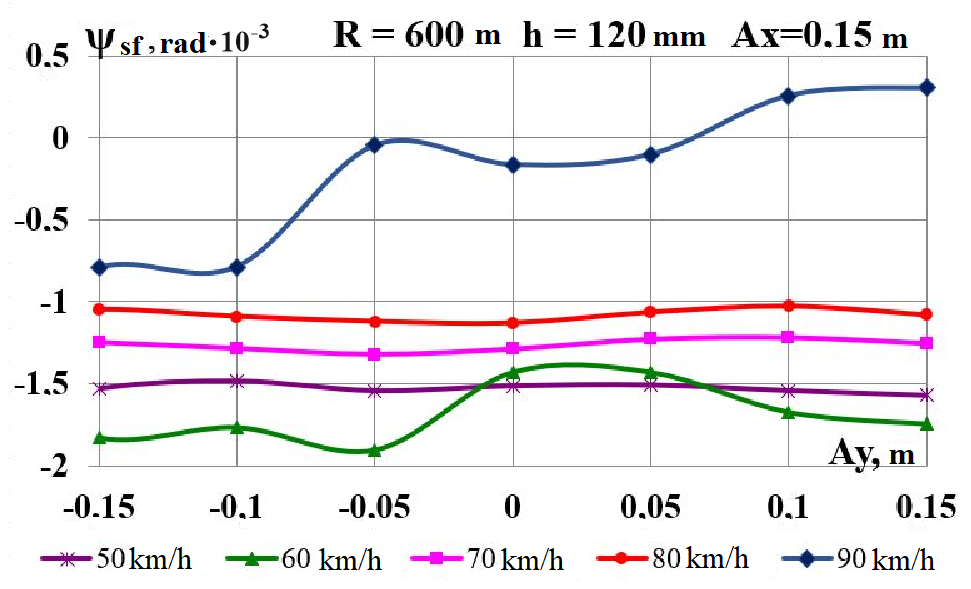

Fig.

5. Graphs of dependence on load displacement in the transverse

direction:

