ISSN

2307–3489 (Print), ІSSN 2307–6666 (Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2019, № 2 (80)

ТРАНСПОРТнЕ

БУДІВНИЦТВО

транспортнЕ

БУДІВНИЦТВО

UDC 624.94.014.2:69.059.7

N.

G.

KRUHLIKOVA1*,

D. О.

BANNIKOV2*

1*Fac.

«Industrial and Civil Engineering»,

Dnipro National University of Railway Transport

named after

Academician V. La-zaryan, Lazaryan, St. 2, Dnipro,

Ukraine, 49010,

tel. +38 (063) 94 67

288, e-mail dnuzt@diit.edu.ua,

ORCID 0000-0003-2822-6696

2*Dep.

«Construction Production

and Geodesy»,

Dnipro National University of Railway

Transport named after

Academician V. Lazaryan, Lazaryan, St. 2,

Dnipro, Ukraine,

49010,

tel. +38 (063) 400 43 07, e-mail bdo2020@yahoo.com

ORCID

0000-0002-9019-9679

RATIONAL

DESIGN OF

SHORT-SPAN

INDUSTRIAL

BUILDING ROOF

FOR RECONSTRUCTION CONDITIONS

Purpose.

Recently, the demand for reuse of industrial buildings that have not

been in operation for some time has been increasing in Ukraine.

Herewith, quite often the design of their roof requires the complete

replacement and renovation by using modern roofing materials to meet

the requirements of new government standards. Therefore, the choice

and justification of the rational design of steel roof on the example

of a short-span industrial building (18-24 m span), which is

planned to be returned to exploitation after idle time, is the main

goal of this publication. The object of the analysis is an unheated

building equipped with bridge cranes of a small capacity (up to 10

tons). Methodology.

To achieve this purpose, the comparison of structural variants of a

roof steel collar tie was performed. Such variants include two types

of collar tie cross-section – a

lattice truss and a solid I-girder. The first type was analyzed for

four possible types of section of elements – double angles, a

roll-welded square profile, an electric-welded round tube and a

rolled round tube. The second type was analyzed for two possible

types of section – rolled I-section made of normal strength steel

and fabricated sections of thin-gage high-strength steel. The design

variants were compared on the basis of a numerical analysis of their

work using the finite element method based on the software complex

SCAD for Windows. Findings. According to the research results

it should be stated that for the conditions of the city of Dnipro the

most cost-effective variant of the steel collar tie cross section for

the short-span industrial building is the truss made of

electric-welded round tubes. Also the construction of collar tie made

of roll-welded square profiles or fabricated section of thin-gage

high-strength steel is considered quite effective. Originality.

The research presented in the publication allows

estimating the possibility and economic efficiency of usage for

various types of cross-sections for the collar tie of a steel

non-insulated roof of the industrial building for the reconstruction

conditions in the Dnipro-city. Practical value. A practical

estimation of mass and cost parameters for steel collar ties of

various types has been carried out, and the methodology for

conducting such estimation has been substantiated.

Keywords:

industrial

building;

collar tie; girder;

truss;

software

complex

SCAD

for

Windows;

finite

element

method

Introduction

Currently, in

Ukraine one of the key problems in the field of exploitation of the

industrial enterprise structures is the level of their technical

condition. This is especially true for such buildings, which for

some time were not in operation, but were, so to speak, «on their

own». During such an idle period some structures degraded, maybe

went to ruins, and the other remained in a semi-usable state of

operation. However, attempts to return such structures to operation

are increasingly observed in practice, because it is often a cheaper

option than the construction of a completely new object.

As a rule, such reuse of

building structures is accompanied by their full or partial renewal,

depending on their technical condition, and the building itself is

redesigned to the requirements of new modern design standards and

potentially new equipment to be installed. Most often it is the roof

that requires renovation, because, on the one hand, it is in the

most unfavorable conditions during idle time, and on the other hand,

the roof itself often limits the dimensions for the installation of

new equipment in the building.

It should also be noted that the

demand for short-span buildings, such as storage buildings, has been

particularly active recently. This is due to their relatively low

cost, as well as the desire to use them in the future for production

processes in the small business.

Purpose

Taking into account the

foregoing, the main purpose of the study conducted by the authors is

to choose and justify the rational design of steel roof on the

example of a short-span industrial building (18-24 m span), which is

planned to be returned to exploitation after idle time. The object

of the analysis is an unheated building equipped with bridge cranes

of a small capacity (up to 10 tons).

To achieve this, it was

necessary first to analyze the existing and approved roof design

variants, suitable for use in such buildings, then to compare these

variants, taking into account both their carrying capacity and the

estimated cost, and to choose the best variant that can be proposed

for practical implementation.

Methodology

Given the nature of the

industrial building in question, the design of its roof should

provide for the use of bearing collar ties, which include a system

of purlins and steel profiled flooring. This roof type is proved

itself good in practice and is considered to be the main one for

modern non-heated industrial buildings [10].

