Purpose

For the railway transport the

most widely used superstructure is the ballasted track [23, 24]. The

ballast bed bears significant forces and plays important role in

load carrying «chain». Each part of the track receives static and

dynamic effects in different proportions [1, 2, 50, 52]. The forces

and stresses do not transmit consistently in the «sleeper-ballast

bed» interface, as well as «grain-grain» connections in the

ballast bed. These kinds of effects are the following (without

completeness):

dead weight loading (according

to the authors’ analysis, it is negligible),

vehicle

forces and effects (on perfect or quite perfect quality track),

previous

geometric and/or structural features on defective track (defects of

track geometry, «hammering» of rails at rail joints, defects of

welding…etc.) [1, 2, 4, 38, 39, 40, 41, 50, 52],

natural and environmental

effects (freeze, melt, sunshine, rain, wind, flood, etc.),

effects at turnouts caused be

railway vehicles [50, 52],

effects at level crossing

caused by road vehicles,

effects of tamping machines’

hammers during operation,

other relevant effects (e.g.

other vehicle effects, etc.) [0032, 0034].

The

degradated ballasted track cause significant geometric changes that

cause structural, stability and drainage problems. These problems

could shorten the lifetime of the track even in a short term [1,

50, 51, 52].

In nowadays

practice it is obvious aspect that required quality ballast [9, 13,

29, 30, 33, 34, 35, 36, 37,

46, 47, 49] is achievable in requested quantity.

It would be important to embed

crushed stone materials with better rock physic properties as

railway ballast bed. Using these ballast materials would also

facilitate production, transportation, installation, operation and

maintenance.

In reality,

the previous assumption is not evidence: the employed and developed

laboratory testing methods by the authors and the MSZ EN 13450:2003

product standard [37] (in Hungary the Modification 4 in MÁV

102345/1995 PHMSZ [30]) can be suitable for redound and raising with

the higher volumes of the LARB

and MDERB.

The developed testing method

may be a proposal for the elaboration or modification of new

assessment and measurement method and the revision of the values’

limits.

There are two types of

standardized laboratory test methods in the EU which could describe

the rock physic characteristics of the railway ballast and

determined in the MSZ EN 13450:2003 product standard [37]:

Los Angeles abrasion test (MSZ

EN 1097-2:2010) [0021],

Micro-Deval

abrasion test (MSZ EN 1097-1:2010) [0020].

These laboratory test methods

are not suitable for modelling the railway loads in a real manner

with the dynamic force and vibration [0035, 0037], but they can be

absolutely useable for satisfy defining the abrasion characteristics

of a given aggregate sample and for ensure the checking of the

quality level. For the objective judgement of conformability special

laboratory breakage test has to be used that consider the more real

operation circumstances and stresses.

The unique laboratory test

method was developed in 2015 [17], because the standardized tests

cannot consider the real breakage and abrasion (i.e. loads from

vehicles and other effects). The results of the test were compared

with the related regulation of MÁV (Hungarian Railways). The

individual laboratory test helps to calculate the required time

intervals of ballast screening.

The authors research the

theme’s extensive international literature. Foreign researchers

are actively publishing in the research topic, so there is a

comprehensive literature in different areas and different methods:

laboratory tests; field tests; DEM and FEM modelling methods and 3D

grain shape improvement [6, 14, 15, 22, 31, 32, 42, 43, 48]. Based

on this the authors represent the own, individual solution for the

unique laboratory test procedure (method) that is able to simulate

the stresses more realistic.

The second,

additional test is very different from the original one. The authors

put ballast particles to a HDPE (water) tube (lined with single

layer 1200 g/m2

geotextile) with its original closing element and loaded by ZD-40

machine static to an ultimate loading value step by step. Before and

after each loading stage, ballast sample – with all the particles

in the tube – are scanned by a CT (computer tomography) equipment

[7, 10, 11, 25, 26]. Because of loading a small aggregate, almost

every particle’s degradation is trackable.

Hopefully with this new method

the authors can achieve breakthrough results, which may serve as a

basis for a later standard.

Methodology

and new directions

Individual laboratory test

In 2014 a Research &

Development project was completed with the finance support of Colas

Északkő Ltd.; the public information was published in [17].

In 2017-2018 laboratory test

series with improved parameters and modified circumstances were

performed [16, 18, 19, 20, 21, 27].

The authors

executed the tests with two types of ballast samples because of the

different rock mechanic properties (ballast samples from Colas

Északkő Ltd.). The samples’ basic properties were different from

each other (LARB

and MDERB

values). The load cycles were the following: 0.1 million; 0.2

million; 0.5 million; 1 million; 1.5 million, 3 million and 5

million. Every ballast sample should be separate for each fatigue

test.

The aspects and detailed

parameters of the laboratory test are included in a previous

publication [27]. Such parameters which have been taken from the

wide literature research are the follows used by the authors to get

results:

FV

(%),

BBI,

BR,

d<22.4 mm in mass

percentage,

d<0.5 mm in mass

percentage,

d<0.063 mm in mass

percentage,

d60/d10

ratio,

Cc

ratio,

M ratio,

λ ratio.

The goal was to effort

determine mathematical-physical trends and correlation between

characteristics (see above point) and loading cycles of fatigue

test.

