ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2018, № 4 (76)

рухомий

склад залізниць і тяга поїздів

UDC

629.463.027.23-027.45

O.

G. REIDEMEISTER1,

O. А. SHYKUNOV2*

1Dep.

«Cars and Car Facilities», Dnipropetrovsk National University named

after Academician V. Lazaryan, Lazaryan St., 2, Dnipro, Ukraine,

49010, tel. +38 (056) 373 15 04,

e-mail reidemeister.a@gmail.com,

ORCID 0000-0001-7490-7180

2*Dep. «Cars and Car

Facilities», Dnipropetrovsk National University named after

Academician V. Lazaryan, Lazaryan St., 2, Dnipro, Ukraine, 49010,

tel. +38 (056) 373 15 04,

e-mail tri_s@ua.fm, ORCID

0000-0002-8256-2634

SENSITIVITY

OF STRESSES TO THE FORCES ACTING ON THE

CAST

PARTS

OF FREIGHT-CAR

BOGIE

Purpose. To

determine the effect of the force components acting in the axle box

and the central spring suspension on the stresses occurring in the

side frame of the three-piece bogie. Methodology. To assess

the effect of the forces acting on the side frame on the stresses in

it, we developed a finite element model of the side frame. After

that, we carried out an assessment of its stress-strain state under

loading conditions corresponding to the І and ІІІ design modes.

According to the results obtained, we determined the stress

concentration points in the construction, which are selected as check

ones for further studies. Also, as checkpoints we took the points

corresponding to the sensor locations when estimating the stresses in

the side frame during the tests. At the next stage, we applied unit

loads in sequence at the interaction points of the side frame with

the boxes and the central spring group. To obtain a more accurate

result, the unit forces were balanced by the corresponding forces and

moments of inertia. With each loading variant, tensors of stresses

arising from the action of unit loads were obtained at checkpoints.

On the basis of the stress tensors obtained, we determined the

corresponding equivalent stresses – the sensitivity coefficients.

Findings. The paper determines the stress sensitivity

coefficients in the three-piece bogie side frame to external loads

acting on the side frame from the side of axle box and central spring

group. Based on the results of the assessment of the coefficients

obtained, we determined the forces having the greatest influence on

individual sections of the side frame. We estimated the possibility

of using the obtained results in optimizing the parameters of the

bogie spring suspension to increase the strength and durability of

the side frame. Originality. For the first time, the effect of

individual components of the forces acting on the side frame on the

stresses in it has been estimated. Practical value. The

obtained result can be used in the design and optimization of

three-piece bogies, to improve the side frame durability. The stress

tensors obtained can be used to estimate the effect of complex

loading on the side frame strength and durability.

Key words:

strength; side frame; three-piece bogie; durability; freight car

Introduction

The

absence in the three-piece bogies of freight cars of devices

preventing from falling onto the track its main supporting elements

such as the bolster and the side frame sharply raise the reliability

requirements imposed on these elements. However, a fairly large

part of the freight train derailment at the current moment is caused

precisely by defects in the cast parts of the bogies, namely, the

side frame fractures.

The

railway enterprises have been facing the problem of mass fracture of

side frames since 2006 [3, 5, 16] and two main directions can be

identified as the main possible causes.

The

first one is low

quality of casting. Work

in this direction revealed two possible causes – hidden defects in

casting [6] and non-compliance with the established steel viscosity

requirements KCV (-60°C) [2]. To solve these problems, the

works are in progress to improve the casting technology –

regulating the metal cooling by updating the moulding flasks or the

design of the side frame itself. Besides, monitoring more strictly

the quality of metal and casting methods by destructive and

non-destructive controls.

The

second possible cause of mass fractures is structural. In 2001,

there was a transition from the I-section of the arch bar on the

supra-box area to the box-like section [14]. It was suggested that

the I-section of the side frame extension acted as an

elastically deforming quencher of torque, which occurs during

critical loosening of side frames relative to each other and the

corresponding angular displacements of the set of wheels in the

pedestal jaw opening. In other words, the I-section design was less

rigid in the horizontal plane and had a slightly loaded position –

the I-section pedestal, which had a compensating effect of the

bending moments of the set of wheels, and in abnormal operation

modes, all defects in the side frame operation were visible. The

solution to this problem is related to the development of methods

for strengthening the side frame structure on the basis of

calculations and tests to determine its strength [7,

13,

15, 17, 23],

reliability, as well as the dynamic characteristics of the car as a

whole [4, 8,

9, 16,

19, 21, 22].

Possible

solutions are attempts to create welded structures of side frames

[1, 11]. This solution, although it will eliminate the problems of

casting, however raises many questions related to the reliability of

welded joints.

To

increase the reliability of the bogie cast parts, it is also

possible to consider the possibility, at the design stage, of the

influence of the spring suspension parameters on the stresses

arising in the parts.

Purpose

To

determine the effect of the force components acting in the axle box

and the central spring suspension on the stresses occurring in the

side frame of the three-piece bogie.

