ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука та прогрес

транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2019,

№ 4

(82)

ЗАЛІЗНИЧНА

КОЛІЯ ТА АВТОМОБІЛЬНІ ДОРОГИ

ЗАЛІЗНИЧНА

КОЛІЯ та автомобільні дороги

UDC

629.4.015:625.1.032

I. O.

BONDARENKO1*,

L. О. NЕDUZha2*

1*Dep.

«Track and Track Facilities», Dnipro

National University

named after

Academician V.

Lazaryan, Lazaryan St.,

2, Dnipro,

Ukraine,

49010, tel.

+38 (063) 802 21 80,

e-mail

irina_bondarenko@ua.fm, ORCID 0000-0003-4717-3032

2*Dep.

«Theoretical and

Structural Mechanics»,

Dnipro

National

University named after Academician V. Lazaryan,

Lazaryan St., 2,

Dnipro, Ukraine, 49010,

tel. +38 (067) 810 51 65, e-mail

nlorhen@i.ua,

ORCID

0000-0002-7038-3006

INVESTIGATION OF THE influence

OF THE ROLLING STOCK DYNAMICS

ON

THE INTENSITY OF USING

THE RAILWAY TRACK ELEMENTS

Purpose. The

main purpose of this work is to research deformability parameters of

the railway track under various operating conditions as the initial

data for the formation of forced oscillations of rolling stock and

the trackform use intensity. Methodology.

For the research, an original model of the trackform,

described with using the basic concepts of the theory of elasticity

and the propagation of elastic waves was developed. Findings.

It has been established that the ratio between the intensity of

work of elements and the trackform, as criteria for deformability,

can be used as the estimated parameters of the functionally safe

operation of the track. It can be the basis for the classification of

critical track states under which it had to perform work to restore

its working capacity in order to ensure the required level of

efficiency of use construction during the service life.

Originality. Trackform

and parameters of the elements of the track superstructure and

substructure can be described using the railway tracks deformability

behaviour. In the future this conclusion will help to increase the

efficiency of the dynamic properties of rolling stock when designing

and maintain in readiness the infrastructure while in operation.

Practical value. Changes in the regulatory framework of

rail transport in recent years provide for the observance of its

functional safety, therefore, the question of the need to assess the

impact of rolling stock on the way to be regarded as a dynamic

process with consideration to the deformability resistance track.

This research provides a basis for record of the stiffness of

deformation that allows creating the regulatory framework for the

functional safety of the railway track in Ukraine.

Keywords: trackform;

deformability parameters; oscillation;

deformability of the railway track

Introduction

The issue of providing the

reliable and safe operation of the railway track and rolling stock

during their interaction has existed since the introduction of

railway transport. The requirements for the said objects of

interaction were forming gradually and depended on the level of

knowledge and technologies. Thus, before introduction of rails of

Р50, UIC60, Р65 types and reinforced concrete sleepers in the

trackform, the main requirements were the provision of railway track

element strength and the track panel stability under the influence

of increasing loads and speeds of the rolling stock. The use of the

aforesaid track structure components completely provided the

superstructure strength under the weight of a rolling stock.

From 70s of the last century, the new requirements were forming, and

it has resulted in approving the international standards such as IEC

62278:2002, EN 50126-1-2017, EN 50126-2-2017 and IEC 60300-3-3:2017.

The modern

requirements for transport system maintenance strategy are directed

for minimizing the lifecycle cost, and for maximizing the

reliability, availability, maintainability and safety (RAMS) of the

transport systems. All the issues related to defining the

functionally safe operation of transport systems imply the study and

evaluation of dynamic processes resulting from the interaction in

time between the railway track and rolling stock. The influence of

dynamic processes in time becomes decisive while assessing the

functionally safe operation of modern speed projects such as «Aero

Train» (Yasuaki

Kohama), «Hyperloop»

(Elon Musk). In order to ensure the functionally safe operation of

any transport system, it is required to know which changes occur in

its elements in time and how the functionally safe status of each

element as well as their aggregate affect the system’s operation.

Indeed, in order to predict the operation of subgrade under actual

climate and service conditions, it is required to consider in time

the process of permanent deformation accumulation in it. In other

words, it is required to figure out the following issues: a) which

changes occur in the subgrade as a result of multiple force impact

by a rolling stock with respect to the change in temperature and

soil moisture; b) how the process of change in temperature and

moisture in the subgrade occurs under the influence of force,

electromagnetic and gravitational fields.

The influence of force fields

in the hard texture elements is researched insufficiently. The study

of stress-strain state of the railway track elements results in

identifying the peak stresses and deformations while using the full

force value. The deformability of the railway trackform as the

aggregate of deformations and shifts is presented as an influence

line (field, when the finite element method is used). It is

considered that the influence line shifts together with the force

motion. In all the mathematical models of railway track calculation,

it is taken that the influence of force field spreads evenly in all

directions, i.e. the principle of force field transfer is used due

to longitudinal waves how it occurs in liquid and gaseous media. The

influence of longitudinal waves is not taken into account in the

models. It may cause the error during calculation because it does

not allow reflecting the physical process of transferring the force

fields in the solid bodies and between them.

While

running the test on the rolling stock’s influence on the railway

track, a huge number of statistical data on strain-stress state of

the track have been obtained. They describe different deformability

of the same length of the track under the influence of the same

rolling stock. The different statistical data are conditioned by the

process of mutual influence of the rolling stock and the railway

track. We consider next the issue of analyzing the parameters of

railway track deformability under various operating conditions as

the initial data for forming the forced oscillations of the railway

rolling stock and the intensity of using the trackform elements.

Purpose

The main purpose of this work

is to study deformability parameters of the railway track under

various operating conditions as the initial data for the formation

of forced oscillations of rolling stock and the intensity in the use

of elements of the trackform. The object of the study is the process

of mutual influence of the railway rolling stock and the track. The

subject of the study is the deformability of the railway track under

various operating conditions as a factor in the formation of dynamic

irregularities.

Methodology of investigation

The main

macro indicators of the operation of the railway transport

infrastructure are the availability and economic efficiency

coefficients. Currently, many studies have been devoted to the

problems of studying the mathematical description of perturbations

acting on the track and the crew during their interaction [2-3,

5-23]. Each article adds an important part of the overall process of

the track and

rolling stock interaction. Articles

[2, 5-6, 10,

12, 13, 15-17,

20, 21-23]

focus on analysing

the simulation results delivered with implementation of the

mathematical models of the rolling stock: for transport carriages

[2, 5, 22], for real locomotives [6, 13, 16, 20,

21], for locomotive-roller rig coupled

system [9], for general rail vehicle [10, 12, 15, 17, 23]. Paper [3]

describes the mechanism of transferring force from the rolling stock

to the trackform. The simplified method to determine a vertical

impact force of the wheel with flat and rail interaction is

presented in this article. This article demonstrates the influence

of the wheel with flat geometrical parameters, speed of a vehicle to

maximum contact force and its distribution in the contact zone.

