ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука та прогрес

транспорту. Вісник

Дніпропетровського

національного університету

залізничного транспорту, 2018, № 5

(77)

Експлуатація

та ремонт засобів транспорту

Експлуатація

та ремонт засобів транспорту

UDC

629.42.083-047.58

B. E.

BODNAR1,

O. B.

ОCHKАSОV2*,

Е. B. BODNAR3,

Т. S.

HRYSHECHKINA4,

М. V. OCHERETNYUK5

1Dep.

«Locomotives», Dnipropetrovsk National University named after

Academician V. Lazaryan, Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. + 38 (056) 733 19 01, e-mail bodnarz@nz.diit.edu.ua, ORCID

0000-0002-3591-4772

2*Dep.

«Locomotives», Dnipropetrovsk National University named after

Academician V. Lazaryan, Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. + 38 (056) 733 19 61, e-mail abochkasov@gmail.com, ORCID

0000-0002-7719-7214

3Dep.

«Locomotives», Dnipropetrovsk National University named after

Academician V. Lazaryan, Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. + 38 (056) 733 19 61, e-mail Melnar78@gmail.com,

ORCID 0000-0001-6040-913X

4Dep.

«Higher Mathematics», Dnipropetrovsk National University named

after Academician V. Lazaryan, Lazaryan St., 2, Dnipro, Ukraine,

49010, tel. +38 (0562) 36 26 04, e-mail grishechkina.tatiana@gmail.com, ORCID

0000-0003-1570-4150

5Dep.

«Locomotives», Dnipropetrovsk National University named after

Academician V. Lazaryan, Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. + 38 (056) 733 19 61, e-mail ocheretniukmaksym@gmail.com, ORCID

0000-0002-9032-8602

SIMULATION

OF LOCOMOTIVE REPAIR

ORGANIZATION BY THE METHODS

OF QUEUE SYSTEMS

THEORY

Purpose.

The article is aimed to evaluate the influence

of locomotives` operation and reliability indicators on the system of

locomotives repair organization in depot, using the methods of queue

theory. Methodology.

The article describes the locomotive repair workshop using the terms

and concepts of the queue systems

theory (QST).

The tasks solved during simulation of the repair workshop operation

are formulated, the list of initial data and simulation results is

given. A graphical simulation environment Simulink was used as a

software simulation tool. Findings.

It was established that the main indicators of locomotive depot

operation are affected by the volume of traffic, the reliability of

locomotives, the rule used to select locomotives from the queue, the

number of operating repair bays. The developed model of the depot

repair workshop will make possible rational planning of the repair

workshop`s equipment use, the human capital, the time of putting the

locomotives into repair taking into account the workshop loading

uniformity, as well as to improve the repair parts supply logistics.

This model in a simplified form describes the repair process of the

main diesel locomotive fleet, and can be supplemented depending on

the repair type performed in the depot. Originality.

The paper presents the locomotive repair depot as an object of the

queue systems theory. The simulation model of the locomotive repair

depot was developed. It allows analyzing the influence of various

factors on the system of locomotives` repair organization in the

depot. Practical value. The obtained results make it possible

to determine the influence of locomotives` operation and reliability

indicators on the organization of the locomotive repair depot

operation. In further studies, the developed model can be used to

improve the system of repair organization on the railway network when

introducing new series of locomotives and changing the strategy of

their maintenance.

Keywords: locomotive

repair workshop; simulation; queue system theory; organization of the

repair workshop operation

Introduction

Improvement

of the locomotives` repair system organization is one of the ways to

reduce operating costs. Management system restructuring of

Ukrzaliznytsia`s locomotive facilities involves the separation of

operation and repair functions of traction rolling stock. Such an

approach is already used at large industrial transport enterprises

(metallurgical enterprises, ore mining and processing enterprises).

Foreign railway companies (RR, Lithuanian Railways, etc.) also

carried out the functions` separation of locomotive operation and

their repairs between the locomotive depots. On the basis of the

largest depots, the repairs of locomotives allocated not only in

this depot, but also in the other ones, are performed. Another part

of the depots performs solely the locomotive maintenance during

operation. At this stage in Ukrzaliznytsia operate locomotive depots

specialized in locomotive series and repair types (CR-2, CR-3).

Separation

of depots into operational and repair ones requires careful

consideration, as the repair program is changing, which can lead to

the formation of locomotives queue waiting for repairs, and this in

turn will lead to increase in their downtime. On the one hand, when

using this approach, the enterprise`s costs increase, this is due to

the locomotive's withdrawal from operation and the costs of their

transportation from the operating depot to the repair one. On the

other hand, there may be a low loading of repair enterprises, which

leads to the idle of repair facilities waiting for the locomotives

supply. The described situations eventually lead to the maintenance

costs increase for both the locomotives and the technological

equipment. The positive thing is that the creation of specialized

depots reduces the capital costs for the repairs organization,

increases the equipment use efficiency, increases the labor

productivity, and, as a consequence, the repair quality. The

distribution task of the repair program between the repair depots of

the railway network and the methodology of selecting the specialized

depots is an urgent task [7,

10, 16]. Solution of this task involves the development of general

model for the locomotives` repair organization at a level not less

than that of the Ukrzaliznytsia`s regional branch. The part of this

model is the model of locomotives` repair organization at the level

of repair depot. This article is devoted to the analysis of methods

and approaches to simulating the operation organization of the

repair locomotive depot.

The

initial data when simulating the repair organization in the

locomotive depot is the need for locomotive repairs. From the point

of view of the operating company, the locomotive is a part of the

overall locomotive fleet management system. To maintain a given

level of locomotive reliability, the transport companies use a

certain maintenance system. In this case, the choice of the

locomotive maintenance system is influenced by such factors as the

repair enterprise characteristics, the type of service and operating

conditions, the performance history of each locomotive (electronic

passport), the level of equipment and loading of the repair

enterprise, the failure statistics (reliability) of locomotive units

and the locomotives of this series, as well as a number of other

factors.

Based on

the analysis [7,

12, 14, 19, 20] of the existing systems of locomotive fleet

management, the main tasks are formulated that need to be addressed

when choosing a system of technical maintenance of locomotives.

Among them are as follows:

– development

of the methodology for repair units loading planning, taking into

account the technical condition of the locomotive fleet and the

volume of planned repair works;

– development

of methodology for planning logistical support for repair units,

taking into account the technical condition of the locomotive fleet

and the volume of planned repair works.