a,

b

– wear factor; c,

d

– directional force acting from the rail side on the wheel; e,

f

– hunting of the wheel set

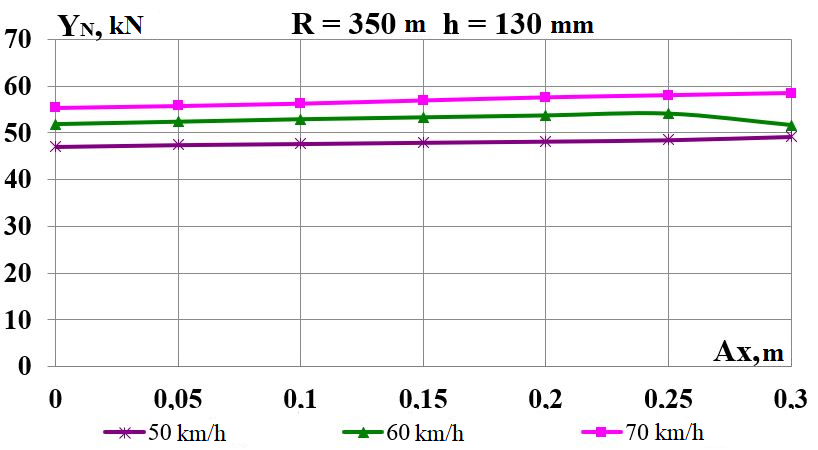

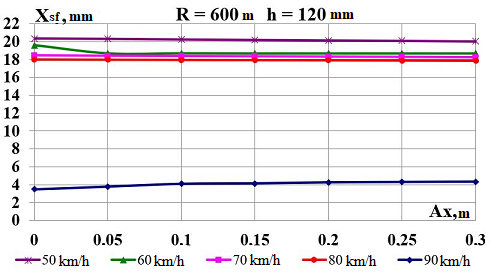

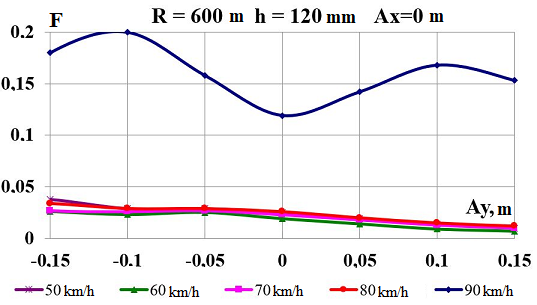

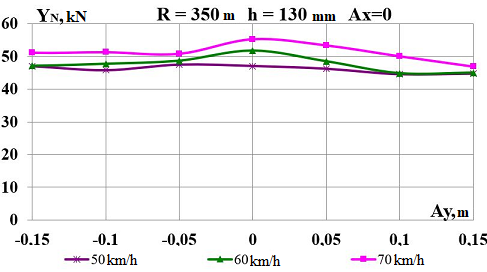

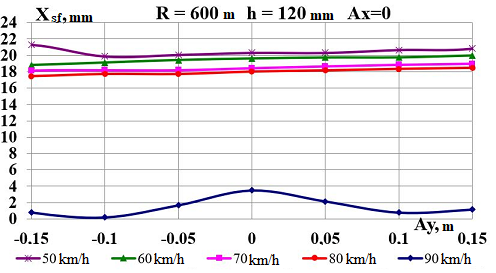

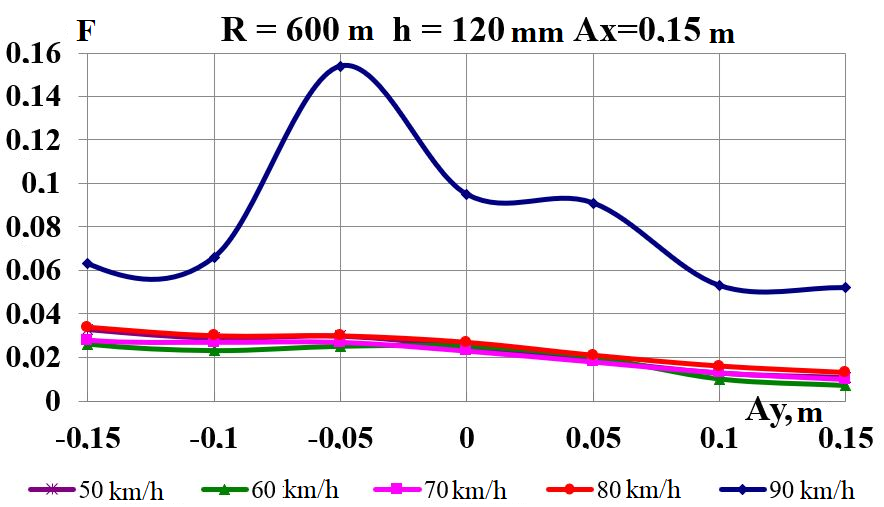

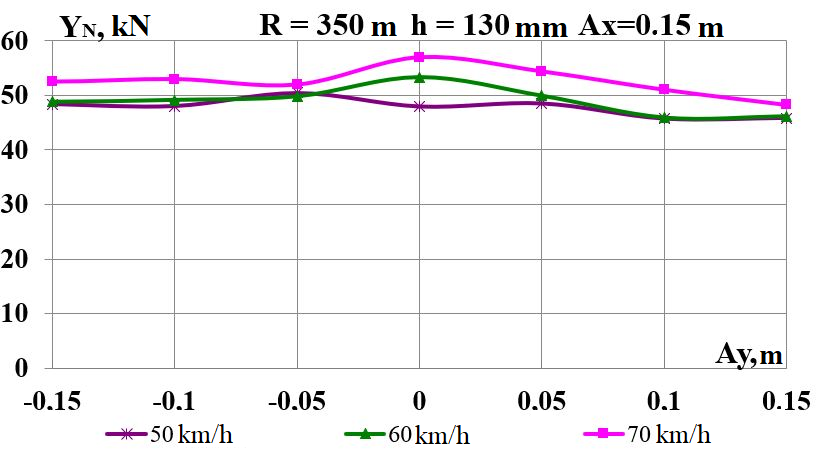

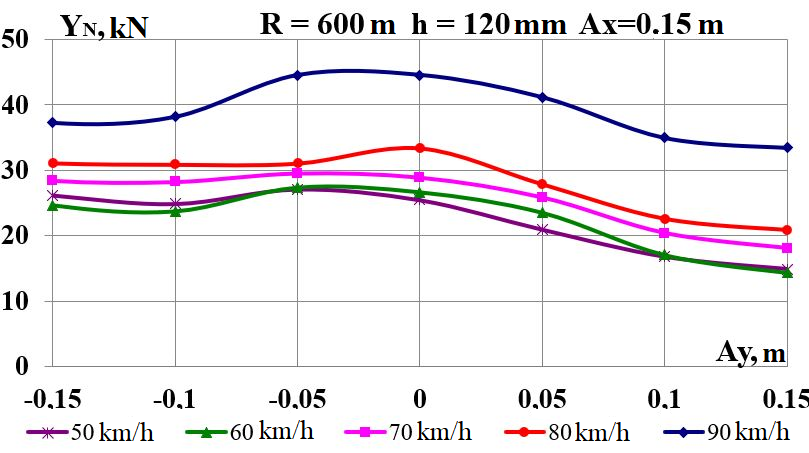

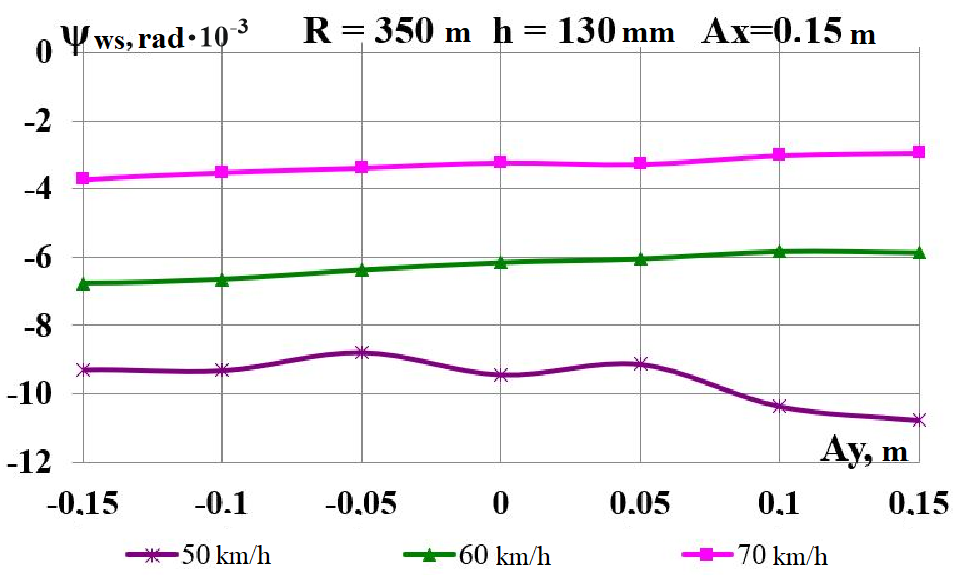

Fig.

5 shows the

effect on

the studied

parameters of

the transverse

displacement of

the load

mass center

in the

curves

in the

curves

m

and

m

and

m,

respectively.

With increased

m,

respectively.

With increased

the wear

factor F

(Fig. 5, a)

in the

curve

the wear

factor F

(Fig. 5, a)

in the

curve

m does

not change

so linearly,

as in

case of

longitudinal

displacement,

but also

decreases in

case of

speed rise.

In the curve

m does

not change

so linearly,

as in

case of

longitudinal

displacement,

but also

decreases in

case of

speed rise.

In the curve

m F

decreases due to the load relief of the climbing wheel. Exception

from the

general picture,

as in

the previous

case, is

the speed

of 90 km/h.

The wear factor curve F

(Fig. 5, b)

has extremes for

m F

decreases due to the load relief of the climbing wheel. Exception

from the

general picture,

as in

the previous

case, is

the speed

of 90 km/h.

The wear factor curve F

(Fig. 5, b)

has extremes for

m in both directions from the axis of symmetry of the flat car

frame. In case of transverse displacement of the load mass center,

there are higher directed forces

m in both directions from the axis of symmetry of the flat car

frame. In case of transverse displacement of the load mass center,

there are higher directed forces

(Fig. 5, c,

d) and hunting angles

(Fig. 5, c,

d) and hunting angles

(Fig. 5, e,

f) in the curves

(Fig. 5, e,

f) in the curves

m. The wheel set hunting

m. The wheel set hunting

at the speed of 90 km/h in the curve

at the speed of 90 km/h in the curve

m is

also significantly different from the speed range

m is

also significantly different from the speed range

km/h and is directed in the track plane

against the direction in both curves.

km/h and is directed in the track plane

against the direction in both curves.

a

b

c

d

Fig.

6. Graphs of

dependence on

load

displacement in

the transverse

direction:

а

–

lozenging

of side frames of the front bogie;

b

–

hunting

of the left side frame of the front bogie;

c

–

mutual

longitudinal displacement of side frame and axle box of the front

wheel set;

