ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2019,

№ 2 (80)

рухомий

склад залізниць і тяга поїздів

UDC

629.463.62.015

O.

V. Shatunov1*,

A. O. shvets2*

1*Dep.

«Cars and Car Facilities»,

Dnipro National University of Railway Transport named after

Academician V. Lazaryan,

La-zaryan St., 2, Dnipro, Ukraine,

49010, tel. +38 (067) 953 60 14, e-mail shatunov220648@gmail.com,

ORCID 0000-0002-1115-0093

2*Dep.

«Theoretical and Structural Mechanics»,

Dnipro National University of Railway Transport named after

Academician

V. Lazaryan, Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. +38 (050) 214 14 19, e-mail angela_Shvets@ua.fm,

ORCID

0000-0002-8469-3902

STUDY

OF DYNAMIC INDICATORS OF FLAT

WAGON WITH LOAD

CENTRE SHIFT

Purpose.

The article deals with the determining the

influence of the longitudinal and lateral shift of gravity centre of

the heavy load on the flat wagons, taking into account the travel

speed based on the main dynamic indicators – the maximum

coefficients of the dynamic supplement of spring-suspended and

unsprung parts, the maximum ratio of frame force to static axle load,

the wheel derailment safety factor.

Methodology.

The study was carried out using the method of mathematical and

computer simulation of the dynamic loading of flat

wagons based on the model of spatial oscillations of five coupled

wagons and the software complex developed in the branch research

laboratory of the rolling stock dynamics and strength (BRL RSDS).

Theoretical studies were carried out during the movement of the model

13-401 flat

wagon on typical 18-100 bogies with speeds in the range from 50

to 90 km/h in curves with radii of 350 and 600 m, with 130 and 120 mm

canting, respectively. Findings. The

paper presents the analysis of theoretical studies of the rolling

stock dynamics on the example of flat wagons. The calculations were

carried out using an application software package.

In the course of performing theoretical studies and after simulation,

taking into account the processes of oscillation of the flat wagon

and load in the presence of longitudinal and lateral shift of its

gravity centre, the dependences of the main dynamic indicators were

obtained with regard to the magnitude of the travel speed.

Originality.

Using the mathematical model of the five coupled wagons, the effect

of shift in two directions from the central symmetry axis of the

heavy load centre was studied with regard to the travel speed along

the curved track of small and medium radius in order to determine the

dynamic loading of the flat wagon. Practical

value. As a result of the above

theoretical studies, the recommendations on the maximum possible

values of the centre shift of heavy loads during their transportation

on flat wagons are substantiated and proposed.

Keywords:

load; flat

wagon; dynamic indicators; curved track; longitudinal and lateral

load; centre shift; travel speed

Introduction

The process of integrating the

railway industry of Ukraine into the European transport system is

one of the urgent problems of today. Its solution is connected with

the formation of a network of international transport corridors on

the territory of Ukraine, the reconstruction of the main railway

lines connecting the Europe and Ukraine, the organization of

high-speed train traffic [10].

In addition, one of the key

issues of transport policy, which is associated with perspectives of

sustainable development of the transport industry in Ukraine, is the

promotion of combined transport. This technology should be in line

with international standards, the main criteria of which are: route

speed, schedule accuracy and cargo safety. Increased speed and

frequency of transportation would accelerate the introduction of a

combined cargo transportation system, including by international

transport corridors. Thus, improvement of speed characteristics of

rolling stock becomes almost the most important task for increasing

the competitiveness of rail transport in mixed traffic systems.

One of the

main obstacles to a significant increase in the velocity of combined

transport is the dynamic properties of the rolling stock. At the

same time, the main characteristics of the rolling stock are being

constantly improved by the producing factories, with the changing of

the range of goods. Among the

heavy loads

transported on

flat wagons,

the more

common is

becoming the

equipment with

asymmetrical

centre of

gravity, which

requires train

speed

limitation. This

causes a reduction in the throughput and transportation capacity

of railways, lengthening of the equipment delivery time to the

consumer [3, 10, 18].

Purpose

Of particular

importance is the further improvement of the transportation

conditions and, in particular, the development of new scientifically

based admissible values of longitudinal and lateral load centre

shifts from the flat wagon symmetry axes. When elaborating them,

particular attention should be paid to the safety of movement, as

there may be intense fluctuations of rolling stock and large dynamic

forces. Therefore, of great interest is the study of spatial

oscillations of a flat wagon with asymmetric load, which in turn

leads to the need for the development of regional, local

(LTC) and unspecified (UTC) technical conditions, the

effect of which would be extended to enterprises serviced by one

railway [1, 3, 7, 9, 11, 12].

The purpose

of this research is

to determine the influence of the longitudinal and lateral shift of

gravity centre of the heavy load on the flat wagon, taking into

account the travel speed based on the main dynamic indicators –

the maximum coefficients of the dynamic supplement of

spring-suspended and unsprung parts, the maximum ratio of frame

force to static axle load, the wheel derailment safety factor.

Methodology

The

above problems

can be

solved

experimentally

or

theoretically.

The first method, although it is

sufficiently reliable, but expensive, requires a long time and

cannot cover all possible options of the load positioning.

Therefore, it is necessary to develop a general theoretical method

for studying the oscillation of the flat wagon with asymmetric

placement of loads of different weights, both with

spring-dissipative elements between the load and the flat wagon

body, and without them [3].

Quantitative

evaluation of

dynamic

indicators can

be obtained

by mathematic

simulation. The

wagon

calculation

scheme should

reflect the

specifics of

the wagon

interaction in

the train:

the possibility

of manifestation

of all

forms of

body

oscillations in

space, the

transmission of

longitudinal

forces in

the vertical

and horizontal

directions from

the neighboring

wagons, the

record of

the technical

condition of

individual parts

of the

wagon and

their design

features, as

well as

operating

conditions –

speed, movement

along the

straight and

curved tracks,

loading mode,

type of load,

its positioning

and fastening,

vertical and

horizontal track

irregularities [5, 8, 13, 15-22].

The

travel speed

when passing

on the

curved track

is limited

by the

lateral impact

of the

railway rolling

stock on

the track,

the lateral

acceleration

value, the

possibility of

wheel unloading

and derailment.

In connection with this, it is necessary

to study the railway vehicle oscillations while driving precisely

along the curved track.