Articles [7, 11,

14, 16, 18, and 19] are dedicated to studying the track and the

rolling stock interaction.

The numerical model [7] is

subsequently used to determine the track vertical and lateral

stiffness. The work [11] proposes a computational methodology to

study how the varying vehicle component characteristics, on normal

and degraded conditions, impact on the vehicle/track interaction

loads and on the track damage. The paper [14] proposes an approach

for the validation of railway vehicle models based on on-track

measurements. The tasks that are addressed in the research [18]: to

perform tests at track irregularities of symmetrical sinusoidal

shape running both along straight and curved tracks, as well as

driving over the junctions along the straight and curved tracks, and

compare the results. A novel wheel–rail contact model [19] is

proposed to be implemented for multi-body dynamics simulation, in

order to facilitate accurate online calculation of damage phenomena

such as wear and rolling contact fatigue.

The above

articles studies are very important issues, but they apply some of

the approaches that restrict their research.

Modern theoretical models, which study the

track and rolling stock interaction, means and methods of recording

oscillations used in experiments, while studying the track and

rolling stock interaction, or assessing geometrical track states,

have no mechanism for determining the source of vibration and the

nature of the process of transferring these vibrations to the

«rolling

stock-track system».

Consequently, the oscillograms of the railway track contain the

superposition of both the impact of the rolling stock on the track

and the response of the track, taking into account its

deformability. The oscillograms on the rolling stock contain a

superposition of both the impact of the rolling stock on the track

and the other way round. These perturbations are not classified

according to physic-mechanical and geometric characteristics of

railway track construction elements that determine its

deformability. Thus, changes in the conditions of rails and wheels

contact with their tortuous motion remain unconsidered. Therefore,

firstly, it has become necessary to study the mechanism of

transferring force from the rolling stock to the trackform and vice

versa in time. Secondly, there was a need to study the physics of

the oscillation process and to differentiate the vibrations from the

physical-mechanical and geometric characteristics of the elements of

the construction of the railway track, which determine its

deformability.

Based on the

experience gained, a model was developed for determining the

processes of deformative operation of the railroad track [1, 4,

8].

The original model was created

for investigating the dynamic problem of railway track deformability

under the influence of the rolling stock. It applies the basic

provisions of the theories of elasticity and propagation of elastic

waves.

In the

model, it is taken that the track and rolling

stock interaction occurs by means of impulses. The impulses are

transmitted via bond pads conditioned by the position of a wheel set

along the track. The impulse duration is characterized by the time

of transferring the load from the rolling stock to the rail and

depends on the rolling stock speed. Any dynamic force is

characterized by the impulse transmission frequency on a particular

bond pad and by the impulse repetition frequency in particular

section [1, 4, 8].

The impulses are characterized by the law of force change and the

law of force intensity change in a contact time. A local system of

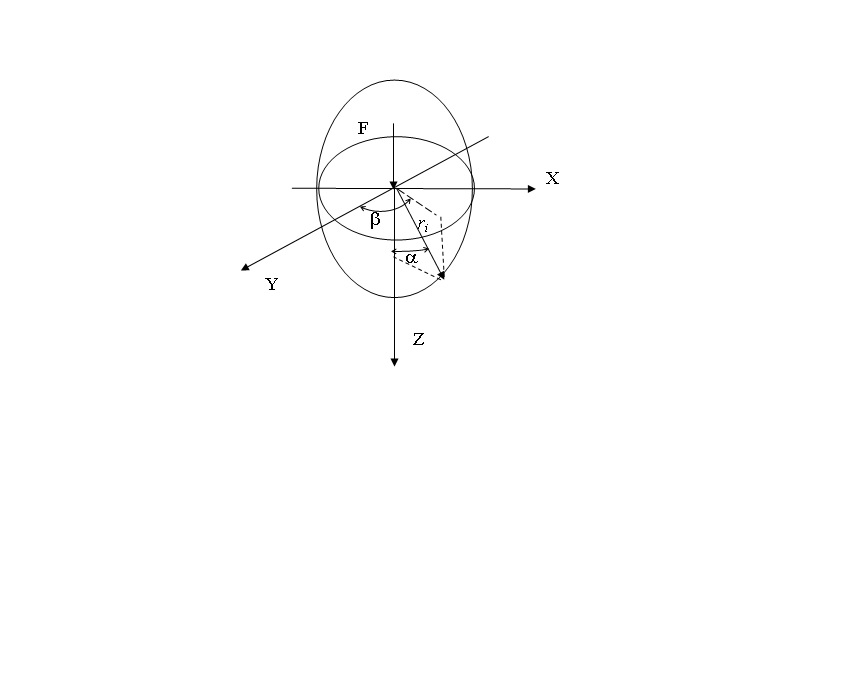

force coordinates for each

propagation of oscillations is always positioned in such a way so

that the x axis

coincides with the direction of force motion and the

axis – direction of force action. An explanation to the directions

and angles is given in Fig. 1.

axis – direction of force action. An explanation to the directions

and angles is given in Fig. 1.

Fig. 1. Determining the directions and angles of

oscillations propagation

Components of the wave vector

along the axes of coordinates that define the plane of equal phases

and amplitudes of oscillatory motion depend on the position of a

local coordinate system of the force relative to the basic

coordinate system of the structure. Thus, the position of a local

coordinate system of the force relative to the basic coordinate

system of the structure defines both the directions of propagation

of longitudinal and transverse waves and polarization of these

waves.

The impulses are transmitted by

the force waves. The process of force wave propagation is described

by using the propagation properties of transverse and longitudinal

waves. All oscillations generated by the contacting surfaces, which,

up to the given point, have not touched or have renewed their

contact after a break, propagate by spherical waves. They

characterize the main direction of propagation of the wave process

from a new or renewed contact between surfaces and account for the

contact and local concentrations of stresses and deformations.

All oscillations generated by

the contacting surfaces, which, up to the given point, have touched

and established contacts, propagate by quasi spherical waves. They

characterize the basic direction of propagation of the wave process

from the contact point of the surfaces and account for the

non-uniformity of oscillating. But one spherical wave of incidence

that carries the longitudinal and transverse mode causes four quasi

spherical refracted waves: two longitudinal and two transverse ones.

Each of them is heterogeneous, as it has vivid dependence of the

change in characteristics on its direction and carries the

consequences from the neighboring refracted waves in other

directions.

Since in the

process of propagation there is the superposition of waves, it

characterizes the non-uniformity of the whole process of

oscillating. Thus, in every point of the structure in a certain

period of action, one will observe either homogeneous spherical or

non-uniform quasi spherical waves. Their availability and velocity

of propagation are conditioned by stress-strain properties of

element materials. Each wave affects the particle in different

directions with respect to the direction of wave propagation. Each

wave, while transiting from one element to the other, changes its

properties. So, the calculation in the model is done with respect to

the directions of force wave front propagation

.