Solution

of the set tasks also requires the creation of the model for the

locomotive repair organization in the repair depot, taking into

account the repair units loading planning, the technical condition

of the locomotive fleet, and the volume of the performed works.

The

methods of the queue system theory [5, 7,

8, 11, 13], optimization [2,

4, 9, 15], the theory of economic and

mathematical modeling [1, 4],

analysis of the large amounts of data and simulation modeling are

used during the development of the repair organization model in the

locomotive depot [18].

Purpose

To analyze

the influence of locomotives` operation and reliability indicators

on the locomotive repair system organization in the depot with the

use of the queue theory methods.

Methodology

The task

of planning the locomotive putting into repair is to reduce the idle

time of locomotives in repair and waiting for repairs, which

significantly affects the locomotive availability. At the same time,

it is necessary to ensure the loading uniformity of the repair

units, the possibility of planning the supply of components and

consumables, as well as to ensure a given level of the locomotive

fleet reliability.

The

existing system of repair planning is based on the control of

overhaul periods. It determines the need for repair or maintenance

on the basis of comparison with the normative values of the

between-repair mileages of locomotives (first of all, when working

in trains) or the operating time (for example, when used for

shunting or export works). Typical standards for between-repair

mileages according to locomotive series can be set individually for

different locomotive series.

The need

for repair or maintenance for this locomotive is fixed in the event

the between-repair mileage, or the operating time, have become more

than the normative ones for the corresponding repair type. In this

case, according to regulatory documents, for the loading uniformity

of the depot repair workshops and locomotive repair plants, it is

possible to regulate the overhauls (usually within -10% + 25%). That

is, fixing of the need for repair or maintenance takes place for a

certain interval of values of between-repair mileage or the

operating time of locomotive.

Current

values of between-repair mileages or locomotive operating time are

determined based on the accounting for their work (by processing the

running schedules of the drivers). At the same time, since the

determination of the need for repair or maintenance should be

carried out for the future, forecasting of changes in these

parameters is used. As a rule, forecasting is carried out based on

their average values.

Planning

of locomotives` putting into repair can be of two types: the

calendar planning and the planning by mileage. When planning

according to calendar time one proceeds from the average daily

mileage during this period or the planned task in order to determine

a planned day of locomotive putting into repair. The disadvantage of

this method of planning is that the actual daily mileage of

locomotives greatly varies due to their different technical

condition, different idle times in the current repair, different

degrees of use at work and other things and it is significantly

different from the planned one. More expedient is the planning

according to the mileage, since in this case the locomotives are put

into repair according to the established frequency. The disadvantage

of this method of planning is possible uneven performance of the

daily maintenance plan. The maintenance schedule of an individual

locomotive is based on the established periodicity of maintenance,

repair cycle and daily mileage of locomotive.

This

approach is used in the case of the planned-preventive locomotive

repair system. However, its use when implementing the combined

repair system or the one, which takes into account the technical

condition of the locomotives, is not rational, since in this case

the repair volume and the overhaul periods are determined for each

individual locomotive taking into account the reliability

characteristics of the locomotive units.

For the

operational planning of putting the locomotives into repair, one has

to know the probabilities of locomotives being in different

conditions (operation, repair type, idle time when waiting for

repair, etc.).

When

solving this problem, it is expedient to use the tools of queue

theory.

Let us

consider in more detail the possibility of using the queue theory

approaches to simulate the processes of putting the locomotive into

repair and its implementation, analyzing the loading of repair bays

and calculating their required quantity.

In the

queue theory the methods of probability theory and mathematical

statistics are used. The queue theory considers the theoretical

basis of rational design and operation of queue systems (QS). The

queue system operation consists in performing the flow of

applications received by it. The subject of the queue theory is the

establishment of a relationship between the nature of the

application flow, the performance of certain channels, the number of

channels and the service efficiency.

The

following indicators can be the efficiency characteristics of

services:

– the

average idle-time of certain channels;

– the

average time of waiting in the queue;

– the

probability that the received application will be accepted for

service immediately;

etc.

The

given characteristics describe the degree of the system's

suitability to perform the application flow (i.e., its capacity).

The average number of applications that a system can serve per unit

of time is considered as capacity.

Maintenance of requirements

in the system is performed by the service channels. A classical

queue system contains from one to an infinite number of channels.

Depending

on the availability of the possibility for the beginning of

servicing the QS are divided into:

– lossy

systems in which the claims that did not find any free handler at

the time of receipt are lost;

– the

systems with waiting, which have an infinite capacity storage for

buffering the received requirements, while the waiting requirements

form a queue;

– the

systems with end capacity storage (with waiting and restrictions),

in which the queue length cannot exceed the storage capacity. At the

same time, the requirement received by the overflow system in which

there is no free place for waiting is lost.

The

selection of the application from the queue is made using the

discipline of service. Its examples are: FIFO (first in, first out),

random, SF (short forward). In systems with waiting, a storage in

the general case can have a complex structure. The system can be

single-channel and multi-channel.

To

simulate the locomotive fleet repair under conditions of locomotive

depot, a waiting system that has infinite capacity storage for

buffering the received requirements is suitable. At this the waiting

locomotives form a queue. Also in this case, from our point of view,

it is most appropriate to choose a requirement from the queue

according to the FIFO system.

In

this system, the repair bays are the service facilities (channels),

the flow of applications is the number of locomotives received by

the service system for a certain time: year, month, week, shift,

hour, minute. The application flow serves as the basis for planning

the production program of the repair bays.

Due

to the randomness of the incoming application flow and the duration

of their execution, there is always some average number of idle

locomotives. Therefore, it is necessary to distribute the number

of repair bays between different subsystems so that the idle time

and, therefore, the losses would be minimal. Note that the

locomotive queue system is

a discrete type physical system S

with a countable set of states:

.

.

At any

moment of time t

the system S can

be in one of these states. Then for any t:

,

,

where

– is the probability that at the moment of time t

the system will be in the state

– is the probability that at the moment of time t

the system will be in the state

.

.

Let us

consider in more detail the repair workshop of the locomotive depot,

in which all types of depot repairs are performed, as a queue system

for locomotives.

