ISSN

2307–3489 (Print), ІSSN 2307–6666 (Online)

Наука

та прогрес транспорту. Вісник

Дніпровського

національного університету залізничного

транспорту, 2019, № 1 (79)

МАтеріалознавство

матеріалознавство

UDC

669.14/15:621.78

I.

O. VAKULENKO1,

S. V.

PROIDAK2,

L. I.

VAKULENKO3,

N.

A. GRISCHENKO4

1Dep.

«Applied Mechanics and Materials Science», Dnipro National

University of Railway

Transport named after Academician V. Lazaryan,

Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. + 38 (056) 373 15 56,

e-mail dnuzt_texmat@ukr.net,

ORCID 0000-0002-7353-1916

2Dep.

«Applied Mechanics and Materials Science», Dnipro National

University of Railway

Transport named after Academician V. Lazaryan,

Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. + 38 (056) 373 15 56,

e-mail proydak.S@gmail.com,

ORCID 0000-0003-2439-3657

3Management

of Prydniprovsk Railway, Yavornytskyi Av., 107, Dnipro, Ukraine,

49054,

tel. +38 (095) 466 08 50, e-mail dnuzt_texmat@ukr.net,

ORCID 0000-0003-2616-740X

4Dep.

«Applied Mechanics and Materials Science», Dnipro National

University of Railway

Transport named after Academician V. Lazaryan,

Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. + 38 (056) 373 15 56,

e-mail dnuzt_texmat@ukr.net, ORCID 0000-0002-0091-1387

SOFTENING OF

HARDENED MEDIUM-CARBON

STEEL DURING HEATING

Purpose. The

work is aimed to clarify the softening mechanism during the heating

of martensite hardened carbon steel, which is of practical

importance, especially in the development of the production

technology of rolled products with different levels of hardening.

Methodology. The samples after martensite hardening were

tempered at the temperatures of 300-500˚С. The microstructure was

investigated under the electron microscope. Thin foils were made

using the Bolman and tweezer methods in chlorous-acetic solution and

Morris reagent. Phase distortions of crystalline lattice were

determined by the methods of X-ray structural analysis, using the

diffractometer. The cold-worked layer of metal after grinding was

removed by electrolytic dissolution. Tensile strength brake of the

metal was determined using the tensile diagrams of samples using the

Instron type machine. Microhardness was measured using the PMT-3

device with indentation load 0.49 N.

Findings. When heating the hardened steel to a temperature of

300˚C, the softening effect is mainly related to the rate of

reduction of the accumulated as a result of martensitic

transformation, density of the crystalline structure defects. The

total result is caused by the development of dislocations

recombination and strengthening because of the emergence of

additional number of cementite particles during the martensitic

crystals decomposition. Starting from the heating temperatures of

400˚C and above, the development of polygonization processes in the

ferrite is accompanied by the emergence of additional sub-boundaries,

which enhance the effect of metal strengthening. With increase in the

heating temperature of the hardened steel, the level of strength

properties is determined by the progressive softening from the

decrease in carbon atoms saturation degree of the solid solution,

dislocations density and increase in the size of cementite particles

over the effect of strengthening from hindering of mobile

dislocations by carbon atoms and the emergence of additional

sub-boundaries. Originality. For the tempering temperature of

300-400˚C, the absence of the phase distortion change indicates the

emergence of additional factor in strengthening the metal from the

formation of sub-boundaries and the dispersion strengthening from the

carbide particles. Practical value. The given explanation of

the mechanism of structural transformations in the process of

tempering in the average temperature range of the hardened carbon

steel can be used to optimize the technology of thermal strengthening

of rolled metal.

Keywords:

microstructure; martensite; cementite; sub-boundaries; hardening;

softening

Introduction

During the

thermal hardening using the heat of rolling heating [2,

4, 10], in the elements of products of

large sections a gradient of structures is formed, which correspond

to certain values of the strength characteristics [1, 9,

11]. The observed structural inhomogeneity

is caused by the cumulative effect of the development of phase

transformation processes with different nature of influence on the

properties. Thus, the achieved level of metal hardening is

proportional to the speed of accelerated cooling, which decreases as

the distance from the cooled rolling surface increases [5]. At the

same time, the heating temperature of the metal will increase when

approaching the central volumes [1, 4].

For the detailed

analysis, the continuous nature of the structure change across the

section of the rolled product, depending on the distance from the

cooling surface, can be conditionally divided into separate volumes

with corresponding structure and ability to work hardening [3].

Based on the above-mentioned, the changes

in the nature of behaviour when loading the specified volumes of

metal will be similar to the influence of the temperature of

individual heating when tempering the hardened steel [1]. Takin into

account the additive nature of influence of the dispersion and

morphology of the structural components on the general level of

carbon steel hardening [3],

the formation of certain gradient of structures across the rolled

product section should be considered as one of the directions of

technology optimization to achieve the required structural state and

the level of strength characteristics [1, 3,

5].

