ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2018, № 4 (76)

рухомий

склад залізниць і тяга поїздів

UDC 629.4.02

M. I. KAPITSA1*,

o. M. HNENNYi2*,

d. V. BOBYR3*

1*Dep.

«Locomotives», Dnipropetrovsk National University of Railway

Transport named after Academician V. Lazaryan,

Lazaryan St., 2,

Dnipro, Ukraine, 49010, tel. +38 (0562) 33 19 61, e-mail

m.i.kapitca@ua.fm, ORCID 0000-0002-3800-2920

2*Dep.

«Economics and Management», Dnipropetrovsk National University of

Railway Transport named after Academician

V. Lazaryan, Lazaryan

St., 2, Dnipro, Ukraine, 49010, tel. +38 (056) 373 15 80, e-mail

oleggnennij@gmail.com,

ORCID 0000-0002-2944-5105

3*Dep.

«Locomotives», Dnipropetrovsk National University of Railway

Transport named after Academician V. Lazaryan,

Lazaryan St., 2,

Dnipro, Ukraine, 49010, tel. +38 (0562) 33 19 61, e-mail

dmitrob@ua.fm, 0000-0003-1441-3861

EFFICIENCY OF MODERNIZATION OF WHEEL-MOTOR BLOCKS

USING ANTI-FRICTION TRACTION MOTOR SUPPORT BEARINGS

Purpose. The use of anti-friction traction motor

support bearings (TMSB) instead of plain friction traction motor

support bearings is a priority direction of locomotive development

both for newly constructed locomotives and for those in operation.

The solution of the set tasks for introduction of wheel-motor blocks

(WMB) with anti-friction bearings demanded the search for alternative

variants and new technical solutions. The purpose of the article is

to determine the feasibility of re-equipping the diesel locomotive

wheel-motor blocks with anti-friction bearings through the life cycle

calculation (LCC). Methodology. The procedure and

criteria for assessing the economic efficiency of project

(investment) proposals and investment projects approved by the

Cabinet of Ministers of Ukraine envisage that the cost-effectiveness

analysis of an investment project is carried out according to the

following criteria: net present value, internal rate of return,

discounted payback period and profitability index. The use of these

criteria of economic efficiency fully corresponds to modern

principles, theoretical-methodical approaches and world practice in

evaluating the efficiency of investments. The evaluation of the

technical and economic efficiency of the modernization of the diesel

locomotive wheel-motor block is made on the basis of calculation and

comparison of the following criteria: the net present value (NPV)

of modernization, the internal rate of return (IRR), the

profitability index (PI) and the discount payback period.

Findings. The results of the calculations of the values of the

main criteria show that the innovative project for the modernization

of the locomotive provides a high level of economic efficiency. At

the same time, the value of the discounted payback period of

investments in modernization indicates that it is expedient to carry

out this operation if the residual life of the upgraded locomotive of

the M62 series is at least 15 months. Originality. Taking into

account the specifics of the type of locomotive work in freight

traffic, we developed a method to determine the individual components

of the average annual economic effect of modernization of the diesel

locomotive wheel-motor block, which includes saving of oil costs,

repairing and servicing the diesel locomotive wheel-motor unit, as

well as change of TMSB brass and saving fuel costs for traction.

Practical value. The results of the work make it possible

to determine the expediency of modernization of diesel locomotives

taking into account the features and conditions of their operation

and the specifics of modernization.

Keywords: diesel locomotive modernization;

wheel-motor block; technical and economic efficiency; anti-friction

bearings; life cycle

Introduction

The priority direction of the

investment policy of PJSC «Ukrzaliznytsia» in the locomotive

economy of Ukraine in recent years is to provide a quick,

comprehensive renovation and optimization of the traction rolling

stock structure. This is due to the fact that most of the traction

rolling stock was procured and delivered to operation even in Soviet

times. Analysis of the state of the operating fleet of the traction

rolling stock of Ukrainian railways indicates that its wear is 97.1%

[11]. As it is known, the results of rail transport activity in

general depend on the level of technical excellence and the state of

the traction rolling stock, conditions of its operation, repair and

maintenance systems [14, 15].