Methodology

The

sensitivity of the indicator

to the value

to the value

(

( – index that separates the considered quantity from the set of

values

– index that separates the considered quantity from the set of

values

,

which

,

which depends

on) means the ratio of the change in the indicator

depends

on) means the ratio of the change in the indicator

to the change

in the argument

to the change

in the argument

,

,

(1)

(1)

In

the case of a linear dependence of the exponent on all arguments,

this definition is unambiguous in the sense that the sensitivity

value

does not depend on the fact at which values of the arguments the

indicator

does not depend on the fact at which values of the arguments the

indicator

was calculated, as well as on the selected increment

was calculated, as well as on the selected increment

.

In the general case it is necessary somehow to characterize the

totality of the values

.

In the general case it is necessary somehow to characterize the

totality of the values

in a compact form. It

is common to use the Morris method for this purpose [20], which

consists in the fact that the sensitivity values are calculated at

random points in the domain of definition with specially chosen

increments of arguments (to reduce the amount of calculations),

and then the mathematical expectation

in a compact form. It

is common to use the Morris method for this purpose [20], which

consists in the fact that the sensitivity values are calculated at

random points in the domain of definition with specially chosen

increments of arguments (to reduce the amount of calculations),

and then the mathematical expectation

and the

and the

mean-square

deviation of the sensitivities

mean-square

deviation of the sensitivities

are

analysed. Fulfilment of condition

are

analysed. Fulfilment of condition

(2)

(2)

indicates

a substantially nonlinear character of the dependence.

Since

the dependence of the stress tensor components on the loads is

linear, and the change in the parameters of the running parts causes

a relatively small change in the loads, the nonlinearities (in

determining the equivalent stresses and the number of cycles before

the appearance of fracture) can hardly be regarded as essential,

which eliminates the need to apply more sophisticated methods of

sensitivity analysis such as Sobol's

indices [18].

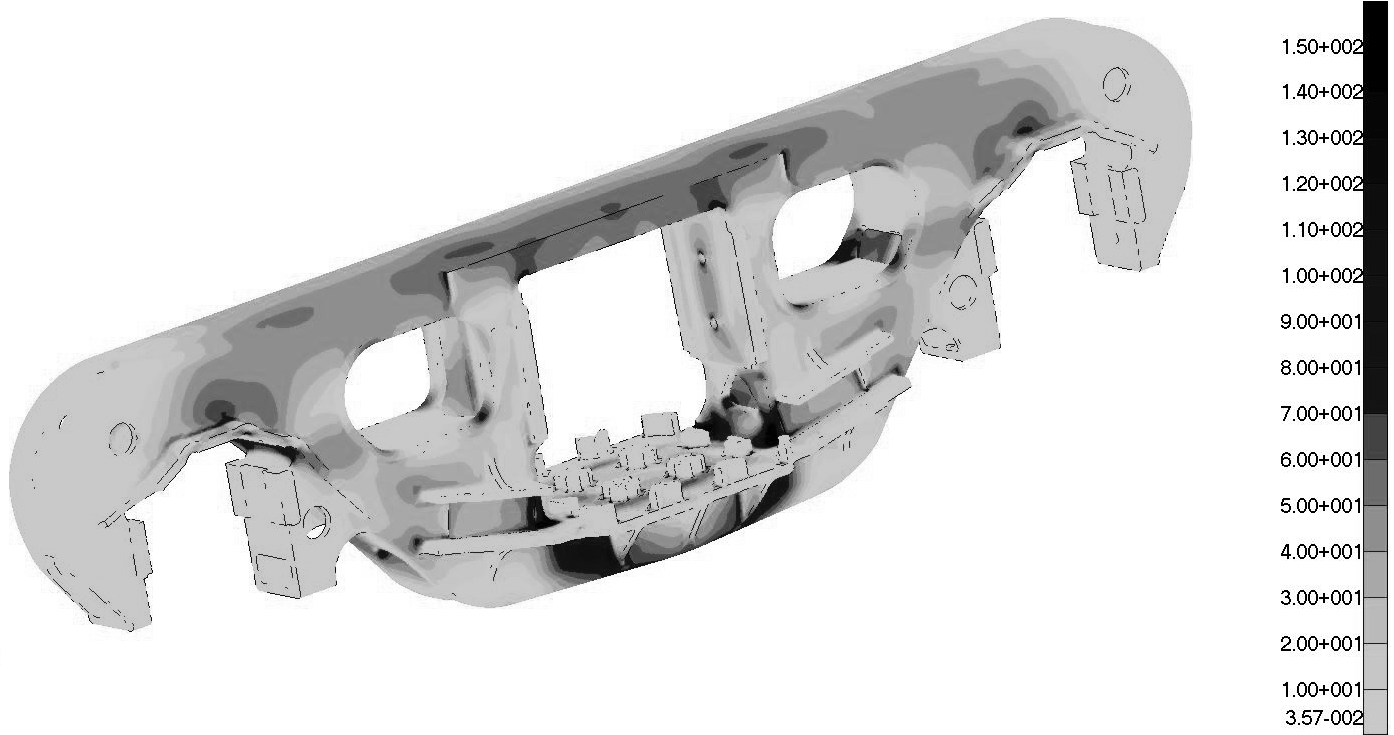

Stresses

that arise in the bogie side frame under the action of a static load

are shown in Figure 1. The heavily loaded areas near the lower

corner of the central spring opening, on the lower side frame member

and at the point R55 of the pedestal jaw opening are clearly

visible. The stress levels in these places for various combinations

of loads are given in Table 1 and approach the maximum permissible

values for 20GL steel. The І calculation mode corresponds to the

loading variants a and b, and III to c...f. Also, the stress

concentration is noticeable in the corners of the process window

(101 MPa) and the upper corners of the central spring opening (114

MPa).