Purpose

The work is aimed to clarify the

mechanism of softening during the heating of the hardened

medium-carbon steel in the average temperature range.

Methodology

The fragments

of the railway wheel set axis made of carbon steel with the

concentration of chemical elements: 0.41% C, 0.36% Si, 0.61% Mn,

0.0022% S, 0.015% P served as a material for the research. The

plates 2 mm thick, 20 mm wide and 250 mm long were the test samples.

The samples were austenitized at temperatures higher than

followed by forced cooling in a water tank. After hardening, the

samples were subjected to tempering at temperatures of 300-500°C

during 1 h. The heating was carried out in the SNOL electric

furnace – 1.6.2.5.1/11-IZ. The temperature was controlled by the

chromel-alumel thermocouple and DC potentiometer. The microstructure

of the samples was studied under electron microscope at accelerating

voltage of 100 kV. Thin foils for the research under electron

microscope were made using the Bolman and tweezer methods in

chlorous-acetic electrolyte and Morris reagent. During the

manufacture of the objects for X-ray studies, the cold-worked layer

of metal, after making the polished sections were removed by

dissolution in the chlorous-acetic electrolyte. The phase

distortions of crystalline lattice (

followed by forced cooling in a water tank. After hardening, the

samples were subjected to tempering at temperatures of 300-500°C

during 1 h. The heating was carried out in the SNOL electric

furnace – 1.6.2.5.1/11-IZ. The temperature was controlled by the

chromel-alumel thermocouple and DC potentiometer. The microstructure

of the samples was studied under electron microscope at accelerating

voltage of 100 kV. Thin foils for the research under electron

microscope were made using the Bolman and tweezer methods in

chlorous-acetic electrolyte and Morris reagent. During the

manufacture of the objects for X-ray studies, the cold-worked layer

of metal, after making the polished sections were removed by

dissolution in the chlorous-acetic electrolyte. The phase

distortions of crystalline lattice ( ),

where

),

where

is the ferrite lattice parameter,

were determined by the methods of X-ray structural analysis using

the DRON-2.0 diffractometer at scintillation registration of

reflexes, in monochromatic

is the ferrite lattice parameter,

were determined by the methods of X-ray structural analysis using

the DRON-2.0 diffractometer at scintillation registration of

reflexes, in monochromatic

radiation, at room temperature. The error in the determination

radiation, at room temperature. The error in the determination

was up to 5%. Tensile strength brake

of the metal was evaluated under tension using the Instron type

machine, at room temperature and deformation rate of 10

was up to 5%. Tensile strength brake

of the metal was evaluated under tension using the Instron type

machine, at room temperature and deformation rate of 10 s

s .

As a characteristic of the strength of metal microvolumes, the

microhardness was used, which was measured using the PMT-3 device

with indentation load 0.49 N.

.

As a characteristic of the strength of metal microvolumes, the

microhardness was used, which was measured using the PMT-3 device

with indentation load 0.49 N.

Findings

The level of

the values of tensile strength break of the studied steel after

hardening and tempering at the temperatures of 300-500˚С

corresponded to the known experimental data for the steels with

similar chemical composition [1, 5,

7].

As the tempering temperature increases, well-defined structural

changes, detected starting from the temperatures of 200-250˚С,

correspond to the progressive metal softening [3,

9].

Indeed, as shown in the works [6, 8] for carbon steels with a

carbon content of about 0.4%, the temperature of the beginning of

martensitic transformation is about 300°C.

This

temperature should be enough to start the emission of cementite

particles from the solid solution during the formation of the

martensitic crystal itself. Thus, depending on the temperature of

the end of forced cooling, a different combination in the

development of the processes of hardening and softening in steel,

determines the final level of strength properties.

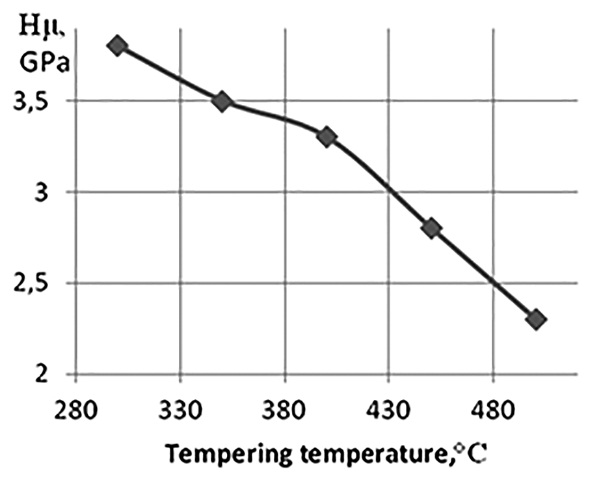

The effect of

hardening from the ordering of carbon atoms in the crystalline

lattice of the martensitic crystal [6] and quenching aging [2, 10],

when tempering at 300°C, is almost completely suppressed by the

progressive

metal softening (Fig. 1, a).