d

–

mutual

hunting of the bogie left side frame relative to the front wheel set

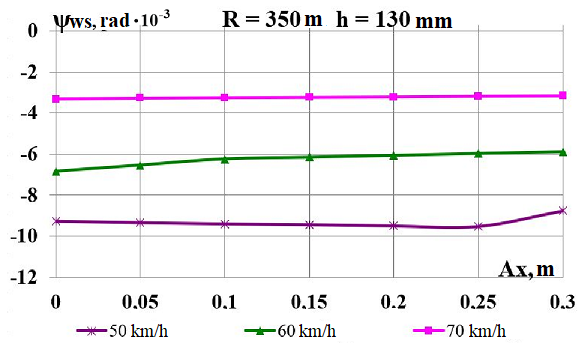

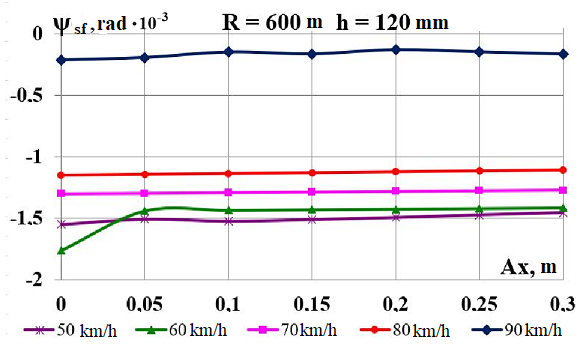

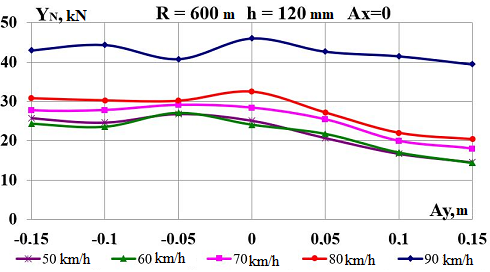

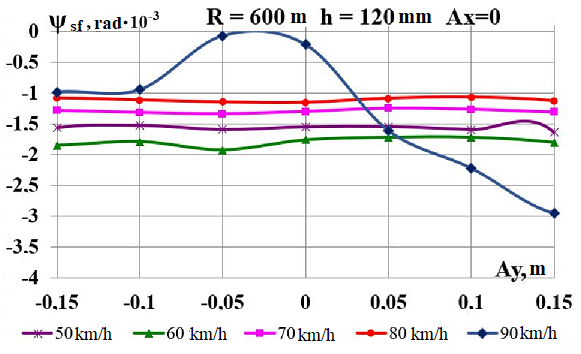

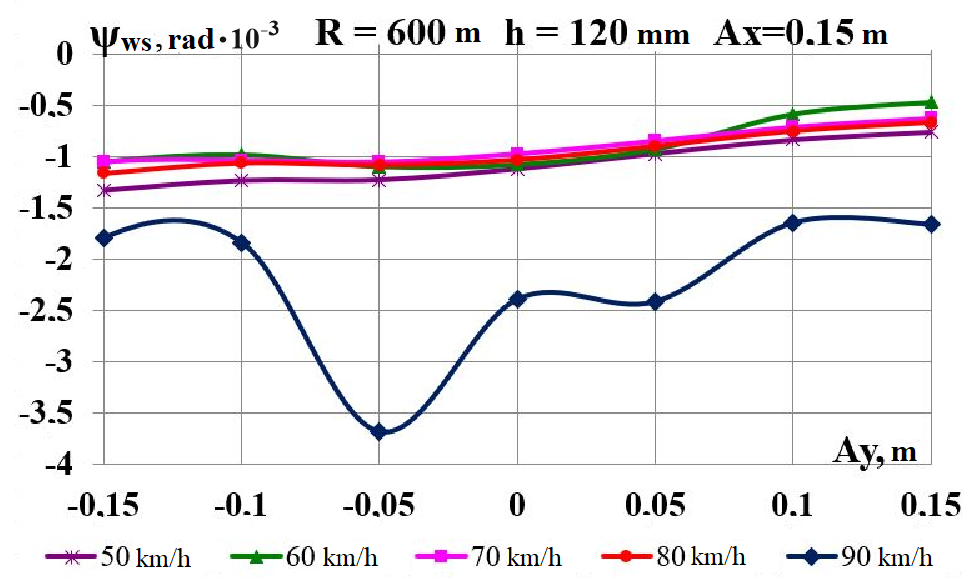

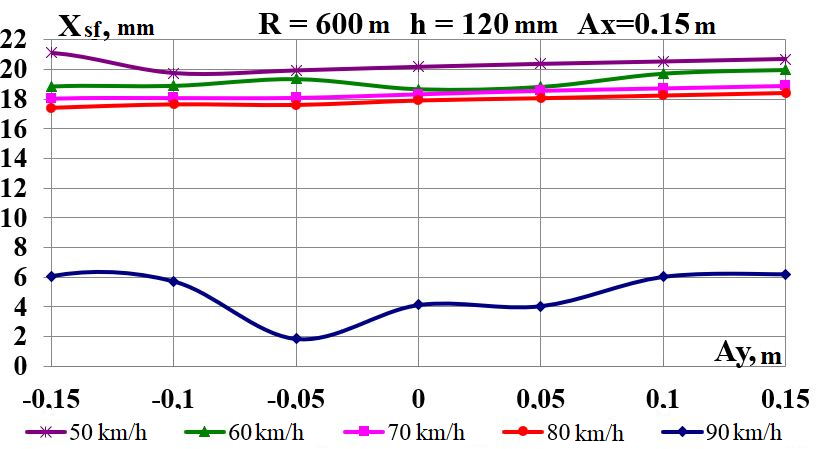

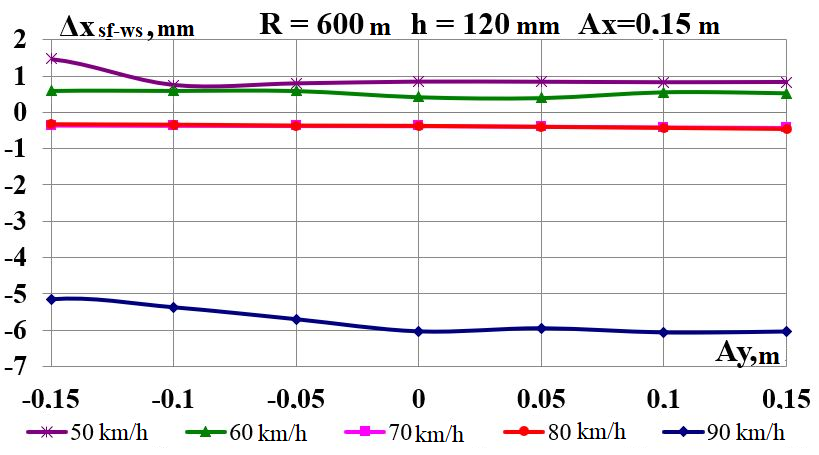

Graphic

dependencies in Fig. 6 show that the front bogie side frame hunting

(Fig. 6, a)

at speed of 90 km/h are 7 times smaller than in the range of

(Fig. 6, a)

at speed of 90 km/h are 7 times smaller than in the range of

km/h

and 2 times smaller than at equivalent value for longitudinal

displacement. Comparing Fig.

4, b

and Fig. 6, b,

we should note that the presence of a transverse displacement of the

load mass center on the flat car leads to significant changes in the

nature of the hunting of the left side frame of the front bogie

km/h

and 2 times smaller than at equivalent value for longitudinal

displacement. Comparing Fig.

4, b

and Fig. 6, b,

we should note that the presence of a transverse displacement of the

load mass center on the flat car leads to significant changes in the

nature of the hunting of the left side frame of the front bogie

at a speed of 90 km/h. The hunting

angles

at a speed of 90 km/h. The hunting

angles

(Fig. 6, b)

also have the «–»

sign. As for longitudinal displacement, a significant increase in

the wheel set hunting angles

(Fig. 6, b)

also have the «–»

sign. As for longitudinal displacement, a significant increase in

the wheel set hunting angles

occurs due to significant mutual

longitudinal displacements of the side frame and the axle box of the

front wheel set

occurs due to significant mutual

longitudinal displacements of the side frame and the axle box of the

front wheel set (Fig. 6, c),

as well as the hunting of the left side frame of the bogie relative

to the front wheel set through the shift of the boxes in the side

frame openings

(Fig. 6, c),

as well as the hunting of the left side frame of the bogie relative

to the front wheel set through the shift of the boxes in the side

frame openings

(Fig. 6, d).

With the exception of the speed of 90 km/h, the values of the

indicators

(Fig. 6, d).

With the exception of the speed of 90 km/h, the values of the

indicators

and

and

due to the load shift in the transverse

direction decrease in case of additional loading of the non-climbing

wheel.

due to the load shift in the transverse

direction decrease in case of additional loading of the non-climbing

wheel.

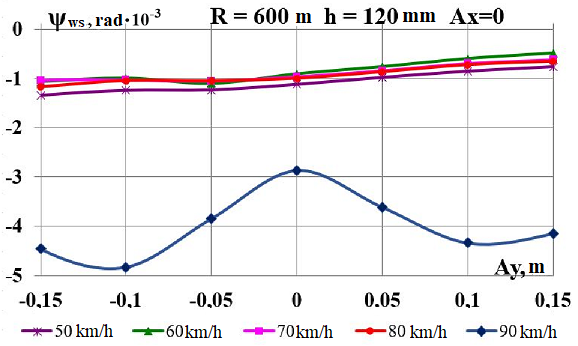

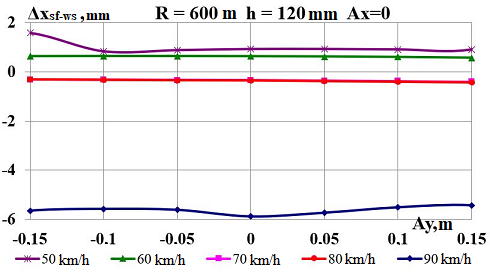

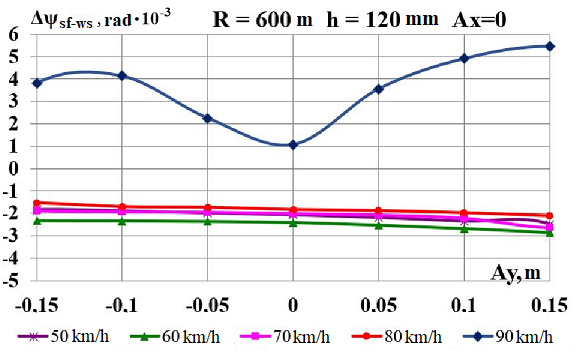

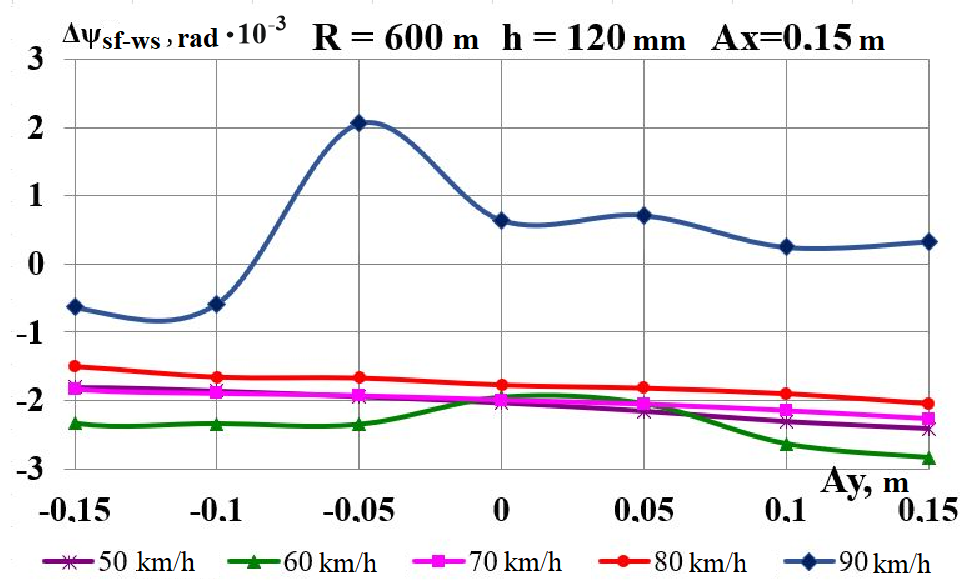

The

simultaneous displacement of the mass center along the axes

is considered for

is considered for

in the range from –0.15

to 0.15 m and

in the range from –0.15

to 0.15 m and

m (Fig. 7) [11].

m (Fig. 7) [11].

a

b

c

d

e

f

Fig

7. Graphs

of

dependence

on

simultaneous

load

displacement

in

the

longitudinal

and

transverse

direction:

a,

b

– wear factor; c,

d

– directional force acting from the rail side on the wheel;

e,

f

– hunting of the wheel set

a

b

c

d

Fig.