It

is also

worth noting

that abroad the

short-span

industrial buildings,

which are

quite popular,

have a

similar roof

design solution

[13].

The main issue, when designing

such short-span roofs, is the choice of type of collar tie. For this

purpose, straight-axis collar ties (trusses or beams) may be used,

as other types of bearing structures, such as arches or frames, are

more suitable for significant spans. The slope of the upper chord of

the collar ties in accordance with the standard requirements [6]

shall be not less than 20% (11°), which is due to the need of

preventing the water flow through the profiled sheet joints to the

building. In case of installation of such roofs on the 10 – 20%

(5.5 – 11°) slopes there are must be provided the sealing of

joints between the flooring sheets. However, as the experience of

operation shows, firstly, such works are technologically costly, and

secondly, over time, sealing requires periodic renewal. Therefore,

the practice of such roofs with small slopes is mostly abandoned.

Taking into account the above

limitations, a triangular truss with a triangular lattice with

additional posts, as the most economical one, was accepted as a

lattice truss during the studies. At the same time, four types of

sections of the elements of such a truss were analyzed, which are

now used in metal structures and available on the Ukrainian steel

market: – angles (according to GOST 8), roll-welded square

profiles (according to GOST [3]), electric-welded round tubes

(according to GOST [1]) and rolled round tubes (according to GOST

[4]). For the first two types of cross-sections, C255 grade

steel was used, which is the minimum allowable for structures of

group 1 according to the standard [7]. For the last two types of

round tube cross-sections, C245 grade steel was used according to

this standard.

As a solid girder, we considered

two types of beams – rolled I-section girder (according to GOST

[2]) and a plate girder made of high-strength steel of C325 grade,

which is becoming more and more popular at the modern market of

Ukraine. To ensure the desired slope, the girder had an asymmetrical

design.

Roof loads were determined

according to the current standards in Ukraine [5]. Since, at a given

angle of inclination of 11° the wind load is upward due to the

negative aerodynamic coefficient, we took into account only the

proper weight of the roof together with the collar tie and snow

load.

To specify the research, we

considered the object – the industrial storage building, located

in the city of Dnipro at the address of Panikakhi street 1, which

for a long time (almost 15 years) was not in operation (Fig. 1).

According to the data of its survey, carried out by a specialized

organization, the roof design should be completely replaced by a

new one, since its technical condition was assessed as the state of

failure.

One

of the

peculiarities of

the building

under

consideration

was a

varying span,

which for

its main

part was

24 m, and

for final

sections

decreased to

18 m. Therefore,

in order

to provide

the required

slope of

the roof,

it was

necessary to

develop a

design of

a universal

collar tie that

would provide

the required

slope of

the roof

without changing

the type

of the

collar tie

itself.

For

conducting variant calculations we used an extremely popular and

approved numerical method of building mechanics – the method of

finite elements [12, 14, 15] based on the well-known domestic

software complex SCAD for Windows [11]. The constructed calculation

models for the considered collar tie design variants are shown in

Fig. 2 – 5. The trusses and the rolled girder were modelled by rod

finite element of universal type, and the plate girder was modeled

by plate four-node finite elements of isoparametric type. All

calculations

were performed

in geometrically

and physically

linear settings.

This approach avoids issues of estimating

the convergence of results peculiar for finite elements of other

types [9].

Findings

According to

the calculation results for truss-type collar ties the sections of

the elements were selected for each of the four constructive types.

Herewith, upon selection the cross sections were adjusted according

to the rules of unification. Also, according to the unification

results, a universal truss for 18 and 24 m spans was formed,

which consisted of the largest profiles. These data are presented in

Table 1.

For the

I-section collar ties the profile 70B1 was selected. For the collar

ties in the form of fabricated sections the 1.3 m high profile was

chosen for the elements thickness of 4 mm and 1.0 m high profile –

for the elements thickness of 6 mm. Herewith the condition of

stiffness was the determining condition.

Based on the

results of calculations, a summary table was drawn up, which takes

into account the total costs for the profiles of the collar ties of

each type. Data are taken as averaged generalizations at the rolled

metal market in the city of Dnipro for November-December 2018.

However, this analysis allows us to reveal a general picture.