Indeed, for

steels with medium carbon content, the degree of supersaturation of

the solid solution achieved during the martensite hardening

determines the resource of maintaining the increased metal strength

after heating to certain temperatures. Based on this, it is safe to

believe that for the studied steel after hardening, the effect from

reducing the tetragonality degree of the ferrite crystalline lattice

(martensitic crystal) during low-temperature tempering can be to

some extent compensated by the increasing role of quenching aging

processes [2, 10]. However, already after

heating of hardened steel, starting from 300°C, the monotonous

nature of the decrease in strength characteristics indicates a

definite excess of softening effect over hardening (Fig. 1, a).

A qualitatively

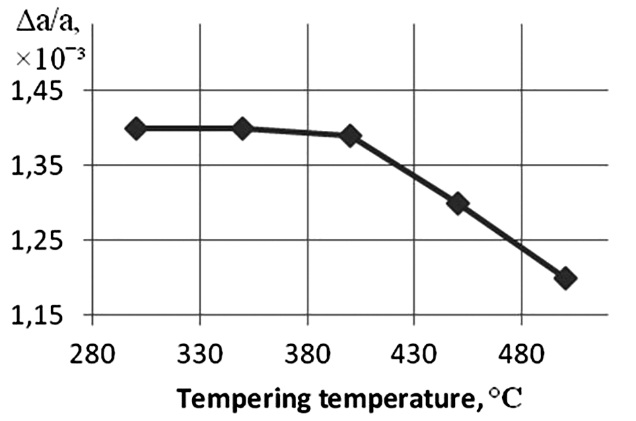

different nature

of the

dependence on

tempering

temperature is

observed for

the value

of the

phase

distortions

(Fig. 1, b).

A comparative analysis of the absolute

values of these characteristics, depending on the structural state

of the metal, showed that as a result of tempering at 400°C, the

reduction reaches about 40-43%, and for

reduction reaches about 40-43%, and for

up to 20% of relatively hardened state. After tempering at 500°C,

the values of the corresponding characteristics are 58 and 30%,

respectively. Thus, the observed differences in the nature of

changes of

up to 20% of relatively hardened state. After tempering at 500°C,

the values of the corresponding characteristics are 58 and 30%,

respectively. Thus, the observed differences in the nature of

changes of

and

and

at

tempering up to 400°C (Fig. 1) can be associated only with

different sensitivity to sub-structural changes during tempering of

the hardened steel. It is hoped that the analysis of the

microstructure of hardened steel after tempering at 400°C made it

possible to explain the nature of change of

at

tempering up to 400°C (Fig. 1) can be associated only with

different sensitivity to sub-structural changes during tempering of

the hardened steel. It is hoped that the analysis of the

microstructure of hardened steel after tempering at 400°C made it

possible to explain the nature of change of

.

.

a

b

Fig. 1. Influence

of tempering temperature

on micro hardness (а) and micro

distortions

(b) of the hardened steel

The

microstructure presented in Fig. 2, a

corresponds to the hardened state, and in Fig. 2, b

– to the state after tempering at

a temperature of 400°C. The

detected sections of the lath martensite with a high dislocation

density (Fig. 2, a)

indicate the development of austenite transformation according to a

shear mechanism. The laths width is generally up to 1 micron.

At

sufficiently careful study, in separate martensitic crystals,

simultaneously with thin twins (designation 1), stroked randomly

oriented cementite emissions of high dispersity (designation 2) were

found, Fig. 2, a.

Analysis of the results [2, 8] indicates that the emergence of the

observed emissions of the carbide phase is in fact caused by the

development of the decomposition processes of martensitic crystals,

which are formed at

a relatively high transformation

temperature.

a

b

Fig. 2.

Microstructure of steel after hardening

(а) and

tempering at 400˚С (b)

As compared

to

,

the absence of the decrease

,

the absence of the decrease

indicates the complex change in the ratio in the development of the

softening and hardening processes of the metal. In the first

approximation, the hardening effect is provided by the simultaneous

influence of the formation of additional interfaces in the ferrite

(sub-boundaries) and dispersion hardening from the emitted carbide

particles (Fig. 2, b).

Considering the influence of cementite

particles on the hardening effect separately, it should be noted

that in addition to the carbide particles formed during steel

hardening, the influence from the emitted particles even when

tempering of the hardened steel is added. As follows from the works

[6, 8], simultaneously with the emission of the dispersed particles

during tempering, the processes of spheroidization and coalescence

for the particles that are formed during martensitic transformation

receive a certain acceleration. Thus,

the expected total hardening effect from the dispersed particles of

cementite, which are formed as a result of tempering, will in fact

be somewhat reduced. However, in fact, based on a comparative

analysis of the microstructure (Fig. 2), no evidence of the

existence of carbide particles with markedly increased sizes was

found. At a sufficiently careful study of the structure, the

particles of cementite located at the sub-boundaries (formed during

tempering) and in the internal volumes of the former martensitic

crystals (hardening precipitation) (Fig. 2, b,

designation 1) have almost identical diameters. On the basis of the

known results of the study, the permanence of particle sizes is

explained by the cyclical nature of the change in the stages of

particles growth, when they are located at the grain boundaries due

to the dissolving particles located inside of the grain. Thus,

despite the fact that at heating temperatures up to 400

indicates the complex change in the ratio in the development of the

softening and hardening processes of the metal. In the first

approximation, the hardening effect is provided by the simultaneous

influence of the formation of additional interfaces in the ferrite

(sub-boundaries) and dispersion hardening from the emitted carbide

particles (Fig. 2, b).