8. Graphs

of dependence

on load

displacement in

the longitudinal

and transverse

direction:

а

–

lozenging

of side frames of the front bogie;

b

–

hunting

of the left side frame of the front bogie;

c

–

mutual

longitudinal displacement of side frame and axle box of the front

wheel set;

d

–

mutual

hunting of the bogie left side frame relative to the front wheel set

In case of

simultaneous longitudinal and transverse displacement, a significant

increase in the wheel set hunting angles

also occurs due to significant

longitudinal mutual displacements of the side frame and the axle box

of the front wheel set

also occurs due to significant

longitudinal mutual displacements of the side frame and the axle box

of the front wheel set

(Fig. 8, c)

and the hunting of the bogie left side frame relative to the front

wheel set through the shift of the boxes in the side frame openings

(Fig. 8, c)

and the hunting of the bogie left side frame relative to the front

wheel set through the shift of the boxes in the side frame openings

(Fig. 8, d).

Unlike indicators

(Fig. 8, d).

Unlike indicators

,

that are almost unchanged at simultaneous

longitudinal and transverse displacement, the values of the

indicators

,

that are almost unchanged at simultaneous

longitudinal and transverse displacement, the values of the

indicators

are much lower.

are much lower.

The Rolling

Stock Dynamic and Strength Research Laboratory of DNURT conducted

dynamic (running) tests of the experimental train in order to

determine the dynamic load of the wheel-rail contact and the

indicators characterizing the wear of the wheel set flanges and the

rail side faces, for the most likely operational deviations from

nominal ones in the dimensions of the carriage elements in the range

of speeds 30-70 km/h. There were tested the freight flat cars of

model 12-532 on three-piece bogie of model 18-100, having different

state of carriage chassis, which to some extent could affect the

wear of wheels and rails. For conducting

the tests, there

was formed

an experimental

train consisting

of a

car-laboratory,

testes flat cars

and ChS-2

electric

locomotive.

To obtain reliable information on the

effect of variations in the dimensions of the chassis elements on

the magnitude of the dynamic loading of the wheel-rail contact, all

stages of the tests were performed on one section of the joint track

[8].

We tested

three loaded gondola cars with the following features in the

carriage chassis dimensions:

1) Gondola

No. 1, which had

6 mm difference of sideframe bases of one of the bogies (2 184.5 and

2 190.5 mm);

2) Gondola

No. 2, which

had 3 mm

deviation in

the wheel

diameters of

one wheel

set (926 and

923 mm);

3) Gondola

No. 3, which

had the

minimum

deviations in

the dimensions

of the

carriage chassis

elements from

the nominal

and was

taken as

a standard

car.

During

the dynamic

testing on

the experimental

gondola, the

following values

were recorded:

frame forces

for wheel

sets; dynamic

increments of

the vertical

forces acting

on the

wheel set

boxes;

longitudinal and

horizontal

transverse

displacement of

the boxes

relative to

the bogie

side frames;

horizontal

transverse

acceleration of

boxes; bolster

hunting angles

relative to

the body;

the value

of lozenging

of bogie side frames. During

the tests, we used the sensors of displacement and bogie side frame

lozenging.

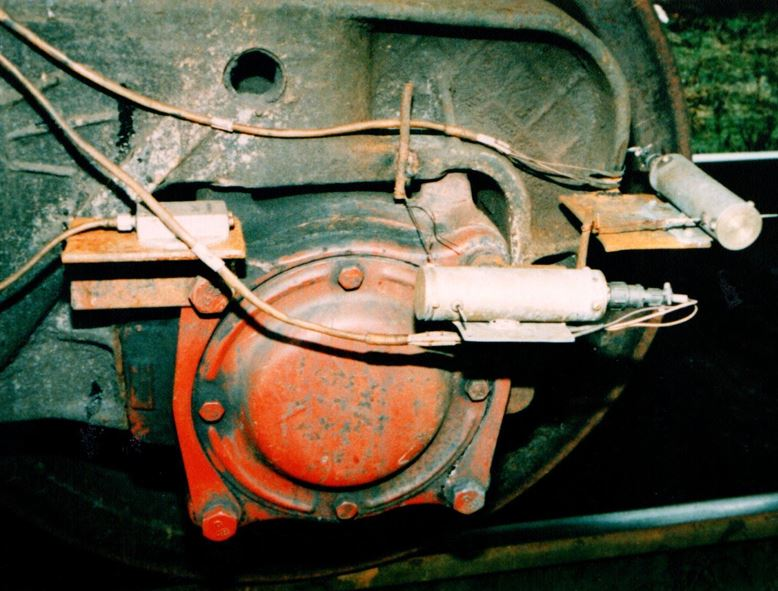

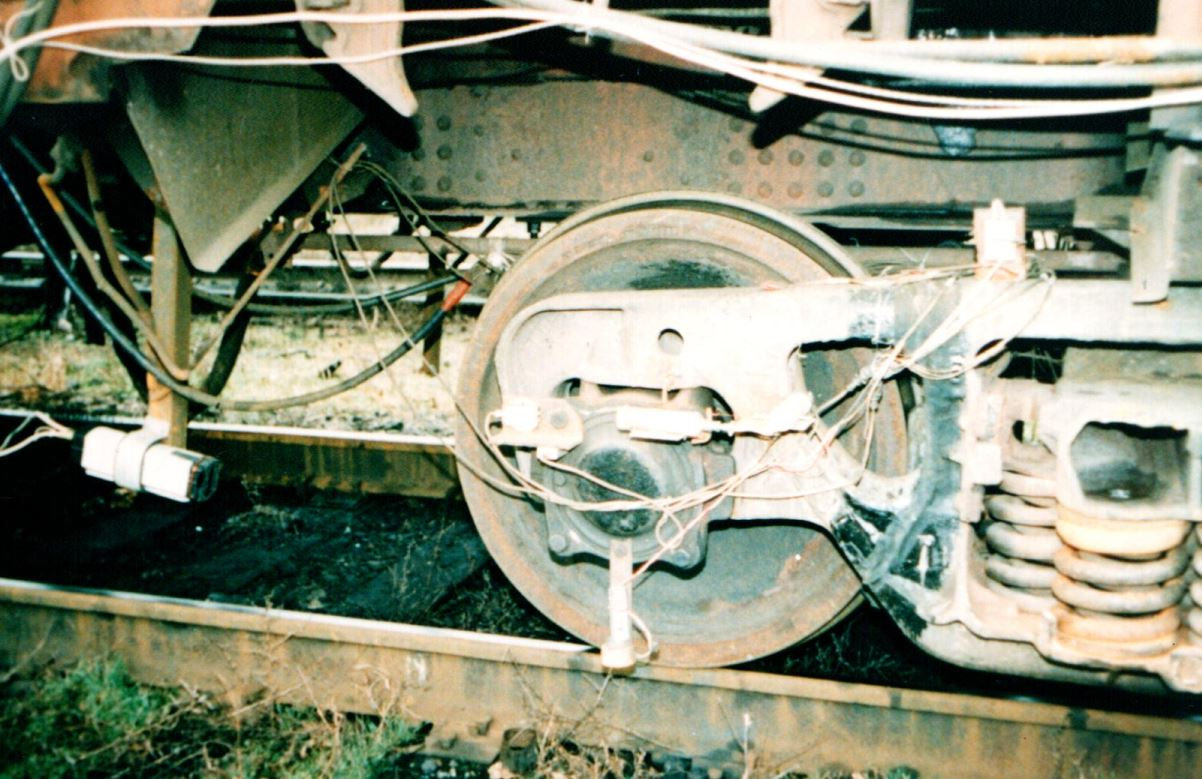

Fig.

