ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2019,

№ 1

(79)

рухомий

склад і тяга поїздів

UDC

629.463.65.015:625.1.032

A.

O. shvets1*,

О. О. BOLOTOV2*

1*Dep.

«Theoretical and Structural Mechanics», Dnipro National University

of Railway Transport

named after Academician V. Lazaryan,

Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. +38 (050) 214 14 19,

e-mail angela_Shvets@ua.fm, ORCID 0000-0002-5537-6617

2*BRL

DSRS, Dnipro National University of Railway Transport named after

Academician V. Lazaryan,

Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. +38 (097) 977 57 08, e-mail bolaks@i.ua,

ORCID

0000-0002-0807-0340

INFLUENCE

OF LOADing FROM

THE AXLE OF a

gondola

car ON ITS DYNAMIC INDICATORS AND

railway track

Purpose.

Increasing the maximum loading from the car axle on the rails during

transportation of goods and the speed of movement of railway vehicles

will enhance the integration processes between the countries. In

order to ensure safe and reliable traffic at the railways it is

necessary to improve control, quantitative evaluation of the dynamic

loading of the rolling stock, which in the process of its operation

is a relevant scientific and technical problem. The purpose of this

work is to study the influence of the axle loading increase in

gondola cars, taking into account the possible speed increase on

their main dynamic indicators and indicators of interaction of

rolling stock and track. Methodology.

The study was carried out by the method of mathematical and computer

simulation of the dynamic loading of a gondola car using the model of

spatial oscillations of the coupling of five cars and the software

complex developed in the branch research laboratory of the dynamics

and strength of rolling stock (BRL DSRS).

The initial data for research are as follows: the movement of gondola

car of the model 12-532 with typical bogies of 18-100 at the speeds

ranging from 50 to 90 km/h in curves with radii of 350 and 600 m,

with superelevation of 130 and 120 mm, respectively. Findings.

The article analyzes the dynamic qualities of a rolling stock

using the example of gondola cars, the calculations are performed

using the package of applied programs with sufficient accuracy for

practice. During the theoretical studies and simulation, taking into

account the processes of freight car oscillation in case of

increasing the axle loading, the dependences of the main dynamic

parameters, taking into account the movement speed were obtained.

Originality. Originality of the work results lies in the study

of the influence of increasing the axle loading in gondola cars,

taking into account the possible movement speed increase on the

dynamic loading in order to solve the problem of forecasting the

rolling stock dynamics. The results of theoretical studies, taking

into account the movement speed in the curved track sections of small

and medium radius were obtained for the first time. Practical

value. The application of these results will contribute to

improving the traffic safety of freight cars and will improve the

technical and economic performance of railway transport.

Keywords:

cargo; gondola cars; dynamic indicators; curved track sections; axle

loading; interaction indicators; rolling stock and track;

gravity center; movement speed

Introduction

In accordance with the

established rules of loading, placing and fastening of cargoes in

cars should ensure: movement and operation safety of railway

transport; possibility of mechanization of loading and unloading

works; preservation of goods and cars.

In addition,

one of the main indicators of the efficiency of the car fleet

operation is the duration of the loading and unloading operations,

which depends on the fitting of freight points at the railway

stations and industrial enterprises with modern means of

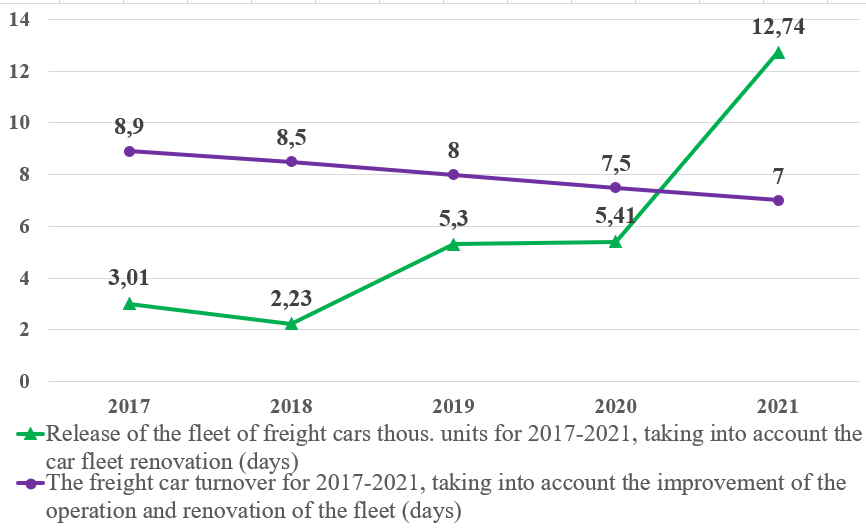

mechanization. The planned reduction of the freight car turnover in

2017-2021, taking into account the improvement of the operation and

re-novation of the car fleet, is presented in Fig. 1 [3].

Fig.

1. Reduction of the freight car turnover

Due to the introduction of new

equipment for loading and unloading operations, it is possible to

reduce the level of car idle and to minimize it in future (Fig. 2).

Fig.

2. Automated system of the dose loading of broken stone in

cars

For example, the automated

system of dose loading of broken stone in cars provides [1]:

– dose

loading of railway cars;

– uniform

loading of cars along the length;

– the

exclusion of time and labor costs arising from inadequate loading of

cars;

– automated

shipping accounting with print output of information and automated

control system of enterprise.

Safety performance during

transportation of bulk cargo of open storage in accordance with the

requirements of the Rules for the transportation of bulk cargo and

the Rules for the transportation of goods in open cars remains the

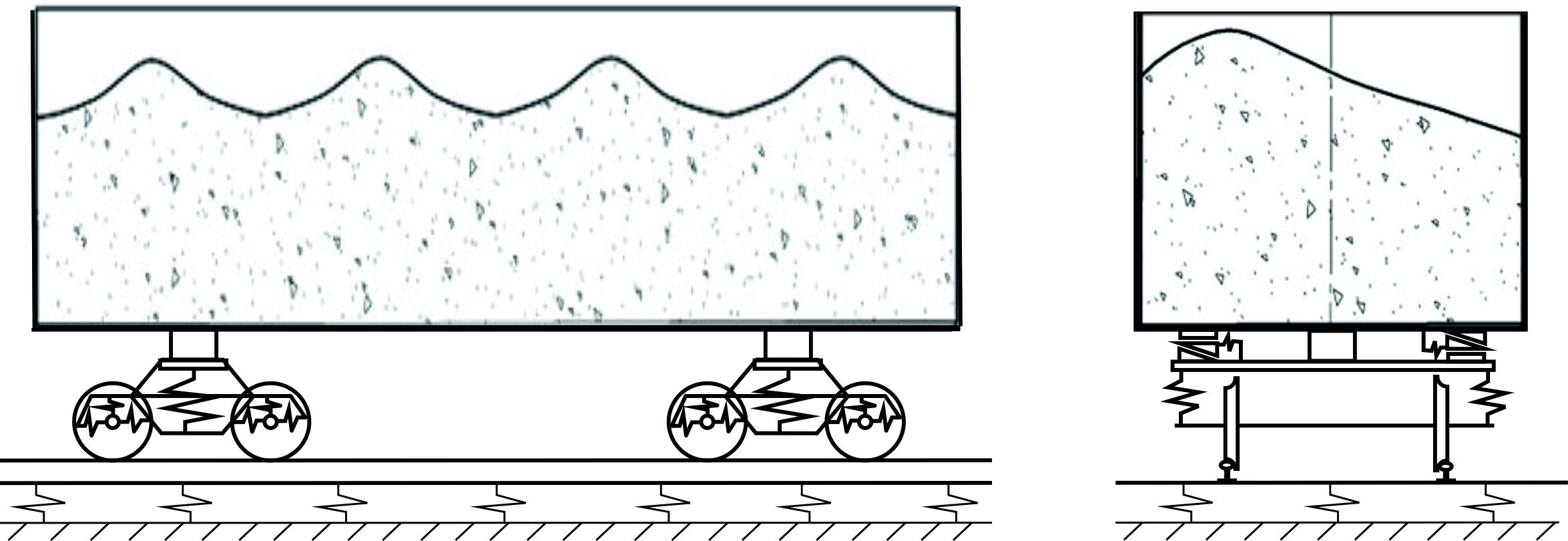

main task of the transport industry enterprises. As it is known,

depending on the method of loading the gondola cars with bulk cargo,

the form of cargo inequalities may be different (Fig. 3). In

accordance with clause 5 of the Rules for the transportation of

goods in open cars, one should in all cases level the cargo surface

[9, 12, 13].

а

b

Fig.

3. The

form of cargo inequality:

а

–

longitudinal;

b

–

transverse

In order to level the cargo, the

most often nonmechanized method is used, which affects the idle

increase of gondola cars under freight operations, as well as

increase of the total transportation cost. In addition, manual

leveling can lead to accidents involving the risk of person`s

falling from height.

The leveling construction (Fig.

4) should allow the leveling of the bulk cargo, regardless of the

form of its position in the gondola car. The proposed designs of

rotary and screw device for the mechanization of bulk cargo leveling

in gondola cars have no analogues in domestic and world practice

[9].

Fig. 4. The device

for bulk cargo leveling

in gondola cars of the UkrDURT system

Each of them has its advantages

and disadvantages, namely:

– rotary

leveler has a lower mass and a significantly lower cost, but it can

only work with cargoes of relatively small bulk density and

satisfactory flowability;

– screw

leveler, which has greater material consumption and price, makes it

possible to mechanize the leveling of heavy cargoes with bad

flowability.

In addition, the loading should

be carried out in accordance with the current technical

specifications. Determination of the displacement of the load

gravity center relative to the railway car symmetry axes using the

car scales (Figure 5) allows us to quickly detect dangerous

deviations in the car stability and thus significantly increase

safety during the train movement [4].