Fig.

1. Stress distribution

in side frame model

for the

III-design mode, MPa.

The

stress concentration at these points is expected from the point of

view of the geometry of the model. Also these points are checkpoints

according to [12].

Table

1

Maximum

stresses in the bogie side frame, MPa

|

Loading

variant

|

Place

of occurrence

|

Permissible

values

|

Estimated

value

|

Checkpoints

|

|

a

|

Lower

corners of the central spring opening

|

250

|

240

|

6,

7, 27

|

|

b

|

Vertical

pedestal roof

|

250

|

235

|

14,

15,

|

|

c

|

Lower

corners of the central spring opening

|

140

|

132

|

6,

7, 27

|

|

d

|

Vertical

pedestal roof

|

140

|

137

|

14,

15,

|

|

e

|

Vertical

pedestal roof

|

140

|

139

|

14,

15,

|

|

f

|

Lower

corners of the central spring opening

|

140

|

131

|

6,

7, 27

|

Taking

into account the obtained results, the points shown in Figure 2 were

chosen to estimate the stressed state of the side frame. Their total

number is 43, they are located in the middle of the lower side frame

member (1-5, 18, 19, 25), in the upper (8, 9) and the lower (6, 7,

26, 27) corners of the central opening for spring suspension, in the

opening between the diagonal tension member and the column (10-13),

in the inner corner of the pedestal opening (14, 15), in the middle

(20-24) and the cantilever part (16, 17) of the arch bar. The points

located symmetrically are not shown in Fig. 2. And they are assigned

with the numbers 4'... 27'.

The

side frame perceives the forces from the central spring suspension

and the axle box. To assess the effect of these forces on the

stresses arising in the side frame, we sequentially determined the

stresses from unit forces acting in three directions at the

appropriate places. To balance the action of unit forces on the side

frame, we applied inertia forces and a moment of inertia

corresponding to the acting forces. The points of application of

unit forces and the direction of the local coordinate axes are shown

in Figure 3

Fig.

2. Checkpoints

.

Fig.

3. Points of application of unit forces

Findings

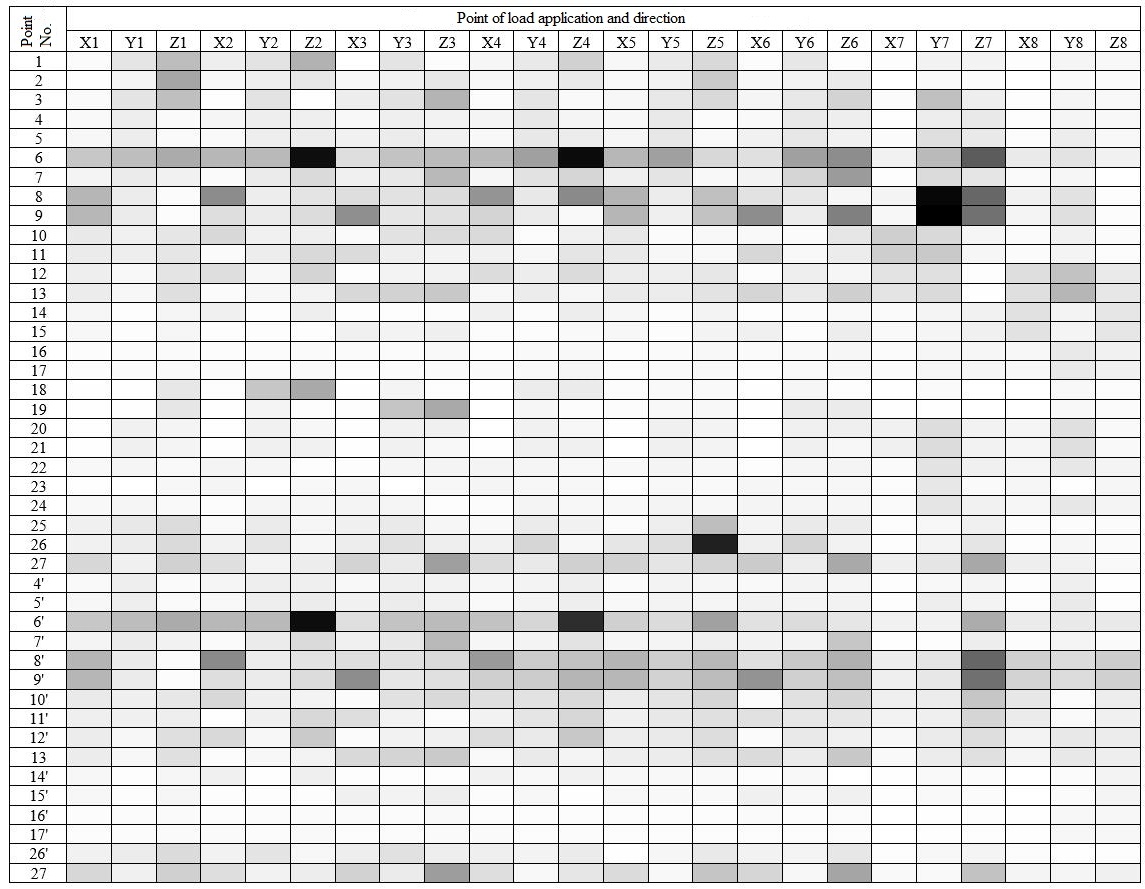

As

a result of the calculation, we obtained the tensors of stresses

arising from the action of unit loads at the side frame checkpoints.

