ISSN

2307–3489 (Print), ІSSN 2307–6666 (Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2019, № 1

(79)

МАшинобудування

машинобудування

UDC 621.86/87(075.8)

L. M.

BONDARENKO1,

O.

P. Posmityukha2*,

K. T.

Hlavatskyi3

1Dep.

«Applied Mechanics and Material Science», Dnipro National

University of Railway

Transport named after Academician V. Lazaryan,

Lazaryan St., 2, Dnipro, Ukraine, 49600,

tel. +38 (056) 373 15 18,

e-mail bondarenko-l-m2015@yandex.ua, ORCID

0000-0002-2212-3058

2*Dep.

«Applied Mechanics and Material Science», Dnipro National

University of Railway

Transport named after Academician V. Lazaryan,

Lazaryan St., 2, Dnipro, Ukraine, 49600,

tel. +38 (066) 150 95 00,

e-mail AleksandrP@3g.ua, ORCID 0000-0002-9701-3873

3

Dep. «Applied Mechanics and Material

Science», Dnipro National University of Railway

Transport named

after Academician V. Lazaryan, Lazaryan St., 2, Dnipro, Ukraine,

49600,

tel. +38 (095) 816 99 90, e-mail kazimir.glavatskij@gmail.com,ORCID 0000-0003-0921-9845

ANALYTICAL DETERMINATION OF THE REDUCED

rotational

RESISTANCE

COEFFICIENT OF

THE CONSTRUCTION MACHINE

slewing gear

Purpose. Designing new models of construction

machines is closely related to the development of slewing gear, and

that, in turn, has a drive whose power and dimensions depend on the

rotational resistance and the reduced friction coefficient in the

units. The absence of analytical dependencies for determining the

reduced coefficient of friction for the rotation of construction

machines, first, restricts the designer's ability to select

materials, and secondly, does not allow the adoption of optimal

design solutions. Therefore, the purpose of the article is to find

analytical solutions to determine the rotational resistance in the

slewing gear of construction machines, which allows projecting more

advanced gears and machines in general. Existing techniques are based

on empirical dependencies and experimental coefficients that reduce

the accuracy of calculations, increase the size and cost of work. It

is proposed to improve the accuracy and simplify the process of

determining the rotational resistance and the magnitude of the

reduced rotational resistance coefficient of the building tower

cranes. Methodology. The set objectives can be achieved by

means of analytical dependencies for determination of rolling

friction coefficients over linear and point contacts. This will

enables to find the more accurate value of the resistance

coefficient, and the constructor during the calculations to take

targeted measures to reduce it, using the mechanical constants of

materials of the units and their geometric parameters. The

calculation is based on Hertz contact deformation theory and the body

point plane motion theory. Findings. The obtained dependencies

will allow analytically to find the resistance of rolling resistance

of rollers in construction machines with fixed and rotating pillars,

with circular rotary devices, as well as in ball and roller slewing

rings. The calculated values of the rotational resistance

coefficients for some types of mechanisms give similar values with

those recommended, while for others they significantly differ and

require their refinement in reference values. Originality of

the work consists in the use of analytical dependences for

determining the reduced coefficient of the rotational resistance over

linear and point contacts using Hertz contact deformation theory and

Tabor partial analytic dependencies theory. Practical value.

The obtained dependencies will allow to design new types of slewing

gear units of the construction machines and to reveal the additional

rotational resistances.

Keywords: construction machine;

resistance; rotation; turn; slewing ring; rail; rolling friction

Introduction

There are the following types

of slewing gears (SG) of the construction machines:

a) with a fixed pillar

consisting of an upper support with a thrust and radial bearings;

b) with a rotating pillar:

consists of a pillar connected to the revolving portion of the

construction tower crane;

c) with a circular flat or

tapered rail consisting of a series of conical or cylindrical

rollers, which come in contact with two rails on the revolving and

non-revolving portions of the construction crane;

g) with a slewing ring:

consists of ball or roller single-row or multi-row structures

(full-slewing and part-slewing excavators, motor graders).

One of the main causes of

rotational resistance is rolling resistance [12, 13]. There are many

studies and suggestions for its definition, but all of them are

either inaccurate, like Reynolds's assertion that rolling resistance

is the result of sliding friction at the contact point, or require

an experimental determination of one or more coefficients.

The analytic

dependence of Tabor [3] on determining the rolling friction

coefficient, which is based on Hertz contact deformation theorem

[6], is quite successful. Tabor obtained the following analytical

dependences for determining the rolling friction coefficient, k;

– for a

linear contact:

,

(1)

,

(1)

– for a

point contact

, (2)

, (2)

where

– half-width of the contact pattern;

– half-width of the contact pattern;

– coefficient of hysteresis losses.

– coefficient of hysteresis losses.

However, the

presence in these formulas of the coefficient

nullifies their practical application.

nullifies their practical application.

In [5],

there are formulas analogous to (1) and (2) without coefficient

,

namely:

,

namely: and

and

,

that essentially differ from those offered by Tabor, and the absence

of their coefficient of hysteresis losses testifies to their

inaccuracy.

,

that essentially differ from those offered by Tabor, and the absence

of their coefficient of hysteresis losses testifies to their

inaccuracy.

In [4], there are proposed the

dependences for determining the rolling friction coefficient with

the use of Tabor analytical dependences and the experimental values

of the rolling friction coefficient for the wheels of cranes with a

flat champignon and bull-headed rails [1, 2].

Similarly to formulas (1) and

(2) they are obtained in the following form:

-for flat champignon rail:

,

(3)

,

(3)

– for

bull-headed rail:

,

(4)

,

(4)

where

– wheel radius, m.

– wheel radius, m.

The

difference in numerical values from the half-width of the contact

pattern is obviously due to the rounding of the coefficient

in experiments to ten millimeters, as well as to the fact that their

values are obtained the same for several wheel diameters (400, 500,

560, 630):

in experiments to ten millimeters, as well as to the fact that their

values are obtained the same for several wheel diameters (400, 500,

560, 630):

mm in the case of a flat champignon rail and

mm in the case of a flat champignon rail and

mm for the bull-headed rail).

mm for the bull-headed rail).

It should be

noted that formulas (3) and (4) are obtained independently of (1)

and (2), and since the coefficients before

for such a class of problems can be considered close by value, we

will assume that the general values of

for such a class of problems can be considered close by value, we

will assume that the general values of

in these formulas coincide. Having considered that the coefficients

before

in these formulas coincide. Having considered that the coefficients

before

in Tabor's formulas are obtained analytically and are exact, the

value of

in Tabor's formulas are obtained analytically and are exact, the

value of

can be found by changing the coefficients before

can be found by changing the coefficients before

in the exponents. This equality can be achieved by taking the

following values

in the exponents. This equality can be achieved by taking the

following values

in formulas (1) and (2):

in formulas (1) and (2):

and

and

.

(5)

.

(5)

Purpose

Designing

new models of construction machines is closely related to the

development of slewing gear, and that, in turn, has a drive whose

power and dimensions depend on the rotational resistance and the

reduced friction coefficient in the units

[14–16].

The absence of analytical dependencies for determining the reduced

coefficient of friction for the rotation of construction machines,

first, restricts the designer's ability to select materials, and

secondly, does not allow the adoption of optimal design solutions.

Therefore, the purpose of the article is to find analytical

solutions to determine the rotational resistance in the slewing gear

of construction machines, which allows projecting more advanced

gears and machines in general. Existing techniques are based on

empirical dependencies and experimental coefficients that reduce the

accuracy of calculations, increase the size and cost of work. It is

proposed to improve the accuracy and simplify the process of

determining the rotational resistance and the magnitude of the

reduced rotational resistance coefficient of the building tower

cranes. More

precise

definition of

the rotational

resistance in

the slewing gear of construction machines

leads to

saving the

machine manufacturing

and operation

costs [21], as

well as

reduction of

their harmful

impact on

the service

staff and

the environment

[17-20].