Fig. 1. Object of

the research – short-span industrial storage building

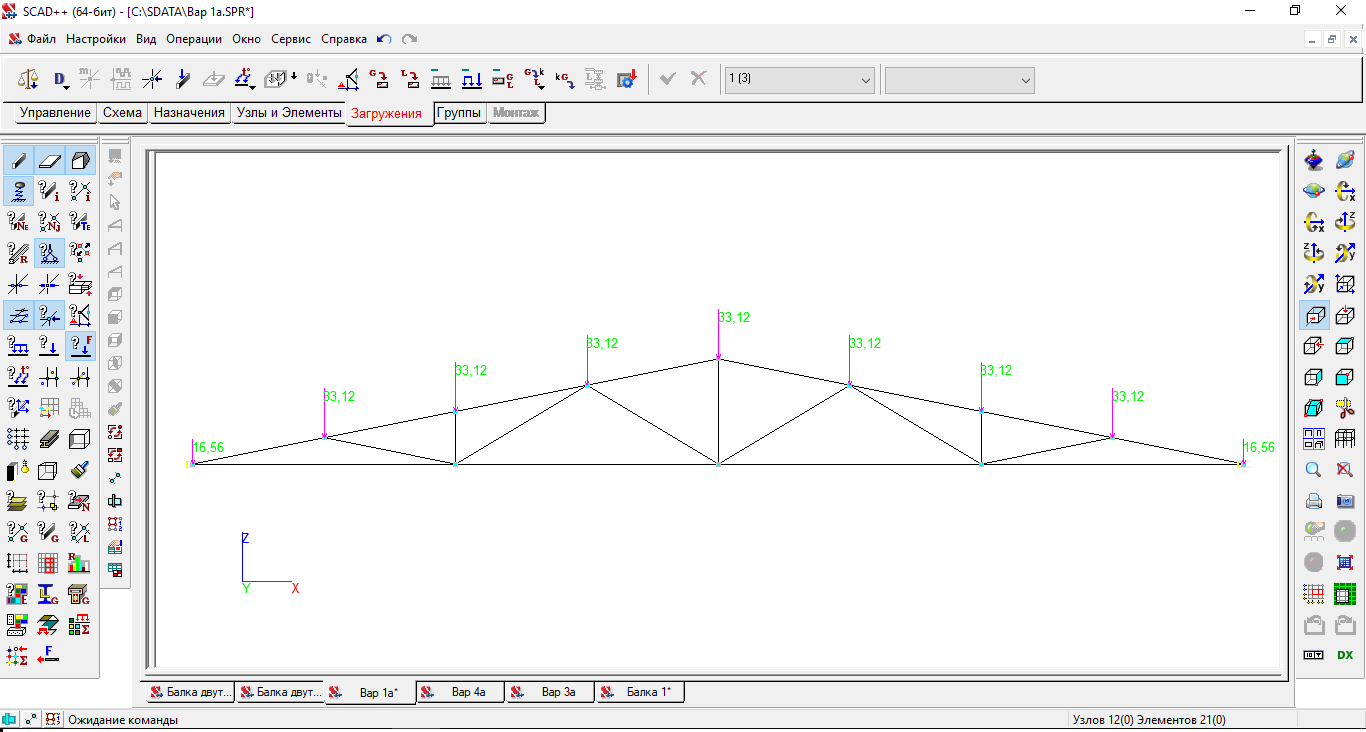

Fig. 2.