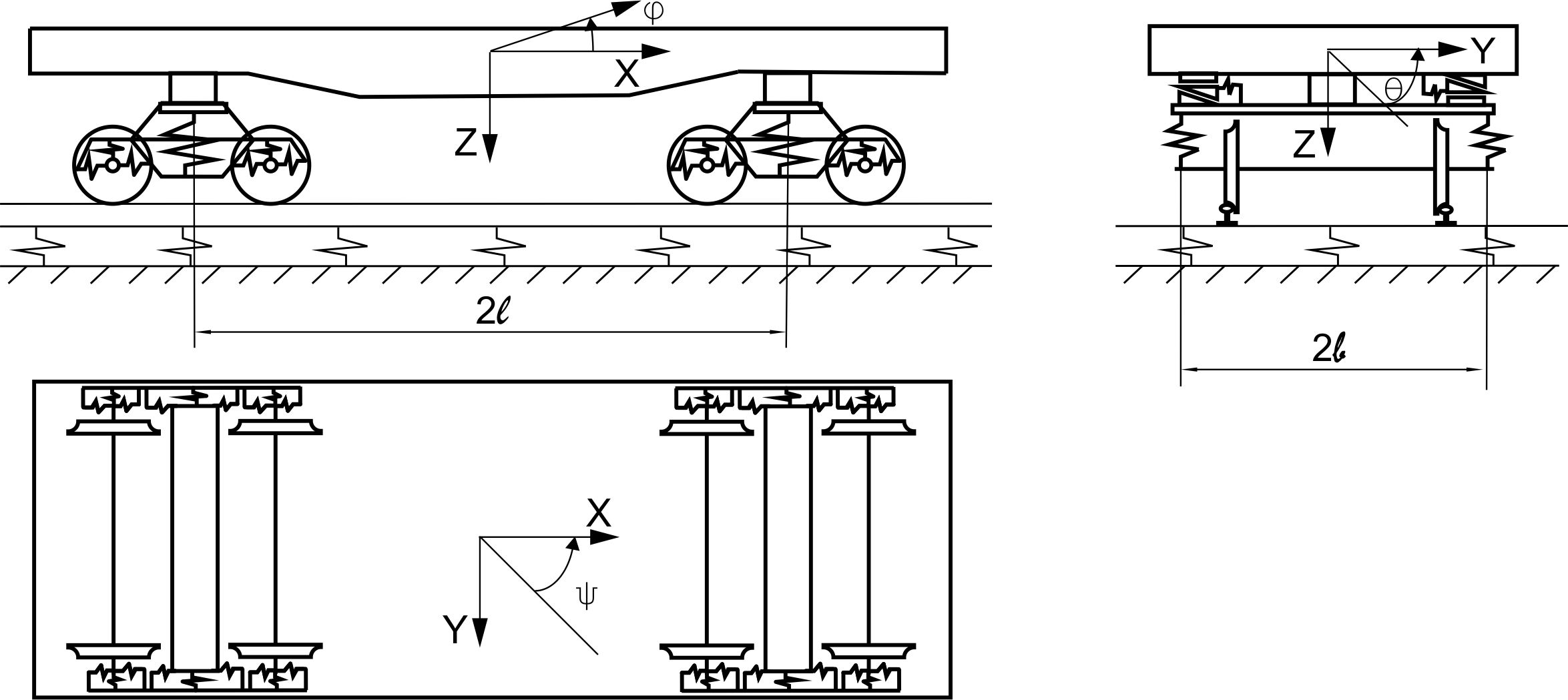

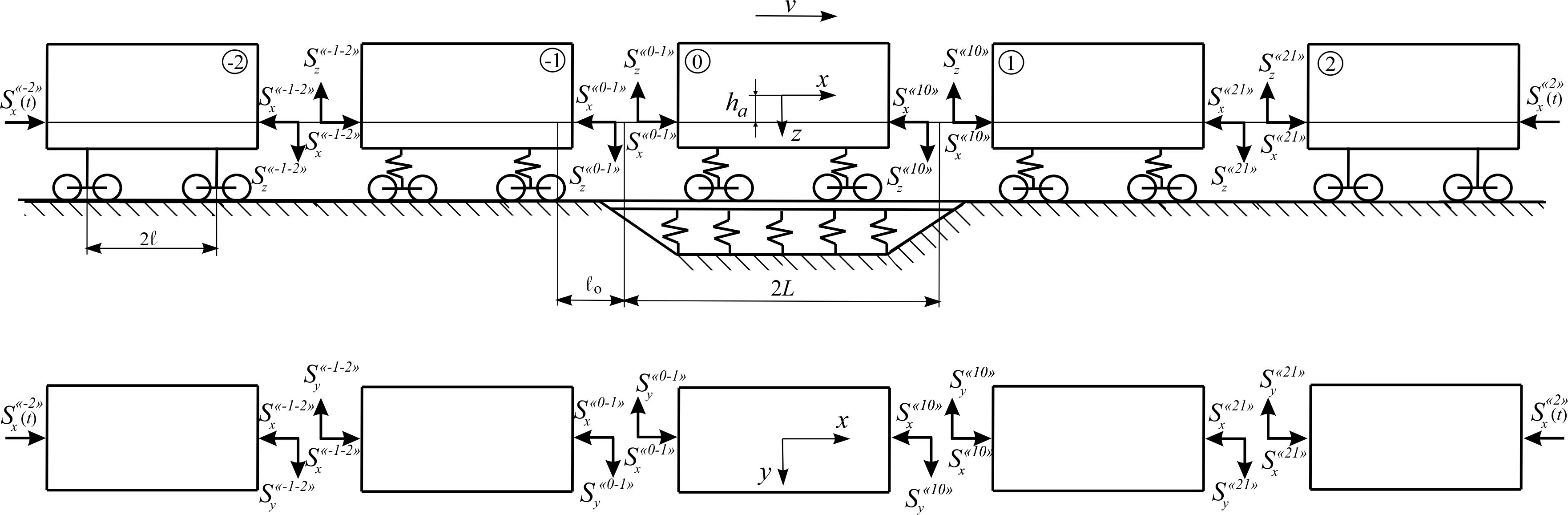

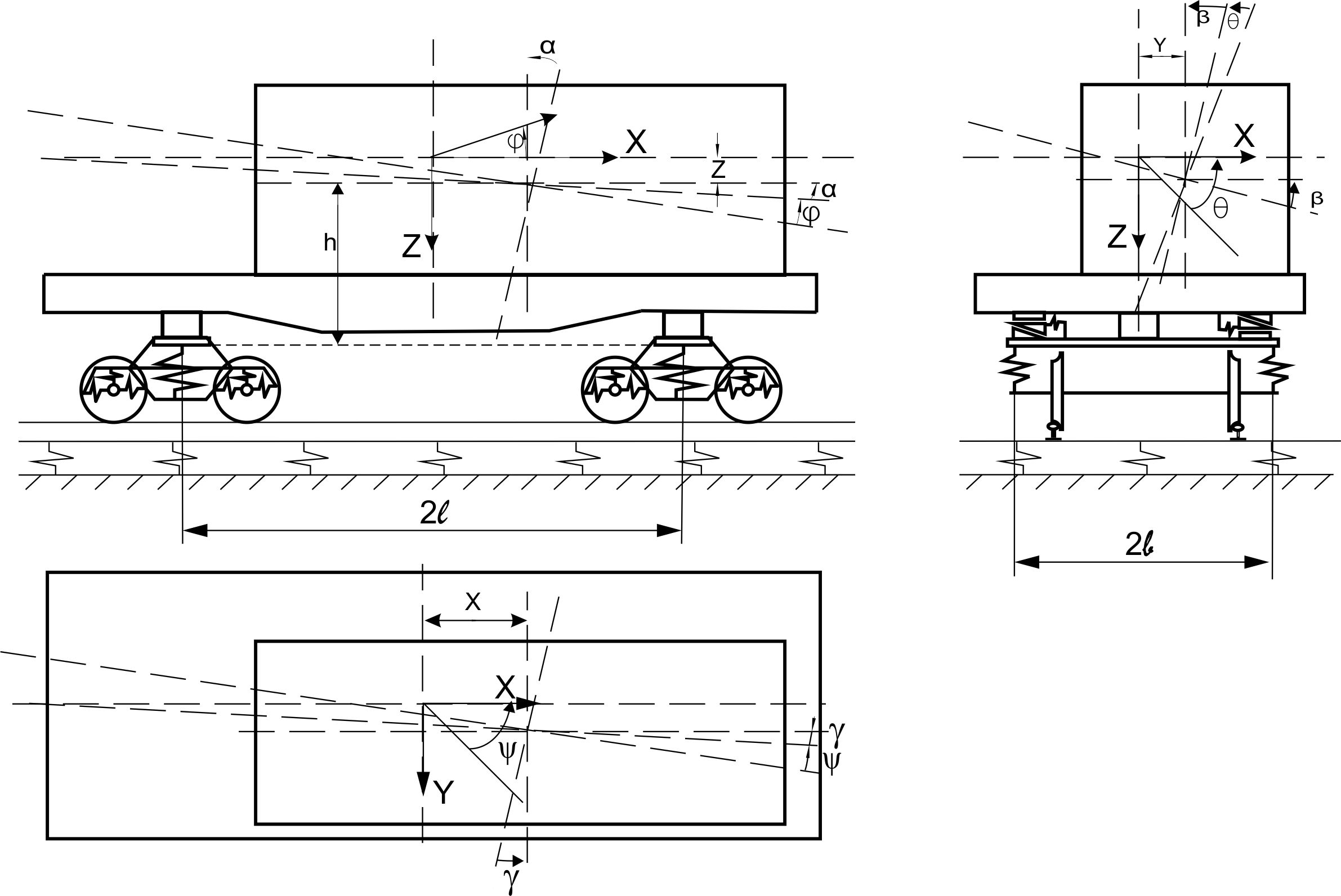

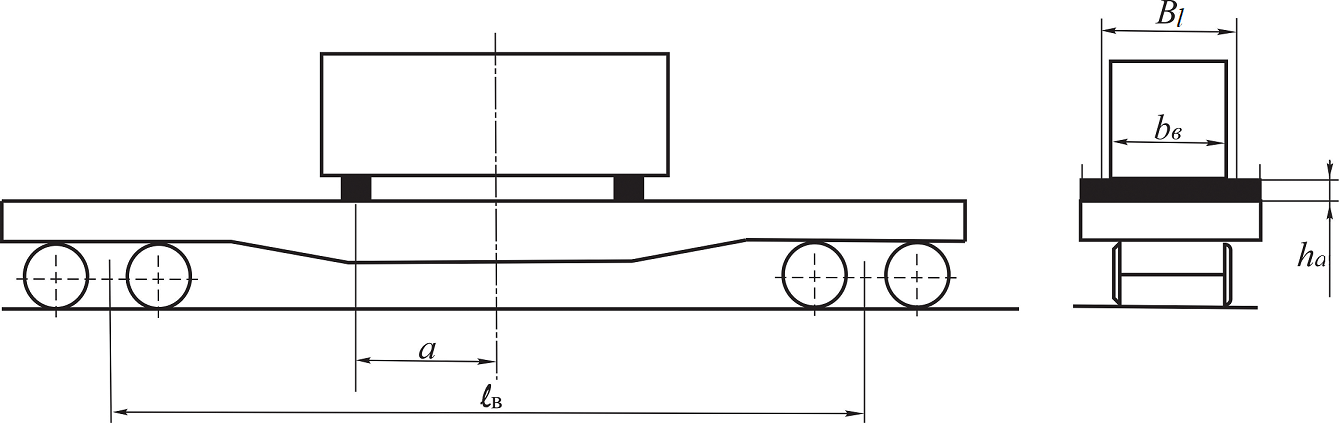

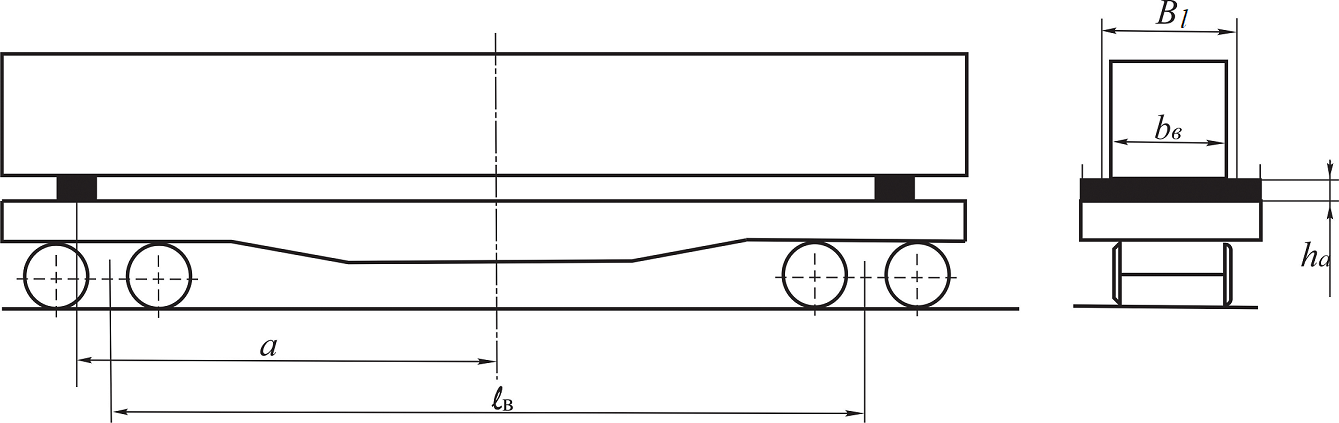

The calculation scheme of the

flat wagon in Fig. 1 shows positive directions for all shifts and

angles of rotation, and Table 1 shows the designation of the system

bodies.

In

Table 1 through

,

,

and

and

we marked

the gravity

centre shift

of the

flat wagon

frame along

the

corresponding

axes, and

through

we marked

the gravity

centre shift

of the

flat wagon

frame along

the

corresponding

axes, and

through

,

,

,

,

– the angles

of its

rotation

relative to

the main

central axis

of inertia.

Similar

displacements of

bolsters are

provided with

the index

– the angles

of its

rotation

relative to

the main

central axis

of inertia.

Similar

displacements of

bolsters are

provided with

the index (

( –

bogie number),

side frames –

with the

index

–

bogie number),

side frames –

with the

index

(

( –left,

–left,

right side

of the

wagon), wheel

sets – with

the index

right side

of the

wagon), wheel

sets – with

the index

(

( – wheel set

number in

the bogie),

rails in

the wheel

contact points

– wheel set

number in

the bogie),

rails in

the wheel

contact points

(movements of rails are assumed only in

two directions – along the axes

(movements of rails are assumed only in

two directions – along the axes

and

and

).

Displacement of the wheels is indicated by

the index

).

Displacement of the wheels is indicated by

the index

.

.

The

mathematical model describing the spatial oscillations of the

coupled wagons in the train (Fig. 2) is proposed in [4], of

which one

rail vehicle

is considered

as per

the most

complete

calculation

scheme (called

«zero»), and

the calculation

schemes of

neighbouring

wagons,

depending from

task setting,

are simplified

with increasing

distance from

the «zero»

vehicle on

both sides.

Fig. 1. Calculation

scheme of a 4-axle flat wagon

Table 1

Systems

bodies and their displacements

|

Systems

bodies

|

Displacement

|

|

|

Linear

along the axes

|

Angle

relative to axes

|

|

|

|

|

|

|

|

|

|

flat

wagon frame

|

|

|

|

|

|

|

|

bolsters

|

|

|

|

|

|

|

|

side

frames

|

|

|

|

|

|

|

|

wheel

sets

|

|

|

|

|

|

|

|

rails

|

-

|

|

|

–

|

–

|

–

|

Fig. 2. Calculation

scheme of five coupled freight wagons

As a

calculation scheme of the «zero» vehicle we adopted a mechanical

system with 58 degrees of freedom [5, 17]. The following values are

adopted as generalized coordinates:

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

.

.

Wagons, adjacent to the «zero»

one, are represented by a system with 12 degrees of freedom. The

calculation schemes describing the oscillations of these wagons

preserve the main features of freight wagon bogies – lozenging of

side frames.

In the study

of spatial oscillations of wagons neighboring with the «zero» one,

which are considered under the simplified calculation scheme, the

following assumptions are introduced. It is assumed that the wagons

have one-stage spring suspension. Each of them consists of eleven

solid bodies: a body, two bolsters, four bogie side frames and four

wheel sets. Unlike the «zero» wagon, the track under adjacent

wagons is considered to be absolutely rigid in the vertical

direction and resilient in the horizontal lateral direction. This

assumption does not lead to an increase in

the number of degrees of freedom, since the speed of the pressed

(displaced) rails in expressions for lateral forces

can be neglected.

As

generalized coordinates for these wagons the following values are

adopted:

,

,

,

,

,

,

where

;

;

– respectively

for the «first»

and «minus first» wagons.

– respectively

for the «first»

and «minus first» wagons.

The end

coupled wagons, which by analogy are called the «second» and the

«minus second», are considered by an even simplified scheme than

«1» and «-1» wagons. In «2» and «-2» wagons we will take

into account only the vibration of the bodies, that is, these wagons

are systems with six degrees of freedom:

,

,

where

– respectively for the «second» and

«minus second» wagons.

– respectively for the «second» and

«minus second» wagons.

In

our study,

the flat

wagon as

a «zero»

wagon is

considered as

a mechanical

system (Fig.

3), which

consists of

12 solids (load,

flat wagon

frame, two

bolsters, four bogie side frames, four

wheel sets). The

flat wagon

frame gravity

center is

located at

the beginning

of the

coordinate

system of

the flat

wagon, and

the load

gravity center,

shifted by

the value

in

the longitudinal

direction and

in

the longitudinal

direction and

in the

lateral direction,

is located

at the

beginning of

the coordinate

system of

the load.

in the

lateral direction,

is located

at the

beginning of

the coordinate

system of

the load.

The work [3]

studied the flat wagon as a mechanical system of 12 solids with an

asymmetric load, but its oscillations were considered only in the

horizontal plane. Each body of the system had three displacements:

recoiling

,

swaying

,

swaying

and hunting

and hunting

.

The connections to the flat wagon were installed on the assumption

that the side frames of the bogie of model 18-100 had the same

swaying

.

The connections to the flat wagon were installed on the assumption

that the side frames of the bogie of model 18-100 had the same

swaying

and hunting

and hunting

;

there are no longitudinal and lateral gaps between the bogie

bolsters and side frames, or they are very small,

and the swaying of bolsters

;

there are no longitudinal and lateral gaps between the bogie

bolsters and side frames, or they are very small,

and the swaying of bolsters

and wheel sets

and wheel sets

is the same; the

gaps between the bogie center plates and center plate bearing are

not taken into account.

is the same; the

gaps between the bogie center plates and center plate bearing are

not taken into account.