Methodology

Now the formulas of Tabor (1)

and (2) can be written as follows:

– for a

linear contact:

, (6)

, (6)

– for a

point contact:

. (7)

. (7)

With formulas (6) and (7), we

can solve the set problems analytically.

In [7] it is

indicated that the value of hysteresis losses

in Tabor formulas is small. We can use formula (5) for its

determination and (6), (7) for determination of the resistance.

in Tabor formulas is small. We can use formula (5) for its

determination and (6), (7) for determination of the resistance.

Findings

1. Wheel

rolling resistance. For a linear

contact, we can take

MPa (steel 65G, crane operating mode 4M [11]), the elastic modulus

MPa (steel 65G, crane operating mode 4M [11]), the elastic modulus

MPa, the Poisson factor is 0.3.

MPa, the Poisson factor is 0.3.

When the

value of the pressure restraining force

[4]

[4]

, (8)

, (8)

the half-width of the contact

pattern will be

, (9)

, (9)

where

–

wheel width, m; while the rolling friction coefficient can be

determined by the formula (6).

–

wheel width, m; while the rolling friction coefficient can be

determined by the formula (6).

For the

point contact we can take

MPa, the radius of the bull-head rail

MPa, the radius of the bull-head rail

mm. Similarly to the formulas (8) and (9) we can determine the

values for the point contact

mm. Similarly to the formulas (8) and (9) we can determine the

values for the point contact

, (10)

, (10)

, (11)

, (11)

where

– coefficient

depending on

the tangent

ellipse equation

coefficient

– coefficient

depending on

the tangent

ellipse equation

coefficient

;

;

– rail rounding radius.

– rail rounding radius.

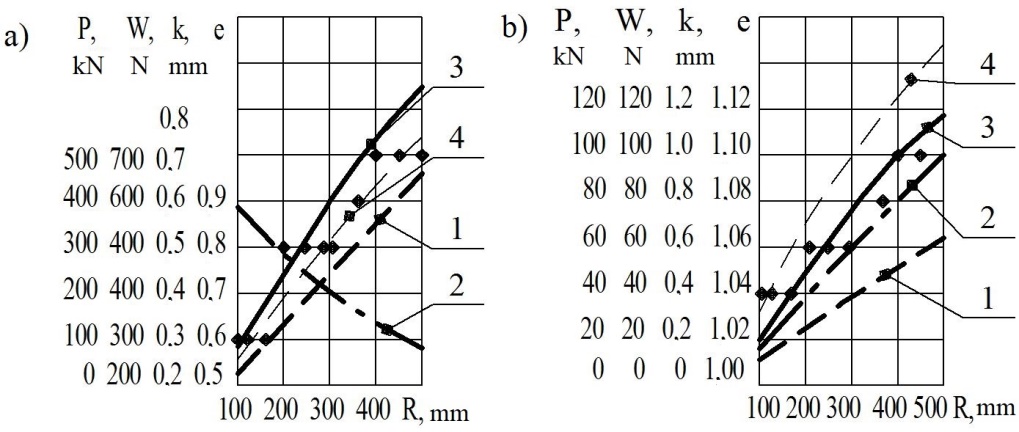

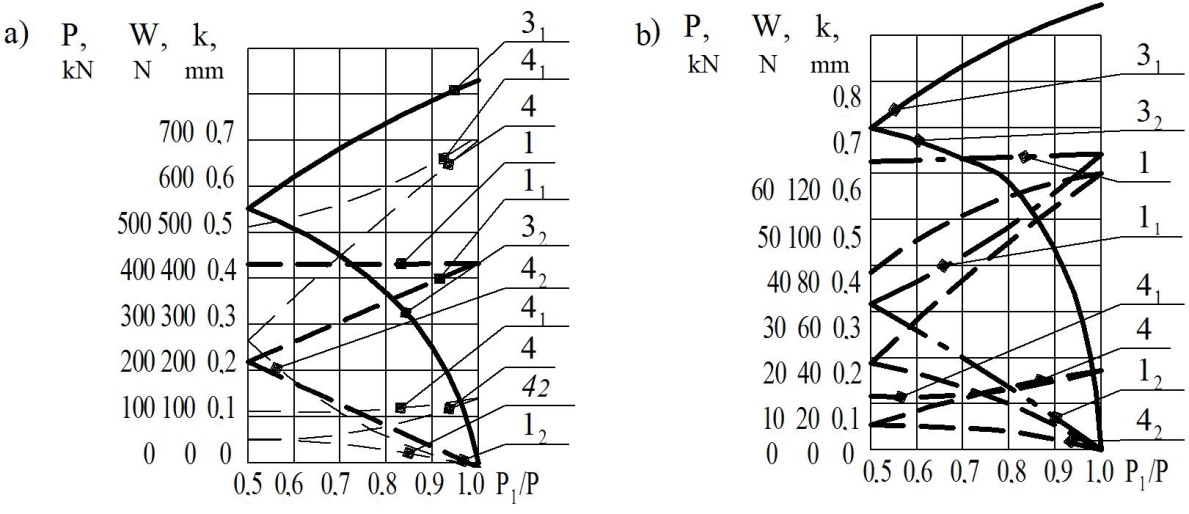

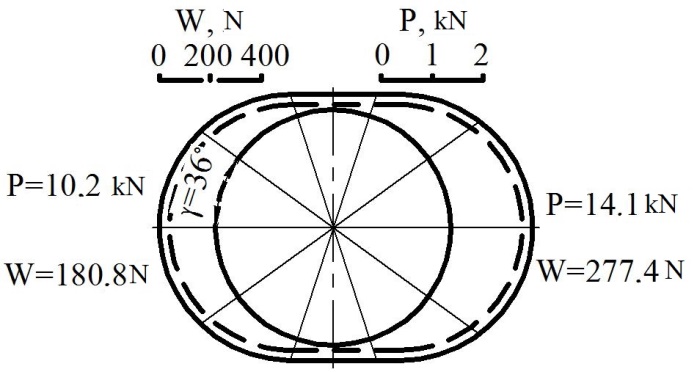

Depending on the wheel radius

of the pressure restraining force, the coefficient of hysteresis

losses, the coefficient of rolling friction and resistance are shown

in Fig. 1.

Since the rolling friction

coefficient for the wheels of the construction cranes corresponds to

their certain radius, it can be assumed that the relationship

between the force of rolling resistance and the load on the wheel is

linear. But the rolling friction coefficient is determined by the

half-width of the contact pattern, depending on several parameters

not linearly, therefore, it is necessary to establish the dependence

of the wheel rolling resistance on the load.

Fig. 1. Dependence on the wheel radius for linear a)

and point contact b)

(points show the reference values of

the rolling friction coefficients):

1

– wheel pressure restraining force;

2 – coefficient of

hysteresis losses;

3

– rolling friction

coefficient; 4

– rolling resistance coefficient

For

this, the

load

on the

wheels with

the radii

on the

wheels with

the radii

mm and

mm and

mm can

be divided

on two

wheels in

the ratio

mm can

be divided

on two

wheels in

the ratio

.

.

Dependences of the coefficients

of rolling friction, loading and rolling resistance of the wheel and

the total resistance of the wheels are shown in Fig. 2

Fig. 2. Dependences of the ratio of

the applied forces for linear

(a)

and point (b)

contacts: 1, 11,

12

– total value of the pressing force

and the force acting on

each wheel, 31,

32

– rolling friction coefficients;

4,

41,

42

– total rolling

resistance value and rolling resistance of each wheel;

lower

position of curves for wheel mm, upper for wheel

mm, upper for wheel mm.

mm.