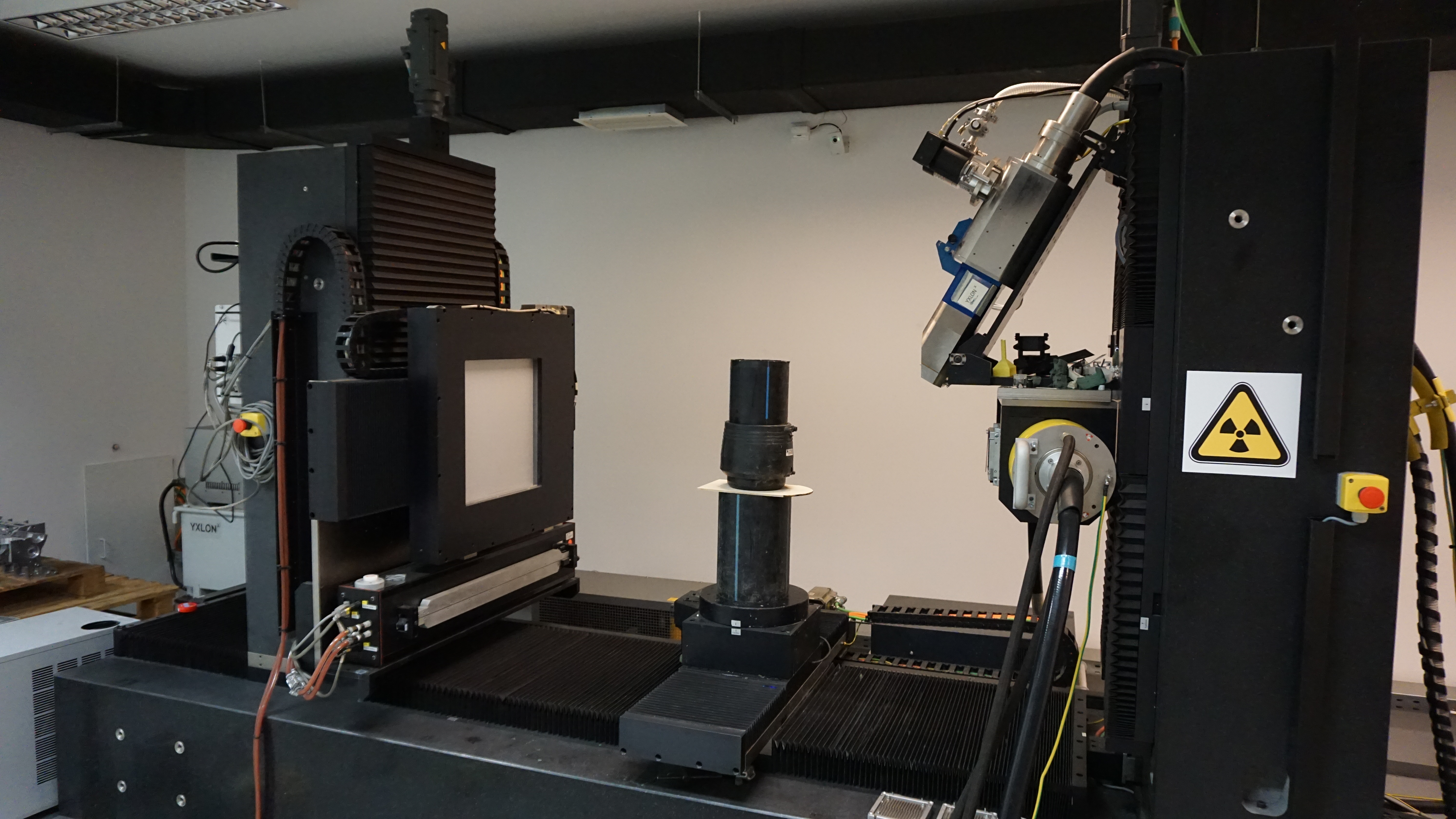

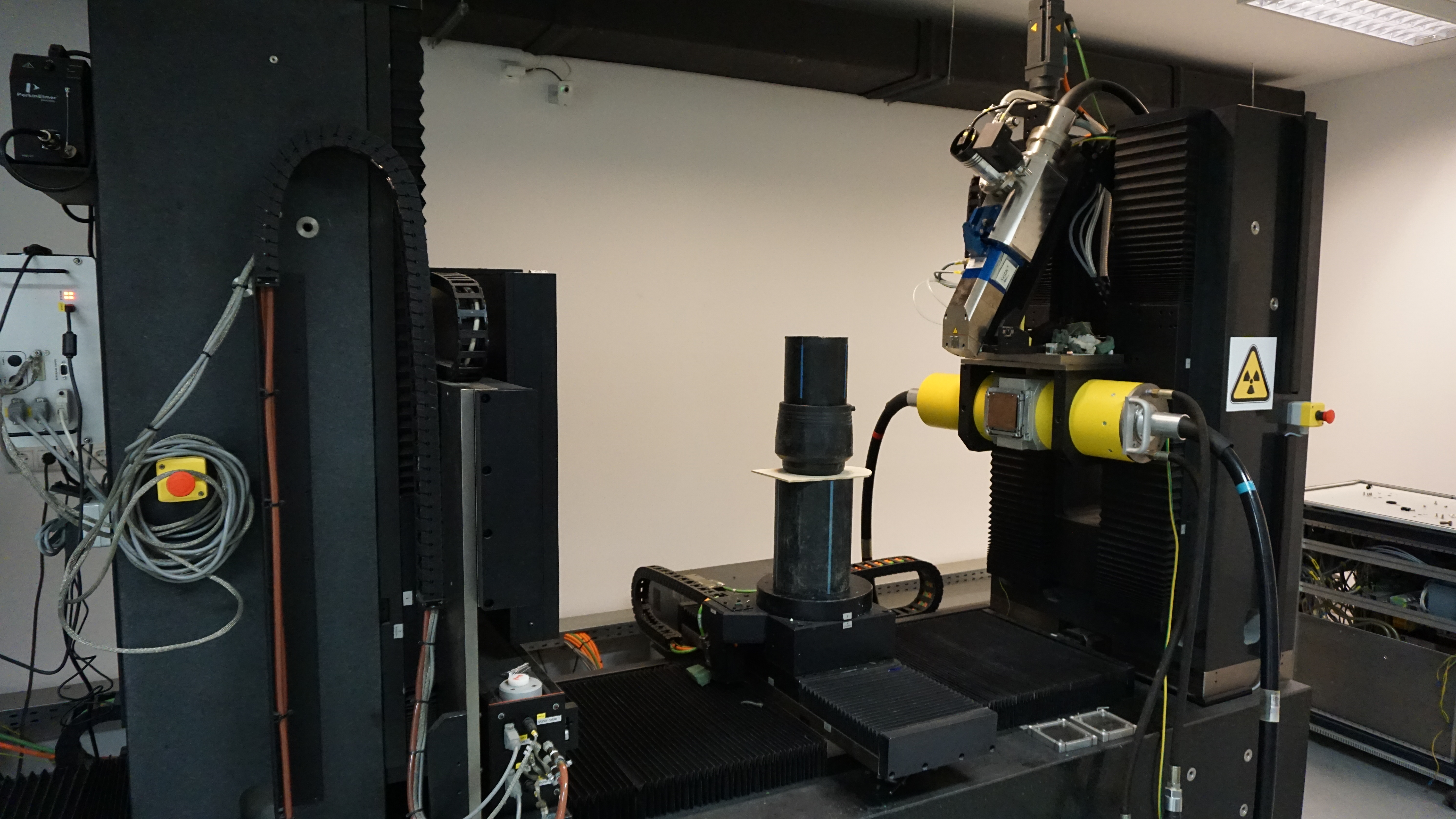

Application of the CT

(X-ray) equipment

While there is a wide range of

literature available for the 3-D image analysis, the authors found

very little source related to testings of railway ballast and/or

civil engineer granular materials with CT equipment. The CT (X-ray)

equipment is available to the authors in the laboratory of Audi

Hungaria Faculty of Automotive Engineering at Széchenyi István

University, Győr (Hungary) [7, 10, 11, 25, 26].

X-rays are a form of energy

distribution in the family of electromagnetic vibrations. Computer

tomography is a development of traditional X-ray screening

technology.

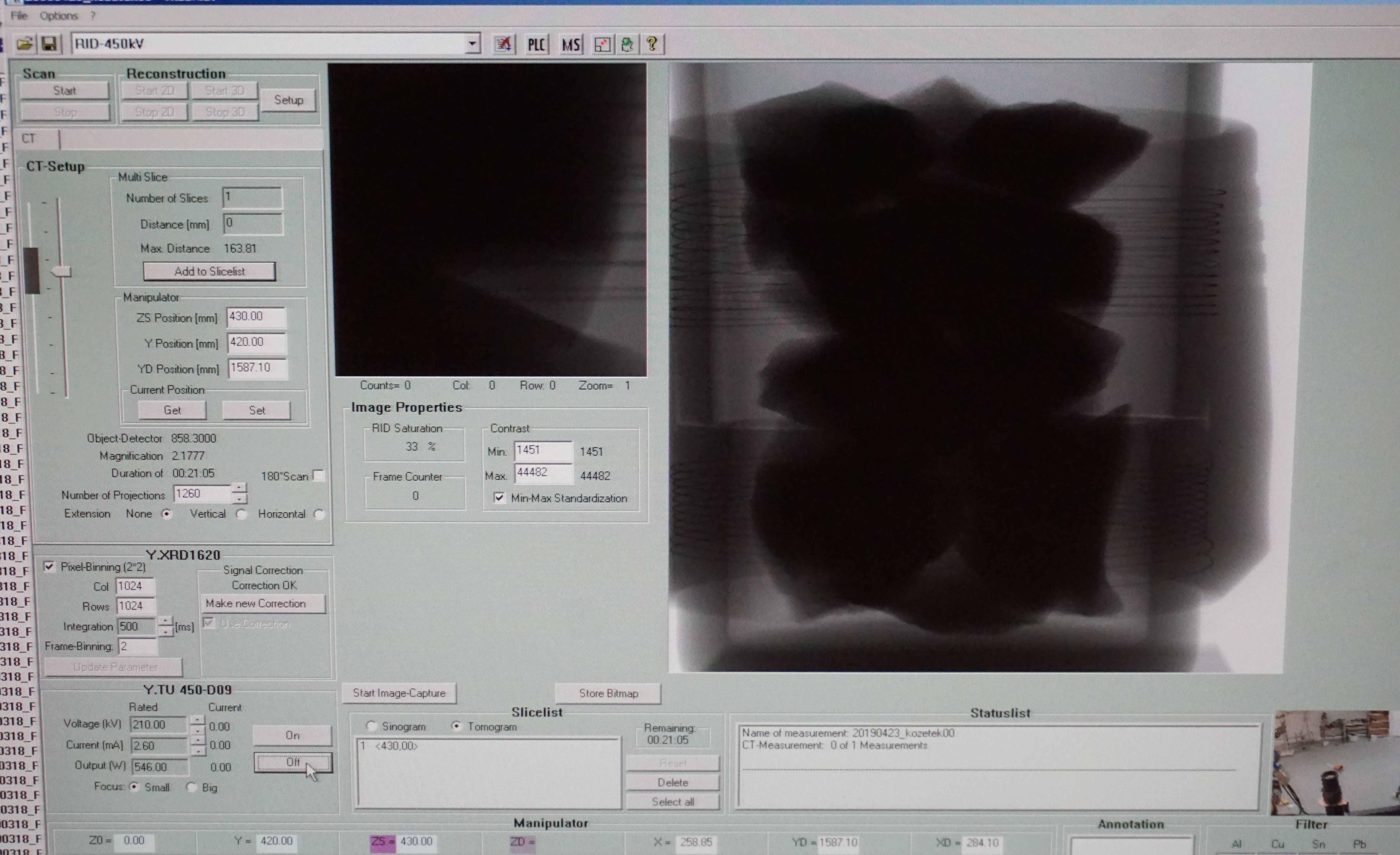

The basic data of the device

and some relevant data for one measurement can be read in the

authors’ previous paper [20].

The numbered and 3-D scanned

ballast particles are placed in a 140 mm diameter (inner dimension)

HDPE tube (originally a water tube) with its original closing

element (see Figure 3) and put it into the CT equipment (digitally

technic).