On the basis of the obtained stress components, the corresponding

equivalent stresses arising from the action of unit loads, the

sensitivity coefficients, were calculated. The intensity of the

effect of unit forces on the stresses at the points of the finite

element model is shown in Fig. 4.

In

Figure 4, the intensity of the shading of individual cells

characterizes the degree of the force effect on equivalent stresses

at the point of the model.

Analyzing

the results of the calculation, we can conclude that the points 6,

8, 9 and symmetrical 6', 8' and 9 '- the lower and upper corners of

the central spring opening – are the most sensitive to changes in

the external load, up to 1.204 MPa/kN. Point 26, strengthening rib

in the lower member, is sensitive to the vertical load from the

sub-key spring – 1.054 MPa/kN.

Fig.4.

The intensity of the effect of unit forces on the stresses at the finite element model points

The

points located on the lower member (p. 1 – 3, 18, 19, 25), the

lower corner of the central spring opening (p. 6, 7, 27) are

sensitive to vertical loads acting on the central opening roof, the

sensitivity factor is 0.411 MPa/kN and 1.154 MPa/kN respectively,

and points 6, 7, 27 are also sensitive to vertical loads from the

friction key – up to 0.772 MPa/kN. The transition from the lower

member to the diagonal tension member (p. 4, 5) is almost equally

sensitive to all loading variants except the longitudinal forces in

the pedestal opening and from the action of the friction keys – up

to 0.156 MPa/kN. The upper corner of the central spring opening (p.

8, 9) is sensitive to vertical and transverse loads from the action

of the friction key – up to 1.204 MPa/kN. The

arch bar

in the

middle part

(p. 20-24) is

more sensitive

to the

transverse loads

acting from

the vibration

dampers and

in the

axle box

– up to

0.166 MPa/kN.

For points located in the process window

area (p. 10 – 13) it is quite difficult to determine a specific

group of forces that exert significant influence, since this area

experiences a complex loading – up to 0.348 MPa/kN.

The

inner corner of the pedestal opening (p. 14, 15) is mostly

influenced by longitudinal and vertical forces from the nearest

pedestal opening – up to 0.143 MPa/kN. The arch bar in the

pedestal opening area (p. 16, 17) is

mostly influenced by the forces in the places of vertical and

transverse axle box intersections as well – up to 0.109 MPa/kN,

the influence of the remaining loads is less approximately twofold.

Thus,

to reduce, for example, the stresses in the lower corners of the

pedestal opening (p. 6, 7, 27) by 5% (6.95 MPa, III design mode), it

is necessary to reduce the vertical load on the central spring

opening by 19.64 kN (average sensitivity coefficient is 0.35

MPa/kN). To reduce

stresses in

the inner

corner of

the pedestal

opening (p.

14, 15) by 5%,

it is

necessary to

reduce the

level of

longitudinal or

vertical load

components in

the axle

box by

52 MPa (average

sensitivity

coefficient is

0.132 MPa/kN).

Reducing the load in this range can be

difficult; therefore, along with changes in the parameters of the

spring sets, it is necessary to provide for an increase in the

strength of the structure due to local reinforcement.

In

operation, static forces act on the side frame from the car gross

weight – about 220 kN with an axial load of 23.5 tons per axle and

the dynamic forces arising from the movement of the car can be from

50% to 80% of the static load [10]. Reduction of static loads is not

advisable, since their main component is the load-carrying capacity

of the car. Dynamic loads, the magnitude of which can reach up to

176 kN, can be reduced through the use of rational parameters of

spring suspension and the structure as a whole. At the same time, a

decrease in the dynamic component of the loads acting on the side

frame by only 5% – 8.8 kN, can lead to a decrease in the stress

level in the side frame by 1.37-10.60 MPa. This decrease is not

significant in evaluating the strength of the structure, however, in

assessing its durability, reducing the dynamic load amplitude by 5%

will cause an increase in longevity by 20% (fatigue curve index 4).

Originality

and practical value

For

the first time, the effect of forces acting on the three-piece bogie

side frame on the stress level arising in it has been estimated.

The

obtained sensitivity factors can be used to optimize the parameters

of the freight car bogie for increase of durability of its details.

The

stress tensors obtained can be used to estimate the effect of

complex loading on the side frame strength and durability.

Conclusions

We

determined stress sensitivity coefficients on the certain sections

of the three-piece bogie side frame to external loads acting on the

side frame from the side of the pedestal and spring openings. The

stress tensors obtained can be used to estimate the effect of

complex loading on the side frame strength and durability.