Repair

workshop with repair bays, in terms of queue theory, has the

following characteristics:

– it is

an open system, since the source of applications is outside the

system (operation depot) and has an infinite number of them;

– by the

nature of the queue creation it is a waiting system with an infinite

queue. Non-preferential service discipline, the service system can

be adopted any of the previously considered ones;

– by the

number of channels it is a multi-channel system with parallel

channel arrangement. In this paper, we consider the depot as a

system with heterogeneous channels, since when performing repairs in

the depot, the bays specialized according to the repair types are

used (M-3, CR-1, etc.).

For the

repair workshop as a queue system, the main factor that determines

the processes occurring in it is the input application flow – the

number of locomotives that need one or another type of repair. The

Poisson application flow was considered during the simulation. The

service time of one application is accepted as distributed according

to the demonstrative law.

To analyze

the random processes with discrete states it is convenient to use

the so-called graph of states and transitions. For further

calculation of the efficiency characteristics of the QS operation,

it is necessary to determine the possible states of the system, as

well as the probability of occurrence of these states (pi),

which are called the limit probabilities of the system.

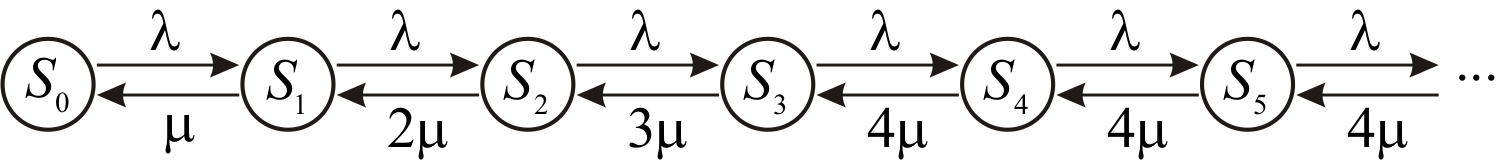

The graph

of the states of the repair workshop with repair positions n

and places in the queue m

is shown in Fig. 1.

Fig.

1. The graph of the repair workshop states

with n repair positions and a limited queue

Let us

introduce the following designations:

i

– is the number of locomotive sections (applications) in the queue

system (in the queue and on the service);

– is the intensity of sections receipt into the system, provided

that there are already i

sections in the system;

– is the intensity of sections receipt into the system, provided

that there are already i

sections in the system;

– is the output flow intensity of the served sections, provided

that there are i

sections in the system;

– is the output flow intensity of the served sections, provided

that there are i

sections in the system;

– is the probability that there are i

sections in the system;

– is the probability that there are i

sections in the system;

– is the summary bay loading intensity (or the channel loading

intensity)

– is the summary bay loading intensity (or the channel loading

intensity)

The repair

workshop of locomotives can take one of the following states:

–  – all positions are free;

– all positions are free;

– the one position is occupied, and the rest ones

– the one position is occupied, and the rest ones

are free;

are free;

–  – two positions are occupied, and the rest ones

– two positions are occupied, and the rest ones

are free;

are free; – all positions are occupied, but there is no queue;

– all positions are occupied, but there is no queue;

–  – all positions are occupied,

one locomotive (section) is in the queue;

– all positions are occupied,

one locomotive (section) is in the queue;

–  – all positions are occupied,

– all positions are occupied,

locomotives (sections) are in the

queue.

locomotives (sections) are in the

queue.

It should

be noted that in this system the service flow intensity will

increase from

to

to

with

the increase in the number of applications from 0 to

with

the increase in the number of applications from 0 to

.

Accordingly, the number of service channels is increased. With the

number of requirements exceeding

.

Accordingly, the number of service channels is increased. With the

number of requirements exceeding

,

the service intensity remains equal to

,

the service intensity remains equal to .

.

When

simulating, the following tasks need to be solved: simulating the

repair workshop operation for a specified number of hours;

determining the probabilities of the repair workshop conditions

;

determining the average number of applications (locomotives) in the

service queue; determining the average number of applications for

service; determining the average number of applications in the

system; determining the average duration of the application stay in

the queue; determining the average duration of the application stay

in the system; determining the system relative capacity; determining

the absolute system capacity.

;

determining the average number of applications (locomotives) in the

service queue; determining the average number of applications for

service; determining the average number of applications in the

system; determining the average duration of the application stay in

the queue; determining the average duration of the application stay

in the system; determining the system relative capacity; determining

the absolute system capacity.

For the

probabilities p1(t),

p2(t),…,

pn(t)

the system of linear differential equations (Erlang equations) will

be:

;

;

;

;

;

;

;

;

;

;

. (1)

. (1)

In the

steady (stationary) state (with

)

the system of equations takes the form:

)

the system of equations takes the form:

;

;

;

;

;

;

;

;

.

(2)

.

(2)

Let us add

a normalizing condition:

. (3)

. (3)

Its

meaning is that at any moment the workshop must be in one of its

states (idle, operation, operation with a queue).

The

initial data for the simulation of the repair workshop operation

are: the number of repair positions; simulation time; the intensity

of the incoming application flow (including the scheduled and

unscheduled repairs); the duration of service at each repair

position for each repair type.

As a

result of simulation, the following indicators of the QS (locomotive

repair workshop) are determined: the probability of the system

conditions

;

the average number of applications (locomotives) in the queue for

service; the average number of applications in the system; the

average duration of stay in the queue; the average duration of

application stay in the system. The simulation results of the repair

workshop operation for a given time include the number of the

received applications and the number of hours spent for service.

;

the average number of applications (locomotives) in the queue for

service; the average number of applications in the system; the

average duration of stay in the queue; the average duration of

application stay in the system. The simulation results of the repair

workshop operation for a given time include the number of the

received applications and the number of hours spent for service.

To

determine the probability of finding a QS in one of the possible

conditions, we use formulas

4–6:

(4)

(4)

,

,

, (5)

, (5)

where k –

is the number of the occupied repair bays;

,

,

(6)

(6)

The probability of queue

formation is determined by the formula:

. (7)

. (7)

The

average application number in a queue:

(8)

(8)

Average

number of applications served:

. (9)

. (9)

The

average number of application stay in the system:

, (10)

, (10)

where Q

– is the relative QS capacity (in this case it is equal to one).