9, a

shows the

general view

of one

of the

axlebox mounts

of the

tested cars

equipped with

an acceleration

sensor and

two small

displacement

sensors, and

Fig. 9, b

shows the

tested bogie

of the

3rd standard

car, with

installed

«in-line»

camcorders, a

curve entry

sensor, attached

to the

box cover,

small and

large

displacement

sensors and

an acceleration

sensor.

а

– a

б

– b

Fig. 9. Equipment

of tested cars with measuring equipment:

а

–

axlebox mount of

the tested car with an acceleration and small displacement sensors;

b

–

look of the tested

standard car bogie;

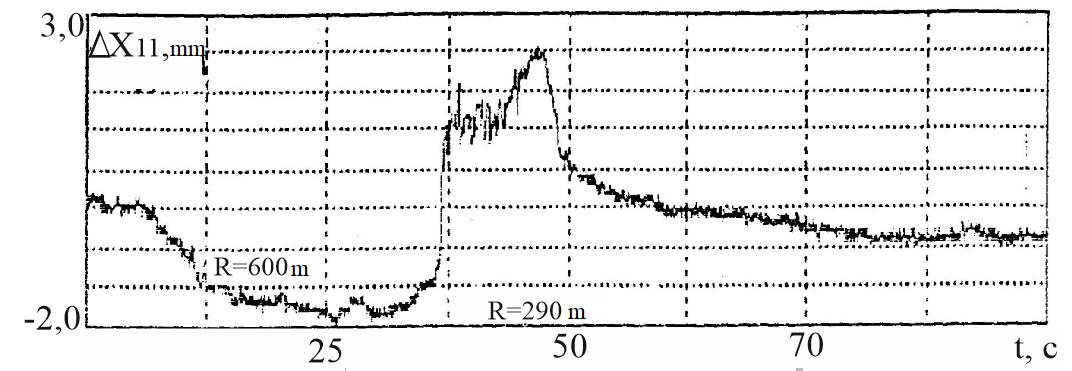

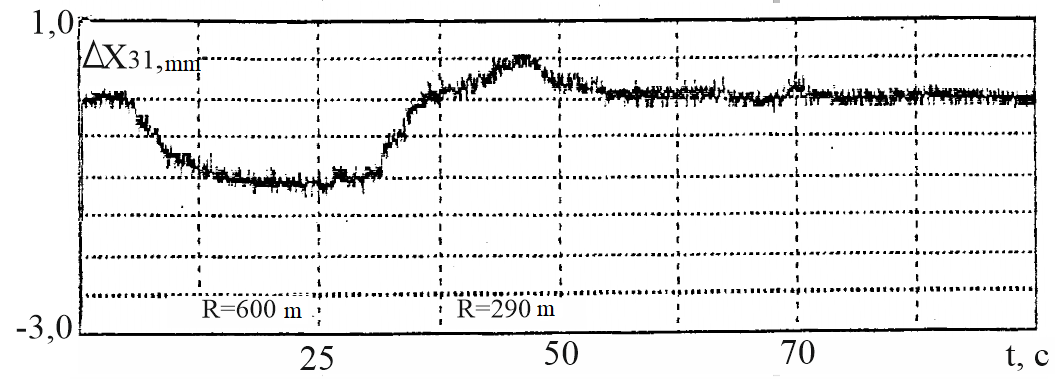

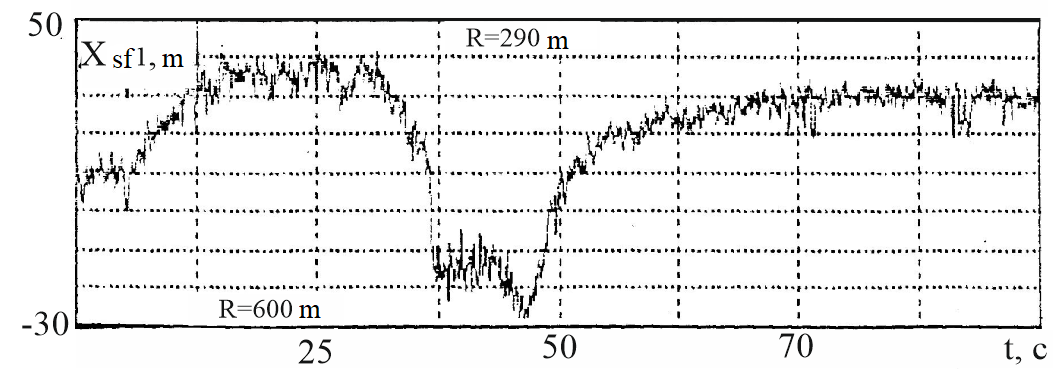

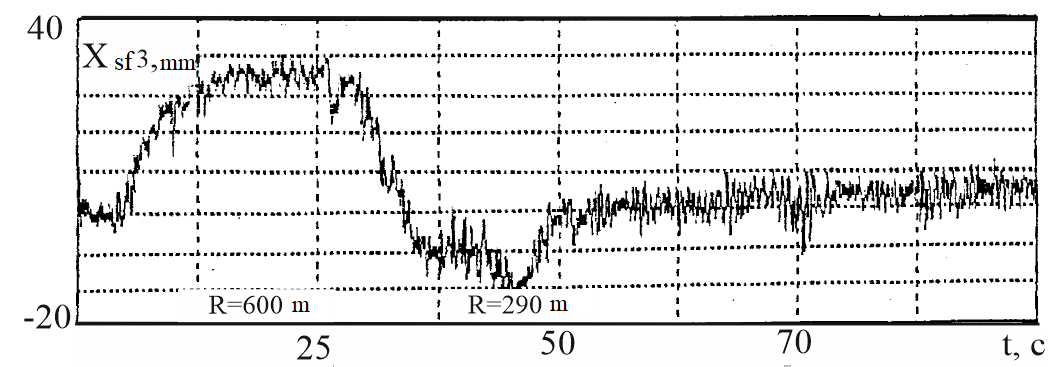

Fig. 10 shows the printouts of

the recorded changes of the longitudinal displacements of the first

wheel set axlebox mount relative to the side frames and lozenging of

the first bogie side frames of the first and third cars during the

movement of the tested train at a speed of 70 km/h. The output value

of the total longitudinal clearance of the box in the box opening

was 16 mm. The scale time (horizontally) is selected so that the

graphs display the records for the entire tested section. At the

printing time of 100 seconds, the graphics correspond to

approximately two kilometres, run by the experimental train along

the section, including a straight line, a curve with 600 m

radius, a short line between curves, a curve with 290 m radius and

a straight line. From these records it is clear that entering

into the curve with 290 m radius has a striking character.

a

b

c

d

Fig. 10. Variances

records:

a,

b –

longitudinal displacements of axle boxes of the first wheel set

relative

to the first bogie side frame of the first and third

cars respectively;

c,

d –

lozenging of the first bogie side frames of the first and third cars

respectively

The

longitudinal displacement of the axle boxes relative to the side

frames (Fig. 10, a, c)

is relatively small, their double amplitude does not exceed 5

mm. Moving during the lozenging of the side frames (Fig. 10, b,

d) have rather large values, their

amplitude reaches 40 mm. The recordings of displacements of the

axlebox mounts and lozenging of side frames show the displacements

that correspond to the break of the frictional forces during the car

negotiation into a curve with 290 m radius. Based on the processing

of the test results, it has been established that the magnitude of

the longitudinal displacements of the axlebox mounts

increase slightly with increasing

velocity. The largest values

increase slightly with increasing

velocity. The largest values

did not exceed 3-4 mm for the first car,

regardless of the radius of the curve. For the second car during

the movement in the curve

did not exceed 3-4 mm for the first car,

regardless of the radius of the curve. For the second car during

the movement in the curve

m the greatest values

m the greatest values

did not exceed 2-3 mm, and in the curve

did not exceed 2-3 mm, and in the curve

m – 1-1.5 mm. For the third car, the

values

m – 1-1.5 mm. For the third car, the

values

in the curve

in the curve

m did

not exceed

3.5 mm, and

in the

curve

m did

not exceed

3.5 mm, and

in the

curve

m – 2-3 mm.