The traction

rolling stock may be renewed due to the purchase of a new one and

the modernization of the existing one. In both cases, this requires

significant capital investments. It is also necessary to take into

account that the return on investments in modernization of

locomotives is 3-4 times faster than in their acquisition.

Therefore, in the context of market relations and financial

constraints, the problem of investment support for the renewal of

the tractive rolling stock of the locomotive economy of Ukrainian

railways is put forward at the level of problems of national

importance, the solution of which directly affects the provision of

national security.

During the

last years, the Department of the Locomotive Economy has introduced

a number of steps for modernization of the traction rolling stock,

aimed at reducing the cost of repairs and fuel and lubricants in

operation. Directions of accomplished and planned modernizations

mainly concern the replacement of power equipment. However, no less

effective direction of modernization of the traction rolling stock

is the improvement of underframe design, namely the refitting of WMB

from plain friction bearings to anti-friction bearings [2].

Anti-friction bearings have

several advantages over plain friction bearings. The main advantage

of anti-friction bearings in comparison with plain friction bearings

is the lower energy consumption for the friction process (friction

moment in ball bearings is approximately 3-6 times less than that of

plain friction bearings [6, 12]).

All new

foreign locomotives are equipped with anti-friction TMSB. Their

implementation allows conducting the locomotive maintenance M-2 not

every 3-4 days, but every 10-12 or more. It is the replenishment of

the plain friction TMSB with axial oil that requires the need for

such frequent maintenance M-2 for 90% of the locomotive fleet [12].

Estimated resource of

anti-friction TMSB is not less than 5 million km of locomotive

mileage. Application of wheel-motor blocks with anti-friction TMSB

increases the cost of a locomotive, but payback is achieved due to

the presence of the following factors:

– Exclusion

from the technological process of servicing and repair of WMB of

axial oils and the necessity of their seasonal change;

– Cost

reduction for technical maintenance and repairs of the WMB with

anti-friction TMSB;

– Increase

of reliability and service life of traction gear and traction

electric motor (TEM) due to absence of distortion caused by wear of

brass inserts of plain friction traction motor support bearings;

– Increase

in the wheel set life cycle due to the lack of wear of the journals

under the plain friction TMSB;

– Absence

of the need to pay fines for environmental pollution by eliminating

the leakage of axial oils on the permanent way;

– Increase

in the locomotive profitability – increase in the use of power for

draft, increase in efficiency by reducing the main resistance of the

locomotive, and, accordingly, reducing fuel consumption for traction

from 2% to 6.6% [8, 12].

Thus, the use of anti-friction

TMSBs instead of plain friction TMSBs is a priority direction for

locomotive development for newly constructed locomotives and for

those in operation.

The solution of the set tasks

for introduction of WMB with anti-friction bearings demanded the

search for alternative variants and new technical solutions.

Therefore, the specialists of «Scientific and Technical Center

«Pryvod» LLC and PJSC «Scientific-Production Enterprise

«Smelyansky Electromechanical Plant» have been developed and

patented in the State Intellectual Property Service of Ukraine

(patent for utility model No. 84796 dated October 25, 2013) the

project for modernization of WMB locomotive with anti-friction TMSB

replacement.

Modernization of WMB consists

of two stages:

– Modernization

of traction electric motor with prolongation of service life for 15

years;

– Modernization

of wheel set and the gear casing (if required).

In accordance with the

technical specifications of TU U 30.2-38414897-004: 2014

«Modernization of wheel-motor blocks of locomotives including

replacement of plain friction TMSB with the anti-friction TMSB»,

modernization of the traction motor is carried out during its

overall repair. This includes the repair of the engine case, anchor

and magnetic system with replacement of windings and isolation of

the class of heat resistance not lower than «H», bearing units

with the restoration of their sizes to drawings and the execution

(if necessary) of improvements in accordance with the requirements

of design documentation for modernization. Conducting of

modernization can increase the TEM life for 15 years.