Finite-element model of 24m span truss

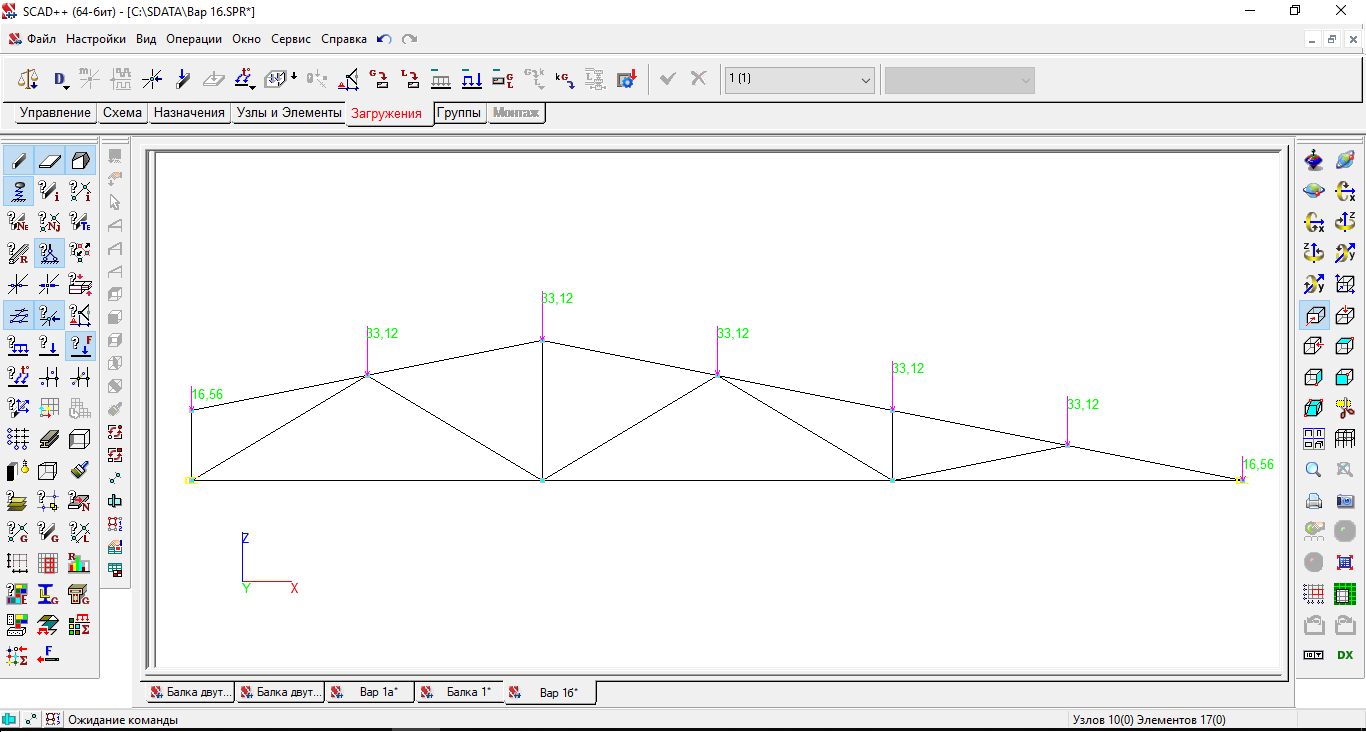

Fig. 3.

Finite-element model of the shortened 18 m span truss

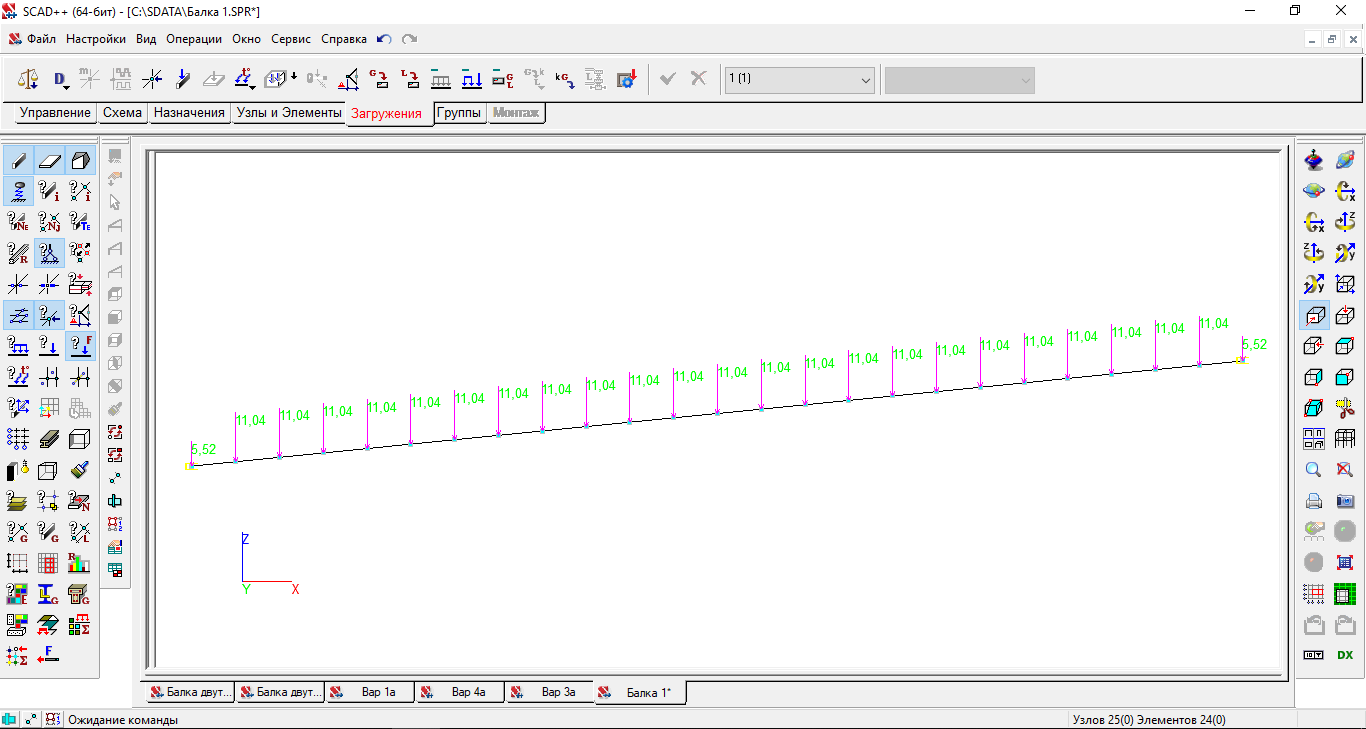

Fig. 4.