The main dependences of motion-direction are shown in [1, 4]. As a

result, the shift of structural particles in time has been obtained

.

The main dependences of motion-direction are shown in [1, 4]. As a

result, the shift of structural particles in time has been obtained

(see Fig. 2-5).

(see Fig. 2-5).

We compared

the values of the stresses at the rail base edge and head and the

rail deflections caused by running of ChS8 locomotive at a speed of

.

The experiment was carried out on a single-track section. The

trackform elements: UIC60 rail track, reinforced concrete sleepers

with KPP-5 type fastening,

.

The experiment was carried out on a single-track section. The

trackform elements: UIC60 rail track, reinforced concrete sleepers

with KPP-5 type fastening,

ballast depth, the roadbed is a sandy loam subgrade. The modulus of

the track elasticity in the vertical plane for calculation by the

existing method was taken from the experimental data and made

ballast depth, the roadbed is a sandy loam subgrade. The modulus of

the track elasticity in the vertical plane for calculation by the

existing method was taken from the experimental data and made

.

Table 1 shows the data calculated by the existing method «Track

strength calculation»,

the proposed method and the experiment obtained ones.

.

Table 1 shows the data calculated by the existing method «Track

strength calculation»,

the proposed method and the experiment obtained ones.

Table

1

Data

of the track stress-strain state

obtained using various methods

and experimentally

|

Method

|

Stresses

(MPa) in rail

|

Rail

deflection, mm

|

|

Base edge

|

Head

|

|

The existing method

|

115.7

|

120.69

|

1.56

|

|

The

proposed method

|

159.5

|

145.9

|

2.81

|

|

Experiment

|

163.3

|

146.1

|

2.5

|

Based on the strain-stress

properties and geometrical characteristics of the elements, the use

of wave properties allows establishing: a) the reaction of elements

to the force impact with respect to the time of its propagation; b)

time ratio of impulse impact and its propagation along the length

and depth of the trackform; c) change in amount of energy in any

point of the structure in time. The aforementioned parameters allow

changing the deformation processes by altering the element geometry

and material properties.

Based on the

described mathematical model, it is proposed to take as a composite

index the deformable work of trackform elements

:

:

(1)

(1)

where

– force that affects the element;

– force that affects the element;

– shift caused by the force during the action [

– shift caused by the force during the action [ ,

,

].

].

The amounts

of shift have three-dimensional nature even for one section of the

trackform. So, it was proposed to define the deformable work of

trackform

as the sum of works performed by all the track elements in one

section under the influence of the rolling stock with respect to the

time of perception and reaction of the elements:

as the sum of works performed by all the track elements in one

section under the influence of the rolling stock with respect to the

time of perception and reaction of the elements:

(2)

(2)

– a number

of elements getting a force impact.

– a number

of elements getting a force impact.

For evaluating and comparing

the use of trackform and elements under different operating

conditions, it was proposed to use I – the intensity of deformable

work of the elements or the structure (deformable work in the unit

of time).

The

investigation is carried out for the trackform model consisting of

the following elements such as rails of R65 type, concrete sleepers

of SB3 type, fastenings of KPP-5-К, ballast stone of

thick, subgrade. They are given in Table 2.

thick, subgrade. They are given in Table 2.

Table

2

The properties of trackform elements

|

Element

|

Density,

kg/m3

|

Poisson's coefficient

|

Young's module Е, МPa

|

Cl, m/s 1

|

Ct, m/s 2

|

|

rail

|

7 830

|

7 830

|

0.24

|

0.3

|

2.1х105

|

2.1х105

|

5 622

|

6 008

|

3 288

|

3 211

|

|

pad

|

918

|

935

|

0.3

|

0.485

|

100

|

200

|

382

|

1 572

|

204

|

268

|

|

sleeper

|

2 200

|

2 500

|

0.1

|

0.15

|

36 000

|

40 000

|

4 090

|

4 110

|

2 727

|

2 637

|

|

ballast

|

1 900

|

2 200

|

0.2

|

0.2

|

100

|

400

|

241

|

449

|

148

|

275

|

|

ground base

|

170

|

175

|

0.3

|

0.35

|

30

|

40

|

487

|

605

|

260

|

290

|

1

–

the speed of longitudinal; 2

–

the speed of transverse waves in the material

The rolling stock influence on

the track was considered with respect to the central position of the

wheel set. As a result of investigation, the following dependences

were obtained, which are shown in Fig. 2-3.