The work [14] shows the effect

of load center shift in the gondola, but even though the flat wagon

and gondola belong to the open rolling stock and have some common

requirements for load positioning, it is expedient to determine the

dynamic load during the operation of not only different types of

railway vehicles, but also of the same type models close by the

technical parameters.

Fig. 3. Calculation

scheme of 4-axle flat wagon with asymmetric load arrangement

Standard and

technical requirements for positioning and fastening of goods in an

open rolling stock are presented in [7, 12]. In accordance with the

current requirements, the total center of gravity of goods ( )

should be located on the intersection of the longitudinal and

lateral plane of symmetry of the wagon. The shift of

)

should be located on the intersection of the longitudinal and

lateral plane of symmetry of the wagon. The shift of relative to the longitudinal and lateral planes of the wagon

symmetry is allowed (Table 2), if there are objective reasons for

this (geometric parameters of the load, arrangement and fastening

conditions).

relative to the longitudinal and lateral planes of the wagon

symmetry is allowed (Table 2), if there are objective reasons for

this (geometric parameters of the load, arrangement and fastening

conditions).

Table 2

Permissible

longitudinal

shift

of

the

common

load

center

in

a

4-axle

wagon

|

Para-meter

|

Load

weight, t

|

|

<10

|

15

|

20

|

25

|

30

|

35

|

40

|

45

|

50

|

55

|

60

|

62

|

67

|

70

|

>70

|

|

lsh

cm

|

during

loading

|

|

270

|

225

|

195

|

155

|

125

|

110

|

95

|

85

|

75

|

68

|

60

|

55

|

20

|

0

|

0

|

|

along

the track

|

|

300

|

248

|

216

|

173

|

144

|

123,5

|

108

|

96

|

86,5

|

78,5

|

72

|

63

|

26

|

6

|

0

|

The

permissible value of

shift

in the longitudinal direction lsh

(relative to the lateral plane of symmetry) during loading and along

the track is determined in accordance with Table 2 depending on the

total weight of the load in the wagon.

shift

in the longitudinal direction lsh

(relative to the lateral plane of symmetry) during loading and along

the track is determined in accordance with Table 2 depending on the

total weight of the load in the wagon.

According to [7, 12], in the

case of necessity of asymmetric arrangement of load in a wagon, the

difference in loading of bogies should not exceed for 4-axle wagons

– 10 t, and the loading, which falls on each of the bogies, should

not exceed half of the carrying capacity of the wagon.

The

permissible value of

shift in the lateral direction bsh

(relative to the longitudinal plane of symmetry) during loading and

along the track is determined in accordance with Table 3 depending

on the total weight of the load in the wagon and the height of the

common gravity centre of the wagon with load (

shift in the lateral direction bsh

(relative to the longitudinal plane of symmetry) during loading and

along the track is determined in accordance with Table 3 depending

on the total weight of the load in the wagon and the height of the

common gravity centre of the wagon with load ( )

above the level of the top of rail TOR [7, 12].

)

above the level of the top of rail TOR [7, 12].

Table

3

Permissible

lateral shift of the common load center in a 4-axle wagon

|

Parameter

|

Load

weight, t

|

|

≤10

|

30

|

50

|

55

|

67

|

>67

|

|

Height

of common gravity center of wagon with load over the TOR, m

|

|

≤1,2

|

1,5

|

2,0

|

≤1,2

|

1,5

|

2,0

|

2,3

|

≤1,2

|

1,5

|

2,0

|

2,3

|

≤1,5

|

2,0

|

2,3

|

≤1,5

|

2,0

|

2,3

|

≤2,3

|

|

bsh,

cm

|

during

loading

|

|

45

|

38

|

29

|

38

|

31

|

25

|

20

|

25

|

20

|

18

|

14

|

15

|

12

|

10

|

12,5

|

9,5

|

8,0

|

7,0

|

|

along

the track

|

|

62

|

55

|

41

|

55

|

45

|

35

|

28

|

35

|

28

|

25

|

20

|

22

|

17

|

15

|

18

|

14

|

12

|

10

|

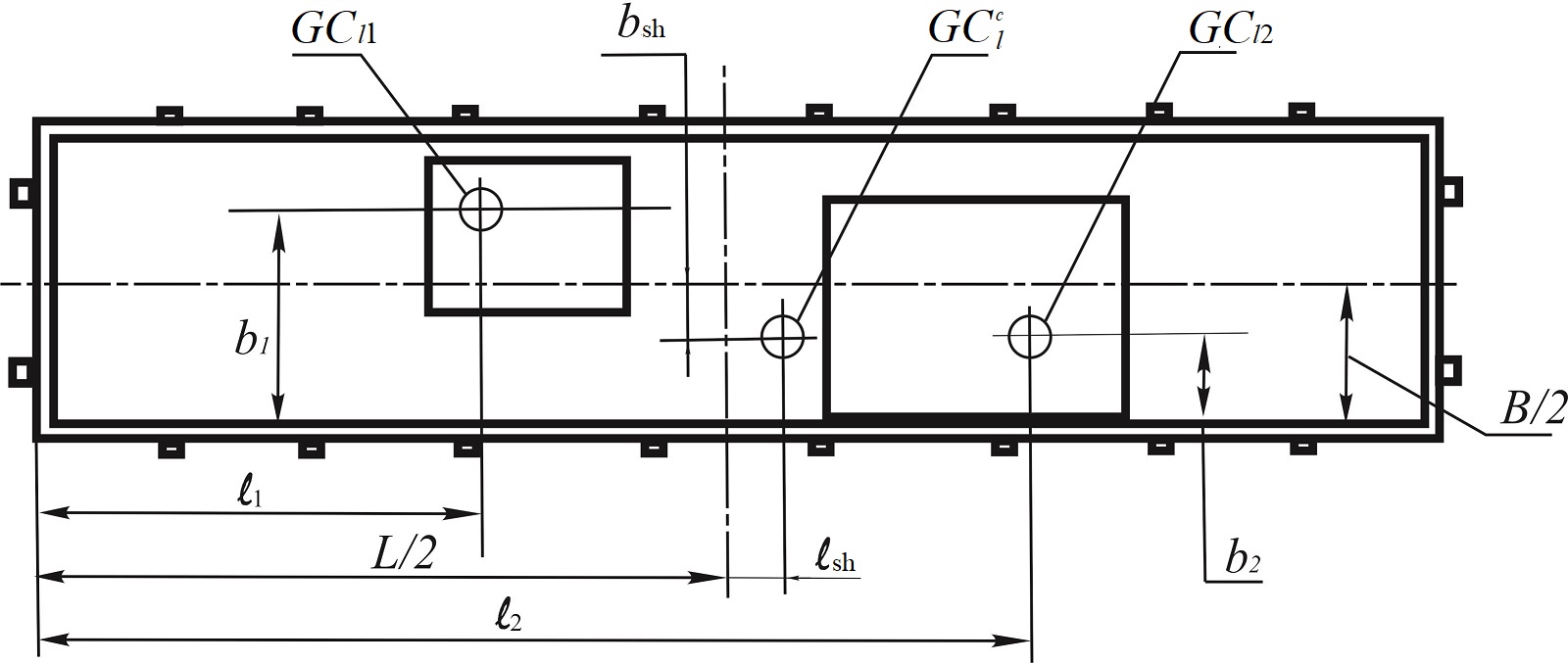

Simultaneous

shift of

relative to the longitudinal and lateral

symmetry of the wagon (Fig. 4) is allowed within the limits given in

Tables 2, 3.

relative to the longitudinal and lateral

symmetry of the wagon (Fig. 4) is allowed within the limits given in

Tables 2, 3.

Fig.

4. Calculation scheme for determining the longitudinal and lateral

shift

of the common load centre in a wagon

It is allowed to transport two

loads (or groups of loads) of the same weight with their

skew-symmetric arrangement in the wagon (Fig. 5), subject to the

following conditions:

– the

height of

the common

gravity center

of the

wagon with

load ( )

above TOR

does not

exceed 230 cm;

)

above TOR

does not

exceed 230 cm;

– the

distances

between the

load gravity

centers

and

and

in the longitudinal and lateral directions

do not exceed the allowable values taking into account the total

load weight in accordance with the Table 4;

in the longitudinal and lateral directions

do not exceed the allowable values taking into account the total

load weight in accordance with the Table 4;

–  is located at the intersection of the

longitudinal and lateral plane of the wagon symmetry.

is located at the intersection of the

longitudinal and lateral plane of the wagon symmetry.

The total weight of the load and

means of its fastening in the wagon shall not exceed its maximum

load capacity, and in the case of loading supported by two wagons,

the proportion of the weight of the load and the means of its

fastening, which falls on each loaded coupled wagon, shall not

exceed the maximum load capacity of the wagon. The load overrun in

its longitudinal direction beyond the limits of the headstock of the

flat wagon frame must not exceed 40 cm [7, 12].

Table 4

Maximum

allowable distances between load centers with skew-symmetric

arrangement in a wagon

|

Parameter

|

Total

weight of two loads, t

|

|

|

≤20

|

30

|

40

|

50

|

55

|

67

|

72

|

|

,

cm ,

cm

|

800

|

700

|

600

|

600

|

600

|

500

|

450

|

|

,

cm ,

cm

|

125

|

90

|

75

|

60

|

50

|

40

|

35

|

When the load

is placed on a flat wagon on two supports, laid across its frame

symmetrically relative to the lateral plane of symmetry of the flat

wagon, the location of the supports is determined depending on the

load on the support and the width

of the load distribution on the flat wagon

frame. In the case of support placement within or outside the flat

wagon base (Fig. 6, a, b),

the minimum permissible distance

of the load distribution on the flat wagon

frame. In the case of support placement within or outside the flat

wagon base (Fig. 6, a, b),

the minimum permissible distance

between the longitudinal axis of the

support and the lateral plane of the flat wagon symmetry is

determined in accordance with Table 5.

between the longitudinal axis of the

support and the lateral plane of the flat wagon symmetry is

determined in accordance with Table 5.

In case of

asymmetric location of gravity centre of the load or the support

relative to the lateral plane of the wagon symmetry, a checking

calculation of the bending moment of the wagon frame shall be

performed. It is also necessary to perform a checking calculation of

the bending moment of the flat wagon frame when arranging support at

a distance that does not meet the requirements of Table 5.

a

b

Fig.

6. Load arrangement on two supports located:

a

– within the flat wagon base; b

– outside the flat wagon base

Table

5

Maximum

permissible distances between the longitudinal axis of the support

and the lateral plane of the flat wagon symmetry

|

Location

of supports

within the

flat wagon

base

|

Location

of supports

outside the

flat wagon

base

|

|

Load

on one support, tc

|

Minimum

permissible distance

(

cm) at width Bl

(cm) of load distribution (

cm) at width Bl

(cm) of load distribution

|

Load

on one support, tc

|

Minimum

permissible distance

(

cm) at width Bl

(cm) of load distribution (

cm) at width Bl

(cm) of load distribution

|

|

|

88

|

178

|

270

|

|

88

|

178

|

270

|

|

<20

|

55

|

32.5

|

0

|

<12.5

|

625

|

635

|

640

|

|

22

|

95

|

75

|

50

|

15.0

|

600

|

605

|

615

|

|

25

|

120

|

110

|

90

|

20.0

|

560

|

565

|

575

|

|

27

|

142.5

|

135

|

1,20

|

25.0

|

540

|

545

|

555

|

|

30

|

167.5

|

160

|

145

|

30.0

|

537

|

542

|

552

|

|

33

|

207.5

|

188.5

|

185

|

33.0

|

535

|

540

|

550

|

|

36

|

310

|

290

|

240

|

36.0

|

533

|

538

|

550

|

It is

generally known that the railway rolling stock ability rating is

essential for ensuring the safety of trains, and the quality of

rolling stock depends on its design, fabrication and acceptance. At

each of these stages, the normative base plays a decisive role.

Levels of estimation and allowable values of ability rating in

accordance with normative documentation are given in Table 6 [6].