LIST

OF REFERNECE

LINKS

Богатов, А.

А. О повышении служебных характеристик

боковой рамы тележки грузового вагона

/ А. А. Богатов, Р. А. Ильиных // Вестник

ВНИИЖТ. – 2010. – № 6. – С. 42–44.

Волченков,

Н. Стальное литье и методы повышения

качества [Electronic resource]

/ Н. Волченков, В. Моисеенков,

Е. Сургаева // ИИС «Металлоснабжение

и сбыт». – 2011. – Available

at: http://www.metalinfo.ru/ru/news/49443

– Title from

the screen. –

Accessed : 18.07.2018.

Демин, Ю. В.

Улучшение технических характеристик

тележек грузовых вагонов / Ю. В. Демин,

Г. Д. Кочмала // Залізн. трансп. України.

– 1999. – № 3. – С. 26–29.

Динамика

грузовых вагонов с учетом поперечного

смещения тележек / Н. И. Луханин, С. В.

Мямлин,Л. А. Недужая, А. А. Швец // Зб.

наук. пр. Донец. ін-ту залізн. трансп. –

Донецьк, 2012. – № 29. – С. 234–241.

ДСТУ

7598:2014. Вагони вантажні. Загальні вимоги

до розрахунків та проектування нових

і модернізованих вагонів колії 1520 мм

(несамохідних). – Чинний від 2014–01–02.

– Київ : УкрНДНЦ, 2017. – 162 с.

Ишмухамметов,

Ф. Рамы грузовых тележек продолжают

ломаться [Electronic resource]

/ Ф. Ишмухамметов // Коммерсант.ru. –

Available at:

http://www.kommersant.ru/doc/2421946 – Title

from the

screen. – Accessed

: 18.07.2018.

Конькова,

Т. Е. О путях повышения эксплуатационной

надежности стальных литых деталей

тележек грузовых вагонов / Т. Е. Конькова,

В. Б. Беловодский, А. В. Великанов //

Вестник ВНИИЖТ. – 2009. – № 1. – С. 22–26.

Манашкин,

Л. А. Об измерении вертикальных сил в

тележках грузовых вагонов / Л. А.

Манашкин, С. В. Мямлин, Е. А. Письменный

// Вісн. Дніпропетр. нац. ун-ту залізн.

трансп. ім. акад. В. Лазаряна. –

Дніпропетровськ, 2004. –

Вип. 5. – С.

132–135.

Мурадян,

Л. А. Залежність величини зносу пари

тертя «п’ятник–підп’ятник» від

пробігу вантажного вагона / Л. А. Мурадян,

Д. О. Подосьонов, В. Ю. Шапошник // Наука

та прогрес транспорту. – 2017. – № 6

(72). – С. 61–69.

doi:

10.15802/stp2017/118136

Мурадян,

Л. А. К вопросу о планах испытаний

надежности механических систем / Л. А.

Мурадян, В. Ю. Шапошник // Зб. наук. пр.

Укр. держ. ун-ту залізн. трансп. – Харків,

2015. – Вип. 157. – С. 119–128.

Перспективы

создания сварных конструкций несущих

элементов тележки грузового вагона /

О. В. Махненко, Г. Ю. Сапрыкина,

И. В. Мирзов, А. Д. Пустовой //

Автоматическая сварка. – 2014. – № 3.

– С. 36–42.

РД

24.050.37.95. Вагоны грузовые и пассажирские.

Методы испытания на прочность и ходовые

качества. – Москва : ГосНИИВ, 1995. – 101

с.

Рейдемейстер,

А. Г. Способы увеличения прочности

боковых рам трехэлементных тележек /

А. Г. Рейдемейстер, А. А. Шикунов // Наука

та прогрес транспорту. – 2015. – № 5 (59).

– С. 141–149.

doi: 10.15802/stp2015/55351

Савчук, В.

Б. Радиус излома на Совете главных

конструкторов / В. Б. Савчук, Г.

М. Зобов // Техника железных дорог.

– 2013. – № 2 (22). – С. 32–36.

Ушкалов,

В. Ф. Определение состава и уровня сил,

действующих на консольную часть боковой

рамы в процессе эксплуатации грузового

вагона / В. Ф. Ушкалов, Н. В. Безрукавый

// Техническая механика. – 2016. – № 2. –

С. 85–90.

Шупелов,

Н. Анализ изломов боковых рам (2006÷2014

гг.) [Electronic resource] / Н.

Шупелов

// MyShared. – Available at: http://www.myshared.ru/slide/992141

– Title from the screen. – Accessed : 18.07.2018.

A

new lever-type variable friction damper for freight bogies used in

heavy haul railway / Ximing

Xu, Maohai Fu, Zhaoxia Xu, Zhongyi Chen //Journal

of Modern Transportation. – 2016. – Vol. 24. – Iss. 3. – P.

159–165.

doi: 10.1007/s40534-016-0116-4

Global

sensitivity analysis. The primer / A. Saltelli, M. Ratto, T.

Andres, F. Campolongo, J. Cariboni, D. Gatelli, M. Saisana, S.