Average

time in the queue:

. (11)

. (11)

Findings

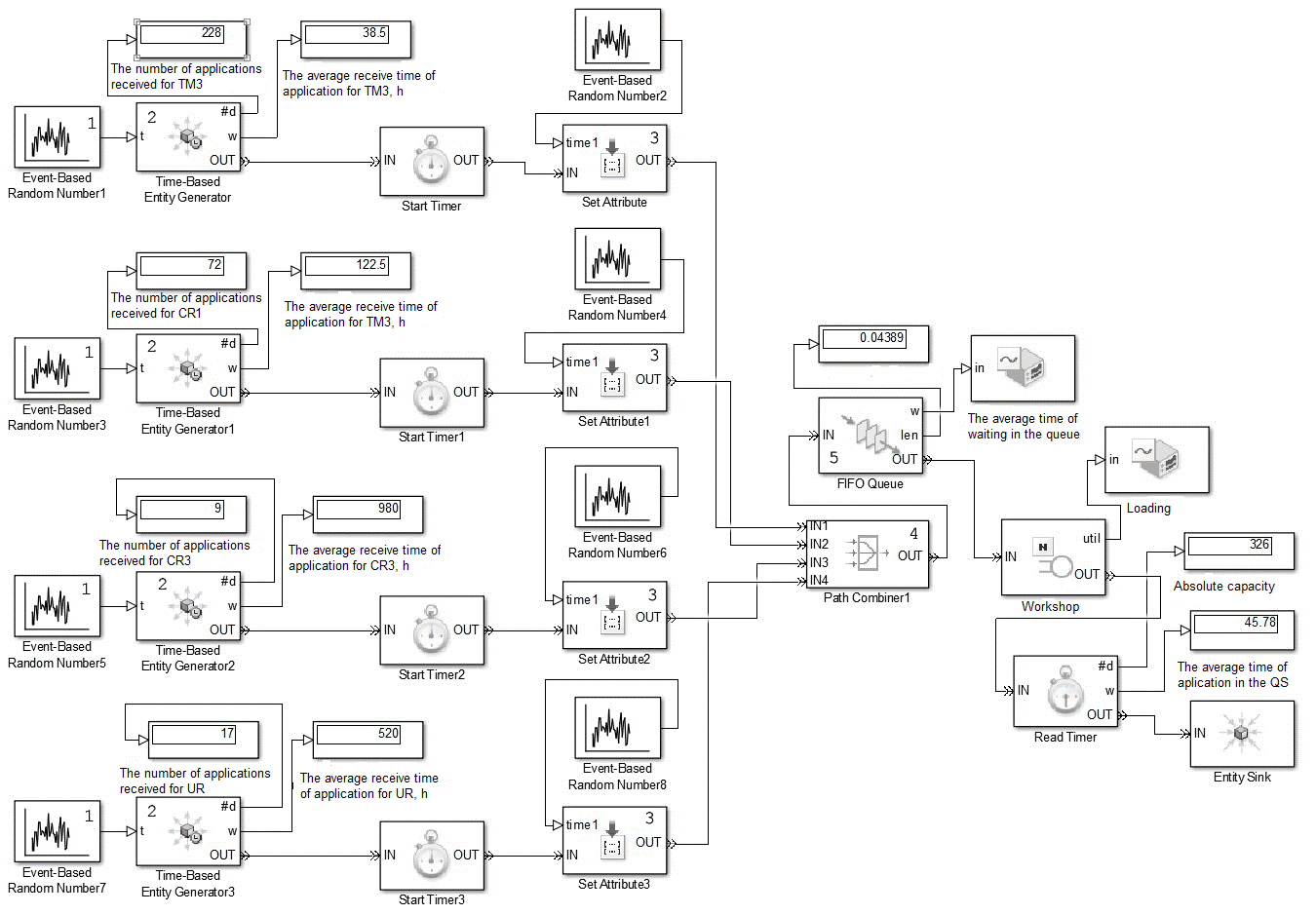

To study

the influence of the system of maintenance, operation and repair

organization of locomotives, as well as their reliability level, a

model was developed and the operation of the main diesel locomotive

repair workshop at the repair depot was simulated. When simulating,

it was taken the performance of all types of depot repair of diesel

locomotives TM-3, CR-1, CR-3 and unscheduled repairs in the repair

workshop. When organizing the applications servicing (locomotive

repair simulation), specialization of repair bays by the repair type

was taken. There are two groups of repair bays. Unscheduled repairs

and CR-3 are performed in one group, CR-1 and TM-3 are performed in

another group of repair bays.

A

graphical environment Simulink was used as a simulation software.

The block diagram of the repair workshop model of the locomotive

depot is presented in Fig. 2

The blocks

1 and 2 form the applications for the diesel locomotives repair

interspaced in time in a random manner. Block 3 forms the time for

performing repair in a random manner. The calculation of application

number and the service time of diesel locomotives is made in

accordance with the current regulatory documentation. In this case,

it is allowed the deviation of the receipt time 20%

from the norm. The block 4 «repair position» was used as a repair

depot in the model. The time required to perform the corresponding

repair type is determined by this block depending on the repair type

20%.

FIFO discipline has been adopted as the discipline for servicing the

applications. The queue of diesel locomotives waiting for repair is

organized by the block 5.

A

simulation of the repair workshop for the allocated locomotive fleet

of

diesel locomotives (36 sections) of the 2TE116 series was performed.

The average daily mileage of diesel locomotives was taken

diesel locomotives (36 sections) of the 2TE116 series was performed.

The average daily mileage of diesel locomotives was taken

,

the simulation time is 365 days, the share of unscheduled repairs is

5%. The simulation results are shown in Table 1–3.

,

the simulation time is 365 days, the share of unscheduled repairs is

5%. The simulation results are shown in Table 1–3.

Fig. 2. Repair workshop model

of diesel locomotives in the form of QS:

1

– former of the receipt time of locomotives for repair;

2

– block of the former of the application distribution in time;

3

– former of diesel locomotive service time at repair position;

4

– diesel locomotive repair positions; 5

– queue of locomotives waiting for repair

In tab. 1

shows the simulation results with a different number of repair

stalls. As can be seen from the obtained results, with the accepted

initial data, the use of three repair stalls is the most rational,

while the loading of the depot workshop is 0.6%.

The Tab. 1

shows the simulation results with a different number of repair bays.

As one can see from the obtained results, with the accepted initial

data the use of three repair bays is the most rational, at this the

loading of the depot workshop is 0.6%.