Analytic

dependencies (6) and (7) are used to determine the coefficients

rolling friction, so it is possible to restore one lacuna in the

reference literature. Losses in roller bearings are found by the

coefficient of friction reduced to the shaft (ball ,

roller

,

roller

[2]). However, this does not take into account, which race is

rotating, inner or outer one.

[2]). However, this does not take into account, which race is

rotating, inner or outer one.

Assuming that the deviation in

the coefficient is negligible, it should be borne in mind that the

number of locally positioned bearings may be significant (conveyors,

vehicles), as well as an increase in the efficiency from 0.99 to

0.995 per ten bearings gives it an increase in more than 5%.

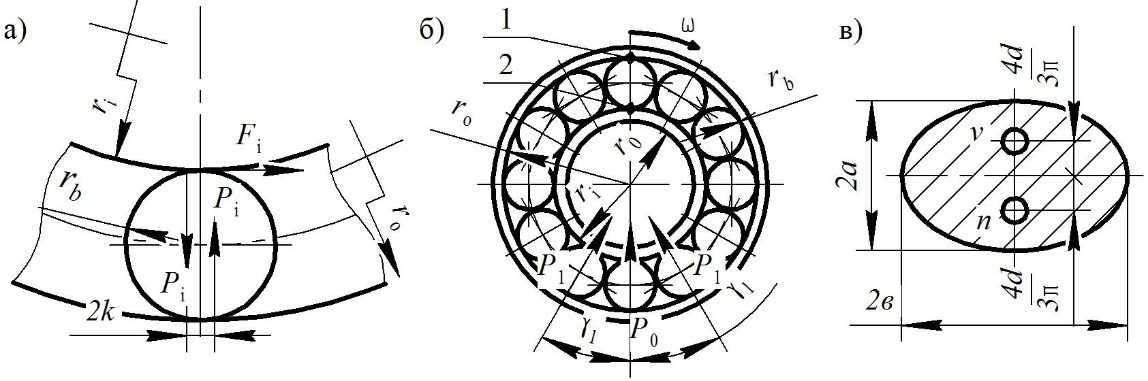

2. Ball

bearings.

The tasks

to be

clarified when

calculating

resistance:

1) To

take into

account the

difference in

the coefficients

of rolling

friction during

rolling of

the ball

on the

inner and

outer races,

since for

calculating

their size

we take

them equal, and

the tangential

force acting

on the

ball (Fig.

3, a) is

defined as

[8]

;

;

2) To take into account the

rotation of the race, since the special feature of the roller

bearings design is that the balls (rollers) pass different lines

during one revolution of the inner or outer race.

Under the

simplified scheme of the bearing, the problem is solved as follows.

If the outer race rotates at an angular velocity

(Fig. 3, b), then the speed of point 1 as the point belonging to the

outer race will equal:

(Fig. 3, b), then the speed of point 1 as the point belonging to the

outer race will equal:

, (12)

, (12)

Where o, i,

b are the letters of the indices of sizes and speed of outer, inner

races and ball;

– frequency of rotation of both inner and outer races.

– frequency of rotation of both inner and outer races.

Fig. 3. Elements of bearings: a – scheme for

determining the tangential force during

the rotation of inner

race [1], b – scheme for determining the speed

of

points of outer race and ball; c – contact pattern

Naturally,

that the instantaneous velocity center of this race is located at

point 2 of the ball touch. Assuming that there is no slip between

the outer race and the ball, then .

.

The length

of the ball rolling track on the outer race

,

and on the inner race

,

and on the inner race

and the length difference will be

and the length difference will be

,

that is, on this track there will be ball sliding on the inner race.

,

that is, on this track there will be ball sliding on the inner race.

In case of

rotation of the inner race with the fixed outer race the difference

is evident that the ball will pass the outer race track that equals

the inner race track.

is evident that the ball will pass the outer race track that equals

the inner race track.

We find the load on the balls

based on their number [8]:

. (13)

. (13)

The force acting on the most

loaded ball is:

. (14)

. (14)

For further calculations, the

radius of the ball (without rounding to the standard one) and of the

rolling bearing track will be equal [8, 9]:

;

;

.

.

For the

number of balls

the load on the bearing

the load on the bearing

(for example, if

(for example, if

)

[8]:

)

[8]:

, (15)

, (15)

where

is the angle between the balls (here

is the angle between the balls (here

).

Based on this, the load on the side balls

).

Based on this, the load on the side balls

,

,

. (16)

. (16)

The values of the half-width of

contact patterns in formulas (9) and (11) are determined from

expressions (17) and (18). When rolling the ball on the inner ring:

, (17)

, (17)

where

– is the coefficient, depending on the tangency ellipse equation

– is the coefficient, depending on the tangency ellipse equation

.

In formulas (13) – (17)

.

In formulas (13) – (17)

– outer bearing diameter;

– outer bearing diameter;

– inner bearing diameter;

– inner bearing diameter; radius of the track of the inner race.

radius of the track of the inner race.

At

for the most loaded ball, it is necessary to set optionally the

value of P,

and for the side balls

for the most loaded ball, it is necessary to set optionally the

value of P,

and for the side balls

or

or

depending on the number of balls.

depending on the number of balls.

When rolling the ball on the

outer race:

, (18)

, (18)

where

is determined as a function;

is determined as a function;

;

;

is the radius of the outer race track.

is the radius of the outer race track.

3.

Influence of resistance in bearings on wheel rolling resistance. Let

us consider two rolling bearings of one series, but of essentially

different sizes.

3.1. Ball

bearing of 304 series. Calculation

output data: bearing of 304 series,

mm,

mm,

mm, static load

mm, static load

kN, average diameter

kN, average diameter

mm,

mm,

mm, number of balls

mm, number of balls

at

at

,

,

mm;

mm;

mm;

mm;

mm.

mm.

Half-width

contact pattern of the ball, loaded with force

N, with the inner race

N, with the inner race

mm for

mm for

,

with the outer race

,

with the outer race

mm for

mm for

.

Correspondingly, the side balls loaded by force

.

Correspondingly, the side balls loaded by force

:

:

mm;

mm;

mm. Resistance to rolling of the most loaded ball: on the inner race

mm. Resistance to rolling of the most loaded ball: on the inner race

N, with the rolling friction coefficient

N, with the rolling friction coefficient

mm, on the outer race

mm, on the outer race

N with

N with

mm; two side balls on the inner race

mm; two side balls on the inner race

N with

N with

mm and

mm and

N with

N with

mm.

mm.

Let us determine the work of

the rolling friction forces during one rotation of the inner and

outer races.

During rotation of the inner

race, Nm:

; (19)

; (19)

During the

rotation of the outer race, Nm:

(20)

(20)

Thus, during

the rotation of the inner race, the rolling friction force work

during one rotation equals

Nm, in case of the outer race rotation

Nm, in case of the outer race rotation

Nm (1.55 times higher), and taking into account sliding

Nm (1.55 times higher), and taking into account sliding

Nm, that is, 6 times higher.

Nm, that is, 6 times higher.

In this

case, the value of the conditional coefficient of friction reduced

to the shaft is equal to: during the rotation of the inner race

,

for the recommended value

,

for the recommended value

,

and during the rotation of the outer race

,

and during the rotation of the outer race

.

.

3.2. Ball

bearing

of 2306 series.