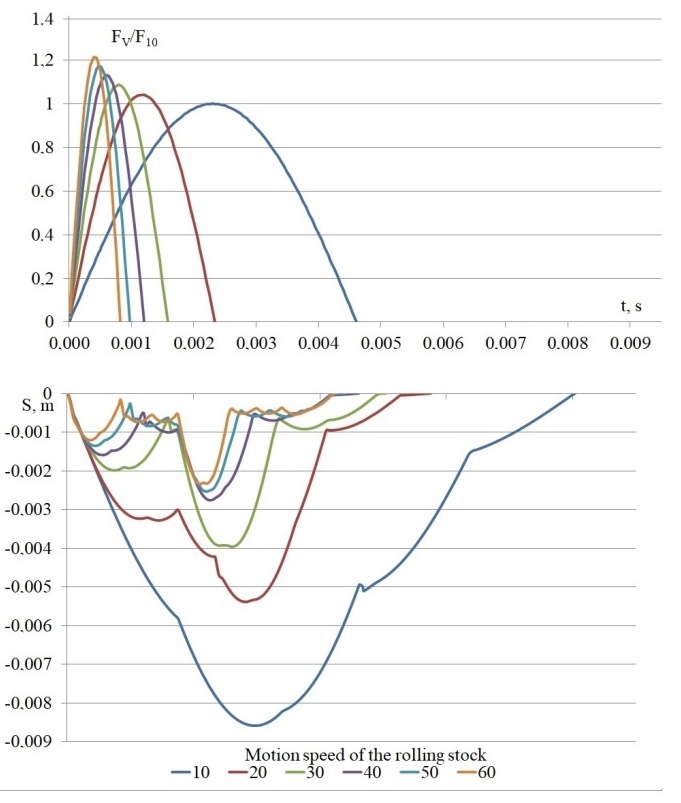

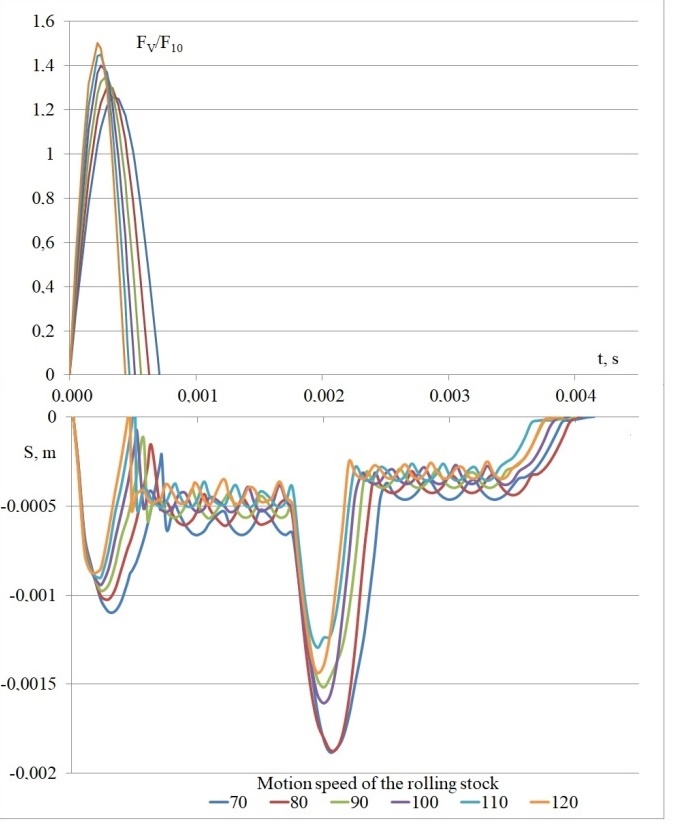

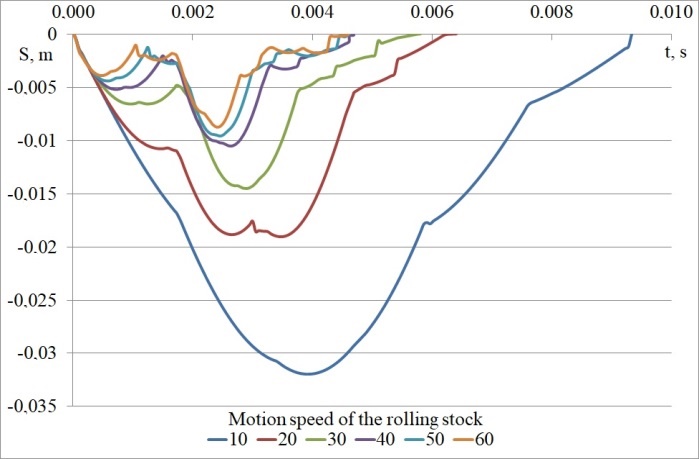

The upper

part of the diagram demonstrates the dependence of forces having an

impact on the track with respect to the time at various motion

speeds. The values of forces are given against the force value at

the speed of

.

The lower part of the diagram demonstrates the dependence of

oscillation amplitudes of the trackform section in time with respect

to different motion speeds under the single force impact on the

section.

.

The lower part of the diagram demonstrates the dependence of

oscillation amplitudes of the trackform section in time with respect

to different motion speeds under the single force impact on the

section.

In the existing models, it is

assumed that the trackform deformability as a result of the rolling

stock influence occurs instantly. Figures 2 and 3 clearly

demonstrate the falsehood of such assumption, depending on the time

of impulse impact conditioned by the motion speed of the rolling

stock.

The time of occurrence of the

deformability process in the railway trackform due to the rolling

stock impact depends on two constituents. The first constituent is

the time of impulse impact that depends on the motion speed. Its

value decreases together with the increase in motion speed. The

second constituent is the time of propagation of force impact in the

trackform elements. It depends on stress-strain and geometrical

characteristics of trackform elements. For the same trackform, in

case of the same-type force impact (the equal direction of force and

place of its application), this value is constant. Therefore, in

case of increase in motion speed, the time of deformability process

running in the trackform approaches the value of second constituent.

With increase in motion speed, we may observe the increase in

temporary delay value between the time of impact on the trackform

and the time when deformability occurs.

Fig. 2. The dependence of oscillation amplitudes

of

the trackform section in time with respect to different motion

speeds under the impact on the section

of single force

Fig. 3. The dependence of oscillation amplitudes

of

the trackform section in time with respect

to different motion

speeds under the impact

on the section of single force

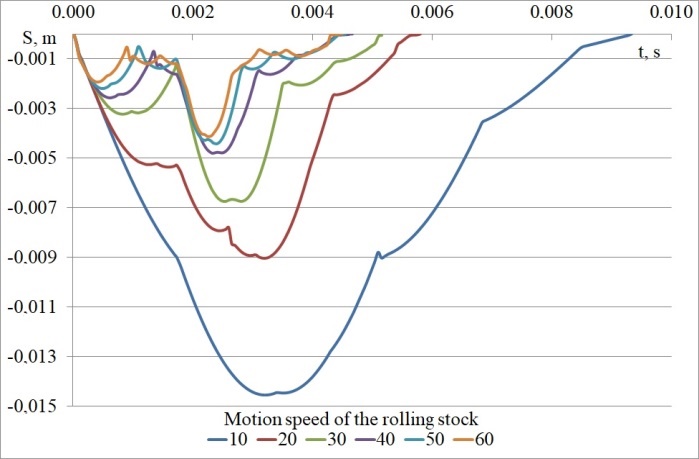

The dependences of oscillation

amplitudes of trackform section in time for various motion speeds

under the single force impact on the section are shown in Fig. 4 and

5, which are similar to Fig. 2. The difference in diagrams is

caused by the difference in force values having an effect on the

track. With increase in action force, the direct variation of

dependences of oscillation amplitudes of trackform section in time

is not traced in diagrams. The form of oscillations changes together

with the change in oscillation amplitudes. The form of oscillation

towards the direction of force impact propagation changes in

propagation time and is connected with the correlation between the

force action time and the time of deformability process propagation

in the trackform elements.

The number

of energy transferred by the wave is proportional to the square of

oscillation amplitudes. The change in energy occurs due to the

following conditions: a) changes in oscillation characteristics

towards directions of wave propagation; b) changes in oscillation

characteristics with respect to the wave properties during their

transition from one element to the other; с) friction forces in the

very oscillation propagation medium; d) friction forces arising

during interaction of element contact pairs. For the same trackform

and with the same-type force action, the change in energy occurs due

to condition а; the rest of conditions change proportionally to the

change in force. This condition а preconditioned the change in the

depth of trackform required for taking up a load. Conditions

are changing the form of dependences only in case of changing the

trackform. However, condition b

is decisive for choosing the number of elements and characteristics

of element materials in the trackform.

are changing the form of dependences only in case of changing the

trackform. However, condition b

is decisive for choosing the number of elements and characteristics

of element materials in the trackform.