Table

1

The simulation results of

the repair workshop operation for diesel locomotives on change

of

the repair bays number

Number

of repair bays, pcs.

|

The

average time of waiting in the queue, h.

|

The

average queue length, sect.

|

Workshop/depot

loading, %

|

The average time of

application in the QS, h

|

2

|

60

|

1.439

|

0.88

|

83.18

|

3

|

1.5

|

0.044

|

0.59

|

45.78

|

4

|

0

|

0

|

0.45

|

44.6

|

The Tab. 2

shows the simulation results when using in the depot three repair

bays and changing the average daily mileage of diesel locomotives

from 400 to 700 km/day. As one can see from the obtained results,

increase in the average daily mileage leads to an increase in the

repair workshop loading to 0.79%, while the queue length increases

by 10 times, and the average waiting time – by 5.6 times. This is

explained by the fact that with increase in the average daily

mileage, the number of applications for repairs is increasing.

The Tab. 3

shows the simulation results when using in the depot three repair

bays and changing the number of unscheduled repairs from 5 to 10%.

The results show that increase in the percentage of unscheduled

repairs leads to a slight increase in the repair workshop loading,

at this, the queue length and average waiting time change slightly

as well.

Table

2

The

simulation results of the repair workshop when changing the

average daily mileage of diesel locomotives

The

average daily mileage of locomotive, km

|

The

average time of waiting in the queue, h

|

The

average queue length, locomotives

|

Workshop/depot

loading, %

|

The average time of

application in the QS, h

|

400

|

0.8

|

0.02

|

0.48

|

44.94

|

500

|

1.5

|

0.04

|

0.59

|

45.78

|

600

|

2.1

|

0.08

|

0.68

|

45.58

|

700

|

4.5

|

0.22

|

0.79

|

48.22

|

Table

3

The

simulation results of the repair workshop when changing the

unscheduled repair percentage

Percentage

of unscheduled repairs of locomotives, %

|

Locomotive average daily

mileage, km

|

The average waiting time

in the queue, h

|

The average queue length,

locomotives

|

Workshop/depot

loading, %

|

The average time of

application in the QS, h

|

5

|

500

|

1.4

|

0.032

|

0.57

|

44.3

|

8

|

500

|

1.5

|

0.044

|

0.59

|

45.78

|

10

|

500

|

1.5

|

0.048

|

0.6

|

46.68

|

Originality and practical

value

The work originality lies in

the presentation of the locomotive depot as the queue system object.

A simulation model of a locomotive repair depot has been developed.

It allows analyzing the influence of various factors on the system

of organizing the locomotive repair in depot.

The use of the developed

model and simulation results allows determining the influence of

operation and reliability indicators of locomotives on the work

organization of the locomotive repair depots. In further studies,

the proposed model can be used to improve the organization of repair

on the road network when introducing new series of locomotives and

changing their maintenance strategy.

Conclusions

The paper

presents the locomotive repair workshop description using the terms

and concepts of the queue system. The tasks for modeling the repair

work workshop operation are formulated, a list of the initial data

and the results of the simulation are given. Based on the simulation

results analysis, it is possible to optimize the repair workshop

structure and the required number of personnel, based on the

transportations volume, locomotive reliability indicators, the

locomotive selection rule used, the number of operating repair bays,

etc. It is established that the listed parameters influence the main

indicators of the locomotive repair depot. The proposed models of

the repair workshop make possible the rational planning of the

equipment use, human capital, the time for putting the locomotive

into repair, taking into account the uniform loading of the

workshop, as well as providing the opportunity to improve the spare

parts supply logistics. The model in a simplified form describes the

process of the mainline locomotive fleet repair and can be

supplemented depending on the repair type performed at the depot.

The

problem of accounting the reliability indicators when simulating the

locomotive putting into unplanned repair types, determining the

probability of locomotive transition from one state to another, as

well as taking into account the reliability indicators when

determining the repair work amount, requires further development.

LIST OF REFERENCE LINKS

Берестовой,

А. М. Моделирование системы технического

обслуживания и ремонта локомотивов /

А.

М. Берестовой,

А.

А.

Лямзин // Вісн. Приазов.

держ.

техн.

ун-ту.

Серія:

Технічні

науки

:

зб.

наук. пр. –

Маріуполь,

2003. – Вип.

13.

– С. 276–280.

Босов,

А. А. Теоретические основы рационального

содержания подвижного состава железных

дорог : монография

/ А. А. Босов, П. А. Лоза.

– Днепропетровск

:

Дриант,

2015.

– 252 с.

Гришечкіна,

Т. С. Побудова математичної моделі

раціональної системи утримання

технічних об’єктів залізничного

транспорту / Т. С. Гришечкіна

// Транспортні системи та технології

перевезень

:

зб.

наук.

пр.

Дніпропетр.

нац.

ун-ту

залізн.

трансп.

ім.

акад.

В. Лазаряна.

– Дніпропетровськ,

2017. – Вип.

14. – С. 30–35.

doi:

10.15802/tstt2017/123165

Гурьева,

А. Г. Основы моделирования процессов

технического обслуживания локомотивов

/

А. Г. Гурьева, Н. Б. Чернецкая-Белецкая

// Вісн.

Східноукр. нац. ун-ту ім. В. Даля. – 2015.

– № 1 (218). – С. 262–265.

Зіненко, О. Л.

Підвищення ефективності використання

локомотивного парку шляхом вдосконалення

управління експлуатаційною роботою

: дис. ... канд. техн. наук : 05.22.20 / Зіненко

Ольга Леонідівна ; Дніпропетр. нац.

ун-т залізн. трансп. ім. акад. В. Лазаряна.

– Дніпропетровськ, 2010. – 200 с.

Исследование

процесса эксплуатации и ремонта

электровозов с использованием

инструментов BIG

DATA

и имитационного моделирования / А. В.

Скребков, А. А. Воробьев, А. Г. Ламкин,

Д. И. Бодриков // Бюллетень результатов

научных исследований. – 2017. – № 4. –

С. 190–198.

Кудаяров,

М. М. Выбор оптимальной организации

ремонта локомотивов на полигоне

железной дороги / М. М. Кудаяров //

Изв.

Петербург. ун-та путей сообщения.

– 2012. – №

3

(32). – С. 99–103.

Кудаяров,

М. М. Оптимизация системы технологического

процесса ремонта тягового подвижного

состава /

М. М. Кудаяров, И. С. Цихалевский //

Современные проблемы транспортного

комплекса России : межвуз. сб.

науч. тр. молодых ученых, магистрантов

и аспирантов. – Магнитогорск,

2012.

–

Вып.

2.

– С. 14–22.

Лоза,

П. А. Оценка

качества выполнения системы содержания

парка электроподвижного состава /

П.