Table 6

Levels of

estimation and allowable values of ability rating

|

Indicator

|

Levels

of estimation

|

Allowable

values

|

|

empty

|

loaded

|

|

Maximum

coefficient

of dynamic

supplement

of the

spring-suspended

parts

(coefficient

of vertical

dynamics of

the central

suspension

stage)

|

excellent

|

0.5

|

0.2

|

|

good

|

0.6

|

0.35

|

|

satisfactorily

|

0.7

|

0.4

|

|

acceptable

|

0.75

|

0.65

|

|

Maximum

coefficient

of dynamic

supplement

of unsprung

parts

(coefficient

of vertical

dynamics of

the box

suspension

stage)

|

excellent

|

0.6

|

0.5

|

|

good

|

0.75

|

0.7

|

|

satisfactorily

|

0.85

|

0.8

|

|

acceptable

|

0.98

|

0.9

|

|

Maximum

ratio of

frame force

to static

axial load

(coefficient

of

horizontal

dynamics)

|

excellent

|

0.25

|

0.2

|

|

good

|

0.3

|

0.25

|

|

satisfactorily

|

0.38

|

0.3

|

|

acceptable

|

0.4

|

0.38

|

|

Wheel

derailment

safety

factor

|

acceptable

|

1.3

|

The Order of the Ministry of

Transport and Communications of Ukraine of May 18, 2010, No. 299 «On

Approval of the Procedure for the Development of Technical

Documentation on the Load Positioning and Fastening in Wagons and

Containers Transported by Rail» establishes requirements for

registration, approval and review of technical documentation for

transportation of loads in wa-gons and containers by railway

transport, control over the correct load positioning.

In accordance with the order for

the development and adjustment of technical documentation for the

carriage of goods by the manner not provided for by regulatory acts,

there must be the following information as well: determination of

inertial forces and wind force acting on the load; determination of

the stability of the wagon with load and load in the wagon; load on

the wagon bogies. The method of calculating the stability of the

wagon with load and load in the wagon contains the determination of

additional vertical load on the wheel from the action of centrifugal

forces and wind force, but does not take into account the dynamic

processes that arise during the movement of wagons on the railway

track in the presence of vertical and horizontal irregularities.

Maximum

coefficients of the dynamic supplement of the spring-suspended and unsprung parts

and unsprung parts ,

the maximum ratio of frame force to static axial load

,

the maximum ratio of frame force to static axial load

and

the wheel derailment safety

factor

and

the wheel derailment safety

factor

are

used to study the dynamic forces acting on the wagon bogie or body

components.

are

used to study the dynamic forces acting on the wagon bogie or body

components.

Findings

Theoretical

studies using the software complex developed by the BRL RSDS are

conducted under the condition of the movement of the flat wagon of

model 13–401 on typical bogies 18–100 at speeds ranging from 50

to 90 km/h in curves with radii of 350 and 600 m, with 130 and 120

mm canting,

respectively. Rails – P65, sleepers – wooden, ballast – broken

stone.

Wooden

sleepers to this day are the main type of rail support and it is

expedient to lay them:

– on

the ribbon

track in

horseshoe curves

with the

purpose of

expansion of

the rail

track to

prevent the

possible

derailment of

wagons;

– on

highly loaded

lines, where

the use

of continuous

welded track

with reinforced

concrete

sleepers is

ineffective.

In addition, wooden sleepers in

comparison with reinforced concrete ones have less rigidity and

resilience for the perception and even distribution of loads from

the rolling stock wheel sets on the rails, are less resistant to

deformation. The trains move smoother on rails with reinforced

concrete sleepers, since there are practically no joints at the

rails, thanks to the high stability in terms of transverse rows.

Therefore, when conducting calculations, wooden sleepers were chosen

as the basis of rail support [2].

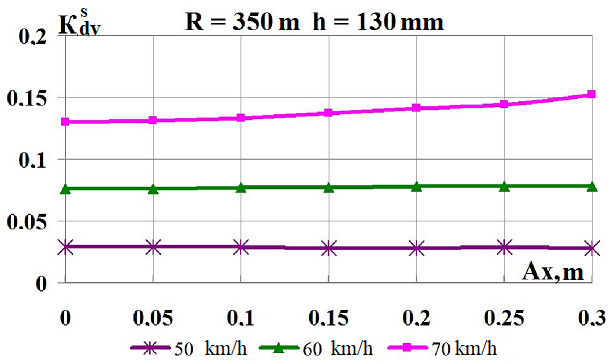

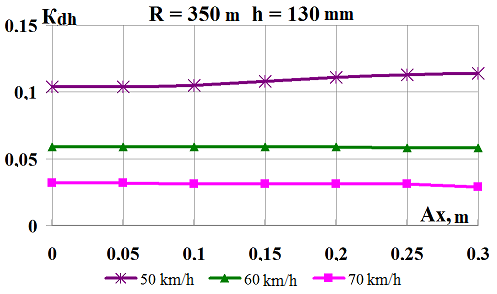

In the given

study we considered the influence of the load center shift on the

flat wagon in the longitudinal and transverse directions, as well as

in both directions simultaneously. Graphs of variance of the dynamic

parameters during the travel on curved tracks

and 350 m are shown in Fig. 7-9. The shift

in the longitudinal direction (Fig. 7) is studied within the limits

and 350 m are shown in Fig. 7-9. The shift

in the longitudinal direction (Fig. 7) is studied within the limits

,

that is permitted

by the standards

(Table 2) [7, 12].

,

that is permitted

by the standards

(Table 2) [7, 12].

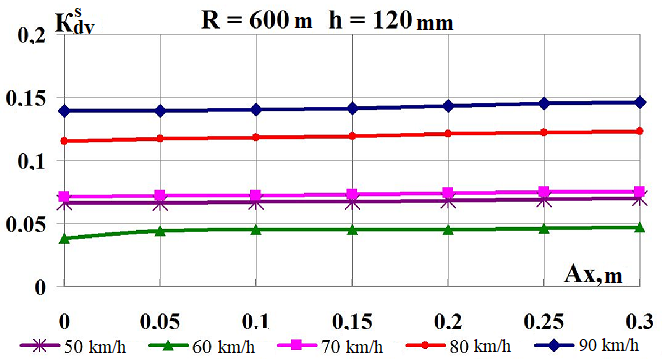

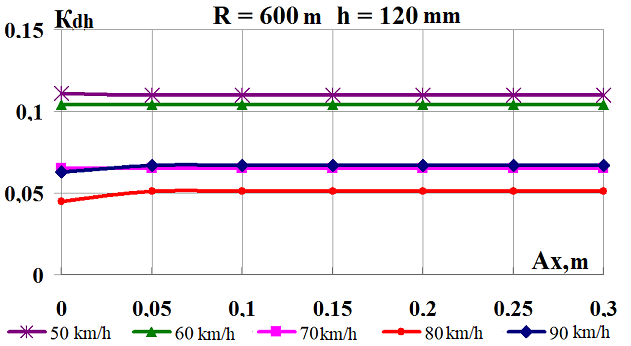

As can be

seen from Fig. 7, with the increased longitudinal shift of the load

center, the studied dynamic coefficients as a whole remain

unchanged. In the whole range of velocities, the indices

(Fig. 7 (a,

b)),

(Fig. 7 (a,

b)),

(Fig. 7 (c,

d)),

(Fig. 7 (c,

d)),

(Fig. 7 (e,

f)), and

(Fig. 7 (e,

f)), and

(Fig. 7 (g,

h)), in case of increasing the

longitudinal shift from 0 to 0.3 m, do not exceed the permissible

norm both in the curve

(Fig. 7 (g,

h)), in case of increasing the

longitudinal shift from 0 to 0.3 m, do not exceed the permissible

norm both in the curve

m and in the curve

m and in the curve

m. The level of assessment is «excellent»

[6].

m. The level of assessment is «excellent»

[6].

From the results obtained, it

follows that the longitudinal shift of the load in case of increased

speed does not cause an increase in the dynamics, and their values

do not exceed the values determined by the current regulatory

documents [5].

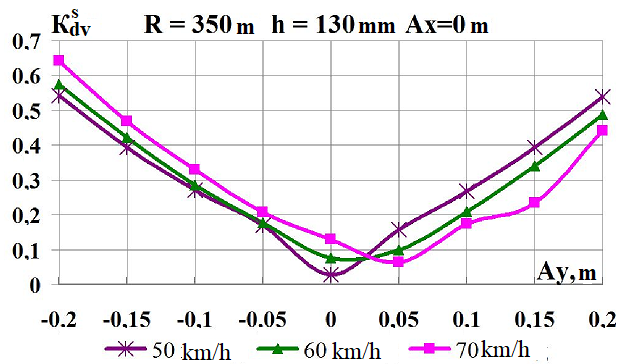

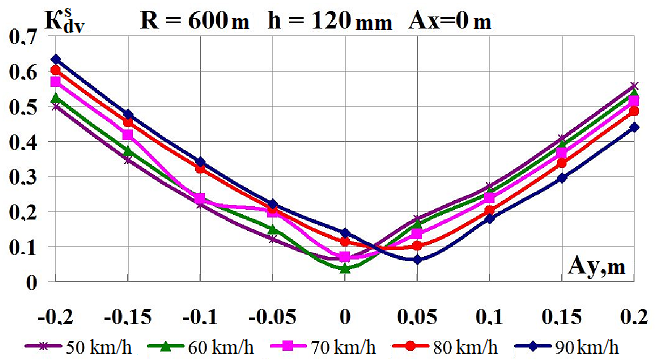

The lateral

shift of the load is considered in the range from

up to 0,2 m with a longitudinal shift

up to 0,2 m with a longitudinal shift

m (Fig. 8). For loads weighing 50

t

with

m (Fig. 8). For loads weighing 50

t

with

m, taken for calculations,

longitudinal shift of

m, taken for calculations,

longitudinal shift of

m is allowed,

this value can be 0.2 m on the travel line

(Table 3, 4) [7, 12].

m is allowed,

this value can be 0.2 m on the travel line

(Table 3, 4) [7, 12].

a

b

c

d

e

f

g

h

Fig.

7. Graphs of dependence on the load shift in the longitudinal

direction

while moving along the corresponding curve:

а,

b

–

coefficients

of the dynamic supplement of the spring-suspended parts;

c,

d

–

coefficients

of the dynamic supplement of unsprung parts;

e,

f

–

ratio

of the frame force to the static axial load;