Considering the influence of cementite

particles on the hardening effect separately, it should be noted

that in addition to the carbide particles formed during steel

hardening, the influence from the emitted particles even when

tempering of the hardened steel is added. As follows from the works

[6, 8], simultaneously with the emission of the dispersed particles

during tempering, the processes of spheroidization and coalescence

for the particles that are formed during martensitic transformation

receive a certain acceleration. Thus,

the expected total hardening effect from the dispersed particles of

cementite, which are formed as a result of tempering, will in fact

be somewhat reduced. However, in fact, based on a comparative

analysis of the microstructure (Fig. 2), no evidence of the

existence of carbide particles with markedly increased sizes was

found. At a sufficiently careful study of the structure, the

particles of cementite located at the sub-boundaries (formed during

tempering) and in the internal volumes of the former martensitic

crystals (hardening precipitation) (Fig. 2, b,

designation 1) have almost identical diameters. On the basis of the

known results of the study, the permanence of particle sizes is

explained by the cyclical nature of the change in the stages of

particles growth, when they are located at the grain boundaries due

to the dissolving particles located inside of the grain. Thus,

despite the fact that at heating temperatures up to 400 C,

the process of carbon atoms emission from the tetragonal insertion

positions is almost completed, as evidenced by the decrease in the

blurring of reflections in microdiffraction photographs and the

broadening of x-ray interferences [2, 6]. The insufficient

acceleration of cementite coalescence is one of the reasons for a

certain decrease in the rate of steel softening. The presence of

unessential anomaly on the monotonous course of the curve

C,

the process of carbon atoms emission from the tetragonal insertion

positions is almost completed, as evidenced by the decrease in the

blurring of reflections in microdiffraction photographs and the

broadening of x-ray interferences [2, 6]. The insufficient

acceleration of cementite coalescence is one of the reasons for a

certain decrease in the rate of steel softening. The presence of

unessential anomaly on the monotonous course of the curve

(Fig. 1, a)

confirms these positions.

(Fig. 1, a)

confirms these positions.

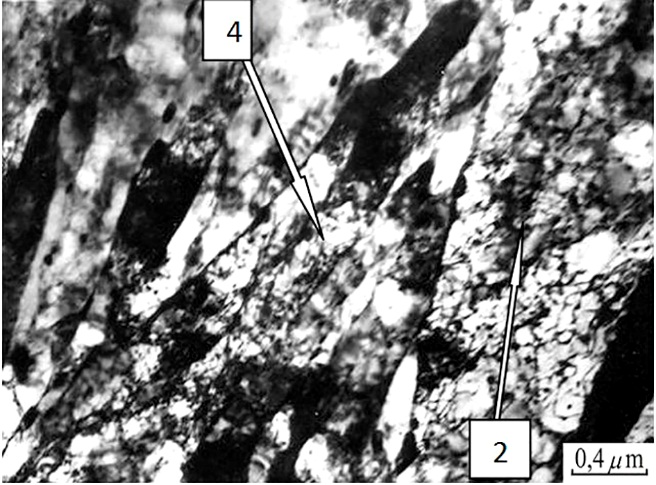

With a

further increase in tempering temperature, the sub-structural

changes observed at 400°C receive additional acceleration. As

follows from the microstructure analysis (Fig. 3), the heating to

500°C is already sufficient for the beginning of the formation of

the sections with almost equiaxial subgrains in the hardened steel.

(Fig. 3, a,

designation 1). At the same time, there are volumes in the metal in

which the formation of sub-boundaries is just beginning (Fig. 3, a,

designation 2).

a

b

Fig. 3.

Microstructure of steel after hardening

and tempering at 500˚С

Based on

this, the differences in the conditions for the beginning of

spheroidization and coalescence processes of cementite particles in

the metal microvolumes are one of the reasons for the formation of a

certain sub-structural heterogeneity. In microvolumes in which a

significant amount of finely dispersed carbide particles have been

preserved, the polygonization processes are significantly inhibited,

as evidenced by the increased dislocation density (Fig. 3, a,

designation 3). In contrast, in the sections with more intensive

polygonization development, the dislocations redistribution leads to

the improvement of sub-boundaries, the purification of the internal

volumes of fragmented martensitic crystals from unbound dislocations

(Fig. 3, b,

designation 4). Considering that the additional formation of

sub-boundaries and the emission of cementite particles by the nature

of their influence are related to hardening, these phenomena should

slow down the development of softening processes with increasing the

tempering temperature. From the analysis of the results, it follows

that the cumulative effect of softening during tempering of hardened

steel from the solid solution decomposition, reducing the

dislocation density and the coalescence of carbide particles exceeds

the hardening from the interaction of dislocations with carbon

atoms, the formation of additional sub-boundaries and the hardening

from cementite particles of various dispersity.