The

aforesaid shows that the change in power loads and motion speeds of

the rolling stock directly affects the process of track

deformability. This process is one of the main factors for the

formation of dynamic track irregularities which serve as disturbance

effect for forming the three-dimensional vibrations of the rolling

stock. Each variety of trackform has its own time of force impact

propagation in the trackform elements. The change in number of

trackform elements, stress-strain properties, geometrical and

inertial characteristics of the trackform elements can cause the

change in time of propagation of the deformability process.

Therefore, we

can trace the interdependence of the rolling stock dynamics and the

process of track deformability.

Fig. 4. The dependence of oscillation amplitudes

of

the trackform section in time with respect

to different motion

speeds under the impact

on the section of single force

Fig. 5. The dependence of oscillation amplitudes

of

the trackform section in time with respect to different motion

speeds under the impact on the section

of single force

The track

deformability is accompanied by the trackform element work to take

up the force impacts from the rolling stock and to react to this

impact. Each element engages in the process of deformability from

the moment the force waves begin impacting on it. Each element has

its own time of propagation and transformation of force waves which

is conditioned by the stress-strain properties and geometrical

characteristics of the material. The trackform structure

characterizes the time of direct presence of force waves in the

trackform elements. Therefore, there exists the time when the

element directly takes and transforms force impacts, and the time

when the element becomes deformed due to deformations and shifts of

the other elements. In other words, the structure elements can work

«actively»

(by transforming the force impacts) and «passively».

For the purpose of evaluating

the operation of the above structure elements, we calculated the

dependences of oscillation amplitudes of the elements and trackform

section in time for various motion speeds during single force

movement (wheel motion). Table 3 shows the relationship between the

values of the deformability behavior of the elements and the

trackform at various motion speeds.

Table

3

Deformability behavior ratios at various

motion

speeds

|

|

structure

|

pad

|

sleeper

|

ballast

|

ground base

|

|

|

|

10

|

1

|

1

|

1

|

1

|

1

|

|

30

|

0.17

|

0.18

|

0.09

|

0.469

|

0.134

|

|

60

|

0.03

|

0.08

|

0.03

|

0.121

|

0.044

|

|

90

|

0.02

|

0.07

|

0.02

|

0.055

|

0.025

|

|

120

|

0.01

|

0.06

|

0.01

|

0.044

|

0.018

|

|

|

|

10

|

1

|

1

|

1

|

1

|

1

|

|

30

|

0.487

|

0.513

|

0.255

|

1.088

|

0.391

|

|

60

|

0.159

|

0.498

|

0.159

|

0.679

|

0.245

|

|

90

|

0.141

|

0.565

|

0.129

|

0.444

|

0.202

|

|

120

|

0.133

|

0.655

|

0.117

|

0.466

|

0.184

|

Following the results of data

analysis given in Table 3, at lower motion speeds, the values of

trackform amplitudes and load impact time exceed the similar values

at higher motion speeds but the load-receiving track length is

shorter. It results in different deformability behavior ratios at

various motion speeds. The evaluation of the trackform and elements

work intensity during the time of load action characterizes the

trackform and elements work intensity at various motion speeds. The

increase in motion speeds results in the intensity of using the rail

pads and railway ballast due to increased load-receiving track

length against the background of total decrease in the intensity of

using the trackform.

Table 4 shows the relationship

between the values of the deformability behavior of the elements and

the trackform at various loads.

Table 4

Deformability behavior ratios

at various loads

|

Object

|

load

|

|

|

|

|

|

|

|

structures

|

1

|

2.21-2.34

|

7.1-7.63

|

|

pad

|

1

|

2.02-2.25

|

5.67-7.03

|

|

sleeper

|

1

|

2.17-2.19

|

6.25-6.83

|

|

ballast

|

1

|

2.18-2.43

|

6.49-8.13

|

|

ground base

|

1

|

2.18-2.48

|

6.42-6.85

|

|

|

|

structures

|

1

|

2.01-2.13

|

5.79-6.02

|

|

pad

|

1

|

1.83-2.06

|

4.47-5.57

|

|

sleeper

|

1

|

1.90-2.00

|

4.94-5.38

|

|

ballast

|

1

|

1.94-2.73

|

5.07-7.7

|

|

ground base

|

1

|

1.98-2.25

|

5.06-6.63

|

Following

the results of data analysis given in Table 4, the railway track,

under the influence of the rolling stock having the load of

,

performs less work than the track having the loads of

,

performs less work than the track having the loads of

and

and

respectively by 2.24 and 6.16 times. The intensity of using the

elements and trackform having the loads of

respectively by 2.24 and 6.16 times. The intensity of using the

elements and trackform having the loads of

is less than that of the tracks having the load of

is less than that of the tracks having the load of

and

and

respectively by 2.08 and 5.66 times. It allows establishing the

interdependences of the rolling stock dynamics and the intensity of

using the railway track elements.

respectively by 2.08 and 5.66 times. It allows establishing the

interdependences of the rolling stock dynamics and the intensity of

using the railway track elements.

The use of proposed evaluation

parameters of deformability behavior will further allow us to define

the effect of the aggregate change in the states of elements on the

trackform operation and, in compliance with the current requirements

for the trackform and its maintenance, to form the set of evaluation

data of the track state in terms of acceptable deviations in the

trackform elements.

Originality and

practical value

Trackform and parameters of the

elements of the track superstructure and substructure can be

described using the railway tracks deformability behavior. In the

future this conclusion will help to increase the efficiency of the

dynamic properties of rolling stock when designing and provide

availability of the infrastructure during operation. Changes in the

regulatory framework of rail transport in recent years provide for

the observance of its functional safety, therefore, the question of

the need to assess the impact of rolling stock on the way to be

regarded as a dynamic process which must be taken into account track

deformability resistance. This study provides a basis which takes

into account the stiffness of deformation to allow forming the

regulatory framework for functional safety of railway track in

Ukraine.

Conclusion

The paper presents the

investigation of deformability parameters of the railway track under

various operating conditions as the initial data for forming the

forced oscillations of a rolling stock and the intensity of using

the elements of a trackform. In paper, the theoretical

provisions are proposed, and new analytical dependences of mutual

influence of railway rolling stock and railway track are determined.

It is found that the ratio

between the work intensity value of the elements and the trackform,

as criteria for deformability behavior, may be used as the

evaluation parameters of the functionally safe operation of the

track. The given parameters will serve as the basis for classifying

the critical track states when it is expedient to repair and

maintain the track to ensure the required level of trackform use

efficiency during its service life.

LIST OF REFERENCE LINKS

Бондаренко, І. О.

Моделювання з метою встановлення

оціночних умов функціональної безпеки

залізничної колії / I. O. Бондаренко //

Восточно-Европейский журнал передовых

технологий. – 2016. – Т. 1, № 7 (79). –

С. 4–10. doi:

10.15587/1729-4061.2016.59874

Татарінова, В. А. Теоретичні

дослідження руху одиниці рухомого

складу / В. А. Татарінова, Л. О. Недужа

// Електромагнітна сумісність та безпека

на залізничному транспорті. – 2018. – №

16. –

С. 121–126.