Purpose

The purpose of the article is

to determine the technical and economic efficiency of the

modernisation of locomotive WMB TMSB with anti-friction bearings

based on LCC calculations.

Methodology

At the present time in Ukraine

there are several normative documents in the field of

cost-effectiveness analysis of investments. The main ones are:

– Procedure

and Criteria for Assessing the Economic Efficiency of Project

(Investment) Proposals and Investment Projects, approved by the

Cabinet of Ministers of Ukraine as of 18.07.2012, No. 684;

– Methodological

Recommendations on Development of State Supported Investment

Projects, approved by Order of the Ministry of Economic Development

and Trade of Ukraine as of 13.11.2012, No. 1279;

– Methodological

Recommendations on Assessment of Economic and Social Efficiency of

State Target Program Implementation, approved by Order of the

Ministry of Economy of Ukraine as of 24.06.2010, No. 742;

– Methodology

of Conducting State Expertise of Investment Projects, approved by

Order of the Ministry of Economic Development and Trade of Ukraine

as of 13.03.2013, No. 243;

– Methodological

Recommendations on Development of Business Plan of Enterprises,

approved by Order of the Ministry of Economy of Ukraine as of

06.09.2006, No. 290;

– Methodology

for Determining the Cost-effectiveness of Research and Development

and their Implementation in Production, approved by Order of the

Ministry of Economy and European Integration and the Ministry of

Finance of Ukraine as of 26.09.2001, No. 218/446.

The Procedure and Criteria for

Assessing the Economic Efficiency of Project (Investment) Proposals

and Investment Projects, approved by the Cabinet of Ministers of

Ukraine as of 18.07.2012 No. 684 stipulate that the assessment of

the economic efficiency of an investment project is carried out

according to the following criteria: net present value, internal

rate of return, discounted payback period and profitability index.

Herewith, the conclusion is positive about the effectiveness of the

investment project, if the net present value is positive, the

internal rate of return is greater than the standard discount rate,

and the profitability index exceeds 1. The use of these criteria of

economic efficiency fully corresponds to modern principles,

theoretical and methodological approaches and world practice

regarding assessment of investment efficiency. However, the

mentioned document does not contain specific methodological

approaches, but suggests that the calculation of the criteria for

the economic efficiency of an investment proposal, an investment

project is carried out in the light of the Methodological

Recommendations on Development of State Supported Investment

Projects, approved by the Ministry of Economic Development and

Trade.

Methodological

Recommendations on Development of State Supported Investment

Projects, approved by Order of the Ministry of Economic Development

and Trade of Ukraine as of 13.11.2012, No.

1279 contains

(paragraph 2.8) the methodology for determining the above mentioned

investment efficiency indices. At the same time, the methodological

recommendations do not explain the issue of considering risks when

assessing the effectiveness of the project. It is intended to

provide in the project a separate section on information on project

risks, precautionary measures and risk insurance in cases stipulated

by law (paragraph 2.10). Herewith, only a qualitative characteristic

of risks is foreseen. That is, the above Methodological

Recommendations do not contain quantitative methods for assessing

investment risks and their accounting procedure when assessing the

cost-effectiveness of an investment project.