Originality and practical

value

During the research it was for

the first time established that for the tempering temperatures of

300–400°C, the absence of phase distortions change indicates the

emergence of additional factor in the metal hardening from the

formation of sub-boundaries and the dispersion hardening from

carbide particles.

The given explanation of the

mechanism of structural transformations in the process of tempering

in the average temperature range of the hardened carbon steel can be

used to optimize the technology of thermal hardening of rolled

products.

Conclusions

1. During the tempering of

hardened steel in the temperature range of 300-500˚С, the effect

of softening from the solid solution decomposition, the reduction of

dislocation density and the coalescence of carbide particles exceeds

hardening from the dislocations interaction with carbon atoms, the

formation of additional sub-boundaries and dispersion hardening from

cementite particles.

2. The

dependence of the value

of the phase distortion indicates the development of complex

structural changes during the tempering of 300–400°C in hardened

steel with the opposite nature of influence on the strength

properties.

LIST OF

REFERENCE LINKS

Бабаченко,

А. И. Надежность и

долговечность железнодорожных колес

и бандажей. – Днепропетровск

: Приднепров. гос. акад.

стр-ва и архитектуры, 2015. –

350 с.

Большаков,

В. И. Атлас структур металлов и сплавов

/ В. И. Большаков, Г. Д. Сухомлин,

Н. Э.

Погребная. – Днепропетровск : Gaudeamus,

2001. – 114 с.

Гриднев,

В. Н. Прочность и

пластичность холодно деформированной

стали / В. Н. Гриднев,

В. Г. Гаврилюк,

Ю. Я. Мешков. – Киев :

Наукова думка, 1974. – 231 с.

Кинетика

превращения аустенита в рельсовых

сталях марок М74 и 75ХГСМ при непрерывном

охлаждени / Ф. К. Ткаченко, С. О. Кузьмин,

В. Г. Ефременко, В. Г.

Казанков // Вісн. Дніпропетр.

нац. ун-ту

залізн. трансп.

ім. акад.

В. Лазаряна. – Дніпропетровськ,

2009. – Вип. 29. – С. 198–201.

Совершенствование

химического состава стали для

железнодорожных колес, обеспечивающего

повышение их стойкости к образованию

дефектов на поверхности катания / А.

И. Бабаченко,

П. Л.

Литвиненко, А. В. Кныш,

Ж. А. Дементьева, А.

Н. Хулин, Е. А. Шпак

//

Фундаментальные и прикладные проблемы

черной металлургии : сб. науч. тр. –

Днепропетровск, 2011. – Вып. 23. – С.

226–233.

Bhadesha,

H. K. D. H. Bainite in steels:

Transformations, Microstructure and Properties

/

H. K.

D. H.

Bhadesha. – Cambridge : The

University

Press, 2001. – 478

p.

Effect

of morphologies of martensite–austenite constituents on impact

toughness in inter critically reheated coarse-grained heat-affected

zone of HSLA steel / Xiang

Luo, Xiaohua Chen, Tao Wang, Shiwei Pan, Zidong Wang

// Materials Science and Engineering: A.

– 2018. – Vol.

710. – P. 192–199.

doi:

10.1016/j.msea.2017.10.079

Powder

metallurgical

nanostructured

medium

carbon

bainitic

steel:

Kinetics, structure, and in situ thermal stability studies /

I. Lonardelli, M. Bortolotti, W. van Beek [et al.] // Materials

Science and Engineering: A. – 2012. –

Vol. 555. – P. 139–147. doi:

10.1016/j.msea.2012.06.043

Structure

and properties of the steel railway wheel disc after forced cooling

/ I.

Vakulenko, N. Grischenko,

L.

Vakulenko, V.

Efremenko, S.

Proiydak, O.

Perkov // Scientific Journal of Silesian University of Technology.

Series

Transport.

– 2018. – Vol. 98. – P.

173–180. doi:

10.20858/sjsutst.2018.98.16

Vakulenko,

I. Influence of cooling rate on the strength of the ring of railway

wheel / I. Vakulenko // Materials Science. –

2016. – Vol. 51. – Iss. 6. – P.

839–842. doi:

10.1007/s11003-016-9910-8

Vakulenko,

I. Investigation of slide mechanism of tread during operation of

railway wheel / I. Vakulenko,

S. Proidak,

O. Perkov // Scientific Journal of

Silesian University of Technology. Series

Transport.

– 2016. – Vol. 90. – P.

185–193. doi:

10.20858/sjsutst.2016.90.16

І.

О. ВАКУЛЕНКО ,

С. В. ПРОЙДАК

,

С. В. ПРОЙДАК ,

Л. І. ВАКУЛЕНКO

,

Л. І. ВАКУЛЕНКO ,

М. А. ГРИЩЕНКО

,

М. А. ГРИЩЕНКО

1Каф.