For comparison:

the longitudinal

displacement of

the boxes

relative to

the flat

car side

frames in

the curve

m – 2-3 mm.

For comparison:

the longitudinal

displacement of

the boxes

relative to

the flat

car side

frames in

the curve

m according

to the

results of

the calculations

was 0.5-2

mm, and

lozenging of bogie side frames 17-22

mm in

the velocity

interval

m according

to the

results of

the calculations

was 0.5-2

mm, and

lozenging of bogie side frames 17-22

mm in

the velocity

interval

km/h

for all

variants of

the load

gravity center

displacement.

Somewhat lower values of the parameters

can be explained by the larger truck-center spacing.

km/h

for all

variants of

the load

gravity center

displacement.

Somewhat lower values of the parameters

can be explained by the larger truck-center spacing.

Taking into

account the fact that the experimental train for conducting dynamic

(running) tests was formed from the gondola cars of the model

12-532, and the theoretical calculations are given for the flat car

of the model 13-401, we note that the obtained results have a rather

high coincidence. The results

of calculations,

as well

as the

data of

experiments,

indicate that

the wear

indicators in

these cases,

in general,

grow with

increasing

speed. The

value of

wear indicators

for other

equal conditions

during the

movement of

cars in

the curve

with 300 m

radius is

higher than

during movement

in the

curve with

600 m radius.

Originality

and practical value

In the

process of research, we obtained the following scientific and

practical results:

– Mathematical

model of

coupling of

five freight

cars was

used to

study the

effect of

the loading

characteristics

of the

flat car

on the

value of

the wheel-rail

pair wear

factor;

– There

are assessed

such indicators

as the

wear factor,

the directional

force, and

hunting of

the wheel

set of

freight rolling

stock in

the event

of load

gravity centre

displacement

when moving

along curved

sections of

the railway

track;

– To

establish the

possible cause

of intensive

wear of

the wheels

and rails,

the following

parameters were

analysed:

lozenging of

front bogie

side frames;

hunting of

the left

side frame

of the

front bogie;

mutual

longitudinal

movement of

the side

frame and

axle box

of the

front wheel

set; mutual

hunting of

the left

side frame

of the

bogie relative

to the

front wheel

set;

– The

influence of speed on the mentioned indicators is investigated.

Conclusions

Based on the

analysis of theoretical studies conducted on the example of a flat

car, the following conclusions can be drawn:

– Lozenging

of bogie

side frames

of a

flat car

in the

range of

speeds of

50-80 km/h

does not

affect the

factor of

wear of

wheels and

rails both

at longitudinal

and transverse

displacement of

the load

mass center;

– Longitudinal

displacement of

load on

flat cars

does not

cause an

increase in

the studied

parameters;

– The

most probable reason for the intensive wear of wheels and rails

under the same conditions of motion is the temporary change in the

running characteristics of some carriages, namely, an increased

angle of climbing of individual wheels due to the bogie rotation

relative to the track or due to the rotation of the wheel set axle

due to the box shift in the bogie side frame openings.

LIST OF REFERENCE LINKS

Бороненко,

Ю. П. Инновации в тележках грузовых

вагонов: реальность и перспективы / Ю.

П. Бороненко, Е. А. Рудакова, А. М. Орлова

// Наука и транспорт.

– 2009. – № S. – С. 14–17.

Данович, В.

Д. Колебания в горизонтальной плоскости

4-осн. платформы с несимметрично

расположенным тяжеловесным грузом /

В. Д. Данович, П. С. Анисимов // Вестн.

ВНИИЖТ. – 1989. – № 3. – С. 5–9.

Данович, В.

Д. Математическая модель пространственных

колебаний сцепа пяти вагонов, движущихся

по прямолинейному участку пути / В. Д.

Данович, А. А. Малышева // Транспорт.

Нагруженность и прочность подвижного

состава : сб. науч. тр.

/ Днепропетр. гос. техн.

ун-т ж.-д. трансп. – Днепропетровск,

1998. – С. 62–69.

Данович, В.

Д. Пространственные колебания вагонов

на инерционном основании : дис. … д-ра

техн. наук : 05.22.07 / Данович

Виктор Данилович ;

Днепропетр. ин-т инж. ж.-д. трансп.

– Днепропетровск, 1981.

– 465 с.

Знос коліс

та рейок при нерівномірному завантаженні

піввагонів / Анжела О. Швець, О. М.

Болотов, Л. С. Сапарова, Анжеліка О.

Швець // Вісн. сертифікації залізн.

трансп. – 2019. – № 1. – С. 4–17.

Определение

показателей безопасности движения

платформ с порожним автопоездом / А.

В. Шатунов, В. В. Соборницкая, Е. Н. Ковтун,

О. М. Маркова // Транспорт : сб.

науч. тр. / Днепропетр.

гос. техн. ун-т ж.-д. трансп. –

Днепропетровск, 2001. – Вып. 7. – С. 116–120.

Петров, Г.

И. Модернизация грузовых тележек:

установка поперечной связи / Г. И.

Петров, Н. Ю. Черняев, М. А. Мещеряков //

Мир транспорта. – 2015. – № 5. – С. 58–62.

Разработка

рекомендаций по снижению износа колес

и рельсов за счет снижения сил

динамического взаимодействия

железнодорожных экипажей и пути с

учетом стационарных и нестационарных

режимов движения. В 3 т. Т. 3. Натурные

исследования факторов, влияющих на

повышенный износ рельсов и гребней

колес грузовых вагонов : отчет о НИР

(заключ.) : 91.134.95.97/379.95.97 ЦТех / Днепропетр.

нац. ун-т ж. д. трансп. им. акад. В. Лазаряна

; рук. Блохин Е. П., Пшинько А. Н. ; исп.:

Данович В. Д. [и др.].

– Днепропетровск, 1998. –

190 с. – № ГР 0196U023134. –

Инв. № 416(III).

Совершенствование

конструкции тележек грузовых вагонов

с целью снижения износа гребней колес

и рельсов / И. Э. Мартынов, В. Г. Маслиев,

С. Д. Мокроусов, В. П. Щербаков, В. И.

Нестеренко // Зб. наук.

пр. Укр.

держ. акад.

залізн. трансп. – 2013. –

Вип. 139. – С. 25–34.

Теоретическая

оценка динамических качеств платформ,

загруженных автопоездом с грузом / А.

В. Шатунов, В. В. Соборницкая, Е. Н. Ковтун,

О. М. Маркова // Транспорт : сб.

науч. тр. /

Днепропетр. гос. техн. ун-т

ж.-д. трансп. – Днепропетровск,

2000. – Вып. 3. – С. 21–27.

Технические

условия размещения и крепления грузов.

Приложение 3 к Соглашению о

международном железнодорожном грузовом

сообщении (СМГС). – Київ

: Девольта, 2011.

– Т. 1. – 436

с.

Шатунов, А.

В. Нагруженность

сцепа из двух платформ при ресурсосберегающем

способе транспортировки длинномерных

грузов : автореф. дис.

… канд. техн. наук : 05.22.07 /

Шатунов Александр Васильевич ;

Днепропетр. ин-т инж. ж.-д. трансп. –

Днепропетровск, 1992.

– 17 с.

Швець,

А. О. Вплив поздовжнього та поперечного

зміщення центру ваги вантажу в піввагонах

на їх динамічні показники / А. О. Швець

// Наука та прогрес

транспорту. – 2018. – № 5

(77). – С. 115–128.

doi: 10.15802/stp2018/146432

Ashtiani,

H. Influence of friction wedge characteristics on lateral response

and hunting of freight cars with three-piece bogies / H. Ashtiani,

S. Rakheja, A. K. W. Ahmed // Proceedings of the Institution of

Mechanical Engineers, Part F: Journal of Rail and Rapid Transit. –

2017. – Vol. 231. – Iss. 8. – P. 877–891. doi:

10.1177/0954409716647095

Effect

of the state of car running gears and railway track on wheel and

rail wear / E. P. Blokhin, O. M. Pshinko, V. D. Danovich, M. L.

Korotenko // Railway Bogies and Running Gears : Proc. of the 4th

Intern. Conf. / Technical University of Budapest. – Budapest,

1998. – P. 313–323.

Effects

of profile wear on wheel-rail contact conditions and dynamic

interaction of vehicle and turnout / J. Xu, P. Wang, L. Wang, R.

Chen // Advances in Mechanical Engineering. – 2016. – Vol. 8. –

Iss. 1. – P. 1–14. doi:

10.1177/1687814015623696

Generation

mechanism and remedy method of rail corrugation at a sharp curved

metro track with Vanguard fasteners [Electronic resource]/ B. W.