g,

h

–

wheel

derailment safety factors

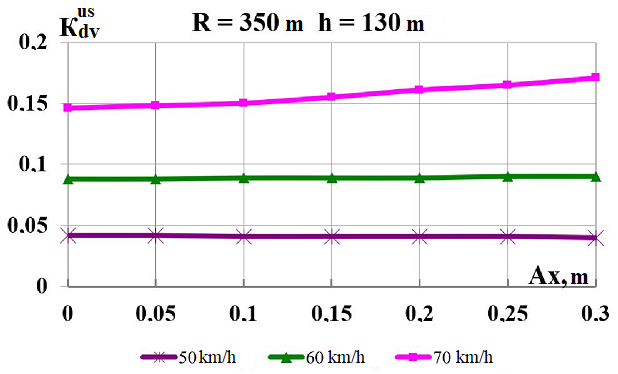

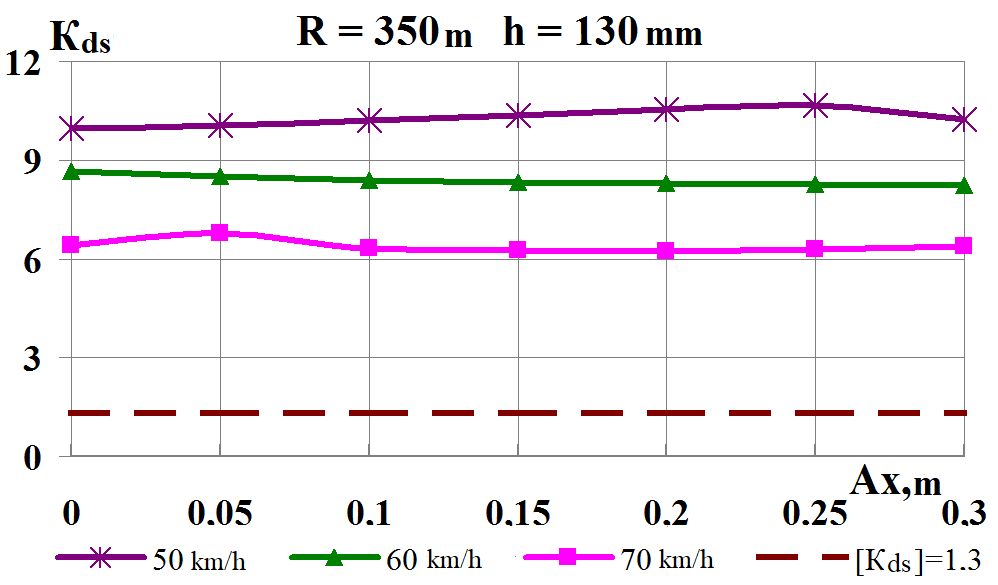

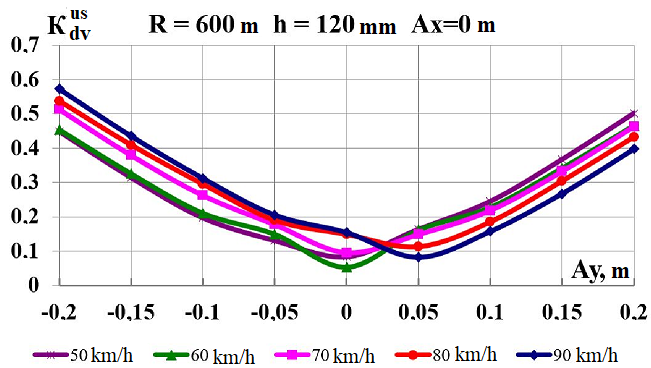

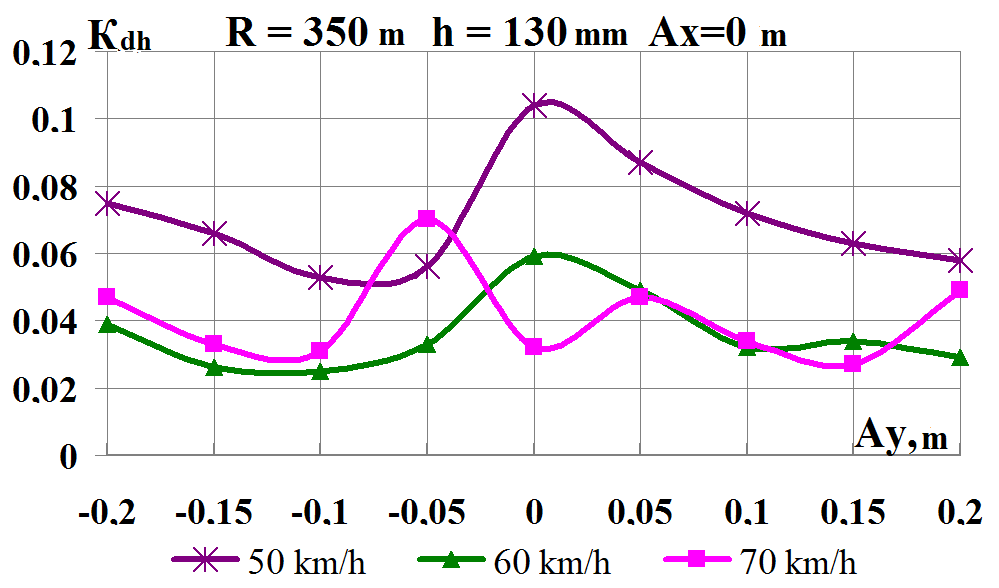

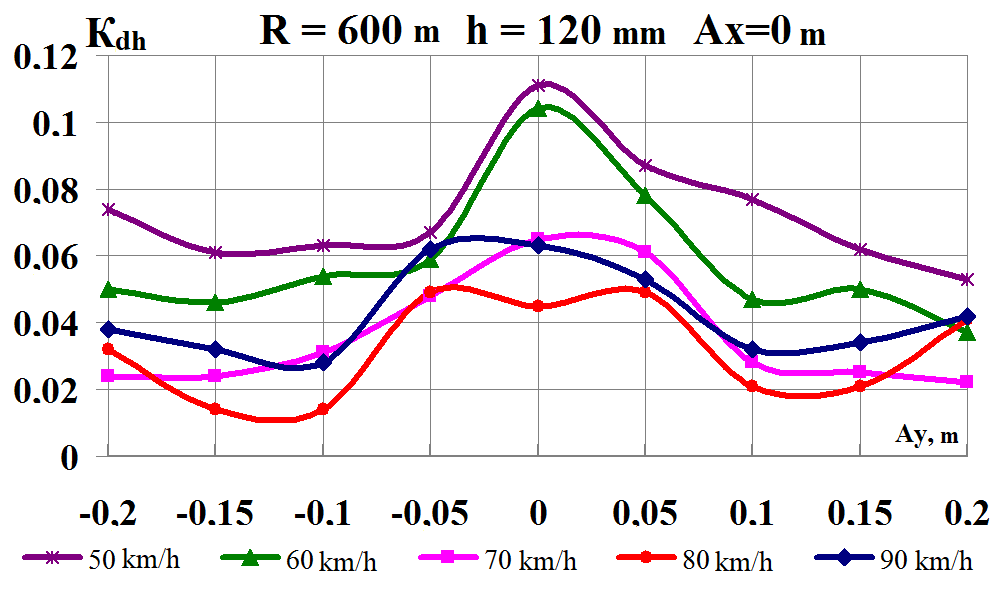

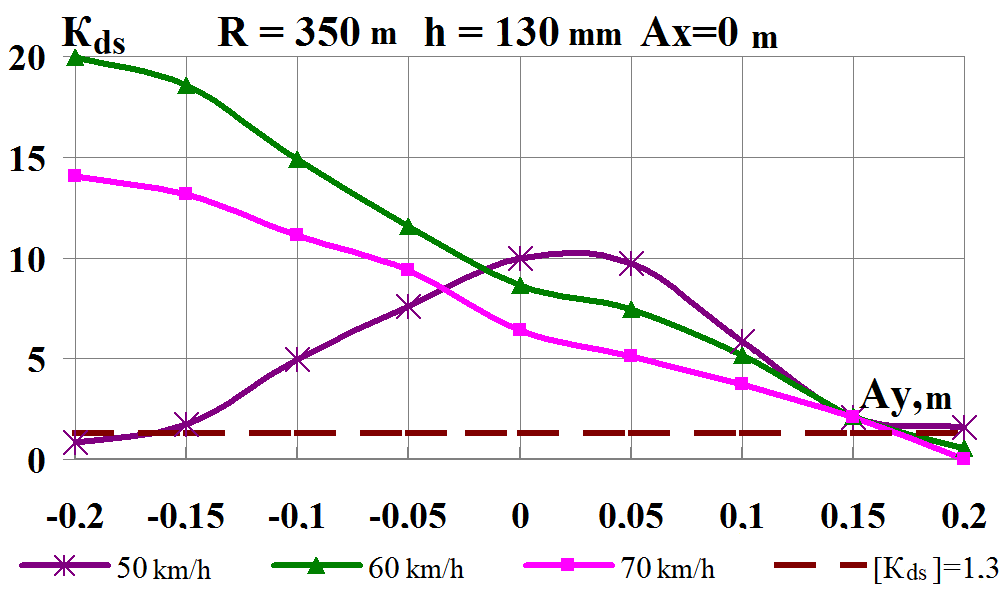

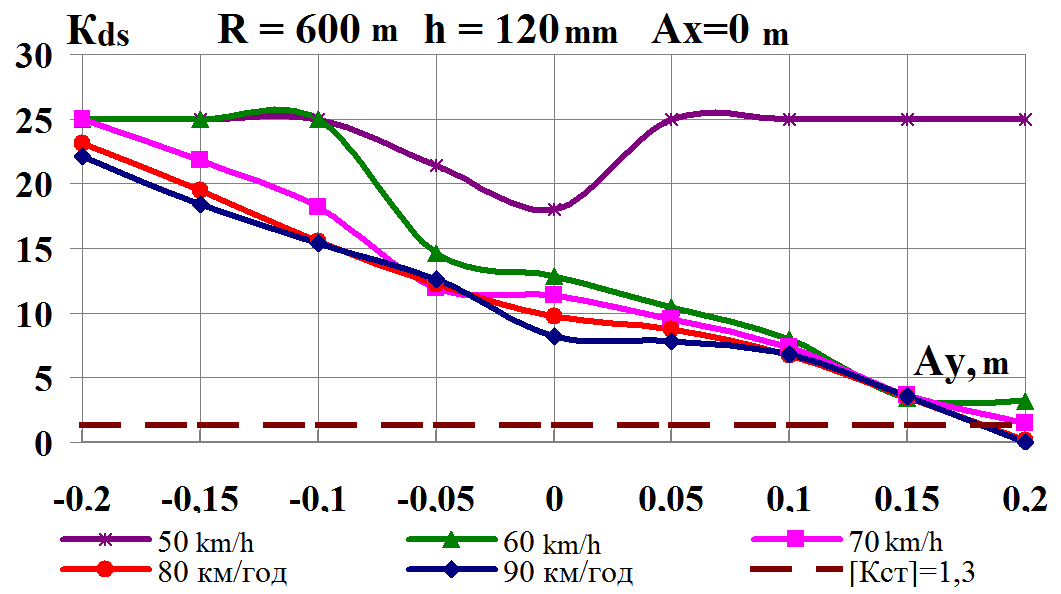

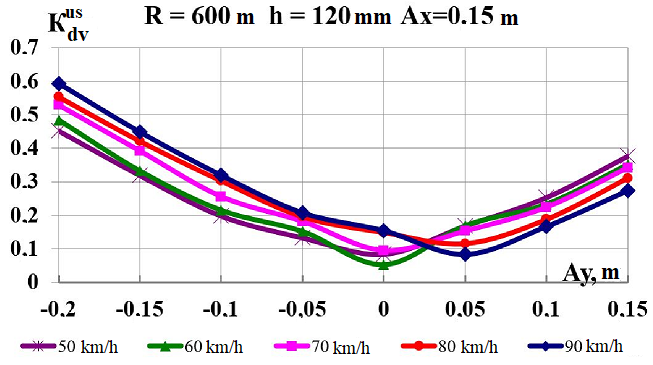

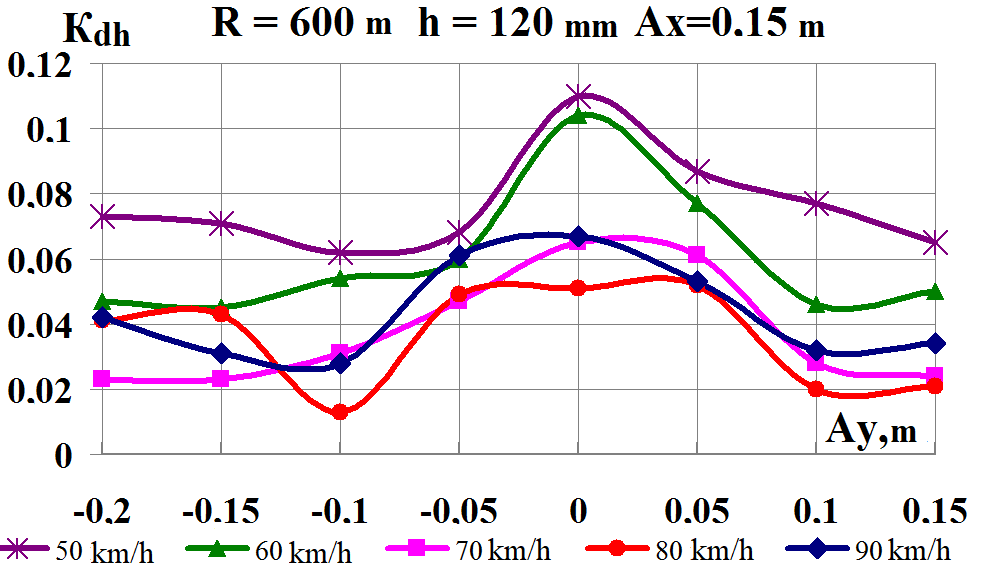

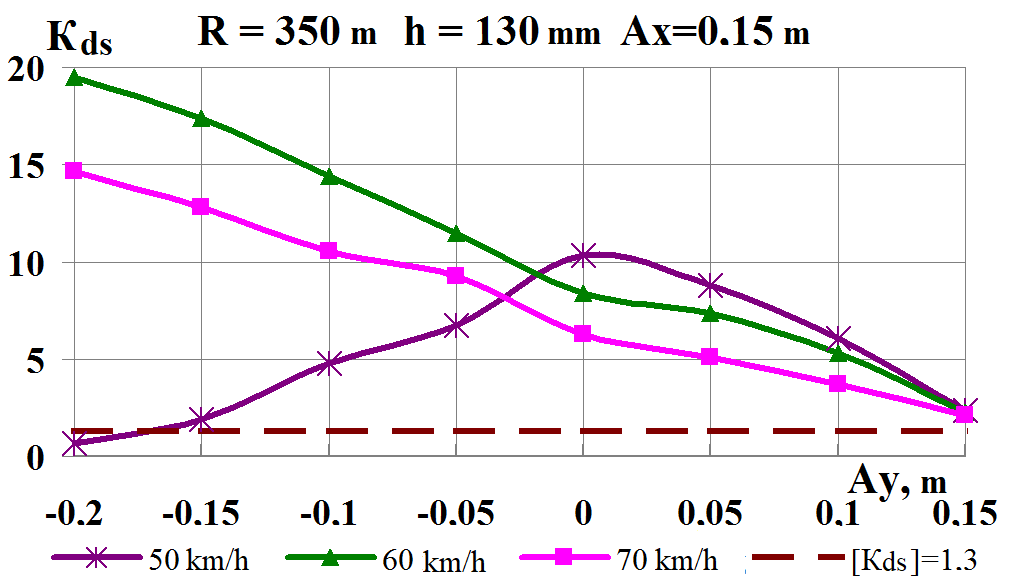

The

Figure 8 shows

the effect

on the

dynamic

indicators of

the lateral

load center

shift in

curves

m and

m and

m, respectively.