«Прикладна механіка і матеріалознавство»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38 (056) 373 15 56,

ел. пошта

dnuzt_texmat@ukr.net,

ORCID 0000-0002-7353-1916

2Каф. «Прикладна

механіка і матеріалознавство»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38 (056) 373 15 56,

ел. пошта

proydak.S@gmail.com, ORCID 0000-0003-2439-3657

3Управління

Придніпровської залізниці, просп.

Дмитра Яворницького, 107, Дніпро, Україна,

49054,

тел. + 38 (095) 466 08 50, ел. пошта dnuzt_texmat@ukr.net

,

ORCID 0000-0003-2616-740Х

4Каф. «Прикладна

механіка і матеріалознавство»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38 (056) 373 15 56,

ел. пошта dnuzt_texmat@ukr.net

,

ORCID 0000-0002-0091-1387

ЗНЕМІЦНЕННЯ

ПІД ЧАС НАГРІВАННЯ ЗАГАРТОВАНОЇ

СЕРЕДНЬОВУГЛЕЦЕВОЇ СТАЛІ

Мета.

У роботі необхідно провести уточнення

механізму пом’якшення при нагріві

загартованої на мартенсит вуглецевої

сталі, що має важливе практичне значення,

особливо при розробці технології

виробництва прокату з різним рівнем

зміцнення. Методика.

Зразки після гартування на мартенсит

відпускали при температурах 300–500˚С.

Мікроструктуру досліджували під

електронним мікроскопом. Фольги

виготовляли методами Больмана і пінцету,

в хлорно-оцтовому розчині й реактиві

Морріса. Викривлення другого роду

кристалічної решітки визначали за

методиками рентгенівського структурного

аналізу з використанням дифрактометра.

Наклепаний шар металу після шліфування

видаляли електролітичним розчиненням.

Тимчасовий опір руйнуванню визначали

з діаграм розтягання зразків на машині

типу «Інстрон». Мікротвердість вимірювали

з використанням приладу ПМТ-3, з

навантаженням на индентор 0,49 Н.

Результати.

При нагріванні до температури 300 ˚С

загартованої сталі ефект пом’якшення

пов’язаний з темпом зниження накопиченої

в результаті мартенситного перетворення

щільності дефектів кристалічної будови.

Сумарний результат обумовлений розвитком

рекомбінації дислокацій та пом’якшенням

від появи додаткових частинок цементиту

при розпаді мартенситних кристалів.

Починаючи від температур нагріву 400 ˚С

і вище, розвиток процесів полігонізації

у фериті супроводжується виникненням

додаткових субмеж, які підсилюють ефект

зміцнення металу. З підвищенням

температури нагріву загартованої сталі

рівень міцності властивостей визначається

прогресуючим пом’якшенням від зниження

ступеня пересичення атомами вуглецю

твердого розчину, густини дислокацій

і збільшення розміру частинок цементиту

над ефектом зміцнення від гальмування

рухомих дислокацій атомами вуглецю та

виникнення додаткових субмеж. Наукова

новизна. Для температур

відпуску 300–400 ˚С

відсутність зміни спотворень другого

роду свідчить про появу додаткового

фактора в зміцненні металу від формування

субмеж і дисперсійного зміцнення від

карбідних частинок. Практична

значимість. Наведене

пояснення механізму структурних

перетворень в процесі відпуску в

середньому інтервалі температур

загартованої вуглецевої сталі може

бути використано для оптимізації

технології термічного зміцнення

прокату.

Ключові

слова: мікроструктура; мартенсит;

цементит; субмежі; гартування; пом’якшення

И. А.

ВАКУЛЕНКО ,

С. В. ПРОЙДАК

,

С. В. ПРОЙДАК ,

Л. И. ВАКУЛЕНКО

,

Л. И. ВАКУЛЕНКО ,

Н. А. ГРИЩЕНКО

,

Н. А. ГРИЩЕНКО

1Каф.

«Прикладная механика и материаловедение»,

Днипровский национальный университет

железнодорожного

транспорта имени

академика В. Лазаряна, ул. Лазаряна, 2,

Днипро, Украина, 49010, тел. +38 (056) 373 15 56,

эл. почта dnuzt_texmat@ukr.net, ORCID

0000-0002-7353-1916

2Каф.

«Прикладная механика и материаловедение»,

Днипровский национальный университет

железнодорожного

транспорта имени

академика В. Лазаряна, ул. Лазаряна, 2,

Днипро, Украина, 49010, тел. +38 (056) 373 15 56,

эл. почта proydak.S@gmail.com, ORCID

0000-0003-2439-3657

3Управление

Приднепровской железной дороги, просп.

Дмитрия Яворницкого, 107, Днипро, Украина,

49054,

тел. + 38 (095) 466 08 50, эл. почта

dnuzt_texmat@ukr.net , ORCID 0000-0003-2616-740Х

4Каф.