А. Лоза,

Т.

С. Гришечкина // Електрифікація

транспорту.

– 2015. – № 9. – С. 87–93.

Методика

и алгоритм оптимального распределения

локомотивов по ремонтным предприятиям

/

А.

В. Горский, А. В. Скребков, Т. О. Чигамбаев,

И. С. Цихалевский // Транспорт Урала. –

2008. –

№

3 (18). – С. 25–27.

Моделювання

процесу оперативного планування роботи

локомотивного парку і локомотивних

бригад

/ І. В.

Жуковицький, В. В. Скалозуб, О. В. Вєтрова,

О. Л. Зіненко

// Вісн.

Дніпропетр. нац. ун-ту залізн. трансп.

ім. акад. В. Лазаряна. – Дніпропетровськ,

2006.

–

Вип.

12.

– С. 74–78.

Моделювання

зміни коефіцієнту технічного використання

маневрового тепловозу для різних

систем утримання / А. П. Фалендиш, А. Л.

Сумцов, О. В. Артеменко, О. В. Клецька //

Восточно-Европейский журнал передовых

технологий. – 2016. – № 1/3 (79). – С. 24–31.

doi: 10.15587/1729-4061.2016.60640

Очкасов,

А. Б. Подходы

к моделированию системы технического

обслуживания локомотивов

/

O.

Б.

Очкасов,

Т.

С.

Гришечкина, М.

В. Очеретнюк

// Актуальні проблеми автоматизації

та управління

: тези доп. V

міжнар. наук.-практ. інтернет-конф.

молодих учених і аспірантів (Луцьк,

28–30 бер. 2017 р.) / Луцьк. нац. техн. ун-т,

НУ «Львівська політехніка», Київ. нац.

ун-т харчових технологій, Нац. гірн.

ун-т, Херсон. нац. техн. ун-т, Люблінська

політехніка. – Луцьк, 2017. – № 5. –

С. 99–104.

Сумцов,

А. Л. Удосконалення методів та

моделей визначення системи технічної

експлуатації модернізованих маневрових

тепловозів : дис. … канд. тех. наук :

05.22.07 / Сумцов Андрій Леонідович

; Укр. держ. ун-т залізн. трансп. – Харків,

2017. –

165

с.

Шантаренко,

С. Г. Моделирование процессов технического

обслуживания локомотивов /

С. Г.

Шантаренко // Изв. Томск. политехн.

ун-та.

Инжиниринг

георесурсов. – 2005. – Т. 308, № 5. –

С.

169–171.

Bodnar,

B.

Improving

Operation

and

Maintenance

of

Locomotives

of

Ukrainian

Railways

/ B.

Bodnar,

A.

Ochkasov,

D.

Bobyr

// Technologijos

ir Menas = Technology and Art. –

2016. –

№ 7. –

P. 109–114.

Bodnar,

B. System Choice of the Technical Maintenance of Locomotives

Equipped with on-Board Diagnostic Systems / B. Bodnar, O. Ochkasov

// Transport Means : Proc.

of 21st Intern.

Sci.

Conf.

(Sept.

20–22, 2017)

/ Kaunas University of Technology,

Klaipėda University. – Juodkrante, Kaunas, Lithuania. – 2017.

– Pt.

I. – P. 43–47.

Development

of an Integrated Model for the Evaluation and Planning of Railroad

Track Maintenance

/

Alexander H. Lovett, C. Tyler Dick, Conrad Ruppert, M. Rapik Saat,

Christopher Barkan //

Proc.

of the 2013 Joint Rail Conf.

(Apr.

15–18,

2013, Knoxville, Tennessee, USA).

– Knoxville,

2013.

doi: 10.1115/jrc2013-2407

Ochkasov,

O. Usage of Intelligent Technologies in Choosing the Strategy of

Technical Maintenance of Locomotives / O. Ochkasov, O. Shvets, L.

Černiauskaitė

//

Technologijos ir Menas = Technology and Art. – 2017. – № 8. –

P. 68–71.

Wu,

J. Study on Adjustment

Evaluation of Locomotive Affair Productivity Layout / Jun Wu, Hua

Fei Jia // Applied Mechanics and Materials. – 2013. – Vol.

401–403.

– P. 2120–2126.

doi:

10.4028/www.scientific.net/amm.401-403.2120

Б. Є. БОДНАР1,

О. Б. ОЧКАСОВ2*,

Є. Б. БОДНАР3,

Т. С. ГРИШЕЧКИНА4,

М. В. ОЧЕРЕТНЮК5

1Каф.

«Локомотиви», Дніпропетровський

національний університет залізничного

транспорту імені академіка

В.

Лазаряна, вул. Лазаряна,

2, Дніпро, Україна, 49010, тел. +38 (056) 733 19 01,

ел. пошта bodnarz@nz.diit.edu.ua,

ORCID

0000-0002-3591-4772

2*Каф. «Локомотиви»,

Дніпропетровський національний

університет залізничного транспорту

імені академіка

В. Лазаряна, вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (056) 733 19 61, ел. пошта abochkasov@gmail.com,

ORCID

0000-0002-7719-7214

3Каф. «Локомотиви»,

Дніпропетровський національний

університет залізничного транспорту

імені академіка

В. Лазаряна, вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (056) 733 19 61, ел. пошта Melnar78@gmail.com,

ORCID 0000-0001-6040-913X

4Каф.

«Вища математика», Дніпропетровський

національний університет залізничного

транспорту імені академіка

В.

Лазаряна, вул. Лазаряна, 2, Дніпро, 49010,

Україна, тел. +38 (0562) 36 26 04, ел. пошта

grishechkina.tatiana@gmail.com, ORCID 0000-0003-1570-4150

5Каф.

«Локомотиви», Дніпропетровський

національний університет залізничного

транспорту імені академіка

В.

Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38 (056) 733 19 61, ел. пошта

ocheretniukmaksym@gmail.com,

ORCID 0000-0002-9032-8602

МОДЕЛЮВАННЯ

ОРГАНІЗАЦІЇ РЕМОНТУ

ЛОКОМОТИВІВ

МЕТОДАМИ ТЕОРІЇ

СИСТЕМ МАСОВОГО

ОБСЛУГОВУВАННЯ

Мета.

У науковій роботі необхідно

оцінити вплив показників експлуатації

та надійності локомотивів на систему

організації їх ремонту в депо з

використанням методів теорії масового

обслуговування.