Tarantola. – Chichester, West Sussex, England : John Wiley &

Sons, 2008. – 292 p.

Mathematical

Modeling of Dynamic Loading of Cassette Bearings for Freight Cars /

S. Myamlin, O. Lunys, L. Neduzha, O. Kyryl’chuk // Тransport

Means : Proc. of 21st Intern. Scientific Conf. (20–22nd

September, 2017). – Kaunas, 2017.

– Р. 973–976.

Morris,

M. D. Factorial sampling plans for preliminary computational

experiments / Max D. Morris // Technometrics. – 1991. – Vol.

33, No. 2. – Р. 161–174.

Prospects

for the Use of Gondola Cars on Bogies of Model ZK1 in the

Organization of Heavy Freight Traffic in the Republic of Kazakhstan

/ S.

Abdullayev, G. Imasheva, N. Tomkurzina, N. Adilova, G. Bakyt //

Mechanics. – 2018. – Vol. 24. – Iss. 1. – P. 32–36. doi:

10.5755/j01.mech.24.1.17710

Reidemeister,

O. H. Method of Constructing the Dynamic Model of Movement of the

Multi-Mass System / O. H.

Reidemeister, V. O. Kalashnyk, O. A. Shykunov //

Наука та

прогрес транспорту.

– 2017. – № 5 (71). – С. 99–106.

doi:

10.15802/stp2017/112921

Shykunov,

O. A. Three-element bogie side frame strength / О.

А. Shykunov // Наука

та прогрес

транспорту. – 2017. – № 1

(67). – С.

183–193.

doi: 10.15802/stp2017/92535

О. Г. РЕЙДЕМЕЙСТЕР1,

О. А. ШИКУНОВ2*

1Каф.

«Вагони та вагонне господарство»,

Дніпропетровській національний

університет залізничного транспорту

імені академіка В. Лазаряна, вул.

Лазаряна, 2, Дніпро, Україна, 49010,

тел. +38 (056) 373 15 04,

ел. пошта

reidemeister.a@gmail.com,

ORCID 0000-0001-7490-7180

2*Каф. «Вагони та

вагонне господарство», Дніпропетровській

національний університет залізничного

транспорту імені академіка В. Лазаряна,

вул. Лазаряна, 2, Дніпро, Україна, 49010,

тел. +38 (056) 373 15 04,

ел. пошта tri_s@ua.fm,

ORCID 0000-0002-8256-2634

ЧУТЛИВІСТЬ

НАПРУЖЕНЬ ДО СИЛ, ЩО ДІЮТЬ НА ЛИТІ ДЕТАЛІ

ВІЗКІВ ВАНТАЖНИХ ВАГОНІВ

Мета.

Визначити вплив

компонентів сил, які діють у буксовому

вузлі та центральному ресорному ступені

підвішування, на напруження, що виникають

у бічній рамі трьохелементного візка,

– основна мета наукової роботи.

Методика. Для

оцінки впливу сил на виникнення напруги

в бічній рамі була розроблена її

кінцево-елементна модель. Після цього

проведена оцінка напружено-деформованого

стану бічної рами при варіантах

навантаження, відповідних І і ІІІ

розрахунковим режимам.

За отриманими результатами

визначені точки концентрації напружень

у конструкціях, які обрані в якості

контрольних для подальших досліджень.

Також в якості контрольних прийняті

точки, що відповідають місцям встановлення

датчиків при оцінці напружень у бічній

рамі під час випробувань. На наступному

етапі послідовно прикладалися одиночні

навантаження в місцях взаємодії бічної

рами з буксами і центральним ресорним

комплектом. Для отримання більш точного

результату одиничні сили були врівноважені

відповідними силами та моментами

інерції. При кожному варіанті навантаження

в контрольних точках були отримані

тензори напружень, що виникають під

дією одиничних навантажень. На основі

отриманих тензорів напружень визначалися

відповідні еквівалентні напруження –

коефіцієнти чутливості.

Результати. У роботі

визначені коефіцієнти чутливості

напруг до зовнішніх навантажень у

бічній рамі трьохелементного візка.

Зовнішні навантаження діють на раму з

боку букси і центрального ресорного

комплекту. За результатами оцінки

отриманих коефіцієнтів визначені сили,

що чинять найбільший вплив на окремі

ділянки бічної рами.

Наукова новизна. Вперше

наведена оцінка впливу окремих

компонентів сил, що діють на бічну раму,

на напруги в ній. Подана оцінка можливості

застосування отриманих результатів

під час оптимізації параметрів ресорного

підвішування візка для збільшення

міцності й довговічності бічної рами.

Практична значимість. Отриманий

результат може бути використаний під

час проектування й оптимізації

трьохелементного візка, для підвищення

довговічності бічних рам. Отримані

тензори напружень можуть бути використані

для оцінки впливу складного навантаження

на міцність і довговічність бічної

рами.

Ключові

слова: міцність; бічна рама;

трьохелементний візок; довговічність;

вантажний вагон

А. Г. РЕЙДЕМЕЙСТЕР1,

А. А. ШИКУНОВ2*

1Каф.