Where it is necessary to reduce

the labour intensity, minimize the influence of human factor, reduce

the time spent for the inspection of cars, the appropriate solution

is to automatically scan and check the contents of cars involving

operator only in the case of alarm signals from the control system.

Fig. 5.

Computerized car scales for weighing

in static mode

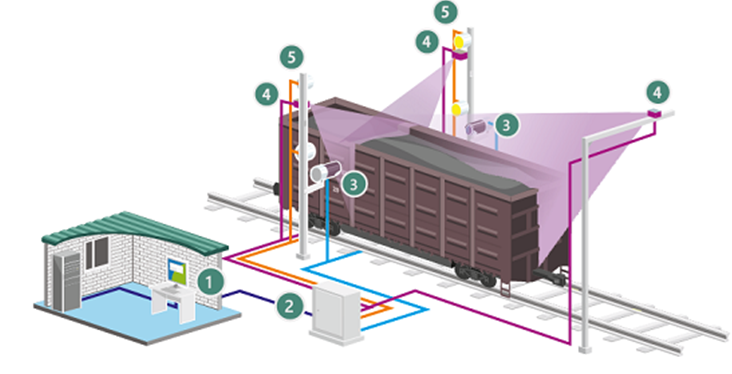

The hardware-software complex

for controlling the car loading is intended for automatic 3D

scanning of gondola cars when moving in order to evaluate the level

of car volume loading, the uniformity of cargo distribution, cargo

volume, detect foreign objects, as well as for other functions in

the interests of production services, logistics and safety (Fig. 6)

[2].

Fig. 6.

Hardware-software complex for controlling the car loading:

1

– computer with ARSCIS.Scanner software; 2

–ARSCIS.Scanner box; 3

– video cameras for detection;

4

– scanner of dimensions; 5

– spotlights

Automation of visual control of

the car contents provides:

– reducing

the time and labor cost for car control operations;

– minimization

of human factor influence;

– safety

improvement of the railway freight transportations;

– reduction

of losses due to underloading/overloading of cars;

– products

thievery prevention by railway transport.

The main functions of the

hardware and software complex are as follows:

– car and

cargo scanning using industrial laser sensors;

– construction

of a three-dimensional model of the car (and its contents) and its

analysis;

– determining

the level of car loading;

– detection

of foreign objects in an empty car;

– control

of the distribution evenness of bulk cargo in a car;

– cargo

volume evaluation in a car;

– detection

of loading errors (overloading, underloading, unevenness).

The leading domestic developer

of unloading systems for unloading bulk cargoes from the railway

transport and the largest producer of technological equipment, which

is the part of unloading complexes, is Dniprovazhmash PJSC (Fig. 7)

[15].

Fig.

7. Stationary rotary car dumper

VRS-93, VRS-93-110

Stationary

rotary car dumpers, which are produced by Dniprovazhmash PJSC, are

intended for unloading of gondola cars with bulk cargo with carrying

capacity

t by means of gondola cars overturning in a rotary car dumper.

t by means of gondola cars overturning in a rotary car dumper.

Composite application of modern

innovative technologies in railway transport will allow the

preservation of cars, reducing their idle time, releasing a

significant number of workers from heavy manual operations and

obtaining significant economic benefits.

Purpose

The State Administration of

Railway Transport of Ukraine established the maximum loading from

the car axle on the rails when transporting the freights destinated

to individual European countries and border crossings along the

track 1520 mm from 20 to 24.5 tons by the telegram dated November 7,

2011, No. CZM-12/2074 according to the Minutes of the meetings on

the harmonization of the volumes of the transportation conditions.

Increasing the permissible

loading on the car axle, with simultaneous increase in the speed of

the railway vehicles, will strengthen the integration processes with

the countries of Europe and Asia. The application of modern railway

innovative technologies described above makes it possible to

increase axle loading, but leads to the need for improved control,

quantitative evaluation of the dynamic loading of rolling stock to

ensure safe and reliable connection at the railways.

The limit axle loading for

freight cars of 23.5 tons per axle was taken into account as one of

the main prerequisites for determining the permissible speeds of

rolling stock, the order and terms for the designation of repair and

track works and labor standards for maintenance of the track and

artificial structures. Increasing the axle loading, in turn, leads

to the failure rate increase of the rails due to defects of

contact-fatigue nature and the deterioration of the track condition.

Therefore, in the design process of rolling stock quantitative

evaluation of dynamic loadings is a relevant scientific and

technical problem [5, 14, 18–22].

The article is aimed to study

the influence of increasing the axle loading in gondola cars, taking

into account the possible increase in the movement speed on their

main dynamic indicators and interaction indicators of track and

rolling stock.

Methodology

During operation of trains,

primarily the ones with increased length and weight, particular

attention is paid to the evaluation of the dynamic performance of

vehicles, among which the most important is the indicator

characterizing the traffic safety of a vehicle – the stability

coefficient against derailment. For this purpose, the mathematical

models of spatial oscillations of the car (or group of cars) moving

in a train are used.

The models of rolling stock, as

a rule, represent the variations of the system of differential

equations in the second-order partial derivatives compiled according

to the Lagrange–d'Alembert principle, which correspond to the set

task. Using such models, the problem can be found analytically.

Mathematical modeling makes it possible to determine the dynamic

parameters of cars during their movement in straight and curved

track sections with real irregularities in the vertical and

horizontal planes, taking into account the actual wheel thread and

the rail head profile [6, 11, 16, 17].