Методика.

У роботі представлено опис цеху з

ремонту локомотивів за допомогою

термінів і понять системи масового

обслуговування (СМО). Сформульовано

завдання, які вирішуються при моделюванні

роботи ремонтного цеху, наведено перелік

вихідних даних і результатів моделювання.

У якості програмного

засобу

моделювання використане графічне

середовище імітаційного моделювання

Simulink.

Результати.

Встановлено, що на основні показники

роботи локомотивного депо впливає

обсяг перевезень, надійність локомотивів,

що використовуються, правило відбору

локомотивів із черги, кількість працюючих

ремонтних стійл. Розроблена модель

ремонтного цеху депо дозволяє раціонально

планувати використання обладнання,

фонду робочої сили, часу постановки

локомотивів у ремонт із урахуванням

рівномірності завантаження цеху, а

також удосконалити логістику поставок

запасних частин. Ця модель у спрощеному

вигляді описує процес виконання ремонту

парку магістральних тепловозів і може

бути доповнена

в залежності від

виду виконуваних у депо ремонтів.

Наукова новизна.

У роботі локомотиворемонтне депо

представлене як об’єкт системи масового

обслуговування. Розроблено імітаційну

модель локомотиворемонтного депо, яка

дозволяє проводити аналіз впливу різних

чинників на систему організації ремонту

локомотивів у депо. Практична

значимість. Отримані

результати дозволяють визначити вплив

показників експлуатації та надійності

локомотивів на організацію роботи

локомотиворемонтного депо.

У

подальших дослідженнях розроблена

модель може бути використана для

удосконалення системи організації

ремонту на мережі доріг при впровадженні

нових серій локомотивів та зміні

стратегії їх технічного обслуговування.

Ключові

слова: цех ремонту

локомотивів; моделювання; система

масового обслуговування; організація

роботи ремонтного цеху

Б. Е. БОДНАРЬ1,

А. Б. ОЧКАСОВ2*,

Е. Б. БОДНАРЬ3,

Т. С. ГРИШЕЧКИНА4,

М. В. ОЧЕРЕТНЮК5

1Каф.

«Локомотивы», Днепропетровский

национальный университет железнодорожного

транспорта имени академика

В.

Лазаряна, ул. Лазаряна, 2, Днипро, Украина,

49010, тел. +38 (056) 733 19 01, эл. почта

bodnarz@nz.diit.edu.ua,

ORCID 0000-0002-3591-4772

2*Каф.

«Локомотивы», Днепропетровский

национальный университет железнодорожного

транспорта имени академика

В.

Лазаряна, ул. Лазаряна, 2, Днипро, Украина,

49010, тел. +38 (056) 733 19 61, эл. почта

abochkasov@gmail.com,

ORCID 0000-0002-7719-7214

3Каф.

«Локомотивы», Днепропетровский

национальный университет железнодорожного

транспорта имени академика

В.

Лазаряна, ул. Лазаряна, 2, Днипро, Украина,

49010, тел. +38 (056) 733 19 61, эл. почта

Melnar78@gmail.com,

ORCID 0000-0001-6040-913X

4Каф.

«Высшая математика», Днепропетровский

национальный университет железнодорожного

транспорта имени академика

В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (0562) 36 26 04, эл. почта

grishechkina.tatiana@gmail.com,

ORCID 0000-0003-1570-4150

5Каф.

«Локомотивы», Днепропетровский

национальный университет железнодорожного

транспорта имени академика

В.

Лазаряна, ул. Лазаряна, 2, Днипро, Украина,

49010, тел. +38 (056) 733 19 61, эл. почта

ocheretniukmaksym@gmail.com,

ORCID 0000-0002-9032-8602

МОДЕЛИРОВАНИЕ

ОРГАНИЗАЦИИ РЕМОНТА

ЛОКОМОТИВОВ МЕТОДАМИ

ТЕОРИИ

СИСТЕМ МАССОВОГО ОБСЛУЖИВАНИЯ

Цель.

В

научной работе необходимо оценить

влияние показателей эксплуатации и

надежности локомотивов на систему

организации их ремонта в депо с

использованием методов теории массового

обслуживания. Методика.

В работе представлено

описание цеха по ремонту локомотивов

с помощью терминов и понятий системы

массового обслуживания (СМО). Сформулированы

задачи, решаемые при моделировании

работы ремонтного цеха, приведен

перечень исходных данных и результатов

моделирования. В качестве программного

средства моделирования использована

графическая среда имитационного

моделирования Simulink.

Результаты.

Установлено, что

на основные показатели работы

локомотивного депо влияет объем

перевозок, надежность локомотивов,

используемое правило отбора локомотивов

из очереди, количество работающих

ремонтных стойл. Разработанная модель

ремонтного цеха депо позволяет

рационально планировать использование

оборудования, фонда рабочей силы,

времени постановки локомотивов в ремонт

с учетом равномерности загрузки цеха,

а также усовершенствовать логистику

поставок запасных частей. Эта модель

в упрощенном виде описывает процесс

выполнения ремонта парка магистральных

тепловозов и может быть дополнена в

зависимости от вида выполняемых

в

депо ремонтов. Научная

новизна. В работе

локомотиворемонтное депо представлено

как объект системы массового обслуживания.

Разработана имитационная модель

локомотиворемонтного депо, которая

позволяет проводить анализ влияния

различных факторов на систему организации

ремонта локомотивов

в депо.

Практическая значимость.

Полученные результаты позволяют

определить влияние показателей

эксплуатации и надежности локомотивов

на организацию работы локомотиворемонтного

депо.

В дальнейших исследованиях

разработанная модель может быть

использована для усовершенствования

системы организации ремонта на сети

дорог при внедрении новых серий

локомотивов и изменении стратегии их

технического обслуживания.

Ключевые

слова: цех ремонта

локомотивов; моделирование; система

массового обслуживания; организация

работы ремонтного цеха

REFERENCES

Berestovoy,

A. M., & Lyamzin, A. A. (2003). Modelirovanie sistemy

tekhnicheskogo obsluzhivaniya i remonta lokomotivov. Visnyk

Pryazovskoho derzhavnoho tekhnichnoho universytetu. Seriia:

Tekhnichni nauky,

13,

276-280. (in Russian)

Bosov,

A. A.,

& Loza, P. A. (2015). Teoreticheskie

osnovy ratsionalnogo soderzhaniya podvizhnogo sostava zheleznykh

dorog: monografiya.