«Вагоны и вагонное хозяйство»,

Днепропетровский национальный

университет железнодорожного транспорта

имени академика В. Лазаряна, ул. Лазаряна,

2, Днипро, Украина, 49010, тел. +38 (056) 373 15 04,

эл. почта reidemeister.a@gmail.com,

ORCID 0000-0001-7490-7180

2*Каф.

«Вагоны и вагонное хозяйство»,

Днепропетровский национальный

университет железнодорожного транспорта

имени академика В. Лазаряна, ул. Лазаряна,

2, Днипро, Украина, 49010, тел. +38 (056) 373 15 04,

эл. почта tri_s@ua.fm,

ORCID 0000-0002-8256-2634

ЧУВСТВИТЕЛЬНОСТЬ

НАПРЯЖЕНИЙ К СИЛАМ, ДЕЙСТВУЮЩИМ НА

ЛИТЫЕ ДЕТАЛИ ТЕЛЕЖЕК ГРУЗОВЫХ ВАГОНОВ

Цель.

Определить влияние

компонентов сил, действующих в буксовом

узле и центральной рессорной ступени

подвешивания, на напряжения, возникающие

в боковой раме трёхэлементной тележки

грузового вагона, – основная цель

научной работы. Методика.

Для оценки влияния сил на возникновение

напряжения в боковой раме была

разработана ее конечно-элементная

модель. После этого проведена оценка

напряженно-деформированного состояния

боковой рамы при вариантах нагружения,

соответствующих І и ІІІ расчетным

режимам. По полученным результатам

определены точки концентрации напряжений

в конструкции, которые выбраны в качестве

контрольных для дальнейших исследований.

Также в качестве контрольных приняты

точки, соответствующие местам установки

датчиков при оценке напряжений в боковой

раме во время испытаний. На следующем

этапе последовательно прикладывались

единичные нагрузки в местах взаимодействия

боковой рамы с буксами и центральным

рессорным комплектом. Для получения

более точного результата единичные

силы были уравновешены соответствующими

силами и моментами инерции. При каждом

варианте нагружения в контрольных

точках были получены тензоры напряжений,

возникающие от действия единичных

нагрузок. На основе полученных тензоров

напряжений определялись соответствующие

эквивалентные напряжения – коэффициенты

чувствительности. Результаты.

В работе определены

коэффициенты чувствительности напряжений

к внешним нагрузкам в боковой раме

трехэлементной тележки. Внешние нагрузки

действуют на раму со стороны буксы и

центрального рессорного комплекта. По

результатам оценки полученных

коэффициентов определены силы,

оказывающие наибольшее влияние на

отдельные участки боковой рамы.

Научная

новизна. Впервые

проведена оценка влияния отдельных

компонентов сил, действующих на боковую

раму, на напряжения в ней. Дана оценка

возможности применения полученных

результатов при оптимизации параметров

рессорного подвешивания тележки для

увеличения прочности и долговечности

боковой рамы. Практическая

значимость. Полученный

результат может быть использован при

проектировании и оптимизации

трехэлементных тележек, для повышения

долговечности боковых рам. Полученные

тензоры напряжений могут быть использованы

для оценки влияния сложного нагружения

на прочность и долговечность боковой

рамы.

Ключевые

слова:

прочность; боковая рама;

трехэлементная тележка;

долговечность; грузовой вагон

REFERENCES

Bogatov,

A. A., & Ilinykh, R. A. (2010). O povyshenii sluzhebnykh

kharakteristik bokovoy ramy telezhki gruzovogo vagona. Vestnik

of the Railway Research Institute, 6, 42-44.

(in Russian)

Volchenkov,

N., Moiseenkov, V., & Surgaeva, Ye. (2011). Stalnoe lite i

metody povysheniya kachestva. IIS

Metallosnabzhenie i sbyt. Retrieved

from http://www.metalinfo.ru/ru/news/49443

(in Russian)

Demin,

Yu. V., & Kochmala, G. D. (1999). Uluchshenie tekhnicheskikh

kharakteristik telezhek gruzovykh vagonov.

Zaliznychnyj transport Ukrajiny, 3, 26-29.

(in Russian)

Lukhanin,

N. I., Myamlin, S. V., Neduzhaya, L. A., & Shvets, A. A.

(2012). Dinamika gruzovykh vagonov s uchetom poperechnogo

smeshcheniya telezhek. Zbirnik

naukovih prac' of Donetsk Railway Transport Institute,

29,

234-241. (in

Russian)

Vagoni

vantazhnі. Zagalnі vimogi do rozrakhunkіv ta proektuvannya

novikh і modernіzo-vanikh vagonіv kolії 1520 mm

(nesamokhіdnikh), 162 DSTU 7598:2014 (2017). (in Ukranian)

Ishmukhammetov,

F. (2014). Ramy gruzovykh telezhek prodolzhayut lomatsya.

Kommersant.ru.

Retrieved from http://www.kommersant.ru/doc/2421946 (in

Russian)

Konkova,

T. Ye., Belovodskiy, V. B., & Velikanov, A. V. (2009). O

putyakh povysheniya ekspluatatsionnoy nadezhnosti stalnykh litykh

detaley telezhek gruzovykh vagonov. Vestnik of the

Railway Research Institute, 1, 22-26. (in

Russian)

Manashkin,

L. A., Myamlin, S. V., & Pismennyy, Y. A. (2004). About

measuring vertical forces in freight car bogies.