Fig. 3. The HDPE tube with the sample

The

measurement method is the following (for the 3-step loading):

washing, drying and numbering

of all the stones,

measuring the weight of the

stones and taking photo of all of them,

inserting the stones into the

HDPE tube (lined with single ,

placing the

HDPE tube into the CT equipment and recording CT 3-D model (initial

model),

loading

with ZD-40 machine (until 300 kPa),

another

recording by CT equipment (2nd model),

loading

with ZD-40 machine (until 600 kPa),

another

recording by CT equipment (3rd model),

loading

with ZD-40 machine (until 900 kPa),

another

recording by CT equipment (4th model),

measuring

the particles after the loading (weight, photographing),

washing and drying the

particles,

measuring the weight and

photographing once again.

The one-step loading

measurement method is very similar to the previous mentioned one,

the authors had to save two recording with the CT equipment (before

as well as after loading) and the loading was up to 1800 kPa.

X-ray

procedure

Homogeneous beam was emitted

through the sample, which diffuses and penetrates (it depends on the

material) and as a result of the adsorption, the distribution of the

quantum of the x-ray changes and weakens in the image plane,

blackens the detector to varying degrees. This creates the x-ray

images; that depends on the quality of the ballast material. X-rays

can also detect tiny cracks after the loading.

Computer tomography

procedure

The object

under examination is illuminated with a thin, flat X-ray beam. There

is a detector which placed behind the object senses where and how

much of the beam has been absorbed along a line. In the same

plain, the beam is illuminated from several directions, and a

drawing of the details in the plain (slice) is drawn from the

measured intensity curves. The plain is then pushed away and rotated

again. At the end of the procedure, the spatial structure of the

test body can be mapped. «Structure» refers to the arrangement of

details that can be distinguished from X-ray transmission

capability. Modern CT (X-ray) equipment crawls several slices (up to

1260) at a time, and a test can be performed in a few minutes with

the necessary calculations. The available CT equipment can be seen

in Figure 4.

Figure 5

shows an example for measurement.

Basic

data of the device, and some relevant data for one measurement:

A 360° rotation produces 1260

projections (CT-images).

The number

of the lines are 104.

In case of multi slice:

distance between two slices is 210 mm.

Number of the pixels: 2048 ×

2048 (used: 1024 × 1024).

2D-pixel

size: e.g. 0.19124188 mm.

3D-XY-pixel

size: e.g. 0.18966927 mm (the edge length of 1 spatial pixel – so

called ‘voxel’).

3D-Z-pixel

size: e.g. 0.1896692 mm.

X-ray tube: Y.TU 450-D09.

Tube voltage: 0…450 kV (used

210 kV).

Current: 2.60 mA (it is

related to 210 kV; e.g. 1.213 mA for 450 kV).

Focus: small.

Filters:

Al: 0.00 mm,

Cu: 1.50 mm,

Sn: 0.00 mm,

Pb: 0.00 mm.

Fig. 4. The CT (X-ray) equipment with

the

HDPE tube from two viewpoints

Fig.

5. Preview of a CT measurement, as well

as the board of the

software

As described

above, before and after the loading tests – like the fatigue test

– the HDPE tube with the ballast material was scanned by the CT

equipment. The authors used CT equipment for the analysis of the

breakage. The CT machine’s own software is able to build the

spatial frame of the ballast set and the 3-D model could be used in

the free software version of GOM 2018 (projection system). The

parameters are the following that can be determined by using the 3-D

model:

The weight of the particles

after the test was redefined.

After that, the authors

performed some loading test with just one-step and the values

reached even the 1800 kPa (2000 kPa). The step-by-step loaded and

scanned sets can be compared with the software.

Figure 6

and Figure 7

show some photo from the laboratory measurement.