Wu, G. X. Chen, J. Z. Lu, Q. Zhu, X. Kang // Journal of Low

Frequency Noise Vibration and Active Control. – 2019. –

Available at:

https://journals.sagepub.com/doi/10.1177/1461348419845992

– Title from the screen. – Accessed :

26.06.2019.

doi:

10.1177/1461348419845992

Lack,

T. Freight car bogie properties analysis by means of simulation

computations / T. Lack, J. Gerlici, M. Manurova //

Manufacturing Technology. – 2016. – Vol. 16. – Iss. 4. – P.

733–739.

Light

weight freight rolling stock bogie frame: Design methodology

validated with field oscillation trials / S. Shukla, U. Kumar,

S. K. Sharma, P. Gupta, A. Kumar // International Journal of

Vehicle Structures and Systems.

– 2017. – Vol. 9. – Iss. 4. – P. 245–250. doi:

10.4273/ijvss.9.4.10

Modeling,

simulation and applications of

longitudinal train dynamics / C.

Cole, M.

Spiryagin, Q.

Wu, Y.

Q. Sun //

Vehicle System Dynamics.

– 2017. –

Vol. 55. – Іss.

10. – P.

1498–1571.

doi:10.1080/00423114.2017.1330484

Shatunov,

O. V. Study of dynamic indicators of flat car with load centre

shift / O. V.

Shatunov, A. O. Shvets // Наука та

прогрес транспорту. –

2019. – № 2 (80). – С. 127–143.

doi: 10.15802/stp2019/165160

Wu,

Q. Longitudinal

train dynamics: an

overview / Q.

Wu, M. Spiryagin,

C. Cole //

Vehicle System Dynamics.

– 2016. –

Vol. 54. –

Іss. 12.

– P. 1688–1714.

doi: 10.1080/00423114.2016.1228988

Ye,

Y. Small-amplitude hunting diagnosis method for high-speed trains

based on the bogie frame’s lateral–longitudinal–vertical data

fusion, independent mode function reconstruction and linear local

tangent space alignment [Electronic resource]/ Y. Ye, J. Ning //

Proceedings of the Institution of Mechanical Engineers, Part F:

Journal of Rail and Rapid Transit. – 2019. – Available at:

https://journals.sagepub.com/doi/10.1177/0954409718825412 – Title

from the screen. – Accessed : 26.06.2019.

doi:

10.1177/0954409718825412

О.

В. Шатунов1*,

А. О. Швець2*,

О. А. Кирильчук3*,

А. О. Швець4*

1*Каф.

«Вагони та вагонне господарство»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел.

+38 (067) 953 60 14,

ел. пошта shatunov220648@gmail.com,

ORCID 0000-0002-1115-0093

2*Каф. «Теоретична

та будівельна механіка», Дніпровський

національний університет залізничного

транспорту імені академіка В. Лазаряна,

вул. Лазаряна, 2, Дніпро, Україна, 49010,

тел. +38 (050) 214 14 19,

ел. пошта

angela.shvets69@gmail.com, ORCID 0000-0002-8469-3902

3*Каф.

«Вагони та вагонне господарство»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38 (056) 776 82 27,

ел. пошта

e-mail o.a.kirilchuk@gmail.com, ORCID 0000-0002-0565-1692

4*Каф.

«Вагони та вагонне господарство»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел.

+38 (095) 235 19

67,

ел. пошта

angela_Shvets@ua.fm, ORCID 0000-0002-0717-2521

ДОСЛІДЖЕННЯ

ЗНОСУ КОЛІС ТА РЕЙОК

ЗА НЕСИМЕТРИЧНОго

ЗАВАНТАЖЕННя

ПЛАТФОРМИ

Мета.

У науковій роботі потрібно провести

визначення впливу несиметричного

завантаження вагона-платформи на

величину фактора зносу пари «колесо-рейка»

в разі зміни параметрів, що мають місце

в експлуатації. Методика.

Динамічну навантаженість вагона-платформи

моделі 13–401 з типовими трьохелементними

візками досліджено з використанням

моделі просторових коливань зчепу з

п’яти вагонів за допомогою математичного

й комп’ютерного моделювання. Теоретичні

розрахунки виконано для найбільш

небезпечних ділянок залізничної

колії-кривих малого й середнього радіуса

в інтервалі допустимих швидкостей

руху. Результати.

Проаналізовано показники

зносу коліс рухомого складу й рейок на

прикладі вагонів-платформ за наявності

поздовжнього й поперечного зміщення

центра мас вантажу відносно центра

симетрії вагона. Для отримання інформації

про вплив допустимих відхилень

розташування вантажу у вагоні на

величину динамічної навантаженості

контакту «колесо-рейка» виконано

теоретичні дослідження просторових

коливань рейкового екіпажу та його

взаємодії з колією. Наукова

новизна. Для визначення

зносу пари «колесо-рейка» досліджено

вплив зміщення у двох напрямках від

центральної осі симетрії центра мас

вантажу з огляду на величину швидкості

руху по кривих ділянках колії малого

й середнього радіуса із застосуванням

математичної моделі зчепу з п’яти

вантажних вагонів.

Практична значимість.

У результаті проведених теоретичних

досліджень оцінено такі показники, як

фактор зносу, напрямлена сила й виляння

колісної пари вантажного рухомого

складу в разі зміщення центра мас

вантажу під час руху по криволінійних

ділянках залізничної колії. Для

встановлення ймовірної причини

інтенсивного зносу коліс і рейок

проаналізовано параметри: забігання

бокових рам переднього візка; виляння

лівої бокової рами переднього візка;

взаємне поздовжнє переміщення бокової

рами й буксового вузла передньої

колісної пари; взаємне виляння лівої

бокової рами візка відносно передньої

колісної пари.

Ключові

слова: вантаж; вагон-платформа;

забігання бокових рам візка; зміщення

центра тяжіння вантажу; кут виляння

колісної пари; швидкість руху; фактор

зносу

А.

В. Шатунов1*,

А. А. Швец2*,

О. А. кирильчук3*,

А. А. Швец4*

1*Каф.

«Вагоны и вагонное хозяйство», Днипровский

национальный университет железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро,

Украина, 49010, тел. +38 (067) 953 60 14,

эл. почта

shatunov220648@gmail.com, ORCID 0000-0002-1115-0093

2*Каф.

«Теоретическая и строительная механика»,

Днипровский национальный университет

железнодорожного

транспорта имени

академика В. Лазаряна, ул. Лазаряна, 2,

Днипро, Украина, 49010, тел.

+38 (050) 214 14 19,

эл. почта angela.shvets69@gmail.com,

ORCID 0000-0002-8469-3902

3*Каф.

«Вагоны и вагонное хозяйство», Днипровский

национальный университет железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (056) 776 82 27,

эл.

почта e-mail o.a.kirilchuk@gmail.com,

ORCID 0000-0002-0565-1692

4*Каф.

«Вагоны и вагонное хозяйство»,

Днипровский национальный университет

железнодорожного

транспорта имени

академика В. Лазаряна, ул. Лазаряна, 2,

Днипро, Украина, 49010, тел. +38 (095) 235 19 67,

эл. почта angela_Shvets@ua.fm, ORCID 0000-0002-0717-2521

ИССЛЕДОВАНИЕ

ИЗНОСА КОЛЕС И рельсов

при несимметричной

загрузке ПЛАТФОРМЫ

Цель.

В научной работе нужно провести

определение влияния несимметричной

загрузки вагона-платформы на величину

фактора износа пары «колесо–рельс»

при изменении параметров, имеющих место

в эксплуатации. Методика.

Динамическую нагруженность вагона-платформы

модели 13–401 с типовыми трехэлементными

тележками исследовано с использованием

модели пространственных колебаний

сцепа из пяти вагонов с помощью

математического и компьютерного

моделирования. Теоретические расчеты

выполнены для наиболее опасных участков

железнодорожного пути-кривых малого

и среднего радиуса в интервале допустимых

скоростей движения. Результаты.