An

analytical

mathematical

method for

calculation of

the dynamic

wheel-rail

impact force

caused by

wheel flat

/ M.

Bogdevicius, R.

Zygiene, G. Bureika, S. Dailydka

// Vehicle

system dynamics. – 2016. – Vol.

54. – Іss.

5. –

Р. 689–705.

doi:

10.1080/00423114.2016.1153114

Bondarenko, I. Development of

algorithm for calculating dynamic processes of railroad track

deformability work / I. Bondarenko // Eastern-European Journal of

Enterprise Technologies. – 2016. – Vol.

6. – Іss.

7 (84). – P.

28–36. doi:

10.15587/1729-4061.2016.85464

Comparison of

simplified and complete contact modeling

approaches in simulations of high

adhesion locomotives

/ M. Spiryagin,

I. Persson, E. A. H. Vollebregt, C. Cole // Dynamics

of Vehicles on Roads and

Tracks : Proceedings of the 25th

International Symposium (14–18

August 2017, Rockhampton, Queensland,

Australia).

–

London, 2017. – Vol. 2. – Р.

613–619.

Derailment risk and

dynamics of railway vehicles in curved

tracks: Analysis

of the effect of failed fasteners

/ S. Morales-Ivorra, J. I. Real, C.

Hernández, L. Montalbán

// Journal of

Modern Transportation.

– 2016. – Vol. 24.

– Іss. 1.

–

P. 38–47.

doi: 10.1007/s40534-015-0093-z

Development of the procedure for

verifying the feasibility of designing an active suspension system

for transport carriages / N. Ershovа,

I. Bondarenko, O. Shibko, N. Velmagina //

Eastern-European Journal of Enterprise Technologies. – 2018. –

Vol. 3. –

Іss. 7 (93). –

P. 53–63.

doi:

10.15587/1729-4061.2018.131534

Dynamic Track Irregularities

Modeling when Studying Rolling Stock Dynamics

/ I. Bondarenko,

R.

Keršys,

O. Lunys,

L. Neduzha //

Proc.

of 23rd Intern.

Sci. Conf.

(October 2–4, 2019)

/ Kaunas University of Technology. – Palanga,

2019.

Facchinetti, A. Rolling Stock

Dynamic Evaluation by Means of Laboratory Tests / A. Facchinetti,

S. Bruni, W. Zhang // Intern. Journal of Railway Technology. –

2013. – Vol. 2. – Iss. 4. – P. 99–123.

doi:

10.4203/ijrt.2.4.6

Heat capacity and heat transfer

coefficient estimation for a dynamic thermal model of rail vehicles

/ R. N.

Hofstädter, T. Zero, C. Dullinger, G. Richter, M. Kozek //

Mathematical and Computer Modelling of Dynamical Systems. – 2017.

– Vol. 23. –

Iss. 5. – P.

439–452.

doi:

10.1080/13873954.2016.1263670

Impact of maintenance conditions of

vehicle components on the vehicle–track

interaction loads

/ N. Kuka, R. Verardi, C. Ariaudo, J.

Pombo // Proceedings

of the Institution of

Mechanical Engineers, Part C: Journal of

Mechanical Engineering Science. – 2018.

– Vol. 232.

– Iss. 15.

–

P. 2626–2641.

doi: 10.1177/0954406217722803

Kalivoda, J. Enhancing

the scientific level of engineering training of railway transport

professionals / J. Kalivoda, L. О.

Neduzha // Наука та прогрес

транспорту.

– 2017. – № 6 (72).

– С. 128–137. doi:

10.15802/stp2017/119050

Kalivoda, J. Simulation of Safety

Against Derailment Tests of an Electric Locomotive / J. Kalivoda,

L. Neduzha // Еngineering Mechanics

2019 : Proc. of 25th Intern. Conf. (Svratka, Czech Republic, 13–16

May 2019). – Svratka, 2019. – P. 177–180. doi:

10.21495/71-0-177

Kraft, S. An

approach for the validation of railway

vehicle models

based on on-track measurements / S.

Kraft, J. Causse, F. Coudert

// Vehicle System Dynamics. –

2015. –

Vol. 232. –

Iss. 10.

–

P. 1480–1499.

doi:

10.1080/00423114.2015.1054406

Kyryl'chuk, O. High

Speed Stability of a Railway Vehicle Equipped with Independently

Rotating Wheels /

O.

Kyryl’chuk, J. Kalivoda, L. Neduzha //

Еngineering Mechanics 2018 : Proc. of 24th

Intern. Conf. (Svratka,

Czech Republic, May 14–17, 2018). – Svratka, 2018.

– P. 473–476. doi: 10.21495/91-8-473

Mathematical

and Computer Models in Estimation of Dynamic Processes of Vehicles

/ A.

Assemkhanuly,

Z.

Niyazova, R.

Ustemirova,

A.

Karpov,

A.

Muratov,

K.

Kaspakbayev

// Journal

of Theoretical and Applied Information Technology. – 2019. –

Vol. 97, No 10. – P. 2803–2820.

Modelling, simulation and

applications of

longitudinal train dynamics / C.

Cole, M. Spiryagin, Q. Wu, Y. Q. Sun

// Vehicle

System Dynamics.

– 2017. – Vol.

55. – Iss. 10.

– P. 1498–1571. doi:

10.1080/00423114.2017.1330484

Research of Lateral Vibrations of a

Passenger Wagon Running Along the Curved Path

/ R. Skvireckas,

A. Keršys,

R. Keršys,

V. Lukoševičius

// Journal of

Vibroengineering. – 2012. – Vol.

14. – Iss. 2. – P. 706–714.

Sichani, M. S.

A fast wheel–rail contact model for

application to

damage analysis in vehicle dynamics

simulation / M.

S. Sichani, R. Enblom, M. Berg // Wear. –

2016. –

Vol. 366-367. –

P. 123–130.

doi: 10.1016/j.wear.2016.06.015

Simplified and advanced modelling

of traction control systems of heavy-haul

locomotives /

M. Spiryagin,

P. Wolfs, F. Szanto, C. Cole // Vehicle System Dynamics. –

2015. – Vol.

53. – Iss. 5. – P. 672–691.

doi: 10.1080/00423114.2015.1008016

Tatarinova, V. A. Research

of Locomotive Mechanics Behavior

/ V. A. Tatarinova, J. Kalivoda, L. О. Neduzha // Наука

та прогрес транспорту.

– 2018.

– № 5 (77).