The effect of lateral load center shift

has a more significant effect on the dynamic indicators than the

longitudinal shift. With the increase of

m, respectively.

The effect of lateral load center shift

has a more significant effect on the dynamic indicators than the

longitudinal shift. With the increase of

in both sides from the central lateral

axis, the coefficients of the dynamic supplement of the

spring-suspended

in both sides from the central lateral

axis, the coefficients of the dynamic supplement of the

spring-suspended

and

and

unsprung parts increase (Fig. 8, a–d),

the ratio of the frame force to the static axial load varies

considerably (Fig. 8, e, f).

With the growth of

unsprung parts increase (Fig. 8, a–d),

the ratio of the frame force to the static axial load varies

considerably (Fig. 8, e, f).

With the growth of towards

the wheel based on the inner rail, the dynamic figures even

decrease. The wheel derailment safety factors on the contrary are

significantly reduced (Fig. 8, g, h).

towards

the wheel based on the inner rail, the dynamic figures even

decrease. The wheel derailment safety factors on the contrary are

significantly reduced (Fig. 8, g, h).

The level of

assessment from the lateral load center shift of the coefficients of

the dynamic supplement of the spring-suspended parts is

«acceptable», the coefficients of the dynamic supplement of the

unsprung parts

is

«acceptable», the coefficients of the dynamic supplement of the

unsprung parts are «good», and the ratio of the frame force to the static axial

load

are «good», and the ratio of the frame force to the static axial

load is «excellent» [5].

is «excellent» [5].

At

speed of

70-90 km/h,

in case

of increasing

lateral shift

from 0 to

the value

of 0.2 m

acceptable for

the indicated

weight, the

wheel derailment safety factor

from 0 to

the value

of 0.2 m

acceptable for

the indicated

weight, the

wheel derailment safety factor is significantly

reduced in

both curves.

On the

curve

is significantly

reduced in

both curves.

On the

curve

m (Fig.

8, g) the

values

m (Fig.

8, g) the

values

for

for

m reach

a dangerous

value,

especially

taking into

account the

fact that

the given

results are

obtained when

the flat

wagon moves

along a

curve without

irregularities.

Therefore, exceeding the lateral shift

beyond the regulatory value of 0.15 m is inappropriate from the

point of view of traffic safety.

m reach

a dangerous

value,

especially

taking into

account the

fact that

the given

results are

obtained when

the flat

wagon moves

along a

curve without

irregularities.

Therefore, exceeding the lateral shift

beyond the regulatory value of 0.15 m is inappropriate from the

point of view of traffic safety.

Consequently, the lateral load

center shift limitation, as defined by the regulatory documents,

must be observed, it is due to a sharp decrease in the wheel

derailment safety factor.

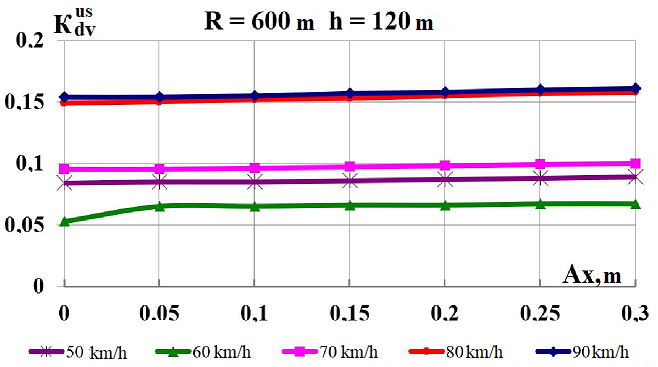

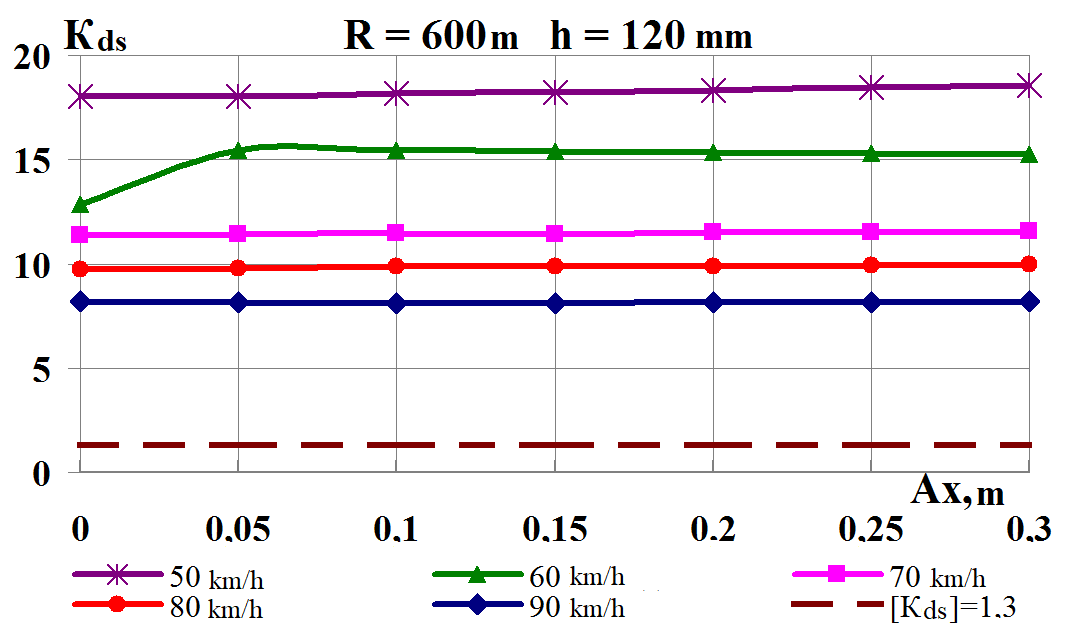

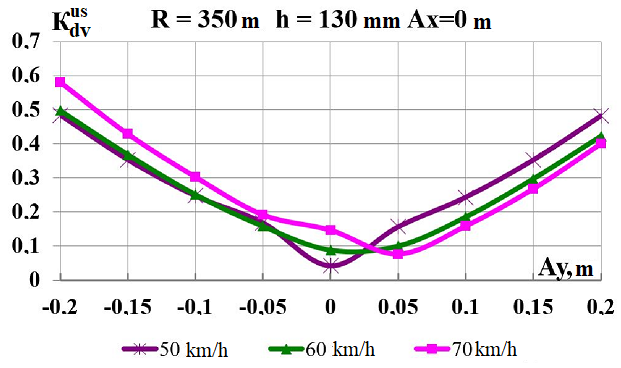

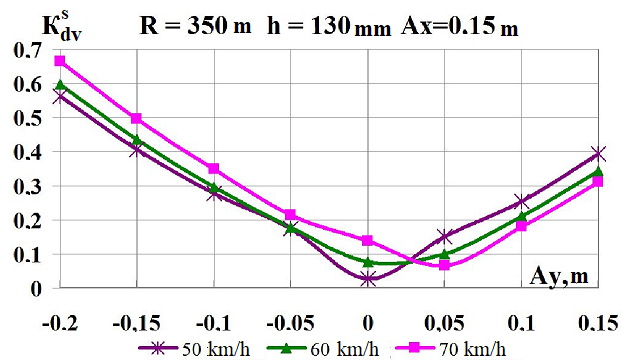

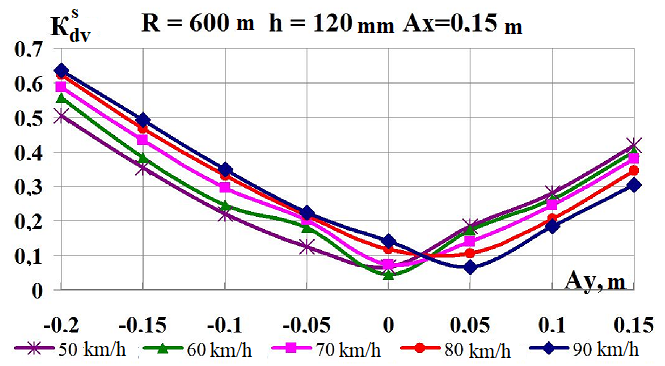

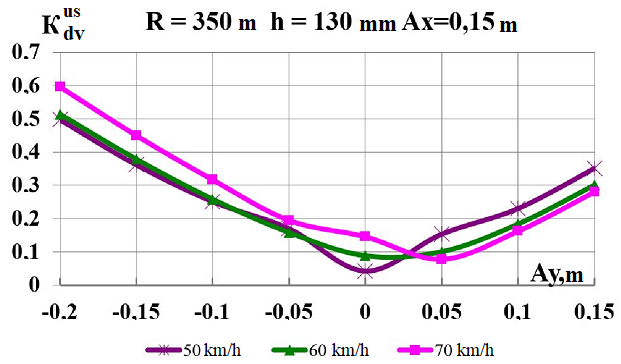

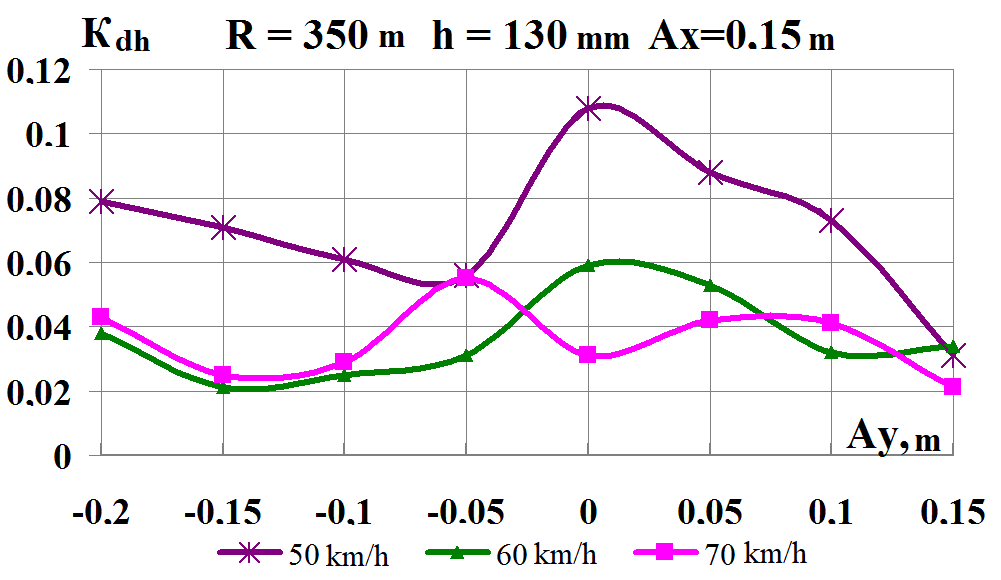

The

simultaneous

shift of

the gravity

center along

the axes

is considered

within

is considered

within

and

and

from 0 and

0.15 m (Fig.

9) [7, 12].

from 0 and

0.15 m (Fig.

9) [7, 12].