Calculation output data for the

bearing of 2306 series:

mm,

mm,

mm, static load

mm, static load

kN, roller diameter

kN, roller diameter

mm, roller length

mm, roller length

mm, number of rollers

mm, number of rollers

at

at

bearing track radius on the inner race

bearing track radius on the inner race

mm, track radius on the outer race

mm, track radius on the outer race

mm.

mm.

The force acting on the most

loaded and side rollers is determined from formulas (15) and (16).

It was proved in [9] that if a

load is applied to a group of bodies according to the cosine law,

then to determine the resistance to their rolling, all loads can be

applied to one body, that is, the rolling resistance of all five

rollers on the inner race for the linear contact is determined from

the expression:

, (21)

, (21)

and on the outer race:

. (22)

. (22)

According to

formula (6), the rolling friction coefficient will be respectively

mm,

mm,

mm. The rolling resistance of rollers: on the outer race

mm. The rolling resistance of rollers: on the outer race

Н, N, and on the inner race

Н, N, and on the inner race

N.

N.

Work of rolling and sliding

friction forces on the inner and outer races, Nm:

(23)

(23)

for the

friction sliding coefficient of rollers on the inner race

.

.

The motion

resistance coefficient is: during the rotation of the inner race

,

during the rotation of the outer race

,

during the rotation of the outer race

,

for the recommended value [9] for the wheel with up to 700 mm

diameter

,

for the recommended value [9] for the wheel with up to 700 mm

diameter

.

.

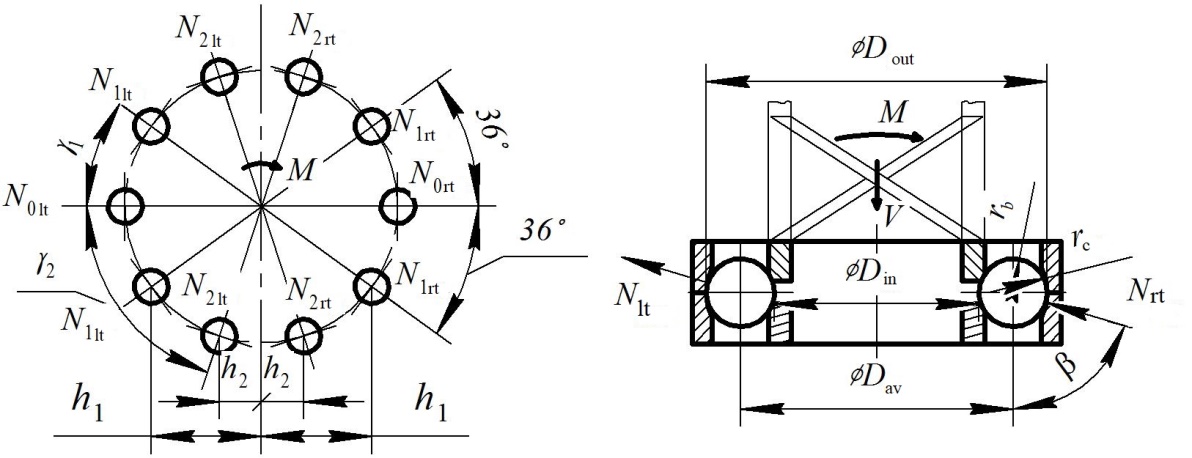

4. Ball-bearing

slewing gear (SG). The formula for

determining the greatest pressure on the ball, given in [11],

contains two unknowns: the average diameter of the rolling circle

and the number of balls.

If the first unknown can be set

on the basis of constructive considerations, then the number of

balls can be set after finding their diameters. In addition, this

formula is acceptable only if the reaction from the moment does not

go beyond the support contour.

We propose finding the moment

of the friction forces in the following sequence.

4.1. The

slewing ring is broken, for example, into 10 sectors with a central

angle

and for constructive reasons the average radius of the ball centers

is taken

and for constructive reasons the average radius of the ball centers

is taken

4.2. We apply the load to one

conditional ball in the sector, similar to the ball bearing (15), we

find the maximum vertical pressure on it from the moment, Nm:

(24)

(24)

Under

the

known

value

of

vertical

pressure

,

the

pressure

on

the

balloon

will

be:

,

the

pressure

on

the

balloon

will

be:

Nm,

(25)

Nm,

(25)

where

is

the angle between the reaction of the ball and the vertical line

(usually

is

the angle between the reaction of the ball and the vertical line

(usually

)

(Fig.

4).

)

(Fig.

4).

Maximum

pressures on conditional side balls, Nm:

(26)

(26)

4.3.

Maximum

pressure

on

the

opposite

(left)

conditional

ball:

Nm.

(27)

Nm.

(27)

The

pressure on the left conditional side balls is found in the same way

as for the right ones.

4.4.

After

the value

,

we roughly take the diameters of the ball

,

we roughly take the diameters of the ball

.

.

4.5.

We

find

the

number

of

balls

in

one

sector

with

geometric

conditions:

.

.

4.6.

Maximum

pressure

on

one

ball

of

the

right

sector

and

the

ball

radius,

based

on

Hertz

contact

pressure

for

the

track

radius

and

the

ball

radius,

based

on

Hertz

contact

pressure

for

the

track

radius

mm:

mm:

Nm,

(28)

Nm,

(28)

where

is the value depending on the ratio of tangible ellipse equation

factors

is the value depending on the ratio of tangible ellipse equation

factors

;

;

– boundary contact stresses depending on the steel grade, contact

type and Brinell-hardness; for

– boundary contact stresses depending on the steel grade, contact

type and Brinell-hardness; for

mm,

mm,

(

( ;

;

[4]).

[4]).

4.7. We find the final diameter

of the ball, while proceeding from conditions 4.4 and 4.6 and

determine the number of balls.

4.8.

Based

on the equations (25), (26), (27) and the number of balls, we

determine the pressure on one ball per sector, the rolling

resistance by the formula (7) of one of the balls of 10 sectors.

We

find the rolling resistance of

balls

and total pressure as the sum of values obtained by the

formulas (25) and (27).

balls

and total pressure as the sum of values obtained by the

formulas (25) and (27).

We find the rotational

resistance coefficient as the ratio of the total rotational

resistance to the total pressure.

Calculations

are carried out according to the following data: the greatest moment

acting on the slewing ring

kNm, the largest vertical reaction

kNm, the largest vertical reaction

kN, the average diameter of the ball centers

kN, the average diameter of the ball centers

mm (

mm ( mm).

mm).

In

this case,

the vertical

pressure from

the moment,

taking into

account the

side balls

(24) will be

kN, and

pressure on

the right

and left

conditional

balls (25) and

(27)

kN, and

pressure on

the right

and left

conditional

balls (25) and

(27)

kN,

kN,

kN. Having

taken the

ball diameter

kN. Having

taken the

ball diameter

mm and

the maximum

pressure on

one ball,

we will

have:

mm and

the maximum

pressure on

one ball,

we will

have:

kN,

kN,

where

is determined from geometric conditions

is determined from geometric conditions

.

Let us check the taken ball radius

.