Fig. 6. Some weighted and numbered particles

before loading

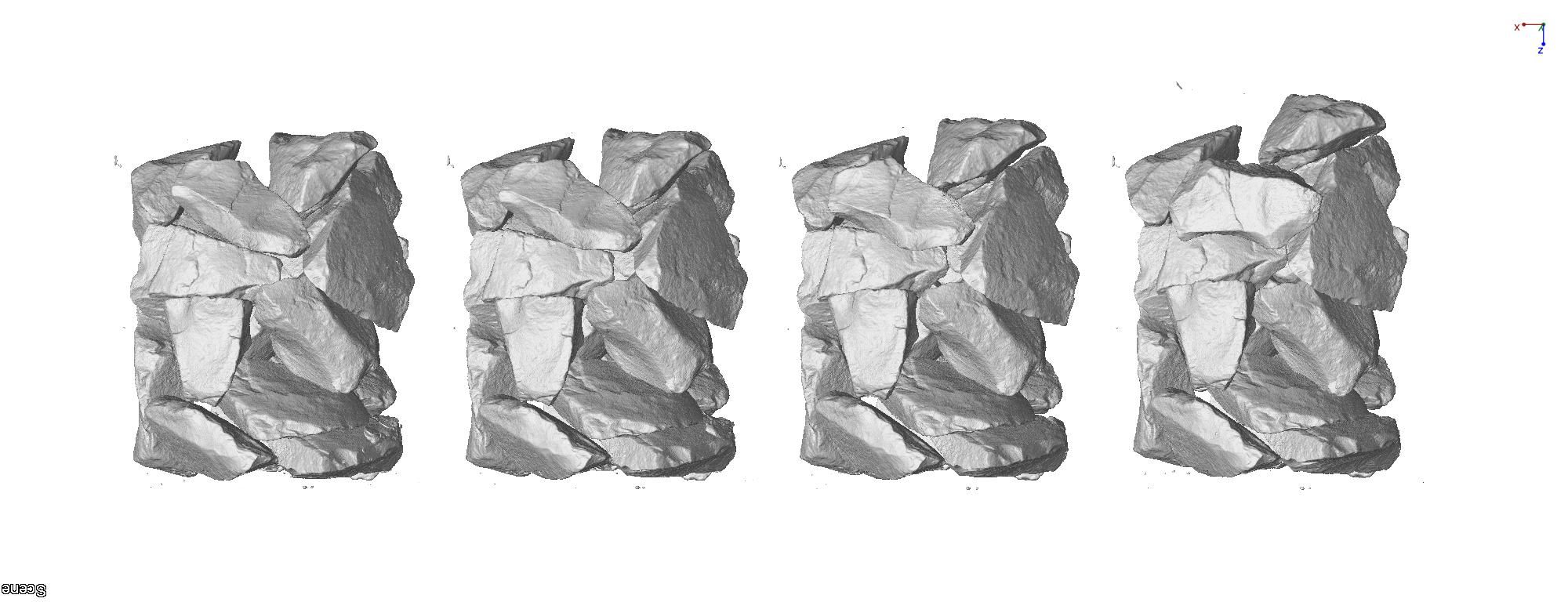

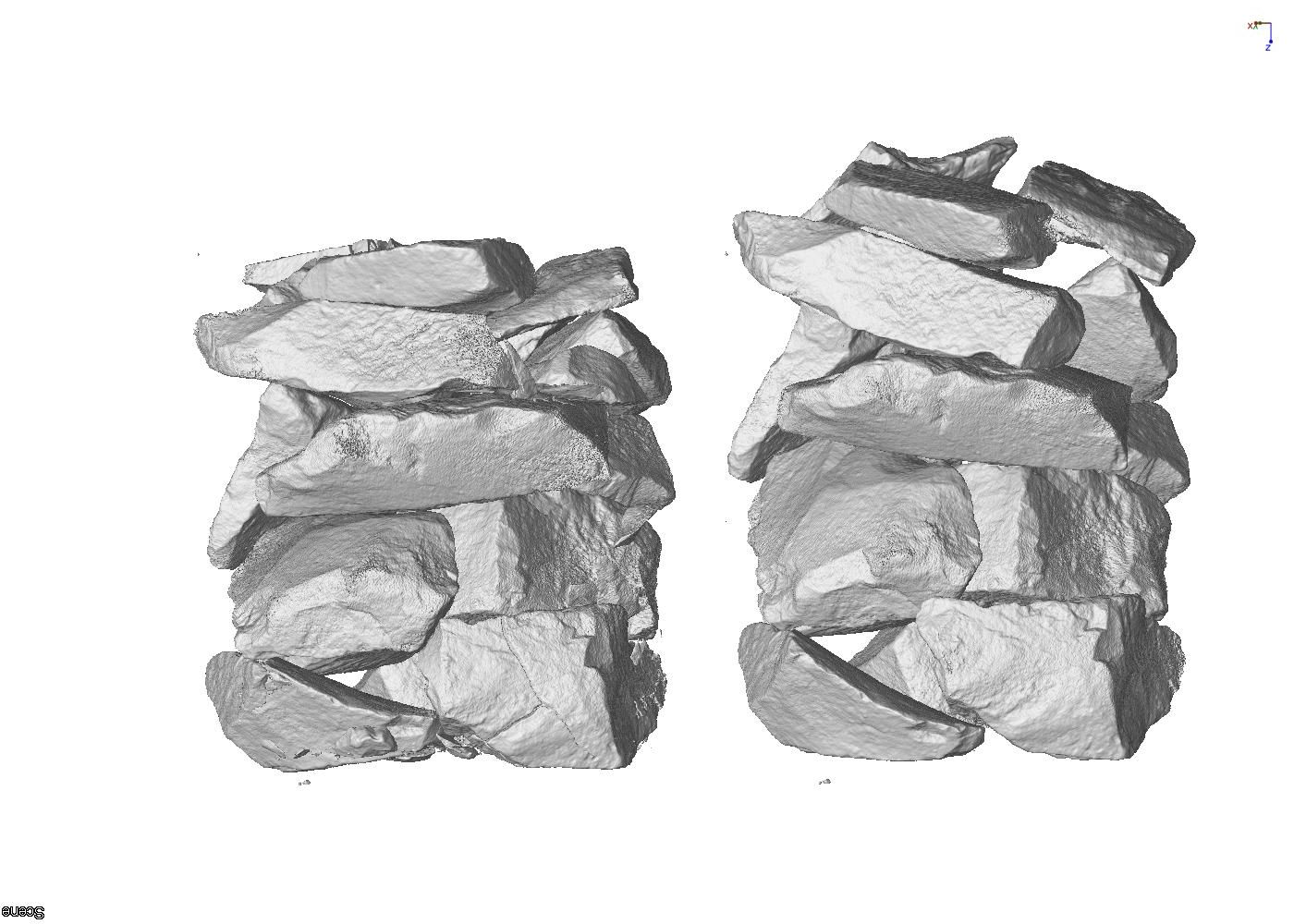

Figure 8

and Figure 9

show 3-D images (models) made by CT (X-ray) equipment. The samples

in the HDPE tube were static loaded with compression stresses of

given values (in Figure 7

from right to left: 0, 300, 600 and 900 kPa; in Figure

8 from right to left: 0, 1800).

Fig. 7. Numbered particles in the lined HDPE tube before (top) and

after (bottom) loading (Test series #3, i.e. maximum compression

stress: 1800 kPa)

Fig. 8. Recorded 3D images (models) from

the loaded aggregates in 3 (4) steps by CT equipment related to test

series #2 (from right to left – step #0: before loading, step #1:

max. compression stress is 300 kPa, step #2: max. compression stress

is 600 kPa, step #3: max. compression stress is 900 kPa)

Fig. 9. Recordings from the loaded

aggregates in 1 (2) steps related to test series #3 (from right to

left – step #0: before loading, step #1: max. compression

stress is 1800 kPa)

The authors suppose that the

speed of the loading is also a relevant parameter that will be

examined in the future.

Findings

and problems

In recent papers [16, 17, 18,

19, 20, 21, 27] the relevant correlations were presented in some

graphs related to the calculated parameters in case of the

individual fatigue laboratory tests.

There is

enormous time requirement of this type of testing method, so this is

the reason why the authors would like to try to find other

measurement methodologies, like the measuring with the CT equipment.

It can take 1 to 1.5 month to reach the 5 million cycles in the

testing method and the authors used «fresh»

ballast material for every measurement (after 100,000, 200,000,

500,000… etc. cycles).

Other problem is the extruded

polystyrol layer was significantly deformed during the dynamic test,

so in this year the main goal is to evolve the modified layer

structure. Changing it for a stiffer and harder layer could help the

research in better way.

At the second laboratory tests

the evaluation of the results is still ongoing.

The graphs

below show the loading curve for the 3-step load and the one-step

load (see Figure 10.

and Figure 11.).

The loading curves show that

they do not reach the upper limit of the load in a straight line,

but they move down in certain places. In these places the ballast

particles displacements from each other and breaking. With

increasing the load, the fractures in the loading curve are

increasingly greater.

Fig. 10. Loading curves of loadings with max.

300-600-900 kPa compression stress values

(3‑step

loading)

Fig. 11. Loading curve of loading with max.

1800

kPa compression stress value (one-step loading)

The loading curve rises much

steeper after every (little) breakpoint.

The

preliminary results show the quantity of the «rest» particles from

the entire ballast aggregate from the 3-step loading laboratory test

(with the HDPE tube). This value calculated from the weight of the

original numbered, washed and dried particles without loading and

washed and dried particles after the latest loading (it is a

percentage value, however it should be

taken into account that up to 30% of some stone have broken down).

The values can be seen in Table 1.

The values written with slanted letters show the values that involve

the rate of those stones that split into several pieces.

Table 1

The

broken particles of the ballast aggregate after 300-600-900 kPa

compression stress (the 3-step loading test)

|

Series

number of the tests

|

The

weight of the broken particles [%]

|

|

1

|

0.18%

|

|

2

|

0.14%

|

|

3

|

3.18%

(6.26%)

|

|

4

|

1.13%

|

|

5

|

1.06%

(3.90%)

|

|

6

|

1.65%

(3.64%)

|

Table 1. shows that none

of the samples contains more than 1.7% (with the exception of Series

2#) of the powder of the stone after the latest loading. The

percentage of broken stones is also less than 4%, including the

number of stones that fell into several larger pieces (not powder,

like the previous case).

The authors

also investigated that in the tube which particles were broken down

mostly of the rows. Table 2

show the degradation for each rows (ratio of after-loading-weight

and before-loading-weight in percentage).

Table 2

The

broken particles of the rows

at the 3-step loading test

|

Series

number of the tests

|

Number

of the row

|

The

weight of the broken particles [%]

|

|

1

|

1

2

3

4

5

|

0.10%

0.06%

0.13%

0.13%

0.47%

|

|

2

|

1

2

3

4

5

6

|

0.00%

0.27%

0.11%

0.09%

0.27%

0.09%

|

|

3

|

1

2

3

4

5

|

5.45%

0.62%

1.28%

5.73%

2.80%

|

|

4

|

1

2

3

4

5

|

0.15%

1.59%

2.04%

0.57%

1.17%

|

|

5

|

1

2

3

4

5

6

|

0.24%

0.34%

0.67%

0.31%

4.33%

0.21%

|

|

6

|

1

2

3

4

5

6

7

|

0.51%

0.05%

0.54%

0.35%

6.68%

0.43%

0.91%

|

According to the values (with

the expection of Series #2) the particles are mostly broken in the

lower and middle part (three before the bottom) of the aggregate.

During the test particles in

the HDPE tube moved significantly during the test (mainly on top of

the aggregate). The authors would like to analyse particle movements

in the future.

Originality

and practical value

The most important goal of the

authors that supplement the currently used regulation with new

measurement methods, because the original standardized tests are not

loading the samples realistic. The authors’ developed and new

methods may serve as a basis for a future instruction or regulation.

Conclusions,

future scope

The authors would like to

reduce the time requirement of newly developed testing methods with

improved manner. The authors combine the compression tests with 3-D

image analysis (full-field 3-D shape measurement) with the help of

CT (X-ray) equipment. The measurement method was developed, the

procedure of evaluation methodology is in progress.

Beside them field tests are

planned in the Hungarian railway lines. The authors plan to collect

samples from old railway lines where ballast aggregates have known

PSD (particle size distribution) at the time of construction.

In the laboratory the authors

always work in idealized conditions. This is the reason why the

particle breakage values are much higher than the values in real

circumstances (see measurement results from 2014 and 2017-2018).

Besides, the authors could test only one kind of loadings. Tamping

machines also break ballast particles during work, so this kind of

effect is also needed to be considered in the future research.

Delivery of the crushed stone to the site can also be an important

parameter that has to be considered.

The authors plan to work with

DEM simulations [12, 44, 45], for this a spatial model must be

built. The simulations with the laboratory tests would be

comparable.

Acknowledgements

The publishing of this paper

was supported by EFOP 3.6.1-16-2016-00017 project.

List of reference links

Курган,

Д. М. До вирішення задач розрахунку

колії на міцність із урахуванням

нерівнопружності підрейкової основи

// Наука та прогрес транспорту. – 2015. –

№ 1 (55). – С. 90–99. doi:

https://doi.org/10.15802/stp2015/38250

Ágh,

Cs. A new arrangement of accelerometers on track inspection car

FMK-007 for evaluating derailment safety / Cs. Ágh // Track

Maintenance Machines in Theory and Practice,

SETRAS 2018 :

Conference Paper (November 2018, Žilina, Slovakia). – Žilina,

2018. – Р. 7–14.

Ágh,

Cs. Egyenértékű kúposság mérése Magyarországon: Pálya és

jármű kapcsolata – futási instabilitás / Cs. Ágh //

Sínek világa. – 2012. – Vol. 54, No. 6. – Р. 10–13.

Ágh, Cs.

Vágánygeometriai irány- és fekszinthibák valós nagyságának

értékelése húrmérési eredmények alapján / Cs. Ágh //

Közlekedéstudományi szemle. – 2018. – Vol. 68, No. 5. – Р.

46–55.