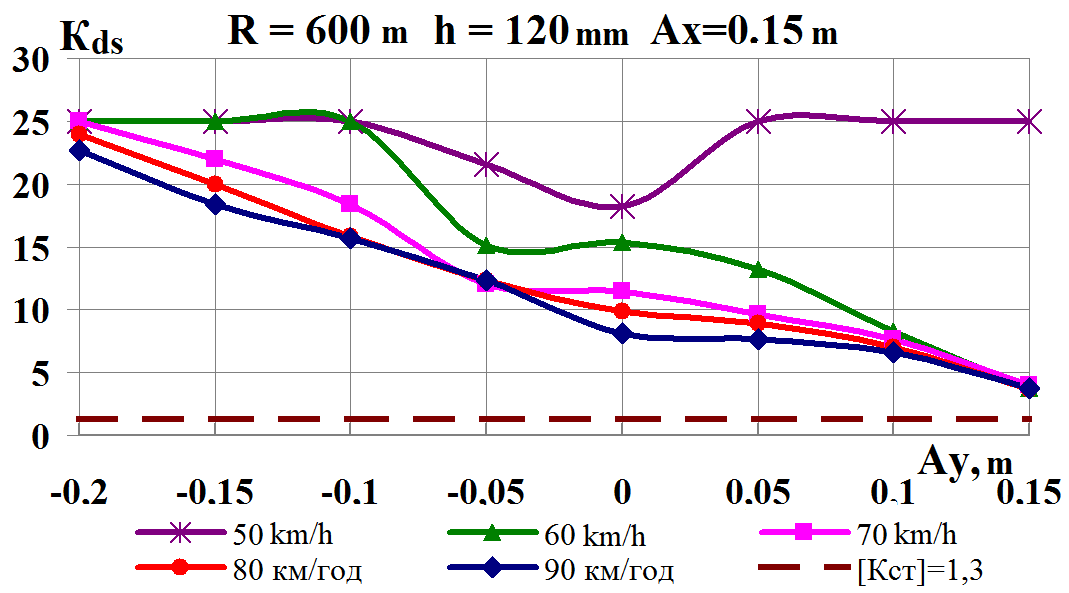

Fig.

9 shows the

graphs of

the dependence

of the

dynamic

indicators on

the value

of the

load centre

shift in

the lateral

direction

for the

value of

the longitudinal

shift

for the

value of

the longitudinal

shift

m. As

can be

seen from

the comparison

of the

graphs given

in Fig.

8 for

m. As

can be

seen from

the comparison

of the

graphs given

in Fig.

8 for

and Fig.

9 for за

and Fig.

9 for за

m, differences

in indicators

m, differences

in indicators

,

,

and

and

are small, that

is, the

presence of

simultaneous

lateral and

longitudinal

load center shifts

practically does

not affect

the dynamic

indicators.

are small, that

is, the

presence of

simultaneous

lateral and

longitudinal

load center shifts

practically does

not affect

the dynamic

indicators.

The

level of

assessment of

the coefficients

of the

dynamic

supplement of

the

spring-suspended

parts

is «acceptable»,

the coefficients

of the

dynamic

supplement of

the unsprung

parts

is «acceptable»,

the coefficients

of the

dynamic

supplement of

the unsprung

parts

is «good»,

and the

ratio of

the frame

force to

the static

axial load

is «good»,

and the

ratio of

the frame

force to

the static

axial load

is «excellent»

for the

simultaneous

longitudinal and

lateral load

center shift. But

this shift

leads to

a significant

decrease in

the factor

is «excellent»

for the

simultaneous

longitudinal and

lateral load

center shift. But

this shift

leads to

a significant

decrease in

the factor

.

As the

lateral load

center shift

of the

flat wagon

.

As the

lateral load

center shift

of the

flat wagon

increases

towards the

wheel based on

the inner

rail, the

indices of

increases

towards the

wheel based on

the inner

rail, the

indices of

vary

considerably, as

can be

seen from

Fig. 9, (g,

h).

Therefore, the

limitation of

simultaneous

longitudinal and

lateral shift,

as defined

by the

regulatory

documents, must

be also

observed.

In addition, the calculations showed the impossibility of increasing

the travel speed in small radius curves due to the high probability

of the rolling stock derailment.

vary

considerably, as

can be

seen from

Fig. 9, (g,

h).

Therefore, the

limitation of

simultaneous

longitudinal and

lateral shift,

as defined

by the

regulatory

documents, must

be also

observed.

In addition, the calculations showed the impossibility of increasing

the travel speed in small radius curves due to the high probability

of the rolling stock derailment.

Originality

and practical value

This study includes the

development of me-thods of mathematical simulation of dynamic

processes of rolling stock and track interaction. Similar

theoretical calculations can be applied in the course of

quantitative and qualitative assessment of the impact of the load

center shift on the rolling stock ability rating, taking into

account the wear of parts and bogies while moving on the straight

and curved track with irregularities.

During the

study, the following scientific and practical results were obtained:

– mathematical

simulation of

five coupled

wagons for

studying the

dynamic loading

of a

flat wagon

with heavy

load;

– assessment

of the

basic dynamic

indicators at

a shift

of the

gravity center

of heavy

load during

movement on

curved railway

track;

– substantiation

and introduction

of the

maximum possible

values of

lateral shift

of the

heavy load

gravity center

during

transportation

on flat

wagons.

a

b

e

f

c

d

g

h

Fig. 8. Graphs of

dependence on the load shift in the lateral direction while moving

along the corresponding curve:

а,

b

–

coefficients of

the dynamic supplement of the spring-suspended parts;

c,

d

–

coefficients of

the dynamic supplement of unsprung parts;

e,

f

–

ratio of the frame

force to the static axial load;

g,

h

–

wheel derailment

safety factors

a

b

c

d

e

f

g

h

Fig.

9. Graphs of dependence on simultaneous load shift in the lateral

and longitudinal

directions while moving along the corresponding

curve:

а,

b

–

coefficients

of the dynamic supplement of the spring-suspended parts;

c,

d

– coefficients of the dynamic supplement of unsprung parts;

e,

f

– ratio of the frame force to the static axial load; g,

h

– wheel derailment safety factors

Conclusions

Based

on the

analysis of

the conducted

theoretical

studies of

the rolling

stock dynamic

qualities on

example of

the flat

wagon, it

is possible

to draw

the following

conclusions:

– Longitudinal

shifts of

the load

weighing 63 tons

do not

result in

increasing of

the coefficients

of the

dynamic

supplement of

the

spring-suspended

and unsprung

parts, the

ratio of

the frame

force to

the static

axle load,

as well

as the

wheel derailment

safety factor;

– Longitudinal

shifts of

the load

center have

a significantly

less influence

on the

dynamic forces

that arise

when the

flat wagon

moves than

the lateral

shift, or

the presence

of simultaneous

shift in

both directions

from the

axis of

symmetry;

– Limitation

of the lateral shift set by the regulatory documents must be

observed; it is caused not by an increase in the dynamics

coefficients, but by a sharp decrease in the wheel derailment safety

factor;

– Exceeding

the lateral

shift of

the load

center on

the flat

wagon frame

beyond the

regulatory value

of 0.15 m

is inappropriate

from the

point of

view of

traffic safety.

LIST OF REFERENCE LINKS

Бабаев, А.

М. Динамико-прочностные качества сцепа

платформ с упругим грузом / А. М. Бабаев,

В. А. Каблуков, А. В. Шатунов // Динамика

вагонов : сб. науч. тр. /

Петербург. ин-т инж. ж.-д. трансп. –

Санкт-Петербург, 1993. – С. 118–120.

Даніленко,

Е. І. Залізнична колія : підручник для

вищ. навч. закл. : у 2 т. / Е. І. Даніленко.

– Київ : Інпрес, 2010. – Т. 1. – 528 с.

Данович, В.

Д. Колебания в горизонтальной плоскости

4-осн. платформы с несимметрично

расположенным тяжеловесным грузом /

В. Д. Данович, П. С. Анисимов // Вестн.

ВНИИЖТ. – 1989. – № 3. – С. 5–9.

Данович, В.

Д. Математическая модель пространственных

колебаний сцепа пяти вагонов, движущихся

по прямолинейному участку пути / В. Д.

Данович, А. А. Малышева // Транспорт.

Нагруженность и прочность подвижного

состава : сб. науч. тр.

/ Днепропетр. гос. техн.

ун-т ж.-д. трансп. – Днепропетровск,

1998. – С. 62–69.

Данович, В.

Д. Пространственные колебания вагонов

на инерционном основании : дис. д-ра

техн. наук / Данович Виктор Данилович

;

Днепропетр. ин-т инж. ж.-д. трансп.

– Днепропетровск, 1981.

– 465 с.

ДСТУ

ГОСТ 33211:2017. Вагони вантажні. Вимоги до

міцності та динамічних якостей

(ГОСТ

33211-2014, IDТ). – Введ.

2017–07–01. – Київ : УкрНДНЦ, 2017. – 58 с.

Збірник

№ 17 Правил

перевезення і тарифів залізничного

транспорту України. – Київ : САМ, 2005. –

176 с.

Определение

допустимых сил при оценке устойчивости

грузовых вагонов от выжимания в поездах

/ А. А. Швец, К. И. Железнов, А. С. Акулов,

А. Н. Заболотный, Е. В. Чабанюк // Наука

та прогрес транспорту. – 2016. – № 1 (61).

– С. 189–192. doi: 10.15802/stp2016/61045

Определение

показателей безопасности движения

платформ с порожним автопоездом / А.

В. Шатунов, В. В. Соборницкая, Е. Н. Ковтун,

О. М. Маркова // Транспорт : сб.

науч. тр. / Днепропетр.

гос. техн. ун-т ж.-д. трансп. –

Днепропетровск, 2001. – Вып. 7. – С. 116–120.

Підвищення

ефективності оперативного керування

локомотивним парком залізниць України

: монографія / Д. М. Козаченко, Р. В.

Вернигора, Л. О. Єльнікова, М. І. Березовий

; Дніпропетр. нац. ун-т залізн. трансп.

ім. акад. В. Лазаряна. – Дніпро : Герда,

2017. – 164 с.

Теоретическая

оценка динамических качеств платформ,

загруженных автопоездом с грузом / А.

В. Шатунов, В. В. Соборницкая, Е. Н. Ковтун,

О. М. Маркова // Транспорт : сб.

науч. тр. / Днепропетр.

гос. техн. ун-т ж.-д. трансп. –

Днепропетровск, 2000. – Вып. 3. – С. 21–27.

Технические

условия размещения и крепления грузов.

Приложение 3 к Соглашению о

международном железнодорожном грузовом

сообщении (СМГС). – Київ

: Девольта, 2011.

– Т. 1. – 436

с.

Шатунов, А.

В. Нагруженность

сцепа из двух платформ при ресурсосберегающем

способе транспортировки длинномерных

грузов : автореф. дис.

канд. техн. наук : 05.22.07 /

Шатунов Александр Васильевич ;

Днепропетр. ин-т инж. ж.-д. трансп. –

Днепропетровск, 1992.

– 17 с.

Швець,

А. О. Вплив поздовжнього та поперечного

зміщення центру ваги вантажу в піввагонах

на їх динамічні показники / А. О. Швець

// Наука та прогрес

транспорту. – 2018. – № 5

(77). – С. 115–128.

doi: 10.15802/stp2018/146432

Determination

of the issue concerning the lift resistance factor of lightweight

car / A. O.

Shvets, К. I. Zhelieznov, А.

S. Аkulov, О.

M. Zabolotnyi, Y. V. Chabaniuk // Наука

та прогрес транспорту. –

2015. –

№

6 (60). – С. 134–148. doi:

10.15802/stp2015/57098

Effect

of the state of car running gears and railway track on wheel and

rail wear / E. P. Blokhin,

O. M. Pshinko, V. D. Danovich, M. L.

Korotenko // Railway Bogies and Running Gears : Proc. of the 4th

Intern. Conf. / Technical University of Budapest. – Budapest,

1998. – P. 313–323.

McKinnon,

A. C.

Freight Transport Deceleration: Its

Possible Contribution to the Decarbonisation of Logistics

/ A.

C. McKinnon // Transport

Reviews. – 2016.

– Vol. 36.

– Iss. 4.

– P. 418–436.

doi:

10.1080/01441647.2015.1137992

Modeling,

simulation and applications of

longitudinal train dynamics / C.

Cole, M.

Spiryagin, Q.

Wu,

Y.

Q. Sun //

Vehicle System Dynamics.

– 2017. –

Vol. 55. – Іss.

10. – P.

1498–1571.

doi: 10.1080/00423114.2017.1330484

Navarrete,

J. A. Experimental and theoretical modeling of cargo sloshing

during braking / J. A. Navarrete,

F. Otremba // ASME

International Mechanical Engineering Congress and Exposition

(Phoenix,

Arizona, USA, Nov.

11–17, 2016). –

Phoenix, 2016.

– Vol. 4B :

Dynamics, Vibration, and Control.

doi: 10.1115/imece2016-65698

Ramos,

A. G. A new load balance methodology for container loading problem

in road transportation /

A. G. Ramos, E. Silva, J. F. Oliveira

// European Journal of Operational Research. – 2018. – Vol.

266. – Іss.

3. – P. 1140–1152. doi:

10.1016/j.ejor.2017.10.050

Wu,

H. Effects of

wheel and rail profiles on vehicle performance

/ H.

Wu // Vehicle

System Dynamics. – 2006.

– Vol. 44. –

Іss.

sup1. – P.