Let us check the taken ball radius

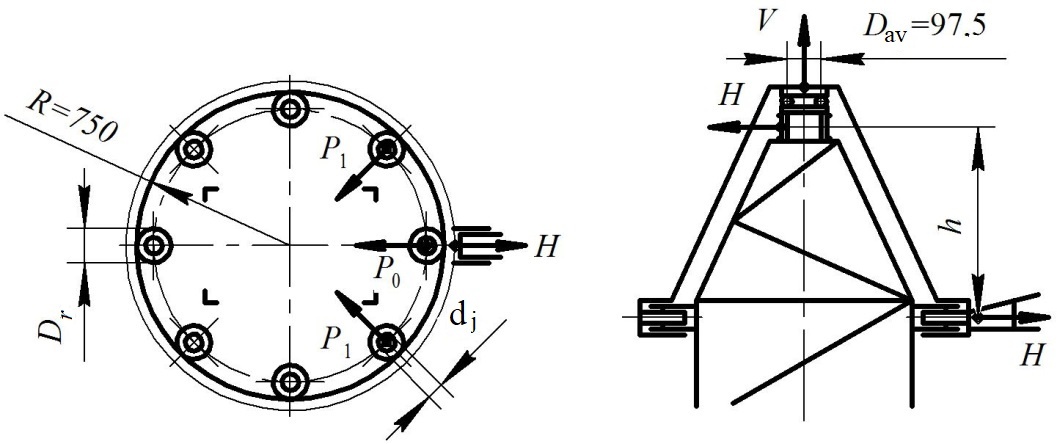

Fig.

4. Design diagram of

the ball-bearing SG

by the

theory of contact stresses provided that

:

:

Nm,

(29)

Nm,

(29)

where

mm for

mm for

MPa (surface hardened steel 45 [2]).

MPa (surface hardened steel 45 [2]).

For

taking into account the number of balls in the sector and pressure

on the conditional central and side balls (26), we find the

half-width of the contact pattern:

taking into account the number of balls in the sector and pressure

on the conditional central and side balls (26), we find the

half-width of the contact pattern:

. (30)

. (30)

The rolling

friction coefficient is determined by the formula (7), and the

rolling resistance subject to two rolling surfaces, i.e.

.

.

The distribution of pressure

per ball on the ring length and the rolling resistance of each ball

in the form of graphs are shown in Fig. 5 [5, 12-13].

When adding

all the pressures on the balls and their resistance to rolling and

disision of

kN by

kN by

kN, we obtained the value of the reduced rotational resistance of

the crane

kN, we obtained the value of the reduced rotational resistance of

the crane

that significantly exceeds the recommended value

that significantly exceeds the recommended value .

.

The reasons

for this discrepancy may be: a) irrelevance of the value adopted

here to the valid one; b) understated value

to the valid one; b) understated value

during

the experiment.

during

the experiment.

It

can be

emphasized that

in the

examples of

SG calculations,

given in

[11, 12], the

coefficient

is taken

in relation

to these

quantities, and

in [13]

is taken

in relation

to these

quantities, and

in [13] .

.

Let us find

the value of the rotational resistance coefficient, which falls on

sliding during rolling along the ring. Usually it is taken into

account only when moving along a cylinder ring. However, in the case

of ball contact with both the plane and the bearing

track, the contact pattern is not a point,

but the ellipse with the axes

and

and

the

length of which is determined from the Hertz contact deformation

formulas.

the

length of which is determined from the Hertz contact deformation

formulas.

The average

pressure per ball during its rotation by 3600

is

kN. Herewith, the minor axis of the

ellipse is

kN. Herewith, the minor axis of the

ellipse is

mm.

mm.

Concentrating

the pressure at 4 points, we find that the pressure at the points v

and n

(see Figure 3)

is

kN. In this

case, the vertical axis of the ellipse [4]:

kN. In this

case, the vertical axis of the ellipse [4]:

mm.

(31)

mm.

(31)

The distance

from these points to is

is ,

i.e.

,

i.e.

mm.

mm.

The

difference in

the distance

travelled by

one rotation

of the

ring is

mm. For

mm. For

kN,

kN,

(steel on

steel, no

lubrication),

the work

of sliding

friction forces

will be

(steel on

steel, no

lubrication),

the work

of sliding

friction forces

will be

Nm. Expressing

the work

of normal

forces

Nm. Expressing

the work

of normal

forces

through the

reduced

coefficient, we

can obtain

through the

reduced

coefficient, we

can obtain

,

wherefrom

,

wherefrom

(32)

(32)

and is about

0.01 of the recommended value of the reduced rotational resistance

coefficient of the building cranes. However, it should be borne in

mind that the denominator of the formula defining

,

includes the average radius of the ball centres

,

includes the average radius of the ball centres

The distribution of pressure per ball on the ring length and the

rolling resistance of each ball in the form of graphs are shown in

Fig. 5

The distribution of pressure per ball on the ring length and the

rolling resistance of each ball in the form of graphs are shown in

Fig. 5

Fig. 5. Distribution of

pressures per one ball and resistance to its rolling along the ring

Fig. 6. Design diagram of the slewing gear of a

construction tower crane

with fixed rollers on roller bearings,

thrust bearing and top slide journal

5.1.

Calculation of support rollers. Load

on the roller, located on the line of force

kN, the force acting on each of the two side rollers is the same and

is equal to

kN, the force acting on each of the two side rollers is the same and

is equal to

kN.

kN.

For the

roller width

mm and

mm and

MPa (steel 75, mode of operation 5M), its radius is determined from

the Hertz contact forces formula:

MPa (steel 75, mode of operation 5M), its radius is determined from

the Hertz contact forces formula:

, (33)

, (33)

it is 130 mm.

Half-width of the contact

pattern

, (34)

, (34)

and it is 1.75 mm.

Rolling

coefficient of the side roller (6)

mm, and that located on the horizontal axis

mm, and that located on the horizontal axis

mm.

mm.

Rolling resistance of three

rollers:

N.

N.

Due to the

high pressure on the rollers and the impossibility of selecting the

appropriate roller bearing, it is possible to apply in the

construction tower cranes the bearings with friction sliding

coefficient and with the journal diameter

and with the journal diameter

mm.

mm.

Friction resistance in roller

journals:

kN. (35)

kN. (35)

For the top

journal diameter

mm the sliding resistance in it

mm the sliding resistance in it

kN. (36)

kN. (36)

5.2.

Resistance in thrust bearing. According

to the value of static load on the bearing

kN we take the bearing of 8216 series with

kN we take the bearing of 8216 series with

mm,

mm,

mm, ball diameter

mm, ball diameter

mm, number of balls

mm, number of balls

,

track radius

,

track radius

mm.

mm.

When loading

one ball

kN, the half-width of the contact pattern

(11)

kN, the half-width of the contact pattern

(11) mm

mm

.

.

The rolling

friction coefficient according to formula (7) is

mm.

mm.

The rolling

resistance of 20 balls

N. The ball sliding resistance coefficient in accordance with (32)

for

N. The ball sliding resistance coefficient in accordance with (32)

for

(thick lubrication)

(thick lubrication)

and for its rolling resistance value is

and for its rolling resistance value is

N, which is about half of the rolling resistance and requires

consideration when calculating the units with thrust bearings.

N, which is about half of the rolling resistance and requires

consideration when calculating the units with thrust bearings.

The total

moment of frictional forces during the turning of a construction

crane with a fixed tower consists of the resistances:

rolling

of support rollers

771 N (20% of

the total);

– in

the roller journals 17 N (0.4% of the total);

– in

the top journal 21 N (0.5% of the total);

– in

the support roller from the rolling of balls 2 160 N (56% of the

total) and their sliding 900 N (23% of the total) for a total

rotational resistance value of 3 870 N.

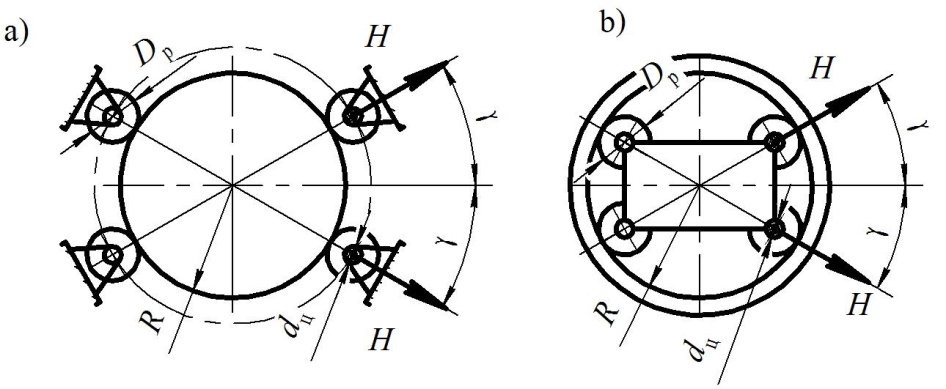

6.