Ágh, Cs. Vasúti

kerékpár futási instabilitása a pályadiagnosztika szemszögéből

/ Cs. Ágh // Sínek világa. – 2017. – Vol. 59, No. 6. – Р.

17–20.

Al-Saoudi,

N. K. S. Behavior of track ballast under repeated loading

/ N. K. S. Al-Saoudi, К.

Н. Hassan //

Geotechnical and Geological Engineering.

– 2014. –

Vol. 32. –

Iss. 1.

– Р. 167–178.

doi: https://doi.org/10.1007/s10706-013-9701-z

Application

of Computed Tomography in Structure Analyses of Metal Matrix

Syntactic Foams / І. Kozma,

І. Zsoldos,

G. Dorogi, Sz.

Papp //

International Journal of Computer Theory and Engineering.

– 2015. –

Vol. 7. –

Iss.

5. – Р.

379–382. doi:

https://doi.org/10.7763/IJCTE.2015.V7.989

Arangie,

P. B. D. The influence of ballast fouling on the resilient

behaviour of the ballast pavement layer /

P. B. D.

Arangie // 6th International Heavy Haul

Railway Conference, IHHA

1997 (6–10

April, 1997, Cape Town, South Africa).

– Cape Town, 1997. – Р. 241–256.

Claisse,

P. Rail ballast: conclusions from a historical perspective / P.

Claisse, C. Calla // Proceedings of the Institution of Civil

Engineers – Transport. – 2006. – Vol. 159. – Іss. 2. –

P. 69–74.

doi: https://doi.org/10.1680/tran.2006.159.2.69

Computer

tomography based reconstruction of metal matrix syntactic foams

/ І. Kozma,

І. Zsoldos, G.

Dorogi, Sz.

Papp //

Periodica Polytechnica Mechanical

Enigneering. –

2014. – Vol.

58. – Iss.

2. – Р.

87–91.

doi: https://doi.org/10.3311/PPme.7337

CT-Based

Reconstruction of Metal Foam Composite Material Reinforced with

Ceramic Spherical Shell Structure / І.

Kozma, І.

Zsoldos, G.

Dorogi, Sz.

Papp //

International Journal of Materials Engineering and Technology.

– 2016. –

Vol. 15.

– Iss.

2-3. – Р.

93–107. doi:

https://doi.org/10.17654/MT015230093

Coupling

finite and discrete element methods using an open source and a

commercial software /

Á. Orosz,

К. Tamás, J. P.

Rádics, P. T.

Zwierczyk //

32nd European Conference on Modelling and

Simulation, EMCS

2018 (Wilhelmshaven,

Germany, May 22nd–May 265h, 2018). –

Wilhelmshaven, 2018.

doi:

https://doi.org/10.7148/2018-0399

DB. «TL DBS 918 061: Technische

Lieferbedingungen Gleisschotter» (TL DBS 918 061: Technical

delivery conditions Railway ballast). – Berlin, 2006/08.

Douglas,

S. C. Ballast Quality and

Breakdown during Tamping /

S. C. Douglas

// 2013 Joint Rail Conference :

Conf. Paper (Knoxville, Tennessee, USA, April 15–18, 2013). –

Knoxville, 2013. – Р. 940‒955.

doi:

https://doi.org/10.1115/JRC2013-2553

Evaluation

of Railway Ballast Permeability Using Machine Vision-Based

Degradation Analysis /

Н. Huang,

М. Moaveni,

S. Schmidt,

Е. Tutumluer,

M. J. Hart //

Transportation Research Record: Journal

of the Transportation Research Board.

– 2018. –

Vol. 2672.

– Iss. 10.

– Р. 62–73

doi: https://doi.org/10.1177/0361198118790849

Fischer,

Sz. Breakage Test of Railway Ballast Materials with New Laboratory

Method / Sz.

Fischer // Periodica Polytechnica Civil Engineering. – 2017. –

Vol. 61, No. 4.

– P. 794–802.

doi: https://doi.org/10.3311/PPci.8549

Fischer,

Sz. Crumbling examination of railway crushed stones by individual

laboratory method /

Sz. Fischer

// Sínek Világa.

– 2015. –

Vol. 57,

No. 3. –

Р. 12–19.

Fischer,

Sz. Individual rock physics investigations of railway ballast

materials [Electronic

resource] / Sz.

Fischer, А.

Németh //

Kő-és Kavicsbányász Napok 2018 :

XI Conference. – Velence,

2018. –

Available at: https://u.to/YmyyFQ

– Title from the screen. – Accessed : 21.06.2019.

Fischer,

Sz. Special laboratory test for evaluation breakage (particle

degradation) of railway ballast

[Electronic resource] /

Sz. Fischer,

А. Németh //

Conference on Transport Sciences (Győr,

2018, march

22–23).

– Győr,

2018. –

Available at: https://u.to/84dpFQ

– Title from the screen. – Accessed : 17.05.2019.

Juhász,

E. Individual laboratory test method for railroad ballast particle

breakage [Electronic

resource] /

Е.

Juhász, Sz.

Fischer //

Conference on Transport Sciences. –

Győr, 2019.

– Available at: https://u.to/H49pFQ

– Title from the screen. – Accessed : 17.05.2019.

Juhász,

E. Investigation of railway ballast materials’ particle

degradation with special laboratory test method

[Electronic resource] /

Е. Juhász,

Sz. Fischer //

14th Miklós Iványi International PhD & DLA Symposium (Pécs,

2018, October

29–30).

– Pécs,

2018. –

Available at: https://clck.ru/G4KnU

– Title from the screen. – Accessed : 17.05.2019.

Khan,

S. N. Numerical analysis of deformation and stability in the

formation for railway tracks [Electronic

resource] :

Thesis for Master

// S. N. Khan

; Universität Weimar.

– Weimar,

2018. –

Available at: https://u.to/95JuFQ

– Title from the screen. – Accessed : 20.05.2019.

Köken,

Е. An

experimental investigation on the durability of railway ballast

material by magnesium sulfate soundness

[Electronic resource] /

E. Köken,

A.

Özarslan, G.

Bacak //

Granular Matter.

– 2018. –

Vol.

20. –

Available at:

https://link.springer.com/article/10.1007%2Fs10035-018-0804-3

– Title from the screen. – Accessed : 20.05.2019.

doi:

https://doi.org/10.1007/s10035-018-0804-3

Köken,

Е. New testing

methodology for the quantification of rock crushability:

Compressive crushing value (CCV)

/ E.

Köken, A.

Özarslan //

International Journal of Minerals

Metallurgy and Materials. –

2018. –

Vol.

25. – Iss.

11. –

Р. 1227–1236.

doi:

https://doi.org/10.1007/s12613-018-1675-7

Kozma,

I. Kerámia gömbhéjakkal erősített fémhab kompozitok

szerkezetének CT alapú rekonstrukciója

/

І. Kozma, G.

Dorogi, Sz.

Papp // Anyagok

világa. –

2014. – Vol.

XII, No.1.

– Р. 60–72.

Kozma,

I. Measurement of the diameter of the imprint based on image

processing using MathCAD and the avaluation software of an

industrial CT / І.

Kozma, Е.

Halbritter //

Acta Technica Jaurinensis.

– 2013. –

Vol. 6,

No. 2.

– Р. 45–58.

Laboratory

fatigue degradation tests of railway ballast materials

[Electronic resource] / Sz.

Fischer,

А.

Németh, D.

Harrach, Е.

Juhász // 22nd

International Conference on Civil Engineering and Architecture,

ЕРКО 2018 (Sumuleu

Ciuc (Csíksomlyó) 8

May–3 June 2018).

– Sumuleu

Ciuc, 2018. – Available at:

https://clck.ru/G46U7

– Title from the screen. – Accessed : 17.05.2019.

Lichtberger,

B. Track compendium:

Formation, Permanent Way, Maintenance,

Economics / В.

Lichtberger. –

Hamburg :

Eurailpress Tetzlaff-Hestra GmbH & Co,

2005. – 634 р.

MÁV.

«A 102345/1995 PHMSZ előírás 3. számú módosítása»

(Modification 3 in MÁV 102345/1995 PHMSZ. Railway substructure and

ballast quality acceptance regulations instruction). – Budapest,

2008. – 5 р.

MÁV.

«A 102345/1995 PHMSZ előírás 4. számú módosítása».

(Modification 4 in MÁV 102345/1995 PHMSZ. Railway substructure and

ballast quality acceptance regulations instruction). – Budapest,

2010. –

14 р.

Migration

of fine particles from subgrade soil to the overlying ballast

[Electronic resource] /

R. S. Kamalov,

G. S. Ghataora, M.

P. N. Burrow, М. Wehbi,

Р. Musgrave

// Railway Engineering Conference

(Edinburgh

2017, June

21–22).

– Edinburgh,

2017. – Available at:

https://u.to/j6dpFQ

– Title from the screen. – Accessed : 17.05.2019.