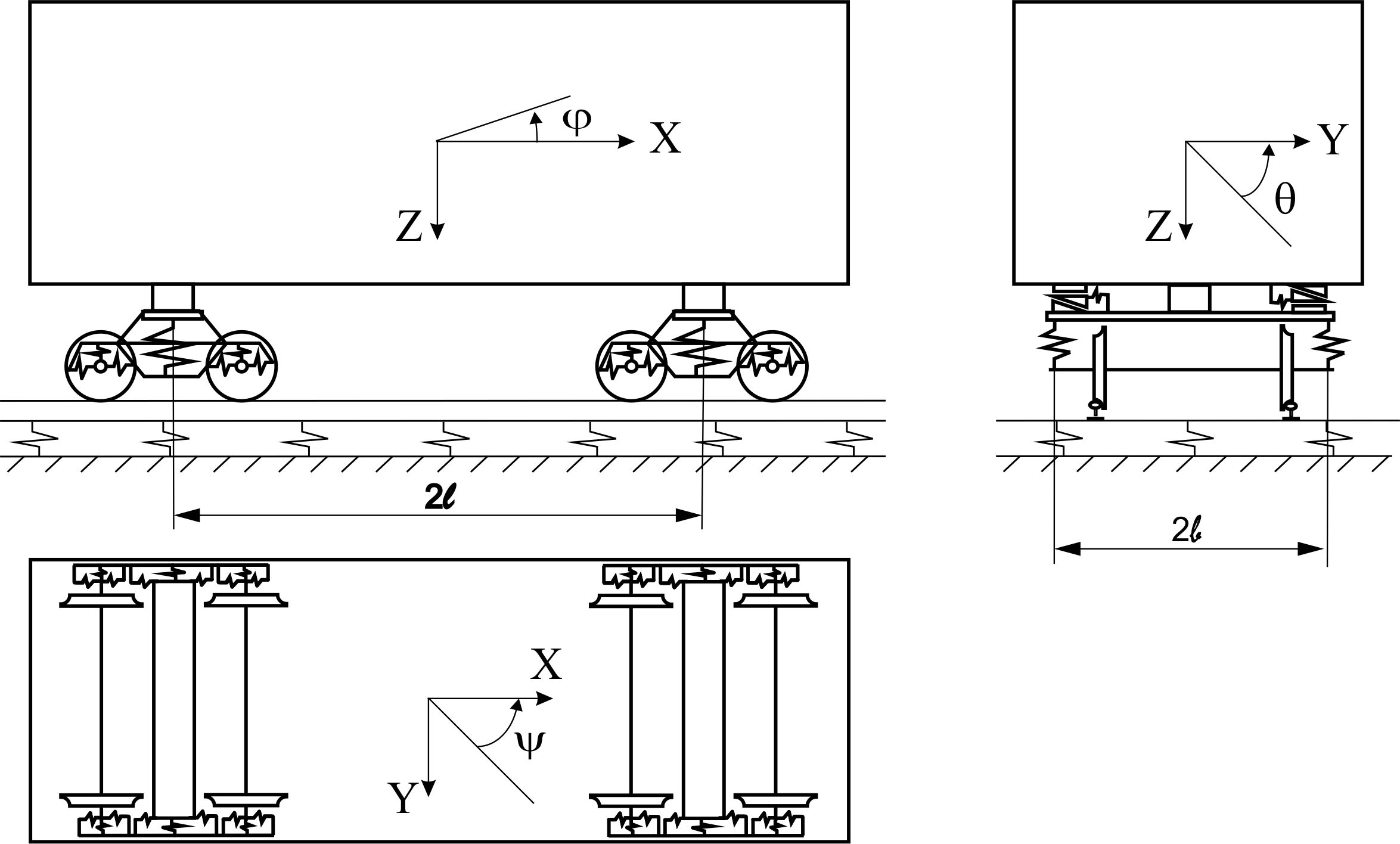

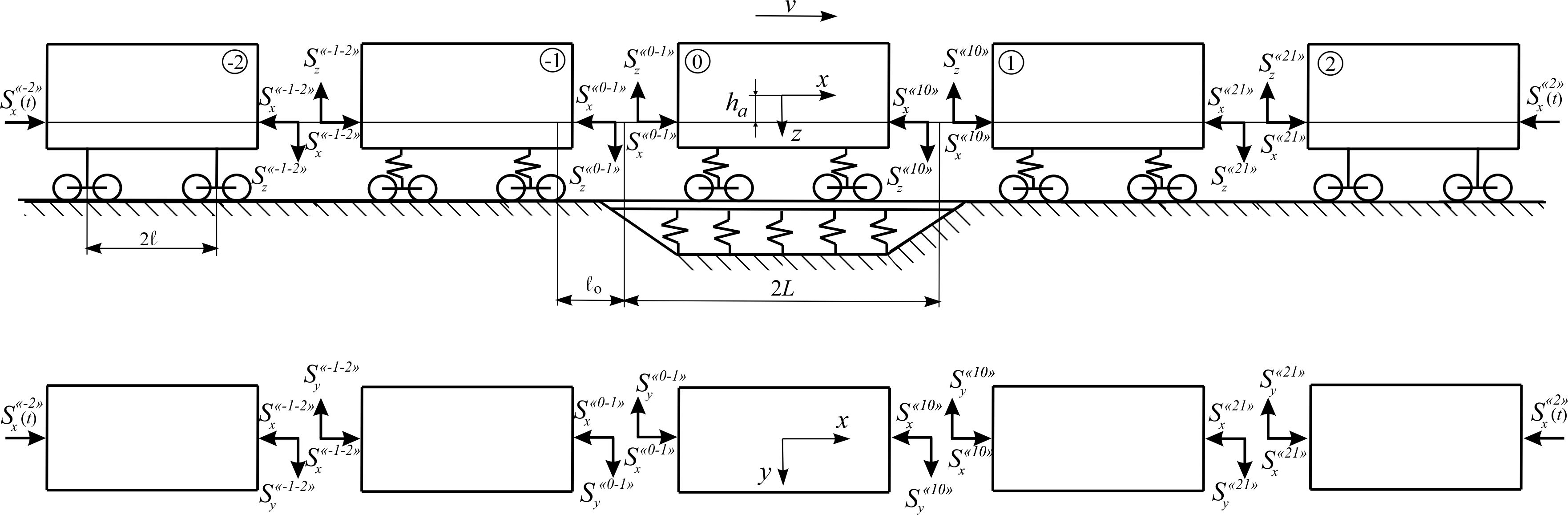

The oscillations of a single car

and its interaction with the rail track are considered using quite

full calculation schemes. Fig. 8 shows the calculation scheme of the

freight car and shows positive directions for all displacements and

rotation angles, and the designation of the system bodies are given

in Table 1.

Fig. 8. Calculation

scheme of 4-axle gondola car

Table

1

System

bodies and their displacements

|

System

bodies

|

Displacement

|

|

Linear

along the axes

|

Angle

along the axes

|

|

|

|

|

|

|

|

|

Body

|

|

|

|

|

|

|

|

Bolsters

|

|

|

|

|

|

|

|

Side

frames

|

|

|

|

|

|

|

|

Wheel

sets

|

|

|

|

|

|

|

|

Rails

|

–

|

|

|

–

|

–

|

–

|

In Table 1

the displacements of the gravity center of the body along the

corresponding axes are indicated by

,

,

and

and

,

and rotation angles of the body relative to the main central inertia

axes – by

,

and rotation angles of the body relative to the main central inertia

axes – by

,

,

,

,

.

Similar bolster displacements are provided by the index

.

Similar bolster displacements are provided by the index

(

( bogie number), side frames – by the index

bogie number), side frames – by the index

(.

(. .–

left,

.–

left,

right side of a car), wheel sets – by the index

right side of a car), wheel sets – by the index

(

( – number of wheel set in a bogie), rails at the contact points

with the wheels

– number of wheel set in a bogie), rails at the contact points

with the wheels

(rail displacements are provided only in two directions – along

the axes

(rail displacements are provided only in two directions – along

the axes

and

and

).

Displacements of the wheels are indicated by the index

).

Displacements of the wheels are indicated by the index

.

.

The work [6] proposes a

mathematical model describing the spatial oscillations of the car

coupling in a train (Fig. 2), one rail carriage of which is

considered according to the fullest calculation scheme (called

"zero"), and the calculation schemes of neighboring cars,

depending on the task setting, are simplified as further is the

distance from the "zero" carriage on both sides.

A mechanical

system with 58 degrees of freedom is taken as a calculation scheme

of the "zero" carriage. The following values are taken as

generalized coordinates:

(n=6, 7),

(n=6, 7),

(n=8, 9),

(n=8, 9),

(

( ),

),

(

( ),

),

(

( ),

),

(

( ),

),

(

( ),

),

(

( ),

),

(

( ),

),

(

( ),

),

(

( ),

),

(

( ),

),

(

( ),

),

.

.

The cars, adjacent to the "zero"

one, are represented by a system with 12 degrees of freedom. In the

calculation schemes describing the oscillations of these cars, the

main features of freight car bogies are preserved – the side

frames lozenging.

Fig.

9. The forces arising from the action

of longitudinal forces in

the auto-couplings of cars

During the

study of spatial oscillations of cars adjacent to the "zero"

one, considered by the simplified calculation scheme, the following

assumptions are introduced. It is assumed that the cars have

single-stage spring suspension. Each of them consists of eleven

solid bodies: a body, two bolsters, four side frames of the bogie

and four wheel sets. Unlike "zero" car, the track under

adjacent cars is considered to be absolutely rigid in the vertical

direction and elastic in the horizontal transverse direction. This

assumption does not lead to increase in the number of degrees of

freedom, since the speed of rails displacement in the expressions

for transverse forces can be neglected.

The following

values are taken as the generalized coordinates for these cars:

,

,

,

,

,

,

where

;

;

– for the «first» and «minus first» cars correspondingly.

– for the «first» and «minus first» cars correspondingly.

Outer cars of

coupling, which by analogy we call «second» and «minus second»,

are considered using even more simplified scheme than the «first»

and «minus first» cars. In «second» and «minus second» cars we

will take into account only oscillations of bodies, that is, these

cars are the systems with six degrees of freedom:

,

,

where

– for the «second» and «minus second» cars, correspondingly.

– for the «second» and «minus second» cars, correspondingly.

As it is known, the traffic

safety of trains and preservation of the transported cargoes depend

directly on the method of placement and fastening of cargoes.

Particular attention is paid to the center of gravity. For stability

and safety of transportation, the bulk cargoes in the gondola car

bodies should be fully leveled, so that the load on the bogies would

be the same and the gravity center is at the intersection of the

central longitudinal and transverse lines.

The complement of the

mathematical models of spatial oscillations by the initial data with

the spe-cified inertial characteristics of the car and cargo

elements makes it possible to approximate the results of

calculations to the real state of objects and thereby increase the

objectivity of mathematical and computer simulation [11, 16, 17].

Different

variants of the axle loading of a car in the range from 21.4 tons to

24.5 tons per axle are considered. Initial calculations were made

with the axle loading of 21.4 tons per axle. The increase in the

axle loading was supposed to be achieved by increasing the load mass

in the body, subject to its uniform distribution. In this case, the

weight of the cars, the inertia moments

,

,

,

,

and the height of the mass center of the body

and the height of the mass center of the body

above the level of rail heads vary. The preparatory calculations

using the "Software complex for determining the inertia moments

of the car bodies" were carried out. They are given in Table 2

[17].

above the level of rail heads vary. The preparatory calculations

using the "Software complex for determining the inertia moments

of the car bodies" were carried out. They are given in Table 2

[17].

Table 2

Inertia

and mass characteristics

of the gondola car during increased

loading from the car axle on the rails

|

,

t ,

t

|

,

t ,

t

|

,

t ,

t

|

Inertia

moments,

|

,

m ,

m

|

|

|

|

|

|

21.4

|

85.6

|

76.5

|

75

|

1050

|

1100

|

1.84

|

|

22.0

|

88.0

|

78.9

|

77.3

|

1082

|

1133

|

1.86

|

|

22.5

|

90.0

|

80.9

|

79.5

|

1113

|

1166

|

1.88

|

|

23.0

|

92.0

|

82.9

|

81.3

|

1138.2

|

1192.4

|

1.9

|

|

23.5

|

94.0

|

84.9

|

83.25

|

1165.5

|

1221

|

1.93

|

|

24.0

|

96.0

|

86.9

|

85.2

|

1192.8

|

1249.6

|

1.97

|

|

24.5

|

98.0

|

88.9

|

87.15

|

1220.1

|

1278.2

|

2.02

|

Findings

Calculations can be made with

sufficient accuracy for practice, limited to consideration of the

movement of a group of five cars (Fig. 2). The research was carried

out by the method of mathematical simulation using the model of

spatial oscillations of the coupling of five cars and a software

complex developed by the BRL DSRS of the Dnipropetrovsk National

University of Railway Transport named after Academician V. Lazaryan.

Initial data for research: movement of gondola car of the model

12-532 with the typical bogies 18-100 with speeds in the range from

50 to 90 km/h in the curves with radii 350 and 600 m, with

superelevation 130 and 120 mm, correspondingly. The rails – P65,

wooden sleepers, broken stone ballast [5–8, 16].