Rotational resistance of SG rollers with stationary and fixed

rollers. In some construction cranes,

the support rollers are stationary (Fig. 7, a) or movable (Fig. 7,

b). Load per a roller

.

.

It is obviously that for

cylindrical rollers, the values of the maximum contact stresses will

be different, and the diameters of the rollers and their rolling

support on the slewing ring will have different values as well.

For

calculations we take the same radius, as in the previous example,

mm, the horizontal reaction is equal to

mm, the horizontal reaction is equal to

kN, the boundary contact stress is

kN, the boundary contact stress is

MPa, the roller width

MPa, the roller width

.

.

The radius

of the roller for the diagram a

(Fig. 7) can be found from formula (33), by replacing

with

with

.

According to the taken values

.

According to the taken values

mm, the journal radius is taken to be equal to

mm, the journal radius is taken to be equal to

mm for cases a

and b

(Fig. 7).

mm for cases a

and b

(Fig. 7).

The radius

of the roller for the diagram b

(Fig. 7) can be found by the same formula (33) in the case of

change of the sign under the radical to the inverse, and it will be

equal to

mm.

mm.

Half-width

of the contact patterns is found by the formula (34) with the change

of the sign to the inverse, according to the diagram b

before

(see Figure 7).

(see Figure 7).

Half-width of the contact

patterns (Fig. 7):

according to

the diagram a

mm, according to the diagram b

–

mm, according to the diagram b

–

mm;

mm;

rolling

resistances of the two rollers are respectively

N and

N and

N.

N.

The

resistance in the journals of the two rollers according to the first

and second diagrams

is

is

kN, that is more than two orders higher than the rolling resistance

of rollers.

kN, that is more than two orders higher than the rolling resistance

of rollers.

Originality

and practical value. The

paper proposes to use analytical dependences to determine the

reduced rotational resistance coefficient for linear and point

contacts using Hertz contact deformations theory and Tabor partial

analytic dependencies. The obtained dependencies will allow to

design new types of slewing gear assemblies of the construction

machines and to find additional rotational supports, which depend on

the overall dimensions, shape and type of material from which the

components of the assembly are made and do not contain any empirical

data.

Fig. 7. Design diagram of the slewing gear of cranes:

a – with stationary

rollers; b

– with moving rollers

Conclusions

The analysis of the

dependencies and graphs obtained makes it possible to draw the

following conclusions and suggestions:

rolling friction coefficient

and rolling resistance of the crane type wheels practically linearly

depends on the wheel radius, and the coefficient of hysteresis

losses linearly decreases from 0.9 to 0.6 per linear contact and

linearly increases from 1.01 to 1.06 per point contact;

the friction coefficient value

of rolling bearings, reduced to the shaft, depends on whether inner

or outer race rotates;

during the outer race rotation

on a different path, passed by a ball or a roller on the tracks of

the outer and inner races, the friction coefficient reduced to the

shaft, which falls on pure rolling, is 1.3...1.5 times higher than

its value during the inner race rotation, and taking into account

the sliding of balls or rollers on the inner race, it is 4...6 times

higher than its size in ball bearings and 3 ... 4 times higher –

in roller bearings;

due to the high value of

friction in case of outer race rotation, during the design of

rolling assemblies, it is necessary to avoid such solutions, and, if

it is impossible, to take into account this fact both for the

determination of resistance and for the lubrication of the assembly;

the given value of the

resistance of the construction crane with the ball-bearing sewing

gear is obtained analytically, is 70% higher than the one

recommended by supplier;

In case of construction cranes

with a turning tower, the greatest resistance to rotation falls on

support rollers (about 80%).

LIST OF REFERENCE LINKS

Бондаренко,

Л. М. Деформаційні опори в машинах / Л.

М. Бондаренко, М. П. Довбня, В. С. Ловєйкін.

– Дніпропетровськ : Дніпро-VAL, 2002. – 200

с.

Бондаренко,

Л. М. Уточнення розрахункової схеми

навантаження групи тіл кочення / Л. М.

Бондаренко, С. В. Ракша, М. Г. Брильова

// Підйомно-транспортна техніка. – 2005.

– № 1. – С. 47–52.

Влияние

сопротивлений качению на динамику

механизмов подъема транспортирующих

машин /

В. М. Богомаз, Л. Н. Бондаренко,

О. В. Богомаз, М. Г. Брылева // Наука та

прогрес транспорту. – 2018. – № 2 (74). –

С. 124–132. doi: 10.15802/stp2018/130441

Грузоподъёмные

машины : учебник для вузов / М. П.

Александров, Л. Н. Колобов, М. А. Лобов

[и др.]. – Москва : Машиностроение, 1986. –

400 с.

Джонсон,

К. Механика контактного взаимодействия

/ К. Джонсон. – Москва : Мир, 1989. – 510 с.

Иванов,

М. Н. Детали машин. Курсовое проектирование

/ М. Н. Иванов, В. Н. Иванов. – Москва :

Высш. школа, 1975. – 551 с.

Ковальський,

Б. С. Вопросы передвижения мостовых

кранов / Б. С. Ковальський

; Восточноукр. нац. ун-т. – Луганск

: [б. и.], 2000. – 63 с.

Кожевников,

С. Н. Теория механизмов и машин / С. Н.

Кожевников. – Москва : Машиностроение,

1969. – 584 с.

Писаренко,

Г. С. Справочник по сопротивлению

материалов / Г. С. Писаренко, А. П. Яковлев,

В. В. Матвеев. – Киев : Наук. думка,

1988. – 736 с.

Расчеты

грузоподъёмных и транспортирующих

машин / Ф. К. Иванченко, В. С. Бондарев,

Н. Т. Колесник, В. Я. Барабанов. – Киев :

Выща школа, 1975. – 520 с.

Справочник

по кранам : в 2 т. / М. П. Александров, М.

М. Гохберг, А. А. Ковин [и др.] ; под общ.

ред. М. М. Гохберга. – Ленинград

: Машиностроение, 1988. –

Т. 2. –

559 с.

Технологічні

процеси під час відновлення

опорно-обертального пристрою будівельних

кранів /

А. М. Храмцов, В. М. Богомаз,

І. М. Щека, І. Є. Крамар // Проблеми та

перспективи розвитку залізничного

транспорту : тези доп. 77 Міжнар.

наук.-практ. конф. (Дніпро, 11–12 трав.

2017 р.) / Дніпропетр. нац. ун-т залізн.

трансп. ім. акад. В. Лазаряна.

– Дніпро, 2017. – С.

315–316.

Akhavian,

R. Remote Monitoring of Dynamic Construction Processes Using

Automated Equipment Tracking / R. Akhavian, А.

Behzadan // Construction Research Congress (May 21–23, 2012). –

West Lafayette, Indiana, United States, 2012. – Р.

1360–1369. doi: 10.1061/9780784412329.137

Criteria

for the selection of sustainable onsite construction equipment / М.

Waris, M. Shahir Liew,

M. F. Khamidi, А.

Idrus // International Journal of Sustainable Built Environment. –

2014. – Vol. 3. –

Іss. 1.