Bulletin of Dnipropetrovsk National University of Railway Transport

named after Academician V. La-zaryan, 5, 132-135.

(in Russian)

Muradyan,

L. A., Podosonov, D. O., & Shaposhnik, V. Yu. (2017).

Theoretical dependence of wear value of friction pair «cenetr

plate – center pad» on a freight car mileage. Science

and Transport Progress, 6(72), 61-69.

doi: 10.15802/stp2017/118136 (in Ukranian)

Muradyan,

L. A., & Shaposhnik, V. Yu. (2015). Question of Plans at Trials

Reliability of Mechanical Systems. Collected

Scientific Works of Ukrainian State University of Railway

Transport,

157, 119-128.

(in Russian)

Makhnenko,

O. V., Saprykina, G. Yu., Mirzov, I. V., & Pustovoy, A. D.

(2014). Perspektivy sozdaniya svarnykh konstruktsiy nesushchikh

elementov telezhki gruzovogo vagona. Avtomaticheskaya

svarka, 3, 36-42. (in Russian)

Vagony

gruzovye i passazhirskie. Metody ispytaniya na prochnost i khodovye

kachestva, 101 RD 24.050.37.95 (1995).

(in Russian)

Reydemeyster,

A. G., & Shikunov, A. A. (2015). Strength increase methods of

the side frame of the bogie in three-piece truck. Science

and Transport Progress, 5(59),

141-149. doi: 10.15802/stp2015/55351 (in

Russian)

Savchuk,

V. B., & Zobov, G. M. (2013). Radius izloma na Sovete glavnykh

konstruktorov. Tekhnika zheleznykh

dorog, 2(22),

32-36. (in

Russian)

Ushkalov,

V. F., & Bezrukavyy, N. V. (2016). Opredelenie sostava i

urovnya sil, deystvuyushchikh na konsolnuyu chast bokovoy ramy v

protsesse ekspluatatsii gruzovogo vagona. Tekhnicheskaya

mekhanika, 2, 85-90.

(in Russian)

Shupelov,

N. (2015). Analiz izlomov bokovykh ram (2006÷2014 gg.). MyShared.

Retrieved from http://www.myshared.ru/slide/992141 (in

Russian)

Xu,

X., Fu, M., Xu, Z., & Chen, Z. (2016). A new lever-type

variable friction damper for freight bogies used in heavy haul

railway. Journal of Modern

Transportation, 24(3),

159-165. doi: 10.1007/s40534-016-0116-4 (in

English)

Saltelli,

A., Ratto, M., Andres, T., Campolongo, F., Cariboni, J., Gatelli,

D., Saisana, M., & Tarantola,

S. (2008). Global

sensitivity analysis. The primer.

Chichester, West Sussex, England: John Wiley & Sons.

(in English)

Myamlin,

S., Lunys, O., Neduzha, L., & Kyryl’chuk, O. (2017).

Mathematical Modeling of Dynamic Loading of Cassette Bearings for

Freight Cars. Тransport

Means:

Proc. of 21st Intern. Scientific Conf, 20-22 September, 2017,

Kaunas, 973-976. (in

English)

Morris,

M. D. (1991). Factorial sampling plans for preliminary

computational experiments. Technometrics,

33(2), 161-174.

(in English)

Imasheva,

G., Abdullayev, S., Tokmurzina, N., Adilova, N., & Bakyt, G.

(2018). Prospects for the Use of Gondola

Cars on Bogies of Model ZK1 in the Organization of Heavy Freight

Traffic in the Republic of Kazakhstan. Mechanics,

24(1),

32–36. doi: 10.5755/j01.mech.24.1.17710

(in English)

Reidemeister,

O. H., Kalashnyk, V. O., & Shykunov, O. A. (2017). Method of

Constructing the Dynamic Model of Movement of the Multi-Mass

System. Science and Transport

Progress, 5(71),

99-106.

doi: 10.15802/stp2017/112921

(in English)

Shykunov,

O. A. (2017). Three-element bogie side frame strength. Science

and Transport Progress, 1(67),

183-193. doi: 10.15802/stp2017/92535 (in

English)

Received:

April 10, 2018

Accepted:

July 17, 2018

d oi

10.15802/stp2018/141186 ©

A. G. Reydemeyster, O. А.

Shykunov, 2018

oi

10.15802/stp2018/141186 ©

A. G. Reydemeyster, O. А.

Shykunov, 2018

to the value

(

– index that separates the considered quantity from the set of

values

,

which

depends

on) means the ratio of the change in the indicator

to the change

in the argument

,

(1)

does not depend on the fact at which values of the arguments the

indicator

was calculated, as well as on the selected increment

.

In the general case it is necessary somehow to characterize the

totality of the values

in a compact form. It

is common to use the Morris method for this purpose [20], which

consists in the fact that the sensitivity values are calculated at

random points in the domain of definition with specially chosen

increments of arguments (to reduce the amount of calculations),

and then the mathematical expectation

and the

mean-square

deviation of the sensitivities

are

analysed. Fulfilment of condition

(2)