541–550.

doi: 10.1080/00423110600875393

Wu,

Q. Longitudinal

train dynamics: an

overview / Q.

Wu, M. Spiryagin,

C. Cole //

Vehicle System Dynamics.

– 2016. –

Vol. 54. –

Іss. 12.

– P. 1688–1714.

doi: 10.1080/00423114.2016.1228988

О.

В. Шатунов1*,

А. О. Швець2*

1*Каф.

«Вагони та вагонне господарство»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел.

+38 (067) 953 60

14,

ел. пошта

shatunov220648@gmail.com,

ORCID 0000-0002-1115-0093

2*Каф.

«Теоретична та будівельна механіка»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел.

+38 (050) 214 14 19,

ел. пошта angela_Shvets@ua.fm, ORCID

0000-0002-8469-3902

дослідження

динамічних ПОКАЗНИКів Платформи

В РАЗІ

зміщення центра Тяжіння вантажу

Мета.

Визначення впливу поздовжнього й

поперечного зміщення центра тяжіння

великовагового вантажу на платформах,

з урахуванням швидкості руху, на основні

динамічні показники – максимальні

коефіцієнти динамічної добавки

обресорених і необресорених частин,

максимальне відношення рамної сили до

статичного осьового навантаження,

коефіцієнт стійкості колеса від

сходження з рейок. Методика.

За основу дослідження взято метод

математичного та комп’ютерного

моделювання динамічної навантаженості

платформи з використанням моделі

просторових коливань зчепу з п’яти

вагонів і програмного комплексу,

розробленого в галузевій науково-дослідній

лабораторії динаміки й міцності рухомого

складу (ГНДЛ ДМРС). Теоретичні дослідження

проведені за умови руху платформи

моделі 13–401 з типовими візками 18–100 зі

швидкостями в інтервалі від 50 до 90

км/год по кривих із радіусами 350 й 600 м,

із підвищеннями зовнішньої рейки 130 і

120 мм відповідно. Результати.

Подано аналіз теоретичних

досліджень динамічних якостей рухомого

складу на прикладі платформ. Розрахунки

проведені з використанням пакета

прикладних програм. У ході виконання

теоретичних досліджень і після проведення

моделювання з урахуванням процесів

коливання вагона-платформи й вантажу,

за наявності поздовжнього й поперечного

зміщення його центра тяжіння, отримано

залежності основних динамічних

показників з огляду на величину швидкості

руху. Наукова новизна.

Для визначення динамічної навантаженості

вагона платформи, із застосуванням

математичної моделі зчепу з п’яти

вантажних вагонів, досліджено вплив

зміщення у двох напрямках від центральної

осі симетрії центра тяжіння великовагового

вантажу з огляду на величину швидкості

руху по кривих ділянках колії малого

й середнього радіуса.

Практична значимість.

У результаті проведених теоретичних

досліджень обґрунтовано рекомендації

стосовно максимально можливих величин

зміщення центра тяжіння великовагових

вантажів під час їх транспортування

на вагонах-платформах.

Ключові

слова: вантаж; вагон-платформа;

динамічні показники; криві ділянки

колії; поздовжнє й поперечне зміщення;

центр тяжіння; швидкість руху

А.

В. Шатунов1*,

А. А. Швец2*

1*Каф.

«Вагоны и вагонное хозяйство», Днипровский

национальный университет железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (067) 953 60 14,

эл. почта shatunov220648@gmail.com,

ORCID 0000-0002-1115-0093

2*Каф.

«Теоретическая и строительная механика»,

Днипровский национальный университет

железнодорожного

транспорта имени

академика В. Лазаряна, ул. Лазаряна, 2,

Днипро, Украина, 49010, тел. +38 (050) 214 14 19,

эл. почта angela_Shvets@ua.fm, ORCID 0000-0002-8469-3902

исследование

ДИНАМИЧЕСКИх ПОКАЗАТЕЛей

платформы

при смещении центра тяжести груза

Цель.

Определение влияния продольного и

поперечного смещения центра тяжести

тяжеловесного груза на платформах, с

учетом скорости движения на основные

динамические показатели – максимальные

коэффициенты динамической добавки

обрессоренных и необрессоренных частей,

максимальное отношения рамной силы к

статической осевой нагрузке, коэффициент

устойчивости колеса от схода с рельсов.

Методика.

Основой исследования является метод

математического и компьютерного

моделирования динамической нагруженности

платформы с использованием модели

пространственных колебаний сцепа из

пяти вагонов и программного комплекса,

разработанного в отраслевой

научно-исследовательской лаборатории

динамики и прочности подвижного состава

(ОНИЛ ДППС). Теоретические исследования

проведены при движении платформы модели

13–401 с типичными тележками 18–100 со

скоростями в интервале от 50 до 90 км/ч

по кривым с радиусами 350 и 600 м, с

возвышением наружного рельса 130 и 120 мм

соответственно. Результаты.

Представлен анализ теоретических

исследований динамических качеств

подвижного состава на примере платформ.

Расчеты проведены с использованием

пакета прикладных программ. В ходе

выполнения теоретических исследований

и после моделирования с учетом процессов

колебания вагона-платформы и груза,

при наличии продольного и поперечного

смещения его центра тяжести, получены

зависимости основных динамических

показателей на основании величины

скорости движения. Научная

новизна. Для определения

динамической нагруженности

вагона-платформы, с применением

математической модели сцепа из пяти

грузовых вагонов, исследовано влияние

смещения в двух направлениях от

центральной оси симметрии центра

тяжести тяжеловесного груза с учетом

величины скорости движения по

криволинейным участкам пути малого и

среднего радиуса. Практическая

значимость. В результате

проведенных теоретических исследований

обоснованы рекомендации относительно

максимально возможных величин смещения

центра тяжести тяжеловесных грузов

при их транспортировке на вагонах-платформах.

Ключевые

слова: груз; вагон-платформа;

динамические показатели; кривые участки

пути; продольное и поперечное смещение;

центр тяжести; скорость движения

REFERENCES

Babaev,

A. M.,

Kablukov, V.

A., &

Shatunov, A.

V. (1993).

Dinamiko-prochnostnye kachestva scepa platform s uprugim gruzom.

Dynamics of cars

(рр. 118-120).

St. Petersburg. (in Russian)

Danilenko,

E. I. (2010). Zaliznychna

koliia:

pidruchnyk

dlia

vyshchykh

navchalnykh

zakladiv.

(Vol. 1-2). Kyiv: Inpres. (in

Ukrainian)

Danovich,

V. D., & Anisimov, P. S. (1989). Kolebaniya v gorizontalnoy

ploskosti 4-osn. platformy s nesimmetrichno raspolozhennym

tyazhelovesnym gruzom. Vestnik of the

Railway Research Institute, 3, 5-9.

(in Russian)

Danovich,

V. D., & Malysheva, A. A. (1998). Mathematical Model of Spatial

Oscillations of the Coupling of Five Cars Moving Along a

Rectilinear Section of the Track.

Transport. Stress loading and

durability of a rolling stock (рр.

62-69).

Dnepropetrovsk.

(in Russian)

Danovich,

V. D. (1981). Spatial Cars

Oscillations in Inertia Track.

(Dysertatsiia doktora tekhnichnykh nauk). Dnepropetrovsk Institute

of Railway Transport Engineering, Dnеpropetrovsk.

(in Russian)

Vahony

vantazhni. Vymohy do mitsnosti ta dynamichnykh yakostei, 58 DSTU

33211:2017 (2017). (in Ukrainian)

Zbirnyk

№ 17 Pravyl perevezennia i taryfiv zaliznychnoho transportu

Ukrainy. (2005). Kуiv: SAM. (in

Ukrainian)

Shvets,

A. A., Zheleznov, K. I., Akulov, A. S., Zabolotny, A. N., &

Chabanyuk, E. V. (2016). Determination the permissible forces in

assessing the lift resistant factor of freight cars in trains.

Science and Transport Progress, 1(61),

189-192. doi:

10.15802/stp2016/61045 (in Russian)

Shatunov,

A. V., Sobornitskaya, V. V., Kovtun, E. N., & Markova, O. M.

(2001). Opredelenie pokazatelej bezopasnosti dvizheniya platform s

porozhnim avtopoezdom. Transport,

7, 116-120. (in Russian)

Kozachenko,

D. M., Vernigora, R. V., Yelnikova, L. O., & Berezovy, M. I.

(2017). Pidvyshchennia efektyvnosti

operatyvnoho keruvannia lokomotyvnym parkom zaliznyts Ukrainy:

Monohrafiia.

Dnipro: Herda.

(in Ukrainian)

Shatunov,

A. V., Sobornitskaya, V. V., Kovtun, E. N., & Markova, O. M.

(2000). Teoreticheskaya ocenka dinamicheskih kachestv platform,

zagruzhennyh avtopoezdom s gruzom. Transport,

3, 21-27. (in Russian)

Tekhnicheskie

usloviya razmeshcheniya i krepleniya gruzov.

Prilozhenie 3 k Soglasheniyu o

mezhdunarodnom zheleznodorozhnom gruzovom soobshchenii (SMGS).

(2011). Kyiv:

Devolta. (in

Russian)

Shatunov,

A. V.

(1992). Nagruzhennost

stsepa

iz

dvukh

platform

pri

resursosberegayushchem

sposobe

transportirovki

dlinnomernykh

gruzov.

(Avtoreferat dysertatsii kandydata tekhnichnykh nauk).

Dnepropetrovsk Institute of

Railway Transport Engineering, Dnеpropetrovsk.

(in Russian)

Shvets,

A. O. (2018). Influence of the longitudinal and transverse

displacement of the center of gravity of the load in gondola cars

on their dynamic indicators. Science

and Transport Progress,

5(77),

115-128.

doi: 10.15802/stp2018/146432 (in

Ukrainian)

Shvets,

A. A., Zhelieznov, K. I., Akulov, A. S., Zabolotnyi, A. N., &

Chabaniuk, Y. V. (2015). Determination of the issue concerning the

lift resistance factor of lightweight car. Science

and Transport Progress,

6(60), 134-148.

doi: 10.15802/stp2015/57098 (in

English)

Blokhin,

E. P., Pshinko, O. M., Danovich, V. D., & Korotenko,

M. L. (1998). Effect of the state of car running gears and railway

track on wheel and rail wear. Railway

Bogies and Running Gears: Proceedings of the 4th International

Conference (рр.

313-323).

Budapest. (in English)

McKinnon,

A. C. (2016). Freight Transport Deceleration: Its Possible

Contribution to the Decarbonisation of Logistics. Transport

Reviews, 36(4), 418-436. doi:

10.1080/01441647.2015.1137992 (in

English)

Cole,

C., Spiryagin, M., Wu, Q., & Sun, Y. Q. (2017). Modeling,

simulation and applications of longitudinal train dynamics. Vehicle

System Dynamics, 55(10), 1498-1571.

doi: 10.1080/00423114.2017.1330484

(in English)

Navarrete,

J. A., & Otremba, F. (2016). Experimental and theoretical

modeling of cargo sloshing during braking. ASME International

Mechanical Engineering Congress and Exposition (Phoenix, Arizona,

USA, Nov. 11-17,

2016).

Dynamics, Vibration, and Control,

4B.

Phoenix. doi: 10.1115/IMECE201665698

(in English)

Ramos,

A. G., Silva, E., & Oliveira, J. F. (2018). A new load balance

methodology for container loading problem in road transportation.

European Journal of Operational

Research, 226(3),

1140-1152.

doi: 10.1016/j.ejor.2017.10.050 (in English)

Wu,

H. (2006). Effects of wheel and rail profiles on vehicle

performance. Vehicle System Dynamics,

44(sup1), 541-550. doi:

10.1080/00423110600875393 (in English)

Wu,

Q., Spiryagin, M., & Cole, C. (2016). Longitudinal train

dynamics: an overview. Vehicle System

Dynamics, 54(12), 1688-1714. doi:

10.1080/00423114.2016.1228988 (in

English)

Received: Nov. 23, 2018

Accepted:

March 27, 2019

,

and

we marked

the gravity

centre shift

of the

flat wagon

frame along

the

corresponding

axes, and

through

,

,

– the angles

of its

rotation

relative to

the main

central axis

of inertia.

Similar

displacements of

bolsters are

provided with

the index

(

–

bogie number),

side frames –

with the

index

(

–left,

right side

of the

wagon), wheel

sets – with

the index

(

– wheel set

number in

the bogie),

rails in

the wheel

contact points

(movements of rails are assumed only in

two directions – along the axes

and

).

Displacement of the wheels is indicated by

the index

.