Проанализированы показатели износа

колес подвижного состава и рельсов на

примере вагонов-платформ при наличии

продольного и поперечного смещения

центра масс груза относительно центра

симметрии вагона. Для получения

информации о влиянии допустимых

отклонений расположения груза в вагоне

на величину динамической нагруженности

контакта «колесо–рельс» выполнены

теоретические исследования пространственных

колебаний рельсового экипажа и его

взаимодействия с колеей. Научная

новизна. Для определения

износа пары «колесо-рельс» исследовано

влияние смещения в двух направлениях

от центральной оси симметрии центра

тяжести груза с учетом величины скорости

движения по кривых участках пути малого

и среднего радиуса с применением

математической модели сцепа из пяти

грузовых вагонов. Практическая

значимость. В результате

проведенных теоретических исследований

оценены такие показатели, как фактор

износа, направленная сила и виляние

колесной пары грузового подвижного

состава в случае смещения центра тяжести

груза при движении по криволинейным

участкам железнодорожного пути. Для

установления возможной причины

интенсивного износа колес и рельсов

проанализированы параметры: забегание

боковых рам передней тележки; виляние

левой боковой рамы передней тележки;

взаимное продольное перемещение боковой

рамы и буксового узла передней колесной

пары; взаимное виляние левой боковой

рамы тележки относительно передней

колесной пары.

Ключевые

слова: груз; вагон-платформа;

забегание боковых рам тележки; смещение

центра тяжести груза; угол виляния

колесной пары; скорость движения; фактор

износа

REFERENCES

Boronenko,

Y. P., Rudakova, Y. A., & Orlova, A. M. (2009). Innovatsii v

telezhkakh gruzovykh vagonov: realnost i perspektivy. Nauka

i transport, S,

14-17. (in

Russian)

Danovich,

V. D., & Anisimov, P. S. (1989). Kolebaniya v gorizontalnoy

ploskosti 4-osn. platformy s nesimmetrichno raspolozhennym

tyazhelovesnym gruzom. Vestnik of the

Railway Research Institute, 3, 5-9.

(in Russian)

Danovich,

V. D., & Malysheva, A. A. (1998). Mathematical Model of Spatial

Oscillations of the Coupling of Five Cars Moving Along a

Rectilinear Section of the Track.

In Transport.

Stress loading and durability of a rolling stock

(рр. 62-69).

Dnepropetrovsk.

(in Russian)

Danovich,

V. D. (1981). Spatial Cars

Oscillations in Inertia Track.

(Dysertatsiia doktora tekhnichnykh nauk). Dnepropetrovsk

Institute of Railway Transport Engineering,

Dnеpropetrovsk.

(in Russian)

Shvets,

Angela O., Bolotov, O. M., Saparova, L. S., & Shvets, Angelika

O. (2019). Wear Wheels and Rails at the Uneven Loading of Gondola

Cars. Visnyk sertyfikatsii

zaliznychnoho transportu,

1(53), 4-17.

(in Ukrainian)

Shatunov,

A. V., Sobornitskaya, V. V., Kovtun, E. N., & Markova, O. M.

(2001). Opredelenie pokazatelej bezopasnosti dvizheniya platform s

porozhnim avtopoezdom. Transport,

7, 116-120. (in Russian)

Petrov,

G. I., Chernyaev, N. Y., & Meshcheryakov, M. A. (2015).

Modernization of Cargo Bogies: Mounting of a Transverse Connection

Assembly. Mir transporta.

5, 58-62. (in Russian)

Blokhin,

E. P., Pshinko, O. M., & Danovich, V. D. (1998). Razrabotka

rekomendatsiy po snizheniyu iznosa koles i relsov za schet

snizheniya sil dinamicheskogo vzaimodeystviya zheleznodorozhnykh

ekipazhey i puti s uchetom statsionarnykh i nestatsionarnykh

rezhimov dvizheniya (Vol. 1-3).

Dnеpropetrovsk

National University of Railway Transport named after Academician V.

Lazaryan,

Dnеpropetrovsk.

(in Russian)

Martynov,

I. E., Masliev, V. G., Mokrousov, S. D., Nesterenko, V. I., &

Shcherbakov, V. P. (2013). Improved design cargo trucks-cars out to

prevent wear paddle wheels and rails. Zbirnyk naukovykh

prats Ukrainskoi derzhavnoi akademii zaliznychnoho transportu,

139,

25-34. (in

Russian)

Shatunov,

A. V., Sobornitskaya, V. V., Kovtun, E. N., & Markova, O. M.

(2000). Teoreticheskaya otsenka dinamicheskikh kachestv platform,

zagruzhennykh avtopoezdom s gruzom. Transport,

3, 21-27. (in Russian)

Tekhnicheskie

usloviya razmeshcheniya i krepleniya gruzov.

Prilozhenie 3 k Soglasheniyu o

mezhdunarodnom zheleznodorozhnom gruzovom soobshchenii (SMGS).

(2011). Kyiv:

Devolta. (in

Russian)

Shatunov,

A. V.

(1992). Nagruzhennost

stsepa

iz

dvukh

platform

pri

resursosberegayushchem

sposobe

transportirovki

dlinnomernykh

gruzov.

(Avtoreferat dysertatsii kandydata tekhnichnykh nauk).

Dnepropetrovsk Institute of

Railway Transport Engineering, Dnеpropetrovsk.

(in Russian)

Shvets,

A. O. (2018). Influence of the longitudinal and transverse

displacement of the cargo gravity center in gondola cars on their

dynamic indicators. Science

and Transport Progress,

5(77),

115-128.

doi: 10.15802/stp2018/146432

(in Ukrainian)

Ashtiani,

H., Rakheja, S., & Ahmed, A. K. W. (2017). Influence of

friction wedge characteristics on lateral response and hunting of

freight cars with three-piece bogies. Proceedings

of the Institution of Mechanical Engineers, Part F: Journal of Rail

and Rapid Transit, 231(8),

877-891. doi: 10.1177/0954409716647095 (in

English)

Blokhin,

E. P., Pshinko, O. M., Danovich, V. D., & Korotenko,

M. L. (1998). Effect of the state of car running gears and railway

track on wheel and rail wear. Railway

Bogies and Running Gears: Proceedings of the 4th International

Conference (рр.

313-323).

Budapest. (in English)

Xu,

J., Wang, P., Wang, L., & Chen, R. (2016). Effects of profile

wear on wheel-rail contact conditions and dynamic interaction of

vehicle and turnout. Advances in

Mechanical Engineering, 8(1),

1-14. doi:

10.1177/1687814015623696 (in English)

Wu,

B. W., Chen, G. X.,

Lu, J. Z., Zhu, Q., & Kang, X.

(2019). Generation mechanism and remedy method of rail corrugation

at a sharp curved metro track with Vanguard fasteners. Journal

of Low Frequency Noise Vibration and Active Control.

doi: 10.1177/1461348419845992 (in English)

Lack,

T., Gerlici, J., & Manurova, M. (2016). Freight car bogie

properties analysis by means of simulation computations.

Manufacturing Technology,

16(4),

733-739. (in English)

Shukla,

S., Kumar, U., Sharma, S. K., Gupta, P.,

& Kumar, A. (2017). Light weight

freight rolling stock bogie frame: Design methodology validated

with field oscillation trials. International

Journal of Vehicle Structures and Systems,

9(4),

245-250. doi: 10.4273/ijvss.9.4.10 (in English)

Cole,

C., Spiryagin, M., Wu, Q., & Sun, Y. Q. (2017). Modeling,

simulation and applications of longitudinal train dynamics. Vehicle

System Dynamics, 55(10), 1498-1571.

doi:

10.1080/00423114.2017.1330484

(in English)

Shatunov,

O. V., & Shvets, A. О. (2019). Study

of dynamic indicators of flat car with load centre shift. Science

and Transport Progress,

2(80), 127-143.

doi: 10.15802/stp2019/165160

(in English)

Wu,

Q., Spiryagin, M., & Cole, C. (2016). Longitudinal train

dynamics: an overview. Vehicle System

Dynamics, 54(12), 1688-1714. doi:

10.1080/00423114.2016.1228988 (in

English)

Ye,

Y., & Ning, J. (2019). Small-amplitude hunting diagnosis method

for high-speed trains based on the bogie frame’s

lateral–longitudinal–vertical data fusion, independent mode

function reconstruction and linear local tangent space alignment.

Proceedings of the Institution of

Mechanical Engineers, Part

F: Journal of Rail and Rapid Transit.

doi: 10.1177/0954409718825412 (in English)

Received:

March 11,

2019

Accepted:

July 08,

2019

km/h in the small and middle radius curves

were performed using the model of spatial oscillations of a five-car

coupling (Fig. 1) [2-4, 6, 10, 21].