– С. 104–114. doi:

10.15802/stp2018/148026

Theoretical

foundations for conceptually new rolling stock modules : monograph

/ M. I. Gorbunov, O. V. Fomin, V. V. Kovalenko, R. Y. Domin. –

Sievierodonetsk

: Volodymyr

Dahl East Ukrainian National University, 2018. – 100 p.

Wu, Q.

Longitudinal

train dynamics:

an overview

/ Q. Wu,

M. Spiryagin,

C. Cole

// Vehicle

System

Dynamics. –

2016. –

Vol.

54. – Iss.

12. – P.

1688–1714.

doi: 10.1080/00423114.2016.1228988

І. О. Бондаренко1*,

Л. О. НЕДУЖА2*

1*Каф.

«Колія та колійне господарство»,

Дніпровський національний університет

залізничного транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел.

+38 (063) 802 21 80,

ел. пошта irina_bondarenko@ua.fm,

ORCID 0000-0003-4717-3032

2*Каф. «Теоретична

та будівельна механіка», Дніпровський

національний

університет залізничного

транспорту імені академіка В. Лазаряна,

вул. Лазаряна, 2, Дніпро, Україна, 49010,

тел. +38 (067) 810 51 65,

ел. пошта nlorhen@i.ua,

ORCID 0000-0002-7038-3006

ДОСЛІДЖЕННЯ ВПЛИВУ ДИНАМІКИ

РУХОМОГО

СКЛАДУ НА ІНТЕНСИВНІСТЬ

ВИКОРИСТАННЯ

ЕЛЕМЕНТІВ

КОНСТРУКЦІЇ КОЛІЇ

Мета.

Основною метою цієї роботи є дослідження

параметрів деформованості залізничної

колії за різних експлуатаційних умов

як вихідних даних для формування

вимушених коливань рухомого складу й

інтенсивності використання елементів

конструкції колії. Методика.

Для дослідження було розроблено

оригінальну модель конструкції колії,

описану з використанням основних понять

теорій пружності й поширення пружних

хвиль. Результати.

Установлено, що

співвідношення між інтенсивністю

роботи елементів і конструкцією колії

як критерієм деформованості можна

використати як оціночний параметр

функціонально безпечної експлуатації

колії. Це може бути основою для

класифікації критичних станів конструкцій

колії за яких необхідно проводити

роботи з відновлення її працездатності,

щоб забезпечити необхідний рівень

ефективності використання конструкції

протягом терміну служби.

Наукова новизна.

Конструкція колії й параметри елементів

ії верхньої та нижньої будов можуть

бути описані з використанням поведінки

деформованості. Надалі цей висновок

допоможе підвищити ефективність

динамічних властивостей рухомого

складу під час проектування й забезпечити

готовність інфраструктури під час

експлуатації. Практична

значимість. Зміни в

нормативно-правовій базі залізничного

транспорту за останні роки передбачають

дотримання його функціональної безпеки.

Тому питання про необхідність оцінки

впливу рухомого складу на колію слід

розглядати як динамічний процес, який

повинен брати до уваги опір деформованості

колії. Це дослідження становить основу

для обліку жорсткості деформації, що

дозволяє сформувати нормативну базу

для гарантування функціональної безпеки

залізничної колії в Україні.

Ключові слова: конструкція

колії; параметри деформованості;

коливання; деформованість залізничної

колії

И. А. Бондаренко1*,

Л. А. НЕДУЖАЯ2*

1*Каф.

«Путь и путевое хозяйство», Днипровский

национальный университет

железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (063) 802 21 80,

эл.

почта irina_bondarenko@ua.fm, ORCID

0000-0003-4717-3032

2*Каф.

«Теоретическая и строительная механика»,

Днипровский национальный

университет железнодорожного транспорта

имени академика В. Лазаряна,

ул. Лазаряна,

2, Днипро, Украина, 49010, тел. +38 (067) 810 51 65,

эл. почта nlorhen@i.ua,

ORCID 0000-0002-7038-3006

ИССЛЕДОВАНИЕ ВЛИЯНИЯ ДИНАМИКИ

подвижного состава на

интенсивность

использования

ЭЛЕМЕНТОВ КОНСТРУКЦИИ

ПУТИ

Цель.

Основной целью данной работы является

исследование параметров деформированности

железнодорожного пути при различных

эксплуатационных условиях в качестве

исходных данных для формирования

вынужденных колебаний подвижного

состава и интенсивности использования

элементов конструкции пути. Методика.

Для исследования была разработана

оригинальная модель конструкции пути,

описанная с использованием основных

положений теорий упругости и

распространения упругих волн. Результаты.

Установлено, что соотношения между

интенсивностью работы элементов и

конструкцией пути как критерием

деформированности можно использовать

в качестве оценочного параметра

функционально безопасной эксплуатации

пути. Это может быть основой для

классификации критических состояний

конструкций пути, при которых необходимо

проводить работы по восстановлению

его работоспособности, чтобы обеспечить

необходимый уровень эффективности

использования конструкции в течение

срока службы. Научная

новизна. Конструкция

пути и параметры элементов его верхнего

и нижнего строений могут быть описаны

с использованием поведения

деформированности. В дальнейшем этот

вывод поможет повысить эффективность

динамических свойств подвижного состава

при проектировании и обеспечить

готовность инфраструктуры во время

эксплуатации. Практическая

значимость. Изменения

в нормативно-правовой базе железнодорожного

транспорта в последние годы предусматривают

соблюдение его функциональной

безопасности. Поэтому вопрос о

необходимости оценки влияния подвижного

состава на путь следует рассматривать

как динамический процесс, который

должен принимать во внимание сопротивление

деформированности пути. Это исследование

обеспечивает основу для учета жесткости

деформации, что позволяет сформировать

нормативную базу для обеспечения

функциональной безопасности

железнодорожного пути в Украине.

Ключевые слова: конструкция

пути; параметры деформированности;

колебания; деформированность

железнодорожного пути

REFERENCES

Bondarenko, I. O. (2016). Modeling

for establishment of evaluation conditions of functional safety of

the railway track. Eastern-European

Journal of Enterprise Technologies, 1/7(79),

4-10.

doi: 10.15587/1729-4061.2016.59874

(in Ukrainian)

Tatarinova, V., & Neduzha,

L. (2018). Theoretical Research of the Traction Vehicle Motion.

Electromagnetic compatibility and

safety on railway transport, 16,

121-126. (in

Ukrainian)

Bogdevicius, M., Zygiene, R.,

Bureika, G., & Dailydka, S. (2016). An analytical mathematical

method for calculation of the dynamic wheel–rail

impact force caused by wheel flat. Vehicle

System Dynamics, 54(5), 689-705.

doi:

10.1080/00423114.2016.1153114

(in English)

Bondarenko, I. (2016). Development

of algorithm for calculating dynamic processes of railroad track

deformability work. Eastern-European

Journal of Enterprise Technologies, 6/7(84),

28-36. doi:

10.15587/1729-4061.2016.85464

(in English)

Spiryagin,

M., Persson, I., Vollebregt, E. A. H.,

&

Cole, C. (2017). Comparison of

simplified

and complete contact modelling

approaches

in simulations of high adhesion

locomotives.