«Прикладная механика и материаловедение»,

Днипровский национальный университет

железнодорожного

транспорта имени

академика В. Лазаряна, ул. Лазаряна, 2,

Днипро, Украина, 49010, тел. +38 (056) 373 15 56,

эл. почта dnuzt_texmat@ukr.net, ORCID 0000-0002-0091-1387

РАЗУПРОЧНЕНИЕ

ПРИ НАГРЕВЕ ЗАКАЛЕННОЙ

СРЕДНЕУГЛЕРОДИСТОЙ

СТАЛИ

Цель.

В работе необходимо провести уточнение

механизма разупрочнения при нагреве

закаленной на мартенсит

углеродистой стали, что

имеет важное практическое значение,

особенно при разработке технологии

производства проката с

разным уровнем упрочнения.

Методика.

Образцы после закалки на мартенсит

отпускали при температурах 300–500˚С.

Микроструктуру исследовали под

электронным микроскопом. Фольги

изготавливали методами Больмана и

пинцета, в хлорно-уксусном растворе

и реактиве Морриса.

Искажения второго рода кристаллической

решетки определяли по методикам

рентгеновского структурного анализа,

с использованием дифрактометра.

Наклепанный слой металла после шлифования

удаляли электролитическим растворением.

Временное сопротивление разрушению

определяли из диаграмм растяжения

образцов при испытаниях на машине типа

«Инстрон». Микротвердость измеряли с

использованием прибора ПМТ-3,

с нагрузкой на индентор 0,49 Н. Результаты.

При нагреве до 300˚С

закаленной стали эффект разупрочнения

связан с темпом снижения накопленной

в результате мартенситного превращения

плотности дефектов кристаллического

строения. Суммарный результат обусловлен

развитием рекомбинации дислокаций и

упрочнением от появления дополнительных

частиц цементита при распаде мартенситных

кристаллов. Начиная от температур 400˚С

и выше, развитие процессов полигонизации

в феррите сопровождается возникновением

дополнительных субграниц, которые

усиливают эффект упрочнения металла.

С ростом температуры нагрева закаленной

стали уровень прочностных свойств

определяется прогрессирующим

разупрочнением от снижения степени

пресыщения атомами углерода твердого

раствора, плотности дислокаций и

увеличения размера частиц цементита

над эффектом упрочнения от торможения

подвижных дислокаций атомами углерода

и возникновения дополнительных

субграниц. Научная

новизна. Для температур

отпуска 300–400 ˚С

отсутствие изменения величины

искажений второго рода свидетельствует

о появлении дополнительного фактора

в упрочнении металла от формирования

субграниц и дисперсионного упрочнения

от карбидных частиц.

Практическая значимость. Приведенное

объяснение механизма структурных

превращений в процессе отпуска в среднем

интервале температур закаленной

углеродистой стали может быть использовано

для оптимизации технологии термического

упрочнения проката.

Ключевые

слова: микроструктура;

мартенсит; цементит; субграницы; закалка;

разупрочнение

REFERENCES

Babachenko,

A. I. (2015). Nadezhnost i

dolgovechnost zheleznodorozhnykh koles i bandazhey.

Dnepropetrovsk: Pridneprovskaya

gosudarstvennaya akademiya stroitelstva i arkhitektury. (in

Russian)

Bolshakov,

V. I., Sukhomlin, G. D., & Pogrebnaya, N. E. (2001).

Atlas struktur metallov i splavov.

Dnepropetrovsk: Gaudeamus. (in Russian)

Gridnev,V.

N., Gavrilyuk, V. G., & Meshkov, Y. Y. (1974). Prochnost

i plastichnost kholodno deformirovannoy stali.

Kiev: Naukova dumka. (in Russian)

Tkachenko,

F. K., Kuzmin,

S. O.,

Yefremenko, V. H. & Kazankov,

V. H. (2009). The

kinetics of austenite transformation in the rail steel grades m74

and 75 хгсм during continuous cooling.

Bulletin of Dnipropetrovsk

National University of Railway Transport, 29,

198-201. (in Russian)

Babachenko,

A. I., Litvinenko, P. L., Knysh, A. V., Dementeva, Zh. A., Khulin,

A. N., & Shpak, Y. A. (2011). Improving

chemical composition of steel railway wheels, ensure their enhanced

resistance to surface defects skating.

Fundamentalnye i prikladnye

problemy chernoy metallurgii, 23,

226-233. (in Russian)

Bhadesha,

H. K.

D. H.

(2001). Bainite

in steels: Transformations,

Microstructure and Properties. Cambridge:

The University

Press.