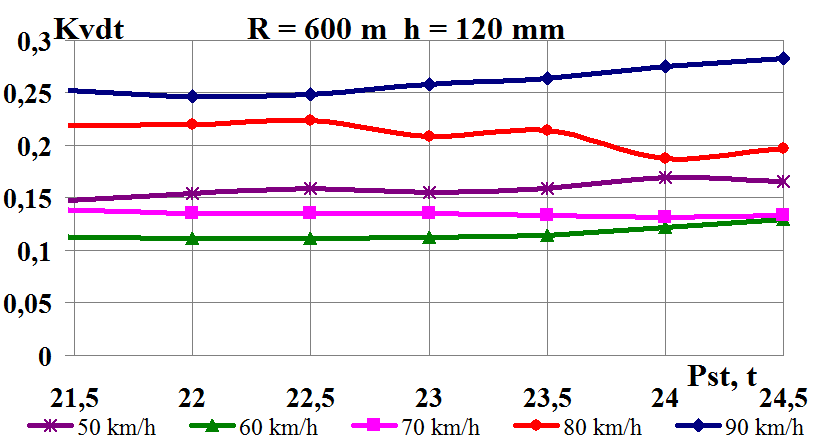

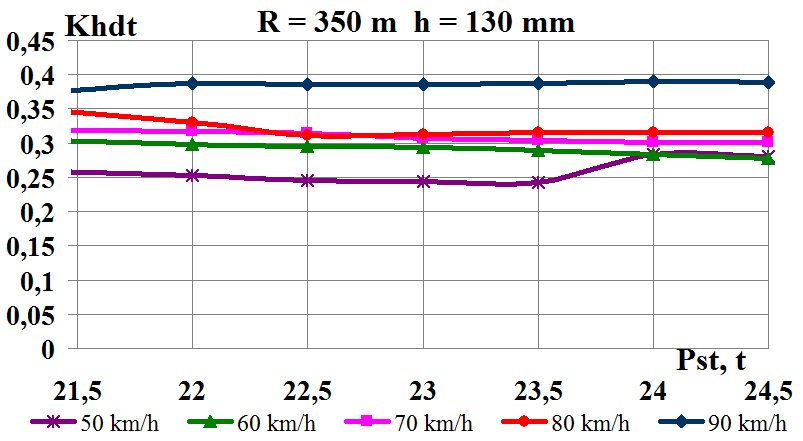

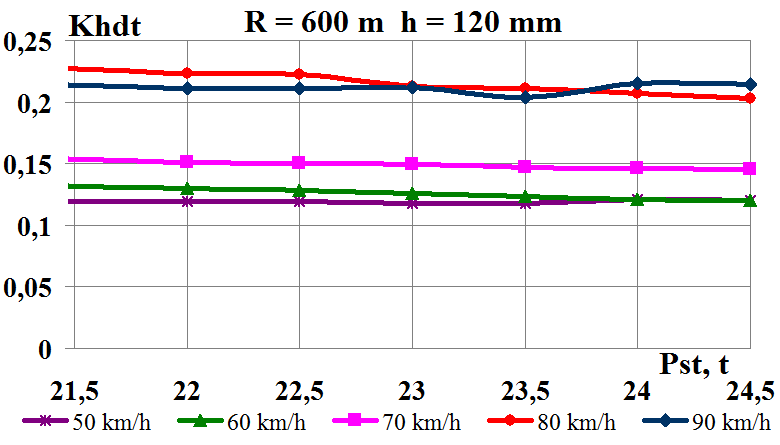

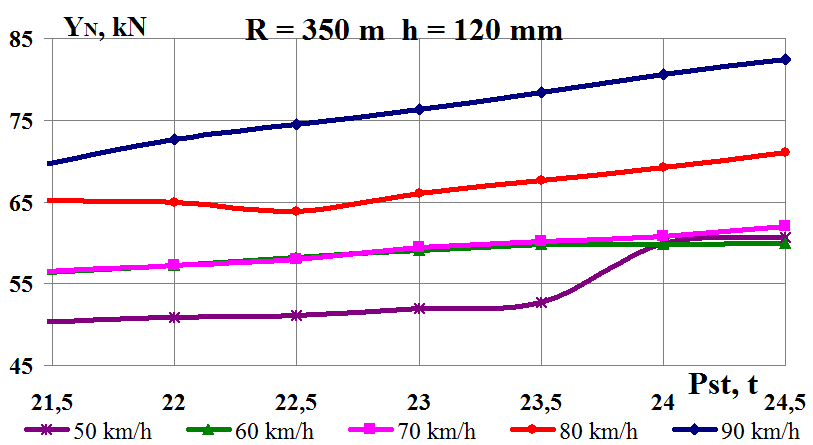

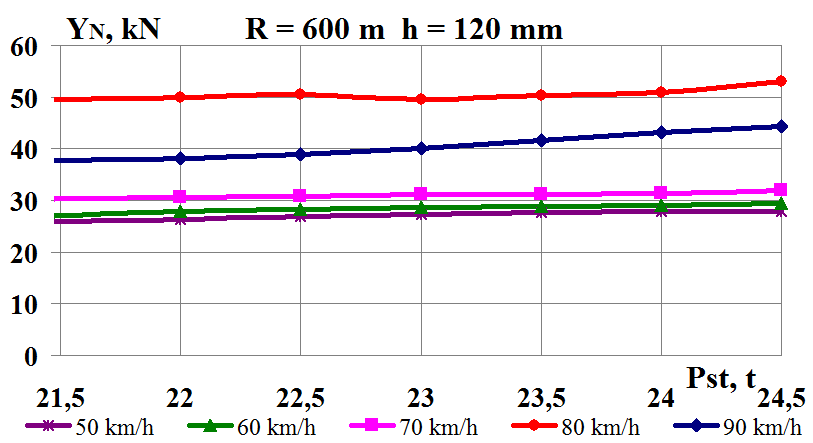

In this

study, the influence of increase of loading from the car axle on the

rails during cargo transportation was considered. The graphs of

changes of indicators under analysis when moving in the curved track

sections of

and 350 m are presented in Fig. 10–13.

and 350 m are presented in Fig. 10–13.

As one can

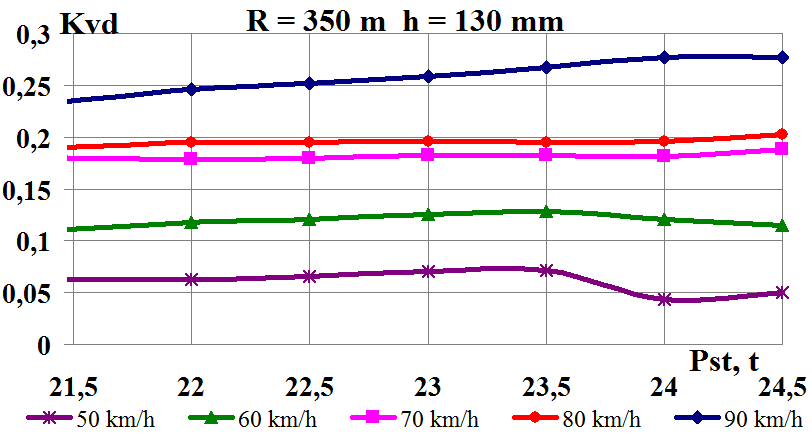

see from Fig. 10 (a, b),

in general, with loading increase from the car axle on the rails the

vertical dynamics coefficients increase in the whole range of

speeds. The

indicators do not exceed the permissible norm both in the curve of

indicators do not exceed the permissible norm both in the curve of

m and in the curve of

m and in the curve of

m and correspond to the excellent level of assessment

m and correspond to the excellent level of assessment

[8].

[8].

a

b

c

d

e

f

Fig.

10. Dependencde

graphs on the axle loading of the car on rails when moving in the

corresponding curve:

а,

b

– coefficients of vertical dynamics; c,

d

– coefficients of horizontal dynamics;

e,

f

– derailment stability coefficient

Fig. 10 (c,

d), presents the coefficients of

horizontal dynamics

when moving in curves with a radius

when moving in curves with a radius

m

and 600 m, correspondingly. From these figures, one can see that

with loading increase from the car axle on the rails, the

coefficients of horizontal dynamics

m

and 600 m, correspondingly. From these figures, one can see that

with loading increase from the car axle on the rails, the

coefficients of horizontal dynamics

slightly change and remain in the curves of

slightly change and remain in the curves of

and

and

m at the excellent level of assessment

m at the excellent level of assessment

[8].

[8].

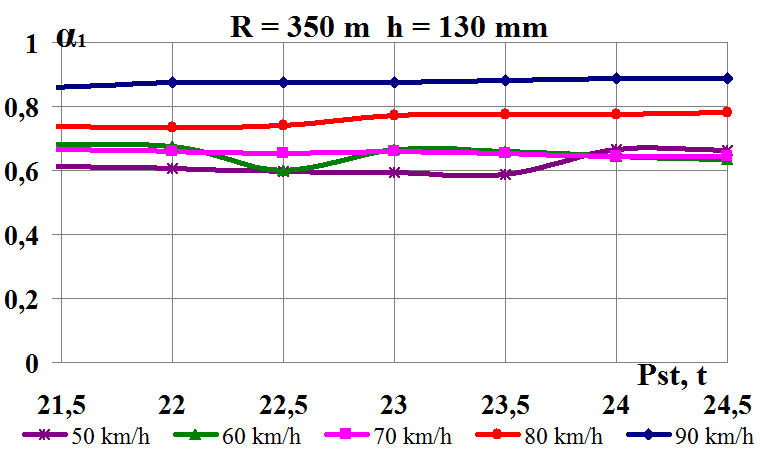

The

derailment stability coefficients in the curves of

and

and

m

(Fig. 10, d, e)

have little dependence on the loading increase from the car axle on

the rails and in both cases do not exceed the minimum permissible

value

m

(Fig. 10, d, e)

have little dependence on the loading increase from the car axle on

the rails and in both cases do not exceed the minimum permissible

value

.

On the average the value

.

On the average the value

in the curves

in the curves

m

is 52.2% lower than the corresponding values in the curve

m

is 52.2% lower than the corresponding values in the curve

m. From the obtained results, it follows that in case of increase of

loading from the car axle on the rails, the movement speed has a

significant influence on the car stability in the curved track

sections.

m. From the obtained results, it follows that in case of increase of

loading from the car axle on the rails, the movement speed has a

significant influence on the car stability in the curved track

sections.