– Р. 96–110. doi:

10.1016/j.ijsbe.2014.06.002

Eldredge,

K. R. The mechanism of roiling friction. I. The plastic range. II.

The elastic range / K. R. Eldredge, D. Tabor // Wear.

– 1958. – Vol. 1. – Іss.

5. – Р. 452. doi:

10.1016/0043-1648(58)90178-9

Holt,

G. Analysis of interrelationships among excavator productivity

modifying factors / G. Holt, D. Edwards // International Journal of

Productivity and Performance Management. – 2015. – Vol. 64.

– Іss. 6.

– Р. 853–869. doi:

10.1108/IJPPM-02-2014-0026

Pries,

F. Innovation in the construction industry: the dominant role of the

environment / F. Pries, F. Janszen // Construction Management and

Economics. – 1995. – Vol. 13. –

Іss. 1.

– Р. 43–51.

doi :

10.1080/01446199500000006

Slemenmeyer,

H. Bearings for large capacity crane applications / H. Slemenmeyer,

S. Aaronson // SAE Technical Paper Series. – 1983. doi:

10.4271/831373

Su,

X. Improving Construction Equipment Operation Safety from a

Human-centered Perspective / Х. Su,

J.

Pan, М. Grinter // Procedia Engineering.

– 2015. – Vol. 118. – Р. 290–295.

doi: 10.1016/j.proeng.2015.08.429

Takahashi,

H. Measurement of the rolling element load distribution in turntable

bearings / H. Takahashi,

H. Omary // SAE Technical Paper Series.

– 1985. doi: 10.4271/850762

Yip,

H. Predicting the maintenance cost of construction equipment:

Comparison between general regression neural network and Box–Jenkins

time series models / Н. Yip, H. Fan, Y.

Chiang // Automation in Construction. – 2014. – Vol. 38. – Р.

30–38. doi: 10.1016/j.autcon.2013.10.024

Л. М. Бондаренко1,

О. П. ПосмітюхА2*,

К. Ц. Главацький3.

1Каф. «Прикладна

механіка та матеріалознавство»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38(056)3731518,

ел. пошта

bondarenko-l-m2015@yandex.ua,

ORCID 0000-0002-2212-3058

2*Каф. «Прикладна

механіка та матеріалознавство»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38 (066) 150 95 00,

ел. пошта

AleksandrP@3g.ua, ORCID

0000-0002-9701-3873

3Каф. «Прикладна

механіка та матеріалознавство»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38 (095) 816 99 90,

ел. пошта kazimir.glavatskij@gmail.com

, ORCID

0000-0003-0921-9845

АНАЛІТИЧНЕ ВИЗНАЧЕННЯ ПРИВЕДЕНОГО

КОЕФІЦІЄНТА ОПОРУ

ОБЕРТАННЮ МЕХАНІЗМІВ

ПОВОРОТУ БУДІВЕЛЬНИХ МАШИН

Мета.

Проектування нових зразків будівельних

машин тісно пов’язане з розробкою

механізмів повороту, а ті, в свою чергу,

мають привід, потужність та габарити

якого залежать від опору повороту та

приведеного коефіцієнта тертя у вузлах.

Відсутність аналітичних залежностей

для визначення приведеного коефіцієнта

тертя обертанню будівельних машин,

по-перше, обмежує можливості конструктора

у виборі матеріалів, а по-друге, не

дає можливості приймати оптимальні

конструктивні рішення. Тому мета статті

– знайти аналітичні рішення для

визначення опорів обертанню в механізмах

повороту будівельних машин, що дозволяє

проектувати досконаліші механізми й

машини у цілому. Існуючі методики

спираються на емпіричні залежності та

експериментальні коефіцієнти, що

зменшують точність підрахунків,

збільшують габарити та вартість робіт.

Пропонується підвищити точність та

спростити процес визначення опору

повороту й величину приведеного

коефіцієнта опору обертанню будівельних

баштових кранів.

Методика. Досягти

поставленої мети можна за допомогою

аналітичних залежностей для визначення

коефіцієнтів тертя кочення за лінійного

й точкового контактів. Це дозволить

точніше знайти величину коефіцієнта

опору, а конструктору під час розрахунків

вжити цілеспрямованих заходів щодо

його зменшення, використовуючи механічні

константи матеріалів вузлів кочення

і їх геометричні параметри. Розрахунок

ґрунтується на теорії контактних

деформацій Герца й теорії плоского

руху точок тіла. Результати.

Отримані залежності дозволять аналітично

знайти опір кочення роликів у будівельних

машинах із нерухомою й обертовою

колонами, із круговими поворотними

пристроями, а також у кулькових і

роликових опорно-поворотних кругах.

З’ясовані значення коефіцієнтів опору

обертанню для деяких їх типів механізмів

дають близькі значення з рекомендованими,

а для деяких – істотно відрізняються

і вимагають їх уточнення у довідкових

величинах. Наукова

новизна роботи полягає

у використанні аналітичних залежностей

для визначення приведеного коефіцієнта

опору обертанню за лінійного і точкового

контактів із використанням теорії

контактних деформацій Герца та частково

аналітичних залежностей Табора.

Практична значимість.

Отримані залежності дозволять проектувати

нові типи вузлів обертання механізмів

повороту будівельних машин і виявляти

додаткові опори обертанню.

Ключові слова: будівельна

машина; опір; обертання; поворот;

поворотний круг; рейка; тертя кочення

Л. Н. Бондаренко1,

А. П. ПосмИтюхА2*,

К. Ц. Главацкий3

1Каф. «Прикладная

механика и материаловедение», Днипровский

национальный университет железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (056) 373-15-18,

эл. почта

bondarenko-l-m2015@yandex.ua,

ORCID 0000-0002-2212-3058

2*Каф. «Прикладная

механика и материаловедение», Днипровский

национальный университет железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (066) 150 95 00,

эл. почта AleksandrP@3g.ua,

ORCID 0000-0002-9701-3873

3Каф. «Прикладная

механика и материаловедение», Днипровский

национальный университет железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (095) 816 99 90,

эл. почта

kazimir.glavatskij@gmail.com, ORCID

0000-0003-0921-9845

АНАЛИТИЧЕСКОЕ ОПРЕДЕЛЕНИЕ приведенного

коэффициента

сопротивления вращению

механизмов поворота

СТРОИТЕЛЬНЫХ МАШИН

Цель. Проектирование

новых образцов строительных машин

тесно связано с разработкой механизмов

поворота, а те, в свою очередь, имеют

привод, мощность и габариты которого

зависят от сопротивления поворота и

приведенного коэффициент трения в

узлах. Отсутствие аналитических

зависимостей для определения приведенного

коэффициента трения вращению строительных

машин, во-первых, ограничивает возможности

конструктора в выборе материалов, а

во-вторых, не дает возможности принимать

оптимальные конструктивные решения.

Поэтому цель статьи – найти аналитические

решения для определения сопротивлений

вращению в механизмах поворота

строительных машин, которые позволят

проектировать более совершенные

механизмы и машины в целом. Существующие

методики опираются на эмпирические

зависимости и экспериментальные

коэффициенты, уменьшающие точность

подсчетов, увеличивающие габариты и

стоимость работ. Предлагается повысить

точность и упростить процесс определения

сопротивления поворота и величину

приведенного коэффициента сопротивления

вращению строительных башенных кранов.

Методика.

Достичь поставленной цели можно с

помощью аналитических зависимостей

для определения коэффициентов трения

качения при линейном и точечном

контактах. Это позволит точнее найти

величину коэффициента сопротивления,

а конструктору при расчетах принять

целенаправленные меры по его уменьшению,

используя механические константы

материалов узлов качения и их

геометрические параметры. Расчет

основывается на теории контактных

деформаций Герца и теории плоского

движения точек тела. Результаты.