Morphological

Characterization of Railroad Ballast Degradation Trends in the

Field and Laboratory /

М. Moaveni,

Y. Qian,

I. I. A. Qamhia,

Е. Tutumluer, С.

Basye, D. Li //

Transportation Research Record: Journal of the Transportation

Research Board. –

2016. – Vol.

2545. – Iss.

1. – Р.

89–99.

doi: https://doi.org/10.3141/2545-10>

MSZ EN 1097-1:2012.

«Kőanyaghalmazok mechanikai és fizikai tulajdonságainak

vizsgálata. 1. rész: A kopásállóság vizsgálata

(mikro-Deval)». (Tests for mechanical and physical properties of

aggregates. Determination of the resistance to wear (micro-Deval).

– Budapest, 2012. – 35 р.

MSZ EN 1097-2:2010.

«Kőanyaghalmazok mechanikai és fizikai tulajdonságainak

vizsgálata. 2. rész: Az aprózódással szembeni ellenállás

meghatározása». (Tests for mechanical and physical properties of

aggregates. Methods for the determination of resistance to

fragmentation). – Budapest, 2010. – 35 р.

MSZ

EN 933-3: Kőanyaghalmazok geometriai tulajdonságainak vizsgálata.

3. rész: A szemalak meghatározása. Lemezességi szám. –

Budapest, 2012. – 12 р.

MSZ EN 1367-2: Kőanyaghalmazok

termikus tulajdonságainak és időjárás-állóságának

vizsgálati módszerei. 2. rész: Magnézium-szulfátos eljárás.

– Budapest, 2010. – 16 р.

MSZ EN 13450:2003.

«Kőanyaghalmazok vasúti ágyazathoz». (Aggregates for railway

ballast). – Budapest, 2003. – 33 р.

Nagy,

R. Analytical

differences between seven prediction models and the description of

the rail track deterioration process through these methods / R.

Nagy //

Intersections. – 2017. – Vol.

14, No. 1. – Р.

14–32.

Nagy,

R. Analytical differences between six prediction models and the

description of the rail track deterioration process through these

methods / R. Nagy // Computational Civil Engineering 2017

: International Symposium (Iasi, Romania,

May 26, 2017). – Iasi,

2017. – Р.

31–50.

Nagy,

R. A vasúti

pályageometria romlási folyamatának leírása /

R. Nagy // Sínek világa.

– 2016. – Vol. 58,

No. 6. – Р.

12–18.

Nagy,

R. Description of rail track geometry deterioration process in

Hungarian rail lines No. 1 and No. 140 / R. Nagy // Pollack

Periodica. – 2017. – Vol. 12. – Iss. 3. – Р.

141–156.

doi: https://doi.org/10.1556/606.2017.12.3.13

Nie,

Z. A three-dimensional particle roundness evaluation method

[Electronic resource] / Z.

Nie, Z. Liang,

Х. Wang

// Granular Matter.

– 2018. – Vol.

20. – Iss.

2. – Available at: https://u.to/WeVuFQ

– Title from the screen. – Accessed :

20.05.2019. doi:

https://doi.org/10.1007/s10035-018-0802-5

Nimbalkar,

S. Field assessment of ballasted rail-roads using geosynthetics and

shock mats / S.

Nimbalkar,

В.

Indraratna //

Procedia Engineering.

– 2016. –

Vol. 143.

– Р. 1485‒1494.

doi:

https://doi.org/10.1016/j.proeng.2016.06.175

Orosz,

Á. Calibration of railway ballast DEM model /

Á. Orosz,

К. Tamás, J.

P. Rádics

// 31st European Conference on Modelling

and Simulation, EMCS

2017 (May

23rd–May

26th, 2017,

Budapest, Hungary).

– Budapest,

2017. doi:

https://doi.org/10.7148/2017-0523

Orosz,

Á. The feasibility of modelling rocks in engineering applications

with the use of discrete element method /

Á. Orosz,

К. Tamás,

J. P.

Rádics //

Hungarian Agricultural Engineering. –

2017. –

Iss.

32. – Р.

51–55.

doi:

https://doi.org/10.17676/HAE.2017.32.51

Paiva, C. E. L. Study of Railway

Ballast Fouling by Abrasion-Originated Particles / Cassio E. L. de

Paiva, Mauro L. Pereira, Lia L. Pimentel // Railway Engineering –

2017 : Proc. of the 14th Intern. Conf. (Edinburgh, Scotland, UK,

21st–22nd June 2017). – Edinburgh, 2017.

Sadeghi,

J. M. Developing Track Ballast Characteristic Guideline in Order to

Evaluate its Performanc /

J. M. Sadeghi, J. Ali Zakeri, M. Emad

Motieyan Najar // International Journal of Railway. – 2016. –

Vol. 9. – Іss. 2. – P. 27–35. doi:

https://doi.org/10.7782/IJR.2016.9.2.027

Sun,

Y. Identification of ballast grading for rail track

/ Y. Sun,

С. Chen, S.

Nimbalkar //

Journal of Rock Mechanics and Geotechnical Engineering.

– 2017. –

Vol. 9. –

Іss. 5.

– Р. 945–954.

doi:

https://doi.org/10.1016/j.jrmge.2017.04.006

Track

ballast in Austria :

Parts 1, 2, 3 [Electronic resource] //

Rail Infrastructure. –

Available at:

https://www.plassertheurer.com/fileadmin/user_upload/Mediathek/Publikationen/ri_12888990.pdf

– Title from the screen. – Accessed

: 11.05.2019.

Sysyn,

M. P. Performance study of the inertial monitoring method for

railway turnouts / M. P. Sysyn,

V. V. Kovalchuk, D. Jiang //

International Journal of Rail Transportation. – 2018. – Vol. 4.

– Р. 33–42.

doi:

https://doi.org/10.1080/23248378.2018.1514282

The

complex phenomenological model for prediction of inhomogeneous

deformations of railway ballast layer after tamping works / M.

Sysyn, U. Gerber, V. Kovalchuk, O. Nabochenko // Archives of

Transport. – 2018. – Vol. 46. – Iss. 3. – Р.

91–107. doi: https://doi.org/10.5604/01.3001.0012.6512

Theoretical

study into efficiency of the improved longitudinal profile of frogs

at railroad switches / V. Kovalchuk, M. Sysyn, J. Sobolevska, O.

Nabochenko, B. Parneta, A. Pentsak // Eastern European Journal of

Enterprise Technologies. – 2018. – Vol. 4, No. 1. – Р.

27–36. doi: https://doi.org/10.15587/1729-4061.2018.139502

Є. Юхас1*, С.

ФІшер2*

1*Каф.

«Інфраструктура транспорту й

гідротехніка», Університет

Іштвана

Сечені, пл. Університетська, 1, Дьєр,

Угорщина, 9026,

тел. +36 (96) 613 544, ел. пошта

juhasz.erika@sze.hu,

ORCID 0000-0002-5544-3146

2*Каф.

«Інфраструктура транспорту й

гідротехніка», Університет

Іштвана

Сечені, пл. Університетська, 1, Дьєр,

Угорщина, 9026,

тел. +36 (96) 613 544, ел. пошта

fischersz@sze.hu,

ORCID 0000-0001-7298-9960

Удосконалена

Методика оцінки

РУЙНУВАННЯ

ЧАСТОК ЗАЛІЗНИЧНого

баласту

Мета.

Більшість залізничних ліній у світі

мають так звану традиційну верхню

будову колії з баластним шаром. На думку

авторів, для гарантування безпеки руху

важливо вивчити процес руйнування

баластного шару. У ЄС існує тільки два

типи стандартних методів лабораторних

випробувань для оцінки ступеня руйнування

часток залізничного баластного шару

й описання їх фізичних характеристик.

Але вони не придатні для моделювання

напружено-деформованого стану залізничних

баластних матеріалів і їх часток. У цій

статті автори представляють методи

випробувань, за допомогою яких процес

руйнування залізничних часток баласту

можна оцінити більш реалістично й

точно. Ці методи базуються на висновках

із досліджень, індивідуальних лабораторних

випробувань на втому, а також із

додаткових випробувань. Методика.

У роботі подано два типи лабораторних

випробувань. Перший був виконаний із

використанням зсувної коробки зі

спеціальною шаруватою структурою, яка

навантажена динамічною, пульсуючою

силою. Другий тип – із використанням

труби з поліетилену високої щільності

діаметром 140 мм з оригінальною запірною

деталлю, навантаженою машиною

ZD–40.

Результати.

Після науково-дослідних розробок,

проведених і опублікованих у 2014 році,

спостерігається розвиток методів

оцінки руйнування баластного шару. У

2017 й 2018 роках під час випробувань

руйнування часток баласту було здійснено

з більшими проміжними циклами втоми

та окремими вимірами, які більш точно

показують повне руйнування часток,

тобто процес руйнування. Проведено

кореляцію між розрахунковими параметрами

й циклами навантаження на втому. Однак

під час випробування залишається багато

факторів, які потребують поліпшення.