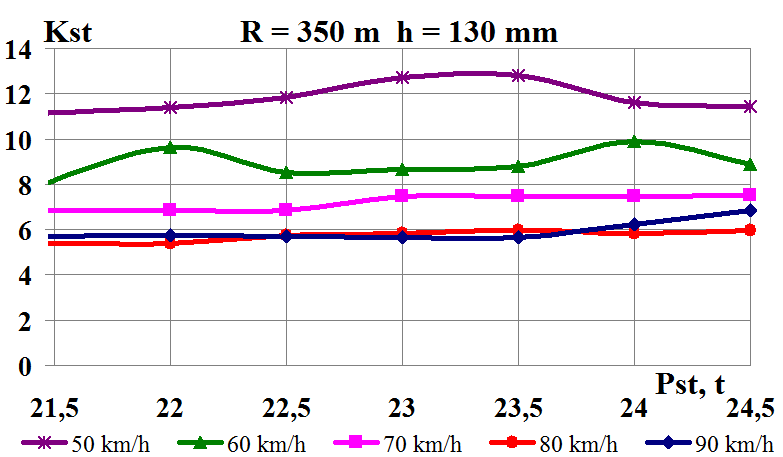

Fig. 11 shows

the coefficients of vertical

and horizontal

and horizontal

dynamics of the track according to the forces of interaction of the

wheels and rails, as well as the displacement stability coefficient

dynamics of the track according to the forces of interaction of the

wheels and rails, as well as the displacement stability coefficient

of

the track panel when moving in the corresponding curved track

sections.

of

the track panel when moving in the corresponding curved track

sections.

a

b

c

d

e

f

Fig.

11. Graphs of dependence on the axle loading of car

on the rails

when moving in the corresponding curve:

a,

b –

coefficient

of vertical dynamics of the track for the forces of interaction of

wheels and rails;

c,

d

–

coefficient

of horizontal dynamics of the track for the forces of interaction of

wheels and rails;

e,

f

–

displacement

stability coefficient of the track panel

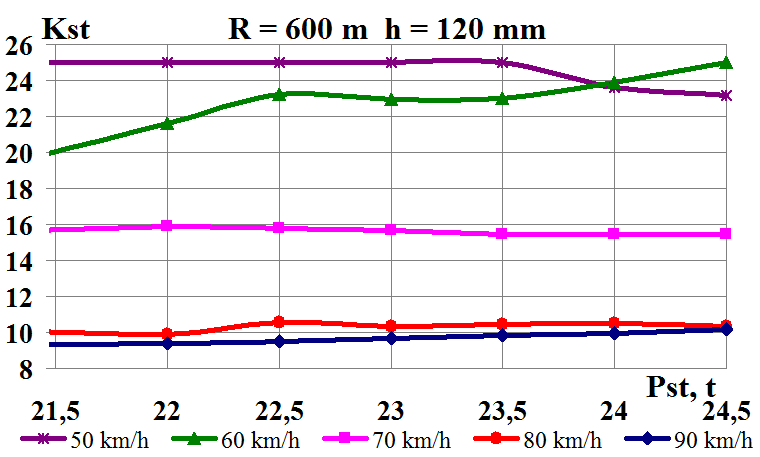

The

permissible value of the coefficient of vertical dynamics of the

track

is calculated according to the permissible dynamic load per unit

length on the railway track from the group of the bogie axles of 168

kN/m and is

is calculated according to the permissible dynamic load per unit

length on the railway track from the group of the bogie axles of 168

kN/m and is

for this type of rolling stock [7]. The coefficient of vertical

dynamics of the track

for this type of rolling stock [7]. The coefficient of vertical

dynamics of the track

(Fig. 11, a, b)

does not exceed the permissible value in the curves with radius of

(Fig. 11, a, b)

does not exceed the permissible value in the curves with radius of

and 600 m.

and 600 m.

The

coefficient of horizontal dynamics of the track

(Fig. 11, e, f),

which is considered the safety criterion against the track panel

displacement, does not exceed the permissible value

(Fig. 11, e, f),

which is considered the safety criterion against the track panel

displacement, does not exceed the permissible value

in the curves with radius of

in the curves with radius of

and 600 m. Only at the speed of 90 km/h in the curve of

and 600 m. Only at the speed of 90 km/h in the curve of

m

m

on average has a value of 0.39 and approaches the maximum

permissible value.

on average has a value of 0.39 and approaches the maximum

permissible value.

The value of

the stability coefficient of the track panel

(Fig. 11, c, d)

in the track with broken stone ballast is 0.6-0.9, which is less

than the permissible value. Therefore for the track with broken

stone ballast at normal movement speeds (

(Fig. 11, c, d)

in the track with broken stone ballast is 0.6-0.9, which is less

than the permissible value. Therefore for the track with broken

stone ballast at normal movement speeds ( km/h)

one should take

km/h)

one should take

[5, 7].

[5, 7].