Finite-element model of rolled girder

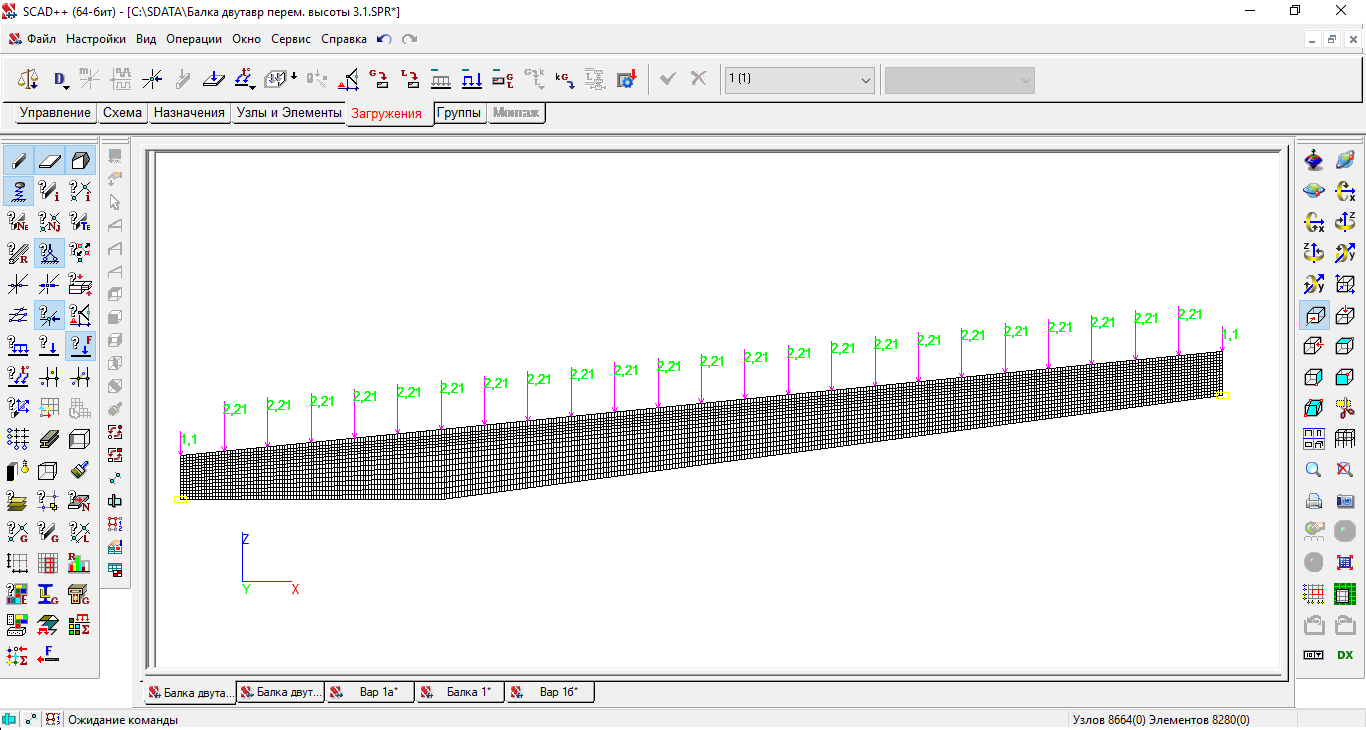

Fig. 5.

Finite-element model of plate girder

Table 1

Cross-sections

of universal trusses with 18-24 m span

|

Truss

element

|

Truss

element cross-section made of

|

|

double

angles

|

roll-welded

square

|

electric-welded

round tubes

|

rolled

round tubes

|

|

upper

chord

|

125х8

|

120×7

|

193.7х5

|

194х5

|

|

lower

chord

|

90х7

|

110х6

|

159х5.5

|

133х6.5

|

|

posts

|

50х3

|

80х5

|

70х4

|

68х3

|

|

diagonal

web elements

|

90х7

|

80х5

|

102х4

|

102х4

|

Table

2

Weight and cost

of constructive variants for roof collar ties

|

No.

|

Collar

tie cross section

|

Weight,

t

|

Cost

per 1 t, UAH

|

Cost,

UAH

|

|

1.

|

Truss

of double angles

|

1.63

|

22 912

|

37 350

|

|

2.

|

Truss

of roll-welded square profile

|

1.33

|

22 150

|

29 460

|

|

3.

|

Truss

of electric-welded

round tubes

|

1.35

|

18 975

|

25 620

|

|

4.

|

Truss

of rolled round tubes

|

1.28

|

28 250

|

36 160

|

|

5.

|

Girder

of rolled I-section

|

3.10

|

19 400

|

60 140

|

|

6.

|

Girder

of fabricated I-section (4 mm)

|

1.58

|

19 670

|

31 080

|

|

7.

|

Girder

of fabricated I-section

(6 mm)

|

2.08

|

19 670

|

40 915

|

From the data in the table it is

clearly seen that the smallest weight for the considered industrial

building roof reconstruction conditions has a collar tie in the form

of the truss of rolled round tubes. A slightly larger weight, but

not much, has a collar tie in the form of trusses of roll-welded

square profile and electric-welded round tubes. The largest weight

has a collar tie of rolled I-section. The welded collar tie of

thin-gage high-strength steel takes an intermediate position.

Taking into account the market

value of each type of cross-section, the lowest cost has the collar

tie in the form of the truss of electric-welded tubes. In the second

place there is the collar tie of roll-welded square profile, the

cost of which is 15% higher. The third is ranked the collar tie in

the form of welded fabricated I-section of thin-gage (4 mm thick)

high-strength steel. Its value is higher by almost 18%. The most

uneconomical is the collar tie made of rolled I-section, the cost of

which is more than 2 times higher than that of the collar tie in the

form of the truss of electric-welded tubes.