Полученные зависимости позволят

аналитически найти сопротивление

качению роликов в строительных машинах

с неподвижной и вращающейся колоннами,

с круговыми поворотными устройствами,

а также в шариковых и роликовых

опорно-поворотных кругах. Найденные

значения коэффициентов сопротивления

вращению для некоторых типов механизмов

дают близкие значения с рекомендованными,

а для некоторых – существенно отличаются

и требуют их уточнения в справочных

величинах. Научная

новизна работы

заключается в использовании аналитических

зависимостей для определения приведенного

коэффициента сопротивления вращению

для линейного и точечного контактов с

использованием теории контактных

деформаций Герца и частично аналитических

зависимостей Табора. Практическая

значимость. Полученные

зависимости позволят проектировать

новые типы узлов вращения механизмов

поворота строительных машин и выявлять

дополнительные опоры вращению.

Ключевые слова: строительная

машина; сопротивление; вращения; поворот;

поворотный круг; рельс; трение качения

REFERENCES

Bondarenko,

L. M., Dovbnia, M. P., & Loveikin, V. S. (2002).

Deformatsiini opory v mashynakh.

Dni-propetrovsk: Dnipro-VAL. (in

Ukrainian)

Bondarenko,

L. M., Raksha, S. V., & Brylova, M. H. (2005). Utochnennia

rozrakhunkovoi skhemy navantazhennia hrupy til kochennia.

Pidiomno-transportna tekhnika, 1, 47-52. (in

Ukrainian)

Bohomaz,

V. M., Bondarenko, L. M., Bohomaz, O. V., & Brylyova, M. G.

(2018). Effect of resistance to rolling on the dynamics of the

lifting mechanisms of the transporting mac. Science and

Transport Progress. 2(74), 124-132.

doi: 10.15802/stp2018/130441 (in

Russian)

Aleksandrov,

M. P., Kolоbov,

L. N., Lobov,

M. A.

Nikolskaya, T.

A., & Polkovnikov,

V. S. (1986).

Gruzopodemnye mashiny: Uchebnik dlya vuzov. Moscow:

Mashinostroenie. (in

Russian)

Dzhonson,

K. (1989). Mekhanika kontaktnogo

vzaimodeystviya. Moscow: Mir.

(in Russian)

Ivanov,

M. N., & Ivanov, V. N. (1975).

Detali mashin. Kursovoe proektirovanie.

Moscow: Vysshaya

shkola. (in

Russian)

Kovalskiy,

B. S. (2000). Voprosy peredvizheniya

mostovykh kranov. Lugansk. (in

Russian)

Kozhevnikov,

S. N. (1969). Teoriya mekhanizmov i

mashin. Moscow:

Mashinostroenie. (in

Russian)

Pisarenko,

G. S., Yakovlev, A. P., & Matveev, V. V. (1988). Spravochnik

po soprotivleniyu materialov. Kiev:

Naukova dumka. (in

Russian)

Ivanchenko,

F. K., Bondarev, V. S., Kolesnik, N. P., & Barabanov, V. Y.

(1975). Raschety gruzopodemnykh i

transportiruyushchikh mashin. Kiev:

Vishcha shkola. (in

Russian)

Aleksandrov,

M. P., Gokhberg, M. M., Kovin, A. A., & Gokhberg, M. M. (Ed).

(1988). Spravochnik po

kranam

(Vol. 1-2). Leningrad:

Mashinostroenie. (in

Russian)

Khramtsov,

A. M., Bohomaz, V. M., Shcheka, I. M., & Kramar, I. Y. (2017).

Tekhnolohichni protsesy pid chas vidnovlennia oporno-obertalnoho

prystroiu budivelnykh kraniv.

The Problems and

Prospects of railway transport: 77th

International scientific and practical conference.

Dnipro:

Dnipropetrovsk National

University of Railway Transport named after Academician V.

Lazaryan. (in Ukrainian)

Akhavian,

R., & Behzadan, A. H. (2012). Remote Monitoring of Dynamic

Construction Processes Using Automated Equipment Tracking.

Construction Research Congress 2012.

West Lafayette, Indiana, United States.

doi: 10.1061/9780784412329.137 (in English)

Waris,

M., Shahir Liew, M., Khamidi, M. F., & Idrus, A. (2014).

Criteria for the selection of sustainable onsite construction

equipment. International Journal of

Sustainable Built Environment, 3(1),

96-110. doi: 10.1016/j.ijsbe.2014.06.002 (in English)

Eldredge,

K. R., & Tabor, D. (1958). The mechanism of rolling friction.

I. The plastic range. II. The elastic range. Wear,

1(5), 452.

doi: 10.1016/0043-1648(58)90178-9 (in English)

Holt,

G. D., & Edwards, D. (2015). Analysis of interrelationships

among excavator productivity modifying factors.

International Journal of Productivity and Performance Management,

64(6), 853-869.

doi: 10.1108/ijppm-02-2014-0026 (in English)

Pries,

F., & Janszen, F. (1995). Innovation in the construction

industry: the dominant role of the environment. Construction

Management and Economics, 13(1), 43-51.

doi: 10.1080/01446199500000006 (in English)

Siemensmeyer,

H., & Aaronson, S. F. (1983). Bearings for Large Capacity Crane

Applications. SAE Technical Paper Series. doi:

10.4271/831373 (in English)

Su,

X., Pan, J., & Grinter, M. (2015). Improving Construction

Equipment Operation Safety from a Human-centered Perspective.

Procedia Engineering, 118, 290-295.

doi: 10.1016/j.proeng.2015.08.429 (in

English)

Takahashi,

H., & Omory, T. (1985). Measurement of the Rolling Element Load

Distribution in Turntable Bearings. SAE Technical Paper

Series. doi: 10.4271/850762 (in

English)

Yip,

H., Fan, H., & Chiang, Y. (2014). Predicting the maintenance

cost of construction equipment: Comparison between general

regression neural network and Box–Jenkins time series models.

Automation in Construction, 38, 30-38.

doi: 10.1016/j.autcon.2013.10.024 (in

English)

Received:

Sep. 06, 2018

Accepted:

Jan. 16, 2019

, (2)

– half-width of the contact pattern;

– coefficient of hysteresis losses.

nullifies their practical application.

,

namely:

and

,

that essentially differ from those offered by Tabor, and the absence

of their coefficient of hysteresis losses testifies to their

inaccuracy.

,

(3)

,

(4)

– wheel radius, m.

in experiments to ten millimeters, as well as to the fact that their

values are obtained the same for several wheel diameters (400, 500,

560, 630):

mm in the case of a flat champignon rail and

mm for the bull-headed rail).

for such a class of problems can be considered close by value, we

will assume that the general values of

in these formulas coincide. Having considered that the coefficients

before

in Tabor's formulas are obtained analytically and are exact, the

value of

can be found by changing the coefficients before

in the exponents. This equality can be achieved by taking the

following values

in formulas (1) and (2):

and

.

(5)

, (6)

. (7)

in Tabor formulas is small. We can use formula (5) for its

determination and (6), (7) for determination of the resistance.

MPa (steel 65G, crane operating mode 4M [11]), the elastic modulus

MPa, the Poisson factor is 0.3.

[4]

, (8)

, (9)

–

wheel width, m; while the rolling friction coefficient can be

determined by the formula (6).

MPa, the radius of the bull-head rail

mm. Similarly to the formulas (8) and (9) we can determine the

values for the point contact

, (10)

, (11)

– coefficient

depending on

the tangent

ellipse equation

coefficient

;

– rail rounding radius.