Тому автори описують інші додаткові

тести. Наукова новизна.

У роботі запропонована вдосконалена

методика оцінки руйнування баластного

шару залізничної колії, яка дає більш

точні результати порівняно з традиційними

методами вимірювань.

Практична значимість.

Методи, розроблені авторами можуть

служити основою для складання нових

інструкцій або правил. Публікація цієї

статті була підтримана проектом EFOP

3.6.1-16-2016-00017.

Ключові слова:

авторський лабораторний метод

випробувань; залізничний баласт;

руйнування часток; випробування на

динамічну втому; випробування на

статичний тиск; КТ-обладнання; аналіз

тривимірного зображення

E. Юхас1*, С.

Фишер2*

1*Каф.

«Инфраструктура транспорта»,

Университет

Иштвана Сечени, пл. Университетская,

1, Дьер,

Венгрия, 9026, тел. + 36 (96) 613 544,

эл. почта juhasz.erika@sze.hu,

ORCID 0000-0002-5544-3146

2*Каф.

«Инфраструктура транспорта»,

Университет Иштвана Сечени, пл.

Университетская, 1, Дьер,

Венгрия, 9026,

тел. + 36 (96) 613 544,

эл. почта fischersz@sze.hu,

ORCID 0000-0001-7298-9960

УСОВЕРШЕНСТВОВАННАЯ МЕТОДИКА

ОЦЕНКИ

разрушения ЧАСТИЦ ЖЕЛЕЗНОДОРОЖНОГО

БАЛЛАСТА

Цель.

Большинство железнодорожных линий в

мире имеют так называемое традиционное

верхнее строение пути с балластным

слоем. По мнению авторов, для обеспечения

безопасности движения важно изучить

процесс разрушения балластного слоя.

В ЕС существует только два типа

стандартных методов лабораторных

испытаний для оценки степени разрушения

частиц железнодорожного балластного

слоя и описания физических характеристик

горных пород. Но они не пригодны для

моделирования напряженно-деформированного

состояния железнодорожных балластных

материалов и их частиц. В данной статье

авторы представляют методы испытаний,

с помощью которых процесс разрушения

железнодорожных частиц балласта можно

оценить более реалистично и точно. Эти

методы базируются на выводах из

исследований авторов, индивидуальных

лабораторных испытаний на усталость,

а также из дополнительных испытаний.

Методика.

В работе представлены два типа

лабораторных испытаний. Первый был

выполнен с использованием сдвиговой

коробки со специальной слоистой

структурой, которая нагружена

динамической, пульсирующей силой.

Второй тип – с использованием трубы

из полиэтилена высокой плотности

диаметром 140 мм с оригинальной запирающей

деталью, нагруженной машиной ZD–40.

Результаты.

После научно-исследовательских

разработок, проведенных и опубликованных

в 2014 году, наблюдается развитие методов

оценки разрушения балластного слоя. В

2017 и 2018 годах во время испытаний

разрушение балластных частиц было

осуществлено с большими промежуточными

циклами усталости с отдельными

измерениями, которые более точно

показывают полное разрушение частиц,

т. е. процесс разрушения. Произведена

корреляция между расчетными параметрами

и циклами нагрузки на усталость. Однако

во время испытаний остается много

факторов, требующих улучшения. Поэтому

авторы описывают другие дополнительные

тесты. Научная новизна.

В работе предложена усовершенствованная

методика оценки разрушения балластного

слоя железнодорожного пути, которая

дает более точные результаты по сравнению

с традиционными методами измерений.

Практическая значимость.

Методы, разработанные авторами, могут

служить основой для составления новых

инструкций или правил. Публикация

данной статьи

была поддержана

проектом EFOP

3.6.1-16-2016-00017.

Ключевые слова: авторский лабораторный

метод испытаний; железнодорожный

балласт; разрушение частиц; испытание

на динамическую усталость; испытание

на статическое давление; КТ-оборудование;

анализ трехмерного изображения

REFEReNCEs

Kurhan, D. M. (2015). To the solution of

problems about the railways calculation for strength taking into

account unequal elasticity of the subrail base. Science

and Transport Progress,

1(55), 90-99.

doi:

https://doi.org/10.15802/stp2015/38250

(in Ukrainian)

Ágh, Cs. (2018). A

new arrangement of accelerometers on track inspection car FMK-007

for evaluating derailment safety, Track Maintenance Machines in

Theory and Practice, SETRAS 2018.

Žilina. (in English)

Ágh, Cs. (2012). Egyenértékű kúposság

mérése Magyarországon: Pálya és jármű kapcsolata – futási

instabilitás. Sínek világa,

54(6),

10-13. (in Hungarian)

Ágh, Cs. (2018). Vágánygeometriai irány- és

fekszinthibák valós nagyságának értékelése húrmérési

eredmények alapján. Közlekedéstudományi

szemle, 68(5), 46-55. (in Hungarian)

Ágh, Cs. (2017). Vasúti kerékpár futási

instabilitása a pályadiagnosztika szemszögéből. Sínek

világa, 59(6),

17-20. (in Hungarian)

Al-Saoudi,

N. K. S., & Hassan, K. H. (2013). Behaviour of Track Ballast

under Repeated Loading. Geotechnical

and Geological Engineering, 32(1),

167-178. doi: https://doi.org/10.1007/s10706-013-9701-z

(in

English)

Kozma,

I., Zsoldos, I., Dorogi, G., & Papp, S. (2015). Application of

Computed Tomography in Structure Analyses of Metal Matrix Syntactic

Foams. International Journal of

Computer Theory and Engineering, 7(5),

379-382. doi:

https://doi.org/10.7763/ijcte.2015.v7.989

(in English)

Arangie,

P. B. D.

(1997). The

influence of ballast fouling on the resilient behaviour of the

ballast pavement layer, 6th

International Heavy Haul Railway Conference,

IHHA 1997.

Cape

Town, South Africa.

(in English)

Claisse,

P., & Calla, C. (2006). Rail ballast: conclusions from a

historical perspective. Proceedings

of the Institution of Civil Engineers - Transport, 159(2), 69-74.

doi: https://doi.org/10.1680/tran.2006.159.2.69

(in English)

Kozma,

I., Zsoldos, I., Dorogi, G., & Papp, S. (2014). Computer

tomography based reconstruction of metal matrix syntactic foams.

Periodica Polytechnica Mechanical

Engineering, 58(2),

87-91.

doi:

https://doi.org/10.3311/ppme.7337

(in English)

Kozma,

I., Zsoldos, I., Dorogi, G., & Papp, S. (2016). Ct-Based

Reconstruction of Metal Foam Composite Material Reinforced with

Ceramic Spherical Shell Structure. International

Journal of Materials Engineering and Technology, 15(2-3),

93-107. doi:

https://doi.org/10.17654/mt015230093

(in English)

Orosz, A., Tamas, K., Radics, J. P., &

Zwierczyk, P. T. (2018). Coupling

Finite and Discrete Element Methods Using an Open Source and a

Commercial Software, 32nd European

Conference on Modelling and Simulation,

ECMS 2018. Wilhelmshaven.

doi: https://doi.org/10.7148/2018-0399

(in English)

TL

DBS 918 061: Technische Lieferbedingungen Gleisschotter. TL DBS 918

061: Technical delivery conditions Railway ballast. (2006).

Berlin, 2006/08. (in German)

Douglas,

S. C. (2013).

Ballast Quality and Breakdown during Transport,

2013 Joint Rail Conference.

Knoxville,

Tennessee, USA.

doi:

https://doi.org/10.1115/JRC2013-2553

(in

English)

Huang,

H., Moaveni, M., Schmidt, S., Tutumluer, E., & Hart, J. M.

(2018). Evaluation of Railway Ballast Permeability Using Machine

Vision–Based Degradation Analysis. Transportation

Research Record: Journal of the Transportation Research Board,

2672(10), 62-73.

doi:

https://doi.org/10.1177/0361198118790849

(in English)

Fischer,

S. (2017). Breakage Test of Railway Ballast Materials with New

Laboratory Method. Periodica

Polytechnica Civil Engineering, 61(4), 794-802.

doi:

https://doi.org/10.3311/ppci.8549

(in English)

Fischer, Sz. (2015).

Crumbling examination of railway crushed stones by individual

laboratory method.

Sínek Világa, 57(3),

12-19. (in

Hungarian)

Fischer, Sz., &

Németh, А. (2018). Individual

rock physics investigations of railway ballast materials.

Kő-és Kavicsbányász Napok 2018: XI Conference. Velence.

Retrieved from https://u.to/YmyyFQ

(in Hungarian)

Fischer,

Sz.,

&

Németh,

А.

(2018).

Special laboratory

test for evaluation breakage (particle degradation) of railway

ballast,

Conference on

Transport Sciences.

Győr.

Retrieved

from

https://u.to/84dpFQ

(in English)

Juhász,

E.,

&

Fischer,

Sz.