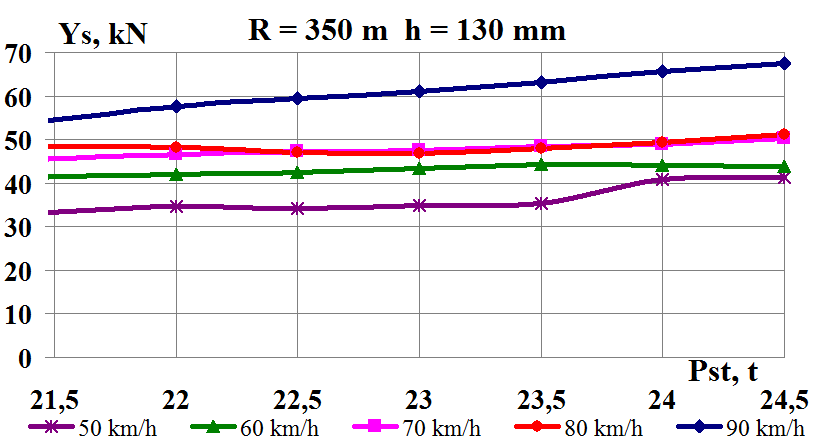

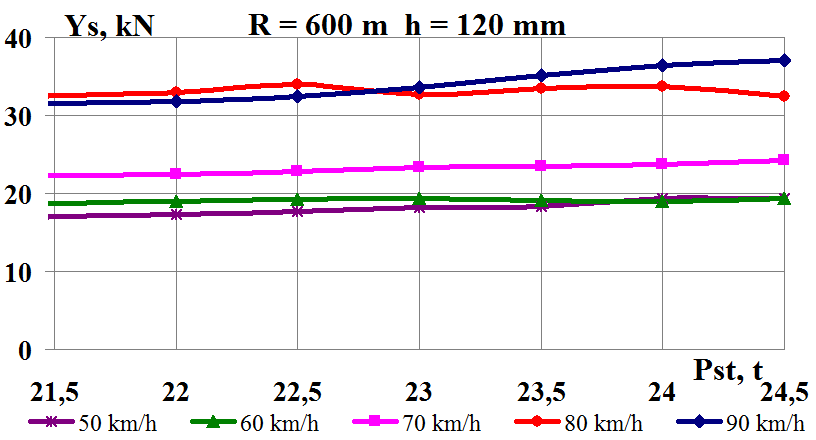

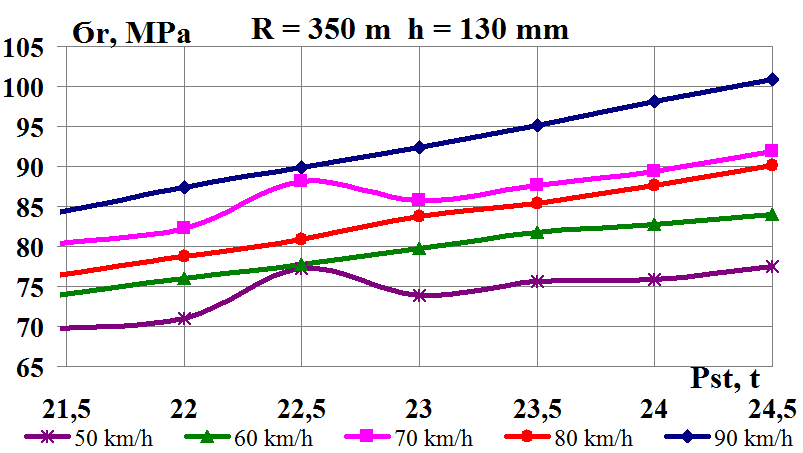

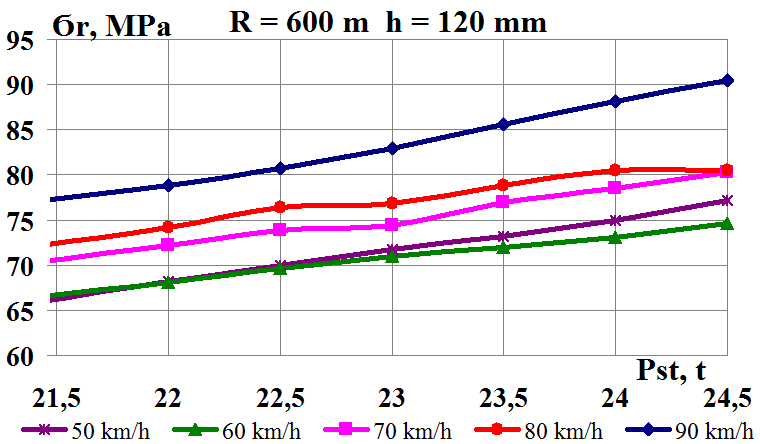

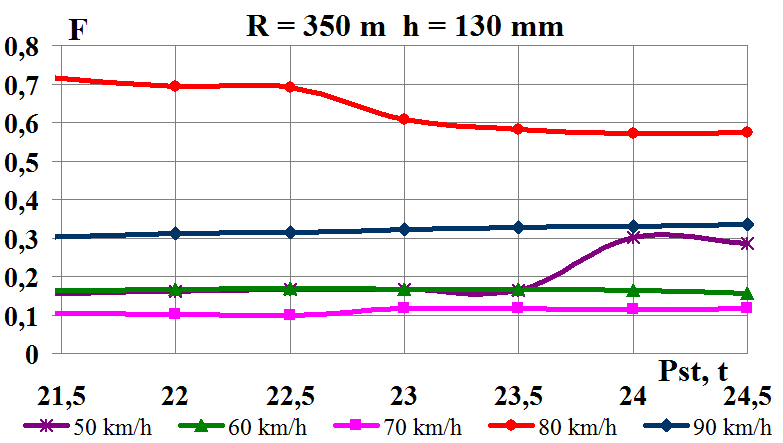

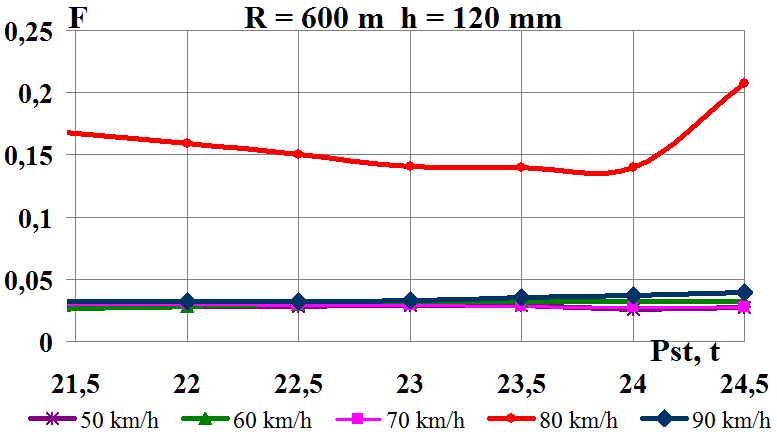

Fig. 12 shows

the speed influence on the interaction indicators of track and

rolling stock in the curves of

and

and

m, correspondingly – the side force acting from the track on the

wheel, the edge stress at the rail base, the wear factor of the side

edge of the wheel tread.

m, correspondingly – the side force acting from the track on the

wheel, the edge stress at the rail base, the wear factor of the side

edge of the wheel tread.

a

b

c

d

e

f

Fig. 12. Graphs of

dependence on the axle loading of the car on rails when moving in

the corresponding curve:

a,

b – side force

acting from the track side on the wheel; c,

d – edge stress at

the rail base;

e, f

– the wear factor

of the side edge of the wheel tread

The side

forces acting from the track on the wheel (horizontal forces)

(Fig. 12, a, b)

increase and, in comparison with the permissible values of 100 kN,

have no excess. The values

(Fig. 12, a, b)

increase and, in comparison with the permissible values of 100 kN,

have no excess. The values

in the curve of

in the curve of

are on the average 46.1 % higher than the corresponding values in

the curve of

are on the average 46.1 % higher than the corresponding values in

the curve of

m.

m.

The dynamic

influence of rolling stock on the track increases with increasing

the speeds of train movement, and, as a result, the stresses at the

rail base edges increase (Fig. 12, c,

d). The maximum stresses occurring at

the edges of the rail bases are used as a criterion for establishing

the permissible speeds and should not exceed 215 MPa before the

passage of the normative tonnage and 165 MPa after the passage of

the normative tonnage for the track with non-heat treated rails P65.

According to

the results of calculations, the edge stresses increase with

increasing the movement speed and do not exceed the permissible

values for both types of rails [5, 7].

As the

movement speed increases, for example at the speed of 80 km/h, the

wear factor of the side edge of the wheel tread F

increases significantly (Fig. 12, e,

f) and in the curve of

m it 74.86% exceeds the corresponding value at

m it 74.86% exceeds the corresponding value at

m. In turn, F

increase at the speed of 80 km/h in the curve

m. In turn, F

increase at the speed of 80 km/h in the curve

m is 66.2% as compared with other speed intervals. The same

indicator in the curve

m is 66.2% as compared with other speed intervals. The same

indicator in the curve

m is 80.5%.

m is 80.5%.

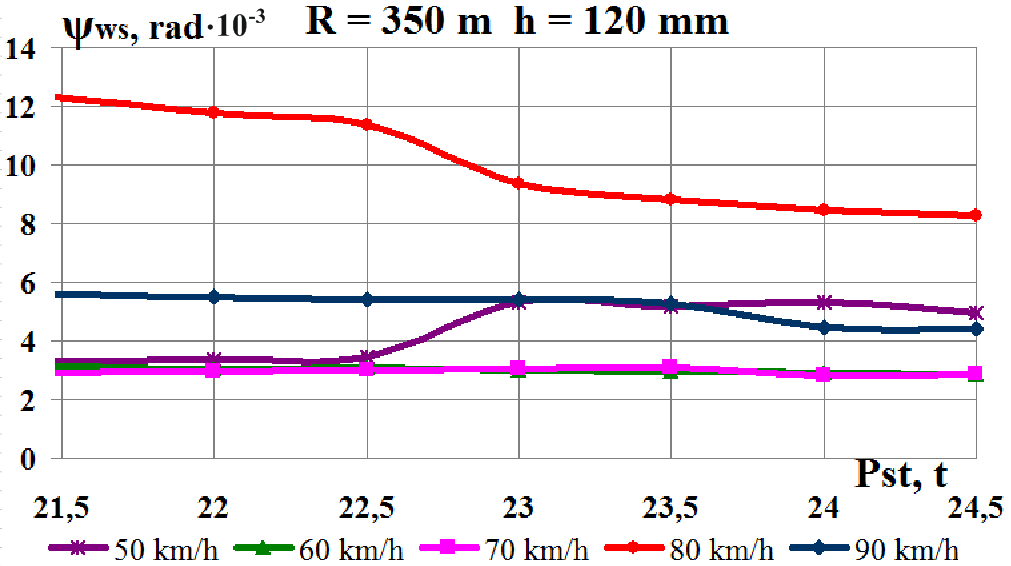

The wear

factor of the side edge of the wheel tread F

is determined as a characteristic equal to the product of the

guiding force

on the angle of hunting (climbing)

on the angle of hunting (climbing)

of the wheel on the rail. Fig. 13 shows the speed influence on the

interaction indicators of rolling stock and track in the curves of

of the wheel on the rail. Fig. 13 shows the speed influence on the

interaction indicators of rolling stock and track in the curves of

m

and

m

and

m,

correspondingly, guiding force acting on the wheel from the track

side on the wheel and the wheel set hunting.

m,

correspondingly, guiding force acting on the wheel from the track

side on the wheel and the wheel set hunting.

а

b

c

d

Fig.

13. Graphs of dependence on the axle loading of the car on the rails

in the corresponding curve:

a,

b –

guiding force acting from the track side on the wheel; c,

d

– wheel set hunting

Guiding

forces acting on the wheel

from the track (Fig. 13, a,

b),

significantly increase in the curve of

from the track (Fig. 13, a,

b),

significantly increase in the curve of

m with increasing the movement speed. The values

m with increasing the movement speed. The values

in

the curve of

in

the curve of

m on the average are 43.6% more than the corresponding values in the

curve of

m on the average are 43.6% more than the corresponding values in the

curve of

m.

m.

The results

of calculations show (Fig. 13, c,

d)

that the hunting angle of the wheel set

at

the speed of 80 km/h in the curves of the small and middle radius is

significantly differ from the other range of the investigated

speeds. The

at

the speed of 80 km/h in the curves of the small and middle radius is

significantly differ from the other range of the investigated

speeds. The

values

in the curve of

values

in the curve of

m on average exceed the corresponding value in the curve of

m on average exceed the corresponding value in the curve of

m by

64.9%.

m by

64.9%.

The need to

limit the speed of cars on the bogies of the model 18-100 is due to

the loss of movement stability, when the dynamic transverse

oscillations of the hunting of the car parts stop damping, becoming

steady (self-oscillations). The wheel sets after the loss of

movement stability continuously oscillate within the rail gap, while

the amplitude of self-oscillations may vary within the rail gap, but

no oscillation damping is observed. The side frames of the bogie are

subject to auto-oscillations of the hunting, since the dynamic

movements of the wheel sets are violated predominantly in the

antiphase. The car body in turn, starts hunting because of antiphase

dynamic displacements of the bogies.

As it is

known, the safe train movement speed, which include the cars on the

serial bogies of the model 18-100, is determined not by the design

speed . .,

but by the critical one

.,

but by the critical one

,

which is unstable. The critical speed

,

which is unstable. The critical speed

varies

according to the following factors [10]:

varies

according to the following factors [10]:

– the

stiffness of the elastic connection between the sidewalls and the

wheel sets;

– the car

weight – the critical speed of empty cars is lower than that of

the loaded ones;

– gravity

center of the car – with the increase in the gravity center the

critical speed is reduced.

In addition,

the critical speed

changes during operation depending on the wear of undercarriages,

primarily the wheel rims, and the track plan - when passing the

curved track sections, the critical speed is higher compared to the

value in the straight track sections. At speeds exceeding the

critical one, the car loses movement stability. As a result, there

are self-oscillations of the lateral swaying of the wheel sets, the

bogies and body hunting. There is increase in the horizontal

transverse accelerations and frame forces, which wor-sens the

stability coefficient against derailment (Fig. 10, e,

f).

changes during operation depending on the wear of undercarriages,

primarily the wheel rims, and the track plan - when passing the

curved track sections, the critical speed is higher compared to the

value in the straight track sections. At speeds exceeding the

critical one, the car loses movement stability. As a result, there

are self-oscillations of the lateral swaying of the wheel sets, the

bogies and body hunting. There is increase in the horizontal

transverse accelerations and frame forces, which wor-sens the

stability coefficient against derailment (Fig. 10, e,

f).

Thus, the movement speed

limitation in the curves of small and medium radius, established by

the norms, should be observed. It caused by a sharp decrease in the

stability coefficient against derailment and increase in the wear

factor of the lateral edge of the wheel tread.

Originality

and practical value

Originality of the work lies in

the study of the influence of increasing the axle loading in gondola

cars on their dynamic parameters and interaction indicators of the

tracks and rolling stock in order to solve the problem of predicting

the rolling stock dynamics and includes the results of theoretical

studies taking into account the movement speed in the curved track

sections of the small and medium radius.