Originality and practical

value

The research

presented in the publication allows estimating the possibility and

economic efficiency of usage for various types of cross-sections for

the collar tie of a steel non-insulated roof of the industrial

building. At the same time, the study outlined the case of

reconstruction of the short-span (18-24 m) building, which is quite

common nowadays, with the complete roof replacement.

The results

obtained are valid for the conditions of Dnipro, but according to a

similar methodology the degree of efficiency of reconstruction and

rebuilding of steel roofs of industrial buildings can be determined

in practice for other regions of Ukraine as well.

Also, it

should be noted that the conducted study allow us to outline the

range of the most rational constructive solutions of bearing collar

ties for short-span industrial buildings.

Conclusions

Based on the material outlined

in the publication, the following conclusions can be drawn:

1. For

the

reconstruction

conditions of

a steel

roof of

a short-span

(18-24 m)

industrial

building, the

use of

the truss

of

electric-welded

round tubes

is the

most cost

effective as

a bearing

collar tie.

2. In

the second

place, according

to the

degree of

economic

efficiency,

there is

the use

of the

truss of

roll-welded square

profiles, the

cost of

which is

15% higher than

the previous

variant.

Taking into account the higher technological efficiency of the

implementation of node connections for such trusses, under certain

conditions this type of collar tie can be considered the most

rational.

3. Also

noteworthy is the collar tie in the form of fabricated I-section of

small thickness (4 mm) of high-strength steel, the cost of which is

18% higher than the first constructive variant. Therefore, this

section can also be considered as competing with the main

recommended variant (truss of electric-welded round tubes), taking

into account its high manufacturability.

4. The

least effective

of all

considered

variants is

the collar

tie made of

rolled I-section.

Its weight and value are more than 2 times higher than the main

recommended variant (truss of electric-welded round tubes).

LIST OF REFERENCE LINKS

ГОСТ 10704-91.

Трубы стальные электросварные

прямошовные. Сортамент. – Москва :

Стандартинформ, 2007. – 17 с.

ГОСТ 26020-83.

Двутавры стальные горячекатаные с

параллельными гранями полок. Сортамент.

– Москва : Изд-во стандартов, 1984. – 6 с.

ГОСТ

30245-2003. Профили стальные гнутые замкнутые

сварные квадратные и прямоугольные

для строительных конструкций. Технические

условия. – Москва : Изд-во стандартов,

2003. – 15 с.

ГОСТ 8732-78*.

Трубы стальные бесшовные

горячедеформированные. Сортамент. –

Москва : Изд-во стандартов, 1989. – 10 с.

ДБН

В.1.2-2-2006 (зі змінами). Система надійності

та безпеки в будівництві. Навантаження

і впливи. Норми проектування. – Київ

: Держбуд, 2007. – 70 с.

ДБН

В.2.6-220:2017. Покриття будівель і споруд.

– Київ : Мінрегіон України, 2017. – 53 с.

ДБН

В.2.6-198:2014. Сталеві конструкції. Норми

проектування. – Київ : Мінрегіон

України, 2014. –

205 с.

ДСТУ 2251-93

(ГОСТ 8509-93). Кутики сталеві гарячекатані

рівнополичні. Сортамент. – Київ :

Держстандарт України, 1993. – 16 с.

Банніков,

Д. О. Оцінка практичної збіжності

результатів аналізу пластинчастих

моделей в методі скінчених елементів

/ Д. О. Банніков // Нові технології в

будівництві. – 2017. – № 1. – С. 26–31.

Буга, П. Г.

Гражданские, промышленные и

сельскохозяйственные здания / П. Г.

Буга. – Москва : Книга по требованию,

2013. – 349 с.

SCAD Office.

Версия 21. Вычислительный комплекс

SCAD++ / В. С. Карпиловский, Э. З. Криксунов,

А. А. Маляренко, С. Ю. Фиалко. А. В.

Перельмутер, М. А. Перельмутер. – Москва

: СКАД СОФТ, 2015. – 850 с.

Bofang,

Z. The Finite Element Method: Fundamentals and Applications in

Civil, Hydraulic, Mechanical and Aeronautical Engineering / Zhu

Bofang. – Singapore : John Wiley & Sons Singapore Pte. Ltd.,

2018. – 843 p. doi: 10.1002/9781119107323

Johnson,

R. P. Composite Structures of Steel and Concrete: Beams, Slabs,

Columns and Frames for Buildings / R. P. Johnson. – Hoboken :

John Wiley & Sons, Inc., 2018. – 265 p. doi:

10.1002/9781119401353

Singiresu,

S. R. The Finite Element Method in Engineering / S. R. Singiresu. –

6th ed. – Oxford : Butterworth-Heinemann, 2018. – 782 p. doi:

10.1016/c2016-0-01493-6

Shames,

I. H. Energy and Finite Element Methods in Structural Mechanics /

I. H. Shames, C. L. Dym. – New York : Routledge, 2017. – 776 p.

doi:

10.1201/9780203757567

Н.