(2019). Individual

laboratory test method for railroad ballast particle breakage,

Conference on

Transport Sciences.

Győr.

Retrieved

from

https://u.to/H49pFQ

(in English)

Juhász,

E.,

&

Fischer,

Sz.

(2018).

Investigation of

railway ballast materials’ particle degradation with special

laboratory test method, 14th

Miklós Iványi PhD & DLA Symposium.

Pécs.

Retrieved

from https://clck.ru/G4KnU

(in English)

Khan,

S. N. (2018).

Numerical

analysis of deformation and stability in the formation for railway

tracks.

(Thesis

for Master).

Universität

Weimar,

Weimar.

Retrieved

from https://u.to/95JuFQ

(in English)

Köken,

E., Özarslan, A., & Bacak, G. (2018). An experimental

investigation on the durability of railway ballast material by

magnesium sulfate soundness. Granular

Matter, 20(2). doi:

https://doi.org/10.1007/s10035-018-0804-3

(in English)

Köken,

E., & Özarslan, A. (2018). New testing methodology for the

quantification of rock crushability: Compressive crushing value

(CCV). International Journal of

Minerals, Metallurgy, and Materials, 25(11), 1227-1236.

doi:

https://doi.org/10.1007/s12613-018-1675-7

(in English)

Kozma,

I.,

Dorogi,

G.,

&

Papp,

Sz.

(2014). Kerámia

gömbhéjakkal

erősített

fémhab

kompozitok

szerkezetének

CT

alapú

rekonstrukciója.

Anyagok

világa,

XII(1),

60-72. (in

Hungarian)

Kozma,

I.,

&

Halbritter,

E.

(2013). Measurement

of the diameter of the imprint based on image processing using

MathCAD and the avaluation software of an industrial CT.

Acta

Technica Jaurinensis, 6(2),

45-58.

(in English)

Fischer,

Sz.,

Németh, A.,

Harrach,

D.,

&

Juhász, E.

(2018).

Laboratory

fatigue degradation tests of railway ballast materials,

22nd International

Conference on Civil Engineering and Architecture, ЕРКО

2018.

Sumuleu

Ciuc.

Retrieved

from https://clck.ru/G46U7

(in

Hungarian)

Lichtberger,

B. (2005).

Track compendium:

Formation, Permanent

Way, Maintenance, Economics.

Hamburg:

Eurailpress Tetzlaff-Hestra GmbH & Co.

(in English)

A

102345/1995 PHMSZ előírás 3. számú módosítása (Modification

3 in MÁV 102345/1995 PHMSZ. ‘Railway substructure and ballast

quality acceptance regulations instruction’), MÁV (2008). (in

Hungarian)

A 102345/1995 PHMSZ előírás 4. számú

módosítása. (Modification 4 in MÁV 102345/1995 PHMSZ. ‘Railway

substructure and ballast quality acceptance regulations

instruction’), MÁV (2010). (in Hungarian)

Kamalov,

R. S.,

Ghataora,

G. S.,

Burrow, M. P. N.,

Wehbi,

M.,

&

Musgrave,

P.

(2017). Migration

of fine particles from subgrade soil to the overlying ballast,

Railway Engineering

Conference.

Edinburgh.

Retrieved

from https://u.to/j6dpFQ

(in English)

Moaveni,

M., Qian, Y., Qamhia, I. I. A., Tutumluer, E., Basye, C., & Li,

D. (2016). Morphological

Characterization of Railroad Ballast Degradation Trends in the

Field and Laboratory. Transportation

Research Record: Journal of the Transportation Research Board,

2545(1),

89-99. doi: https://doi.org/10.3141/2545-10

(in English)

Kőanyaghalmazok

mechanikai

és

fizikai

tulajdonságainak

vizsgálata.

1.

rész: A kopásállóság vizsgálata (mikro-Deval). (Tests for

mechanical and physical properties of aggregates. Determination of

the resistance to wear (micro-Deval), MSZ EN 1097-1:2012 (2012).

(in Hungarian)

Kőanyaghalmazok

mechanikai és fizikai tulajdonságainak vizsgálata. 2. rész: Az

aprózódással szembeni ellenállás meghatározása. (Tests for

mechanical and physical properties of aggregates. Methods for the

determination of resistance to fragmentation), MSZ EN 1097-2:2010

(2010). (in Hungarian)

Kőanyaghalmazok

geometriai tulajdonságainak vizsgálata. 3. rész: A szemalak

meghatározása. Lemezességi

szám. MSZ EN 933-3 (2012). (in Hungarian)

Kőanyaghalmazok

termikus tulajdonságainak és időjárás-állóságának

vizsgálati módszerei. 2. rész: Magnézium-szulfátos eljárás.

MSZ EN 1367-2 (2010). (in Hungarian)

Kőanyaghalmazok

vasúti ágyazathoz. (Aggregates for railway ballast). MSZ EN

13450:2003 (2003). (in Hungarian)

Nagy,

R. (2017). Analytical differences between seven prediction models

and the description of the rail track deterioration process through

these methods.

Intersections, 14(1),

14-32. (in English)

Nagy,

R. (2017). Analytical

differences between six prediction models and the description of

the rail track deterioration process through these methods,

Computational Civil Engineering 2017, International Symposium.

Iasi.

(in English)

Nagy, R. (2016). A vasúti pályageometria

romlási folyamatának leírása. Sínek

világa, 58(6), 12-18. (in Hungarian)

Nagy, R. (2017). Description of rail track

geometry deterioration process in Hungarian rail lines No. 1 and

No. 140. Pollack Periodica, 12(3),

141-156. doi: https://doi.org/10.1556/606.2017.12.3.13

(in English)

Nie,

Z., Liang, Z., & Wang, X. (2018). A three-dimensional particle

roundness evaluation method. Granular

Matter, 20(2).

doi:

https://doi.org/10.1007/s10035-018-0802-5

(in English)

Nimbalkar,

S., & Indraratna, B. (2016). Field Assessment of Ballasted

Railroads Using Geosynthetics and Shock Mats. Procedia

Engineering, 143,

1485-1494.

Retrieved

from https://u.to/WeVuFQ

doi:

https://doi.org/10.1016/j.proeng.2016.06.175

(in English)

Orosz,

A., Radics, J. P., & Tamas, K. (2017). Calibration

of Railway Ballast DEM Model, 31st

European Conference on Modelling and Simulation,

ECMS 2017.

Budapest.

doi:

https://doi.org/10.7148/2017-0523

(in English)

Orosz,

Á., Tamás, K., & Rádics, J. P. (2017). The feasibility of

modelling rocks in engineering applications with the use of

discrete element method. Hungarian

Agricultural Engineering, 32,

51-55.

doi:

https://doi.org/10.17676/hae.2017.32.51

(in English)

Paiva,

C. E. L., Pereira, M. L., & Pimentel, L. L. (2017).

Study of Railway Ballast Fouling by Abrasion

Originated Particles,

Railway Engineering

– 2017.

Edinburgh.

(in

English)

Sadeghi,

J. M., Zakeri, J. Ali, & Najar, M. E. M. (2016). Developing

Track Ballast Characteristic Guideline in Order to Evaluate its

Performanc.

International

Journal of Railway, 9(2), 27-35.

doi: https://doi.org/10.7782/IJR.2016.9.2.027

(in

English)

Sun,

Y., Chen, C., & Nimbalkar, S. (2017). Identification of ballast

grading for rail track. Journal

of Rock Mechanics and Geotechnical Engineering, 9(5), 945-954.

doi:

https://doi.org/10.1016/j.jrmge.2017.04.006

(in English)

Track

ballast in Austria: Parts 1, 2, 3.

Rail

Infrastructure.

Retrieved

from

https://www.plassertheurer.com/fileadmin/user_upload/Mediathek/Publikationen/ri_12888990.pdf

(in

English)

Sysyn, M. P., Kovalchuk, V. V., & Jiang, D.

(2018). Performance study of the inertial monitoring method for

railway turnouts. International

Journal of Rail Transportation, 4,

33-42.

doi: https://doi.org/10.1080/23248378.2018.1514282

(in English)

Sysyn, M., Gerber, U., Kovalchuk, V., &

Nabochenko, O. (2018). The complex phenomenological model for

prediction of inhomogeneous deformations of railway ballast layer

after tamping works. Archives of

Transport, 47(3), 91-107. doi:

https://doi.org/10.5604/01.3001.0012.6512

(in English)

Kovalchuk, V., Sysyn, M., Sobolevska, J.,

Nabochenko, O., Parneta, B., & Pentsak, A. (2018). Theoretical

study into efficiency of the improved longitudinal profile of frogs

at railroad switches. Eastern-European

Journal of Enterprise Technologies, 4/1(94),

27-36. doi: https://doi.org/10.15587/1729-4061.2018.139502

(in English)

Received:

Jan. 21, 2019

Accepted:

May 15,

2019