The obtained results have a

practical orientation. During the theoretical studies and after the

simulation, taking into account the oscillation processes of the

freight car and cargo with increase in the gondola axle loading,

dependences of the main dynamic parameters taking into account the

movement speed are obtained. Application of the results will

increase the traffic safety of freight cars and will improve the

technical and economic performance of railway transport.

Conclusions

The article presents analysis of

theoretical studies of dynamic qualities of rolling stock on the

example of gondola cars, calculations are made using the package of

applied programs.

Based on the theoretical study,

the following conclusions can be made:

– the

movement speed limitation in the curves of the small and medium

radius is caused by a decrease in the level of the derailment

stability coefficient and increase in the wear factor of the side

edges of the wheel tread and should not exceed the values determined

by the norms;

– the

calculations have shown the need to limit the movement speed in the

curves of medium radius to 70 km/h, due to the fact that the average

weighted speed of trains of 80 km/h is critical for the gondolas on

the bogies of the model 18-100, which leads to the loss of stability

and increase in the wear factor of the side edge of the wheel tread;

– axle

loading increase will increase failure rate of the rails due to

defects of contact-fatigue nature, deterioration of the track

condition, artificial structures, and the roadbed, which in turn

will cause the movement speed limitation of passenger and freight

trains, as well as more intense failure of elements of the track

superstructure and increase in the annual operating costs.

LIST OF REFERENCE LINKS

Автоматизированная

система дозированной

погрузки щебня

в вагоны

[Electronic resource].

– Available

at: https://clck.ru/F7bWE

– Title from the screen.

– Accessed :

30.01.2019.

Аппаратно-программный

комплекс контроля

загрузки вагонов

«АРСИС.Сканер»

[Electronic resource]

// ООО

«Малленом Системс».

– Available at:

http://www.mallenom.ru/Docs/ARSCIS.Scanner.pdf

– Title from the screen.

– Accessed :

30.01.2019.

Вагонний

парк ПАТ «Укрзалізниця» та взаємодія

з приватними власниками рухомого

складу / Департамент розвитку і технічної

політики (ЦТЕХ) ; кер. ПАТ «Укрзалізниця».

– Харків, 2017. – 11 с.

Вагонные

весы [Electronic

resource] //

Точное Определение Массы

(ТОМ). – Available at:

http://tom.odessa.ua/index.php?p=vagon

– Title from

the screen.

– Accessed :

28.01.2019.

Даніленко,

Е. І. Залізнична колія : підруч. для вищ.

навч. закл. : у 2 т. / Е. І. Даніленко. –

Київ : Інпрес, 2010. – Т. 2. – 456 с.

Данович, В.

Д. Математическая модель пространственных

колебаний сцепа пяти вагонов, движущихся

по прямолинейному участку пути / В. Д.

Данович, А. А. Малышева // Транспорт.

Нагруженность и прочность подвижного

состава : сб. науч. тр.

/ Днепропетр. гос. техн.

ун-т ж.-д. трансп. – Днепропетровск,

1998. – С. 62–69.

ДСТУ

7571:2014. Рухомий склад залізниць. Норми

допустимого впливу на залізничну колію

1520 мм. – Введ. 2014–02–12. – Київ : УкрНДНЦ,

2014. – 33 с.

ДСТУ ГОСТ

33211:2017. Вагони вантажні. Вимоги до

міцності та динамічних якостей (ГОСТ

33211-2014). – Введ. 2017–07–01. – Київ : УкрНДНЦ,

2017. – 58 с.

Засоби для

механізації розрівнювання насипних

вантажів у напіввагонах / Є. В. Романович,

Г. М. Афанасов, Л. М. Козар, В. В. Бут // Зб.

наук. пр. Укр. держ. акад. залізн. трансп.

– Харків, 2014. – Вип. 148 (1). – С.

116–121.

Лазарян, В.

А. Устойчивость движения рельсовых

экипажей / В. А. Лазарян, Л. А. Длугач, М.

Л. Коротенко. – Киев : Наукова думка,

1972. – 197 с.

Определение

допустимых сил при оценке устойчивости

грузовых вагонов от выжимания в поездах

/ А. А. Швец, К. И. Железнов, А. С. Акулов,

А. Н. Заболотный, Е. В. Чабанюк // Наука

та прогрес транспорту. – 2016. – № 1 (61).

– С. 189–192. doi: 10.15802/stp2016/61045

Правила

перевезення вантажів навалом і насипом

(ст. 37 Статуту) [Electronic

resource] : затв.

Наказом М-ва транспорту та зв’язку

України від 20.08.2001 р. № 542 // Законодавство

України. – 2014. – Available

at:

http://zakon.rada.gov.ua/laws/show/z0795-01

– Title from

the screen.

– Accessed :

28.01.2019.

Правила

перевезення вантажів у вагонах

відкритого типу

(https://zakon.rada.gov.ua/laws/show/457-98-п TARGET="_blank" ст.

32 Статуту)

[Electronic resource]

: затв. Наказом М-ва транспорту та

зв’язку України від 20.08.2001 р. № 542 //

Законодавство України. – 2014. – Available

at:

http://zakon.rada.gov.ua/laws/show/z0796-01 – Title

from the

screen. –

Accessed :

28.01.2019.

Рибкін, В.

В. Проведення випробувань з впливу на

колію та стрілочні переводи рухомого

складу нового покоління з осьовим

навантаженням 25 т на вісь / В. В. Рибкін,

В. Є. Савлук // Зб. наук. пр. Укр. держ.

акад. залізн. трансп. – Харків, 2012. –

Вип. 130. – С. 127–131.

Транспортно-разгрузочное

оборудование [Electronic

resource]

// Предприятие

Днепротяжмаш. – Avai-lable

at:

http://www.dts.dp.ua/ru/factories/dnieprotiazhmash/products/transportno-razghruzochnoie-oborudovaniie

– Title from

the screen.

– Accessed :

28.01.2019.

Швець,

А. О. Вплив поздовжнього та поперечного

зміщення центру ваги вантажу в піввагонах

на їх динамічні показники / А. О. Швець

// Наука та прогрес

транспорту. – 2018. – № 5

(77). – С. 115–128. doi:

10.15802/stp2018/146432

Швець, А. О.

Особливості визначення моментів

інерції кузовів вантажних вагонів /

А. О. Швець // Вісник сертифікації

залізничного транспорту. – 2018. – № 5

(51). – С. 20–34.

Determination

of the issue concerning the lift resistance factor of lightweight

car / A. O.

Shvets, К. I. Zhelieznov, А.

S. Аkulov, О.

M. Zabolotnyi, Ye. V. Chabaniuk // Наука

та прогрес транспорту. –

2015. –

№

6 (60). – С. 134–148. doi:

10.15802/stp2015/57098

Effect of fracture

toughness on vertical split rim failure in railway wheels / T.

Kato, Y. Yamamoto, H. Kato,

S. Dedmon, J. Pilch // Engineering

Fracture Mechanics. – 2017. – Vol. 186. – P. 255–267.

doi:

10.1016/j.engfracmech.2017.09.025

Fatigue

behavior and microstructural characterization of a high strength

steel for welded railway rails / R. Baptista, T. Santos, J.

Marques, M. Guedes, V. Infante // International Journal of Fatigue.

– 2018. – Vol. 117. – P. 1–8.

doi: 10.1016/j.ijfatigue.2018.07.032

Kurhan,

D. Determination of Load for Quasi-static Calculations of Railway

Track Stress-strain State /

D. Kurhan // Acta Technica Jaurinensis. – 2016. – Vol.

9. –

Іss.

1. – Р.

83–96.

doi: 10.14513/actatechjaur.v9.n1.400

Nikas,

D. Evaluation of local strength via microstructural quantification

in a pearlitic rail steel deformed by simultaneous compression and

torsion / D. Nikas, X. Zhang, J. Ahlström // Materials Science and

Engineering: A.

– 2018. – Vol. 737. – P.

341–347. doi: 10.1016/j.msea.2018.09.067

А.

О. Швець1*,

О. О. болотов2*

1*Каф.

«Теоретична та будівельна механіка»,

Дніпровський національний університет

залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел.

+38 (050) 214 14 19,

ел. пошта angela_Shvets@ua.fm, ORCID

0000-0002-8469-3902

2*ГНДЛ ДМРС, Дніпровський

національний університет залізничного

транспорту імені академіка В. Лазаряна,

вул. Лазаряна, 2, Дніпро, Україна,

49010, тел. +38 (097) 977 57 08, ел. пошта bolaks@i.ua,

ORCID 0000-0002-0807-0340

Вплив

навантаження від осі ПІВвагона на його

динамічні ПОКАЗНИКи та залізничну

колію

Мета.

Підвищення максимального навантаження

від осі вагона на рейки під час перевезення

вантажів і збільшення швидкості руху

залізничних екіпажів дозволить посилити

інтеграційні процеси між країнами. Для

гарантування безпечного й надійного

сполучення на залізницях необхідно

вдосконалювати контроль, кількісну

оцінку динамічної завантаженості

рухомого складу, що в процесі його

експлуатації складає актуальну

науково-технічну задачу. Метою цієї

роботи є дослідження впливу збільшення

осьового навантаження в піввагонах, з

урахуванням можливого підвищення

швидкості руху, на їх основні динамічні

показники та показники взаємодії

рухомого складу з колією. Методика.

Дослідження проведене методом

математичного й комп’ютерного

моделювання динамічної завантаженості

піввагона з використанням моделі

просторових коливань зчепу п’яти

вагонів і програмного комплексу,

розробленого в галузевій науково-дослідній

лабораторії динаміки й міцності рухомого

складу (ГНДЛ ДМРС). Вихідні дані для

дослідження: рух піввагона моделі

12-532 з типовими візками 18-100 зі швидкостями

в діапазоні від 50 до 90 км/год в кривих

радіусами 350 і 600 м, із підвищеннями

зовнішньої рейки 130 та 120 мм відповідно.