Г. КРУГЛІКОВА1*,

Д. О. БАННІКОВ2*

1*

Ф-т «Промислове та цивільне будівництво»,

Дніпровський національний університет

залізничного транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна,

49010, тел. +38 (063) 94 67 288, ел. пошта

dnuzt@diit.edu.ua ,

ORCID 0000-0003-2822-6696

2*Каф.

«Будівельне виробництво та геодезія»,

Дніпровський національний університет

залізничного транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна,

49010, тел. +38 (063) 400 43 07, ел. пошта

bdo2020@yahoo.com, ORCID

0000-0002-9019-9679

РАЦІОНАЛЬНА

КОНСТРУКЦІЯ ПОКРИТТЯ

МАЛОПРОГОНОВОЇ

ПРОМИСЛОВОЇ БУДІВЛІ

ДЛЯ УМОВ РЕКОНСТРУКЦІЇ

Мета.

Останнім часом в Україні зростає

попит на повторне використання

промислових будівель, які протягом

певного часу не перебували в експлуатації.

При цьому досить часто конструкція їх

покрівлі потребує повної заміни й

оновлення із сучасних покрівельних

матеріалів з урахуванням вимог нових

державних норм. Тому вибір та обґрунтування

раціональної конструкції сталевого

покриття на прикладі малопрогонової

промислової будівлі (прогін 18–24 м) для

повернення її до експлуатації після

простою є основною метою цієї публікації.

Об’єкт аналізу – неопалювана будівля,

обладнана мостовими кранами незначної

вантажопідйомності (до 10 т). Методика.

Для досягнення поставленої мети виконано

зіставлення конструктивних варіантів

несного сталевого ригеля покрівлі.

Розглянуто два типи перерізу ригеля:

наскрізний – у вигляді ферми й суцільний

– у вигляді двотаврової балки. Перший

тип проаналізовано для чотирьох можливих

типів перерізу елементів – подвійні

кутики, гнутозварний квадратний профіль,

електрозварна кругла труба й прокатна

кругла труба. Другий тип досліджено

для двох можливих типів перерізу –

прокатний двотавровий профіль зі сталі

звичайної міцності і зварний профіль

із тонкостінної сталі підвищеної

міцності. Зіставлення конструктивних

варіантів виконано на основі чисельного

аналізу їх роботи методом скінченних

елементів на базі проектно-обчислювального

комплексу SCAD for Windows. Результати.

Проведене дослідження дає змогу

констатувати, що для умов м. Дніпро

найбільш економічно ефективним варіантом

перерізу сталевого ригеля промислової

будівлі невеликих прогонів є ферма з

електрозварних круглих труб. Також

досить ефективною слід вважати

конструкцію ригеля, виконану з ферм із

гнутозварними квадратними профілями

або зварного двотаврового типу з

тонкостінної сталі підвищеної міцності.

Наукова новизна. Описане в публікації

дослідження дозволяє оцінити можливість,

а також економічну ефективність

використання різних типів перерізів

для ригелів сталевої неутепленої

покрівлі промислової будівлі з метою

реконструкції в м. Дніпро. Практична

значимість. Виконано практичну оцінку

масових і кошторисних показників для

сталевих ригелів різних типів, а також

обґрунтовано методику проведення

подібної оцінки.

Ключові

слова: промислова будівля; ригель;

балка; ферма; проектно-обчислювальний

комплекс SCAD for Windows; метод скінченних

елементів

Н. Г.

КРУГЛИКОВА1*, Д. О. БАННИКОВ2*

1*

Ф-т «Промышленное и гражданское

строительство», Днипровский национальный

университет

железнодорожного транспорта

имени академика В. Лазаряна, ул. Лазаряна,

2, Днипро, Украина,

49010, тел. +38 (063) 94 67 288,

эл. почта dnuzt@diit.edu.ua,

ORCID 0000-0003-2822-6696

2*Каф.

«Строительное производство и геодезия»,

Днипровский национальный университет

железнодорожного транспорта имени

академика В. Лазаряна, ул. Лазаряна, 2,

Днипро,

Украина, 49010, тел. +38 (063) 400 43 07,

эл. почта bdo2020@yahoo.com,

ORCID 0000-0002-9019-9679

РАЦИОНАЛЬНАЯ

КОНСТРУКЦИЯ ПОКРЫТИЯ

МАЛОПРОЛЕТНОГО

ПРОМЫШЛЕННОГО ЗДАНИЯ

ДЛЯ УСЛОВИЙ

РЕКОНСТРУКЦИИ

Цель.

В последнее время в Украине возрастает

спрос на повторное использование

промышленных зданий, которые на

протяжении определенного времени не

находились в эксплуатации. При этом

довольно часто конструкция их покрытия

требует полной замены и обновления из

современных кровельных материалов с

учетом требований новых государственных

норм. Поэтому выбор и обоснование

рациональной конструкции стального

покрытия на примере малопролетного

промышленного здания (пролет 18–24 м)

для возврата в эксплуатацию после

простоя является основной целью

публикации. Объект анализа – неотапливаемое

здание, оборудованное мостовыми кранами

незначительной грузоподъемности (до

10 т). Методика.