(in English)

Luo,

Xiang, Chen, Xiaohua, Wang, Tao, Pan, Shiwei & Wang, Zidong

(2018). Effect

of morphologies of martensite–austenite constituents on impact

toughness in inter critically reheated coarse-grained heat-affected

zone of HSLA steel. Materials

Science and Engineering: A, 710, 192–199.

doi:

10.1016/j.msea.2017.10.079 (in

English)

Lonardelli,

I., Bortolotti, M., van Beek, W., Girardini, L., Zadra, M., &

Bhadeshia, H. K. D. H. (2012). Powder metallurgical nanostructured

medium carbon bainitic steel: Kinetics, structure, and in situ

thermal stability studies. Materials

Science and Engineering: A, 555,

139-147. doi: 10.1016/j.msea.2012.06.043

(in English)

Vakulenko,

I., Grischenko, N., Vakulenko, L., Efremenko, V., Proiydak, S., &

Perkov, O. (2018). Structure and properties of the steel railway

wheel disc after forced cooling. Scientific

Journal of Silesian University of Technology. Series Transport, 98,

173-180. doi: 10.20858/sjsutst.2018.98.16

(in English)

Vakulenko,

I. O. (2016). Influence of Cooling Rate on the Strength of the Rims

of Railway Wheel. Materials Science,

51(6), 839-842.

doi: 10.1007/s11003-016-9910-8 (in

English)

Vakulenko,

I., Proidak, S., & Perkov, O. (2016). Investigation of slide

mechanism of tread during operation of railway wheel. Scientific

Journal of Silesian University of Technology. Series Transport, 90,

185-193.

doi: 10.20858/sjsutst.2016.90.16 (in

English)

Received:

Sep. 03, 2018

Accepted:

Jan. 03, 2019

followed by forced cooling in a water tank. After hardening, the

samples were subjected to tempering at temperatures of 300-500°C

during 1 h. The heating was carried out in the SNOL electric

furnace – 1.6.2.5.1/11-IZ. The temperature was controlled by the

chromel-alumel thermocouple and DC potentiometer. The microstructure

of the samples was studied under electron microscope at accelerating

voltage of 100 kV. Thin foils for the research under electron

microscope were made using the Bolman and tweezer methods in

chlorous-acetic electrolyte and Morris reagent. During the

manufacture of the objects for X-ray studies, the cold-worked layer

of metal, after making the polished sections were removed by

dissolution in the chlorous-acetic electrolyte. The phase

distortions of crystalline lattice (

),

where

is the ferrite lattice parameter,

were determined by the methods of X-ray structural analysis using

the DRON-2.0 diffractometer at scintillation registration of

reflexes, in monochromatic

radiation, at room temperature. The error in the determination

was up to 5%. Tensile strength brake

of the metal was evaluated under tension using the Instron type

machine, at room temperature and deformation rate of 10

s

.

As a characteristic of the strength of metal microvolumes, the

microhardness was used, which was measured using the PMT-3 device

with indentation load 0.49 N.

reduction reaches about 40-43%, and for

up to 20% of relatively hardened state. After tempering at 500°C,

the values of the corresponding characteristics are 58 and 30%,

respectively. Thus, the observed differences in the nature of

changes of

and

at

tempering up to 400°C (Fig. 1) can be associated only with

different sensitivity to sub-structural changes during tempering of

the hardened steel. It is hoped that the analysis of the

microstructure of hardened steel after tempering at 400°C made it

possible to explain the nature of change of

.

,

the absence of the decrease

indicates the complex change in the ratio in the development of the

softening and hardening processes of the metal. In the first

approximation, the hardening effect is provided by the simultaneous

influence of the formation of additional interfaces in the ferrite

(sub-boundaries) and dispersion hardening from the emitted carbide

particles (Fig. 2, b).

Considering the influence of cementite

particles on the hardening effect separately, it should be noted

that in addition to the carbide particles formed during steel

hardening, the influence from the emitted particles even when

tempering of the hardened steel is added. As follows from the works

[6, 8], simultaneously with the emission of the dispersed particles

during tempering, the processes of spheroidization and coalescence

for the particles that are formed during martensitic transformation

receive a certain acceleration. Thus,

the expected total hardening effect from the dispersed particles of

cementite, which are formed as a result of tempering, will in fact

be somewhat reduced. However, in fact, based on a comparative

analysis of the microstructure (Fig. 2), no evidence of the

existence of carbide particles with markedly increased sizes was

found. At a sufficiently careful study of the structure, the

particles of cementite located at the sub-boundaries (formed during

tempering) and in the internal volumes of the former martensitic

crystals (hardening precipitation) (Fig. 2, b,

designation 1) have almost identical diameters. On the basis of the

known results of the study, the permanence of particle sizes is

explained by the cyclical nature of the change in the stages of

particles growth, when they are located at the grain boundaries due

to the dissolving particles located inside of the grain. Thus,

despite the fact that at heating temperatures up to 400

C,

the process of carbon atoms emission from the tetragonal insertion

positions is almost completed, as evidenced by the decrease in the

blurring of reflections in microdiffraction photographs and the

broadening of x-ray interferences [2, 6]. The insufficient

acceleration of cementite coalescence is one of the reasons for a

certain decrease in the rate of steel softening. The presence of

unessential anomaly on the monotonous course of the curve

(Fig. 1, a)

confirms these positions.