Результати. У

статті проаналізовано динамічні якості

рухомого складу на прикладі піввагонів;

розрахунки виконано з використанням

пакета прикладних програм з достатньою

для практики точністю. У ході теоретичних

досліджень і моделювання з урахуванням

процесів коливання вантажного вагона

в разі збільшення осьового навантаження

отримано залежності основних динамічних

показників від швидкості руху. Наукова

новизна роботи полягає

в дослідженні впливу збільшення осьового

навантаження в піввагонах з урахуванням

можливого підвищення швидкості руху

на їх динамічну завантаженість із метою

вирішення задачі прогнозування динаміки

рухомого складу. Уперше отримано

результати теоретичних досліджень з

урахуванням швидкості руху в кривих

ділянках колії малого та середнього

радіуса. Практична

значимість. Застосування

цих результатів сприятиме підвищенню

безпеки руху вантажних вагонів і

дозволить поліпшити техніко-економічні

показники роботи залізничного транспорту.

Ключові

слова: вантаж; піввагони; динамічні

показники; криві ділянки колії; осьове

навантаження; показники взаємодії;

рухомий склад і колія; центр ваги;

швидкість руху

А.

А. Швец1*,

А. А. болотов2*

1*Каф.

«Теоретическая и строительная механика»,

Днипровский национальный

университет железнодорожного

транспорта

имени академика В. Лазаряна, ул. Лазаряна,

2, Днипро, Украина, 49010, тел. +38 (050) 214 14 19,

эл. почта angela_Shvets@ua.fm, ORCID

0000-0002-8469-3902

2*ОНИЛ

ДППС, Днипровский

национальный университет железнодорожного

транспорта имени академика

В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (097) 977 57 08, эл. почта bolaks@i.ua,

ORCID

0000-0002-0807-0340

ВЛИЯНИЕ

НАГРУЗКИ ОТ ОСИ полувагона НА ЕГО

динамические показатели И железнодорожный

путь

Цель.

Повышение максимальной

нагрузки от оси вагона на рельсы при

перевозке грузов и увеличение скорости

движения железнодорожных экипажей

позволит усилить интеграционные

процессы между странами. Для обеспечения

безопасного и надежного сообщения на

железных дорогах

необходимо

совершенствовать контроль, количественную

оценку динамической загруженности

подвижного состава, что в процессе его

эксплуатации составляет актуальную

научно-техническую задачу. Целью данной

работы является исследование влияния

увеличения осевой нагрузки в полувагонах,

с учетом возможного повышения скорости

движения, на их основные динамические

показатели и показатели взаимодействия

подвижного состава с колеей. Методика.

Исследование проведено методом

математического и компьютерного

моделирования динамической загруженности

полувагона с использованием модели

пространственных колебаний сцепа пяти

вагонов и программного комплекса,

разработанного в отраслевой

научно-исследовательской лаборатории

динамики и прочности подвижного состава

(ОНИЛ ДППС). Исходные данные исследования:

движение полувагона модели 12-532 с

типичными тележками 18-100 со скоростями

в диапазоне от 50 до 90 км/ч в кривых

радиусами 350 и 600 м, с повышениями

наружного рельса 130 и 120 мм соответственно.

Результаты.

В статье проанализированы динамические

качества подвижного состава на примере

полувагонов; расчеты выполнены с

использованием пакета прикладных

программ с достаточной для практики

точностью. В ходе теоретических

исследований и моделирования с учетом

процессов колебания грузового вагона

при увеличении осевой нагрузки получены

зависимости основных динамических

показателей от скорости движения.

Научная новизна

состоит в исследовании влияния увеличения

осевой нагрузки в полувагонах с

учетом возможного повышения скорости

движения на их динамическую нагрузку

с целью решения задачи прогнозирования

динамики подвижного состава. Впервые

представлены результаты теоретических

исследований с учетом скорости

движения по кривым участкам пути малого

и среднего радиуса. Практическая

значимость. Применение

полученных результатов будет

способствовать повышению безопасности

движения грузовых вагонов и позволит

улучшить технико-экономические

показатели работы железнодорожного

транспорта.

Ключевые

слова: груз; полувагоны; динамические

показатели; кривые участки пути; осевая

нагрузка; показатели взаимодействия;

подвижной состав и колея; центр тяжести;

скорость движения

REFERENCES

Avtomatizirovannaya

sistema dozirovannoy pogruzki shchebnya v vagony.

Retrieved from

https://clck.ru/F7bWE (in Russian)

Apparatno-programmnyy

kompleks kontrolya zagruzki vagonov «ARSIS.Skaner».

OOO «Mallenom Sistems».

Retrieved from

http://www.mallenom.ru/Docs/ARSCIS.Scanner.pdf

(in Russian)

Vagonnyj

park PAT «Ukrzaliznycja» ta vzajemodija z pryvatnymy vlasnykamy

ruhomogo skladu. (2017). Kharkiv: Department of Development and

Technical Policy; manager PJSC «Ukrzaliznytsya». (in Ukrainian)

Vagonnye

vesy. Tochnoe Opredelenie Massy (TOM).

Retrieved from

http://tom.odessa.ua/index.php?p=vagon

(in Russian)

Danilenko,

E. I. (2010). Zaliznychna

koliia:

pidruchnyk

dlia

vyshchykh

navchalnykh

zakladiv.

(Vol. 1-2). Kyiv: Inpres. (in

Ukrainian)

Danovich,

V. D., & Malysheva, A. A. (1998). Mathematical Model of Spatial

Oscillations of the Coupling of Five Cars Moving Along a

Rectilinear Section of the Track.

Transport. Stress Loading and

Durability of a Rolling Stock (рр.

62-69).

Dnepropetrovsk.

(in Russian)

Rukhomyj

sklad zaliznycj. Normy dopustymogho vplyvu na zaliznychnu koliju

1520 mm. 33 DSTU 7571:2014 (2014). (in

Ukrainian)

Vahony

vantazhni. Vymohy do mitsnosti ta dynamichnykh yakostei, 58 DSTU

33211:2017 (2017). (in Ukrai-nian)

Romanovych,

Y. V., Afanasov, H. M., Kozar, L. M., &

But, V. V. (2014).

Zasoby dlia mekhanizatsii rozrivniuvannia

nasypnykh vantazhiv u napivvahonakh. Collected

Scientific Works of Ukrainian State University of Railway

Transport,

148(1),

116-121. (in Ukrainian)

Lazaryan,

V. A., Dlugach, L. A., & Korotenko, M. L. (1972). Ustoychivost

dvizheniya relsovykh ekipazhey. Kiev:

Naukova dumka. (in Russian)

Shvets,

A. O., Zhelieznov, K. I., Akulov, A. S., Zabolotnyi, O. M., &

Chabaniuk, E. V. (2016). Determination the permissible forces in

assessing the lift resistant factor of freight cars in trains.

Science and Transport Progress, 1(61),

180-192. doi: 10.15802/stp2016/61045

(in Russian)

Pravyla

perevezennia vantazhiv navalom i nasypom (2014). Retrieved from

http://zakon.rada.gov.ua/laws/show/z0795-01

(in Ukrainian)

Pravyla

perevezennia vantazhiv u vahonakh vidkrytoho typu (2014). Retrieved

from http://zakon.rada.gov.ua/laws/show/z0796-01 (in

Ukrainian)

Rybkin,

V. V., & Savluk, V. Y. (2012). Provedennia vyprobuvan z vplyvu

na koliiu ta strilochni perevody rukhomoho skladu novoho pokolinnia

z osovym navantazhenniam 25 t na vis. Collected

Scientific Works of Ukrainian State University of Railway

Transport, 130, 127-131.

(in Ukrainian)

Transportno-razgruzochnoe

oborudovanie. Predpriyatie

Dneprotyazhmash. Retrieved from

http://www.dts.dp.ua/ru/factories/dnieprotiazhmash/products/transportno-razghruzochnoie-oborudovaniie

(in Russian)

Shvets,

A. O. (2018). Influence of the longitudinal and transverse

displacement of the center of gravity of the load in gondola cars

on their dynamic indicators. Science

and Transport Progress, 5(77),

115-128.

doi:

10.15802/stp2018/146432

(in Ukrainian)

Shvets,

A. O. (2018). Specifics of Determining the Moments of Inertia a

Freight Wagons Bodies.

Visnyk sertyfikatsii zaliznychnoho

transportu,

5(51), 20-34.

(in Ukrainian)

Shvets,

A. O., Zhelieznov, К. I., Аkulov, А. S., Zabolotnyi, О. M., &

Chabaniuk, Y. V. (2015). Determination of the issue concerning the

lift resistance factor of lightweight car. Science

and Transport Progress, 6(60),

134-148. doi: 10.15802/stp2015/57098 (in

English)

Kato,

T., Yamamoto, Y., Kato, H., Dedmon, S., & Pilch, J. (2017).

Effect of fracture toughness on vertical split rim failure in

railway wheels. Engineering Fracture

Mechanics, 186, 255-267.

doi: 10.1016/j.engfracmech.2017.09.025 (in

English)

Baptista,

R., Santos, T., Marques, J., Guedes, M., & Infante, V. (2018).

Fatigue behavior and microstructural characterization of a high

strength steel for welded railway rails. International

Journal of Fatigue, 117, 1-8.

doi: 10.1016/j.ijfatigue.2018.07.032 (in

English)

Kurhan,

D. (2016). Determination of Load for Quasi-static Calculations of

Railway Track Stress-strain State. Acta

Technica Jaurinensis, 9(1), 83-96.

doi: 10.14513/actatechjaur.v9.n1.400

(in English)

Nikas,

D., Zhang, X., & Ahlström, J. (2018). Evaluation of local

strength via microstructural quantification in a pearlitic rail

steel deformed by simultaneous compression and torsion.

Materials Science and Engineering: A, 737,

341-347. doi: 10.1016/j.msea.2018.09.067 (in

English)

Received:

Sep. 10, 2018

Accepted:

Jan. 18,

2019