Dynamics

of Vehicles on Roads

and

Tracks.

Vol.

2:

Proceedings

of the 25th

International

Symposium, (pp.

613-619).

London.

(in English)

Morales-Ivorra, S., Real, J. I.,

Hernández, C., & Montalbán, L. (2016). Derailment risk and

dynamics of railway vehicles in curved tracks: Analysis of the

effect of failed fasteners. Journal

of Modern Transportation, 24(1),

38-47.

doi: 10.1007/s40534-015-0093-z

(in English)

Ershovа,

N., Bondarenko, I., Shibko, O., & Velmagina, N. (2018).

Development of the procedure for verifying the feasibility of

designing an active suspension system for transport carriages.

Eastern-European Journal of Enterprise Technologies, 3/7(93),

53-63. doi:

10.15587/1729-4061.2018.131534

(in English)

Bondarenko, I.,

Keršys, R.,

Lunys,

O., &

Neduzha, L. (2019).

Dynamic Track Irregularities Modeling when Studying Rolling Stock

Dynamics. Proceedings

of 23rd International Scientific Conference (October

2–4, 2019).

Palanga.

(in English)

Facchinetti,

A., Bruni, S., & Zhang, W. (2013). Rolling Stock Dynamic

Evaluation by Means of Laboratory Tests. International

Journal of Railway Technology, 2(4),

99-123.

doi:

10.4203/ijrt.2.4.6

(in English)

Hofstädter,

R. N., Zero, T., Dullinger, C., Richter, G., & Kozek, M.

(2016). Heat capacity and heat transfer coefficient estimation for

a dynamic thermal model of rail vehicles. Mathematical

and Computer Modeling of Dynamical Systems, 23(5),

439-452.

doi:

10.1080/13873954.2016.1263670

(in

English)

Kuka, N., Verardi, R., Ariaudo, C.,

& Pombo, J. (2018).

Impact of maintenance conditions of vehicle components on the

vehicle–track

interaction loads. Proceedings of the

Institution of Mechanical Engineers, Part C: Journal of Mechanical

Engineering Science, 232(15),

2626-2641.

doi:

10.1177/0954406217722803

(in English)

Kalivoda, J., & Neduzha, L. O.

(2017). Enhancing the Scientific Level of Engineering Training of

Railway Transport Professionals. Science

and Transport Progress, 6(72),

128-137. doi: 10.15802/stp2017/119050

(in English)

Kalivoda, J., & Neduzha, L. O.

(2019). Simulation

of Safety Against Derailment Tests of an Electric Locomotive,

Еngineering Mechanics

2019: Proc. of 25th Intern. Conf., 177-180.

Svratka. doi:

10.21495/71-0-177 (in English)

Kraft, S., Causse, J., &

Coudert, F. (2015). An approach for the validation of railway

vehicle models based on on-track measurements. Vehicle

System Dynamics, 53(10), 1480-1499.

doi:

10.1080/00423114.2015.1054406

(in English)

Kyryl’chuk, О., Kalivoda, J., &

Neduzha, L. (2018). High

speed stability of a railway vehicle equipped with independently

rotating wheels, Engineering Mechanics 2018:

Proc. of 24th

Intern Conf.

Svratka.

doi:

10.21495/91-8-473 (in

English)

Assemkhanuly,

А., Niyazova,

Z., Ustemirova,

R.,

Karpov,

A.,

Muratov,

А., &

Kaspakbayev,

К.

(2019). Mathematical

and Computer Models in Estimation of Dynamic Processes of Vehicles.

Journal of Theoretical and Applied

Information Technology, 97(10),

2803-2820 (in English)

Cole, C.,

Spiryagin, M., Wu, Q., & Sun, Y. Q.

(2017).

Modelling,

simulation and applications

of

longitudinal train dynamics.

Vehicle

System

Dynamics,

55(10),

1498-1571. doi:

10.1080/00423114.2017.1330484 (in

English)

Skvireckas,

R.,

Keršys,

A.,

Keršys,

R.,

& Lukoševičius,

V.

(2012). Research

of Lateral Vibrations of a Passenger Wagon Running Along the Curved

Path.

Journal of Vibroengineering.

14(2), 706-714.

(in English)

Sichani, M. S., Enblom, R., &

Berg, M. (2016).

A fast wheel–rail contact model for

application to

damage analysis in vehicle dynamics

simulation.

Wear, 366-367,

123-130. doi: 10.1016/j.wear.2016.06.015

(in English)

Spiryagin,

M., Wolfs, P., Szanto, F., & Cole,

C. (2015).

Simplified

and advanced modelling

of traction

control systems of heavy-haul

locomotives.

Vehicle

System Dynamics,

53(5),

672-691. doi: 10.1080/00423114.2015.1008016

(in English)

Tatarinova, V. A.,

Kalivoda, J., &

Neduzha, L. O.

(2018). Research

of Locomotive Mechanics Behavior.

Science and Transport Progress,

5(77),

104-114. doi: 10.15802/stp2018/148026

(in English)

Gorbunov,

M. I, Fomin, O. V, Kovalenko, V. V., &

Domin, R. Y. (2018). Theoretical

foundations for conceptually new rolling stock modules: monograph.

Sievierodonetsk:

Volodymyr

Dahl East Ukrainian National University.

(in English)

Wu, Q.,

Spiryagin, M., & Cole, C. (2016). Longitudinal train dynamics:

an overview. Vehicle

System Dynamics,

54(12),

1688-1714. doi: 10.1080/00423114.2016.1228988

(in English)

Received:

March 11, 2019

Accepted:

July 08,

2019

axis – direction of force action. An explanation to the directions

and angles is given in Fig. 1.

.

The main dependences of motion-direction are shown in [1, 4]. As a

result, the shift of structural particles in time has been obtained

(see Fig. 2-5).

.

The experiment was carried out on a single-track section. The

trackform elements: UIC60 rail track, reinforced concrete sleepers

with KPP-5 type fastening,

ballast depth, the roadbed is a sandy loam subgrade. The modulus of

the track elasticity in the vertical plane for calculation by the

existing method was taken from the experimental data and made

.

Table 1 shows the data calculated by the existing method «Track

strength calculation»,

the proposed method and the experiment obtained ones.

:

(1)

– force that affects the element;

– shift caused by the force during the action [

,

].

as the sum of works performed by all the track elements in one

section under the influence of the rolling stock with respect to the

time of perception and reaction of the elements:

(2)

– a number

of elements getting a force impact.

thick, subgrade. They are given in Table 2.