Dnepropetrovsk: Driant. (in Russian)

Hryshechkina,

T. S. (2017). Mathematical Model

of the Rational Maintenance System of Railway Transport Technical

Objects.

Transport

Systems and Transportation Technologies.

Collection of Scientific Works of Dnepropetrovsk National

University of Railway Transport named after Academician Lazaryan,

14,

30-35. doi: 10.15802/tstt2017/123165

(in Ukrainian)

Hureva,

А. Н., &

Chernetskaia-Beletskaia,

N. B. (2015).

Fundamentals of Modeling of

Processes of Maintenance of Locomotives. Visnyk

Skhidnoukrainskoho natsionalnoho universytetu imeni Volodymyra

Dalia,

1(218),

262-265.

(in Russian)

Zinenko,

O. L. (2010). Pidvyshchennia

efektyvnosti vykorystannia lokomotyvnoho parku shliakhom

vdoskonalennia upravlinnia ekspluatatsiinoiu robotoiu.

(Dysertatsiia kandydata tekhnichnykh nauk). Dnipropetrovsk National

University of Railway Transport named after Academician V.

Lazaryan, Dnipropetrovsk. (in Ukranian)

Skrebkov,

A. V., Vorobiyov, A. A., Lamkyn, A. G.,

& Bodrikov,

D. I.

(2017).

The

Study of Running and Maintenance Process of Electric Locomotives

with Big Data and Simulation Modeling Tools. Byulleten

rezultatov nauchnykh issledovaniy,

4,

190-198.

(in Russian)

Kudayarov,

M. M. (2012). Vybor optimalnoy organizatsii remonta lokomotivov na

poligone zheleznoy dorogi Izvestiya

Peterburgskogo universiteta putey soobshcheniya, 3(32),

99-103.

(in Russian)

Kudayarov,

M. M. (2012). Optimizatsiya sistemy tekhnologicheskogo protsessa

remonta tyagovogo podvizhnogo sostava. Sovremennye

problemy transportnogo kompleksa Rossii, 2,

14-22.

(in Russian)

Loza,

P. A., &

Hryshechkyna, T. S. (2015). Estimation of the quality of

implementation electric rolling stock maintenance system.

Elektryfikatsiia

transportu,

9,

87-93. (in Russian)

Gorskiy,

A. V.,

Skrebkov, A.

V., Chigambaev,

T. O.,

&

Tsikhalevskiy,

I. S.

(2008). Methods

and Algorithm of Optimum Sending of Locomotives to Repair

Enterprises.

Transport Urala, 3(18),

25-27.

(in Russian)

Zhukovytskyi,

I. V., Skalozub, V. V., Vietrova, O. V., & Zinenko, O. L.

(2006). Modeliuvannia protsesu operatyvnoho planuvannia roboty

lokomotyvnoho parku i lokomotyvnykh bryhad. Visnyk

Dnipropetrovskoho natsionalnoho universytetu zaliznychnoho

transportu imeni akademika V. Lazariana, 12,

74-78.

(in Ukrainian)

Falendysh,

A. P., Sumtsov, A. L., Artemenko, O. V., & Kletska, O. V.

(2016). Simulation of changes in the steady state availability

factor of shunting locomotives for various maintenance systems.

Eastern-European

Journal of Enterprise Technologies, 1/3(79),

24-21.

doi: 10.15587/1729-4061.2016.6064040

(in Ukrainian)

Ochkasov,

O. B., Hryshechkina,

T. S., &

Ocheretnyuk, M. V. (2017).

Approaches to

the system

simulation of

maintenance

operations for

locomotives.

Aktualni problemy avtomatyzatsii ta

upravlinnia : tezy dopovidei V mizhnarodnoi naukovo-praktychnoi

internet-konferentsii molodykh uchenykh i aspirantiv (Lutsk, 28–30

bereznia 2017 r.), 5, 99-104.

(in

Russian)

Sumtsov,

A. L. (2017). Udoskonalennia

metodiv ta modelei vyznachennia systemy tekhnichnoi ekspluatatsii

modernizovanykh manevrovykh teplovoziv.

(Dysertatsiia kandydata

tekhnichnykh nauk).

Ukrainskyi derzhavnyi universytet zaliznychnoho transport,

Kharkiv.

(in Ukraininan)

Shantarenko,

S.

G.

(2005). Modelirovanie

protsessov

tekhnicheskogo

obsluzhivaniya

lokomotivov.

Izvestiya

Tomskogo

politekhnicheskogo

universitetata. Inzhiniring georesursov, 308(5),

169-171. (in Russian)

Bodnar,

B., Ochkasov, A. & Bobyr, D. (2016). Improving Operation and

Maintenance of Locomotives of Ukrainian Railways. Technologijos

ir Menas = Technology and Art, 7,

109-114. (in English)

Bodnar,

B., &

Ochkasov,

О. (2017). System

Choice of the Technical Maintenance of Locomotives Equipped with

on-Board Diagnostic Systems.

Transport Means: Proceedings

of 21st International Science

Conference

(Sept.

20–22, 2017).

Juodkrante, Kaunas, Lithuania,

Pt. I,

43-47.

(in English)

Lovett,

A. H., Dick, C. T., Ruppert, C., Saat, M. R., & Barkan, C.

(2013). Development of an Integrated Model for the Evaluation and

Planning of Railroad Track Maintenance. 2013 Joint

Rail Conference.

doi: 10.1115/jrc2013-2407

(in English)

Ochkasov,

O., Shvets, O.,

& Černiauskaitė, L. (2017). Usage of Intelligent Technologies

in Choosing the Strategy of Technical Maintenance of Locomotives.

Technologijos

ir Menas = Technology and Art, 8,

68-71. (in English)

Wu,

Jun,

& Jia, Hua Fei (2013). Study on Adjustment Evaluation of

Locomotive Affair Productivity Layout. Applied

Mechanics and Materials, 401-403,

2120-2126. doi: 10.4028/www.scientific.net/amm.401-403.2120 (in

English)

Received:

June 20, 2018

Accepted:

October 03, 2018

d

oi

10.15802/stp2018/ ©

B.

E.

Bodnar, A.

V.

Оchkаsоv,

Е. B.

Bodnar, Т. S.

Hryshechkina,

М. V.

Ocheretnyuk,

2018

.

,

– is the probability that at the moment of time t

the system will be in the state

.