Для достижения поставленной цели было

выполнено сопоставление конструктивных

вариантов несущего стального ригеля

покрытия. В качестве таких вариантов

рассмотрено два типа сечения ригеля –

сквозной в виде фермы и сплошной в виде

двутавровой балки. Первый тип

проанализирован для четырех возможных

типов сечения элементов – двойные

уголки, гнутосварной квадратный профиль,

электросварная круглая труба и прокатная

круглая труба. Второй тип исследован

для двух возможных типов сечения –

прокатный двутавровый профиль из стали

обычной прочности и сварной профиль

из тонкостенной стали повышенной

прочности. Сопоставление конструктивных

вариантов выполнено на основе численного

анализа их работы методом конечных

элементов на базе проектно-вычислительного

комплекса SCAD for Windows. Результаты.

Проведенное исследование даёт возможность

констатировать, что для условий г.

Днипро наиболее

экономически эффективным вариантом

сечения стального ригеля промышленного

здания небольших пролетов является

ферма из электросварных круглых труб.

Также достаточно эффективной следует

считать конструкцию ригеля, выполненную

из ферм с гнутосварными квадратными

профилями или сварного двутаврового

типа из тонкостенной стали повышенной

прочности. Научная

новизна. Представленные

в публикации исследования позволяют

оценить возможность и экономическую

эффективность использования различных

типов сечений в качестве ригеля

стального неутепленного покрытия

промышленного здания для условий

реконструкции в г.

Днипро. Практическая

значимость. Выполнена

практическая оценка массовых и

стоимостных показателей для стальных

ригелей различных типов, а также

обоснована методика проведения подобной

оценки.

Ключевые

слова: промышленное здание; ригель;

балка; ферма; проектно-вычислительный

комплекс SCAD for Windows; метод конечных

элементов

REFERENCES

Electrically

welded steel line-weld tubes. Range,

17 GOST

10704-91 (2007). (in Russian)

Hot-rolled steel

I-beam with parallel flange edges. Dimensions, 6

GOST 26020-83

(1984). (in Russian)

Steel

bent closed welded square and rectangular section for building.

Specifications, 15 GOST

30245-2003 (2003). (in Russian)

Truby

stalnye besshovnye goryachedeformirovannye. Sortament,

10 GOST 8732-78*

(1989). (in Russian)

Systema

nadiinosti ta bezpeky v budivnytstvi. Navantazhennia i vplyvy.

Normy proektuvannia, 70

DBN

В.1.2-2:2006

(2007).

(in Ukrainian)

Pokryttia

budivel i sporud, 53

DBN B.2.6-220:2017 (2017). (in

Ukrainian)

Stalevi

konstruktsii. Normy proektuvannia, 205

DBN В.2.6-198:2014

(2014). (in

Ukrainian)

Kutyky

stalevi hariachekatani rivnopolychni. Sortament,

16 DSTU 2251-93

(GОSТ

8509-93) (1993).

(in

Ukrainian)

Bannikov,

D. O. (2017). Otsinka praktychnoi zbizhnosti rezultativ analizu

plastynchastykh modelei v metodi skinchenykh elementiv. Novi

tekhnolohii v budivnytstvi, 1, 26-31.

(in Ukranian)

Buga,

P. G.

(2013). Grazhdanskie,

promyshlennye

i

selskokhozyaystvennye

zdaniya.

Moscow:

Kniga po trebovaniyu.

(in Russian)

Karpilovskiy,

V. S.,

Kriksunov, E.

Z., Malyarenko,

A. A.,

Fialko, S.

Y., Perelmuter,

A. V.,

& Perelmuter,

M. A.

(2015). SCAD Office. Version 21.

Software complex SCAD++. Moscow:

SCAD Soft. (in Russian)

Bofang,

Z. (2018). The Finite Element Method:

Fundamentals and Applications in Civil, Hydraulic, Mechanical and

Aeronautical Engineering.

Singapore: John

Wiley & Sons Singapore Pte.

Ltd. doi: 10.1002/9781119107323 (in

English)

Johnson,

R. P. (2018). Composite Structures of

Steel and Concrete: Beams, Slabs, Columns and Frames for Buildings.

Hoboken: John

Wiley & Sons, Inc. doi:

10.1002/9781119401353

(in English)

Singiresu,

S. R. (2018). The Finite Element

Method in Engineering (6th ed.).

Oxford: Butterworth-Heinemann.

doi: 10.1016/c2016-0-01493-6

(in English)

Shames,

I. H., & Dym, C. L. (2017). Energy

and Finite Element Methods in Structural Mechanics.

New York: Routledge.

doi: 10.1201/9780203757567 (in

English)

Received:

Nov. 16,

2018

Accepted:

March 19, 2019