Methodological

Recommendations on Assessment of Economic and Social Efficiency of

State Target Program Implementation, approved by Order of the

Ministry of Economy of Ukraine as of 24.06.2010, No. 742, among

other things, contain an algorithm for calculating the four key

indices of economic efficiency, which coincides with the methods

presented in the above Methodical Recommendations on Development of

Investment Project. It also

proposes the

use of

several specific

indices for

innovative

projects: value

added, ratio

of investments

(private and

public),

commercialization

coefficient and

new product

sales

coefficient. In

addition, the Methodical recommendations under consideration include

methods for assessing the synergistic economic effect of program

interaction, which allow assessing the economic effectiveness of the

program as a system of interconnected projects, that is to move from

the assessment of individual investment projects to the assessment

of the effectiveness of their integrated implementation. The

synergistic effect of program interaction includes the effects of

program centralization, concentration, specialization, cooperation

and replication of intermediate and final results. The mentioned

Methodological Recommendations contain methodological approaches to

the determination of each of these effects. However, these

Methodological Recommendations do not also contain the

methodological approaches to risk assessment in determining the

cost-effectiveness of investment projects and programs.

Methodological Recommendations

on Development of Business Plan of Enterprises, approved by Order of

the Ministry of Economy of Ukraine as of 06.09.2006, No. 290 contain

methodological approaches for forecasting cash flows from the

activity of the enterprise and determination of economic investment

efficiency indices, which, in general, coincide with the

Methodological Recommendations on Development of Investment Project,

are more detailed. The Methodological Recommendations under

consideration also do not include approaches to quantitative

investment risk. However, based on the analysis of paragraph

2.1.10.3 of the Methodological Recommendations, one can conclude

that the main way of taking into account the risks in assessing the

economic efficiency of investments is to increase the discount rate

by the risk premium, since it is determined that «discount rate (r)

is the rate of profit, that investors usually receive from

investments of similar content and degree of risk».

Methodology

for Determining the Cost-effectiveness of Research and Development

and their Implementation in Production, approved by Order of the

Ministry of Economy and European Integration and the Ministry of

Finance of Ukraine as of 26.09.2001, No. 218/446 contains approaches

to the definition of key indices of economic efficiency of projects.

At the same time there are differences with the previously

considered normative acts in determining the «profitability index

«. So in these recommendations it is defined as the ratio of net

discounted income to the discounted investment value, and in all

other regulatory acts – as the ratio of the present value of the

results (net cash inflow) to the present value of investment outlay.

As the Procedure and Criteria for Assessing the Economic Efficiency

of Project (Investment) Proposals and Investment Projects, approved

by the Cabinet of Ministers of Ukraine as of 18.07.2012 No. 684

determines the efficiency criterion as the profitability index

higher than 1, more correct definition of this index is given in the

Methodological Recommendations on

Development of State Supported Investment Projects, approved by

Order of the Ministry of Economic Development and Trade of Ukraine

as of 13.11.2012, No. 1279. However, the Methodology for Determining

the Cost-effectiveness of Research and Development and their

Implementation in Production contains certain elements of

methodological approaches to risk assessment when measuring

efficiency. Thus, the paragraphs 3.20 and 3.21 of the Methodology

stipulate that mid-term and long-term R & D projects concerning

the timing of their implementation need to take into account the

uncertainty and risk factor. The following methods can be used to

take into account the uncertainty and risk factor: verification of

project sustainability, adjustment of project parameters, formal

description of uncertainty. The

project sustainability is determined by the break-even point.

Correction of project parameters is based on refinement of the

initial technical and economic task, including the terms of the

project due to delays in financing its stages, procedural violations

in the implementation of innovations, violation of terms of

feedstock supply and other complications. In all cases of such

violations the resulting losses are added to the project cost

structure. The paragraph 3.22 (formula 3.16) of the Methodology

stipulates the application of a capital asset valuation model to

determine the discount rate allowing for risk.

Thus, domestic regulatory acts

in the field of cost-effectiveness analysis of innovation and

investment projects reflect a certain methodical toolkit on the

structure of forecast cash flows, the definition of their

components, the calculation of the main indicators of economic

efficiency of investment, taking into account the factor of time,

which in general corresponds to the modern theoretical foundations

of cost-effectiveness analysis and project analysis [1, 3, 4, 7, 10,

13, 15].

A cost-effectiveness analysis

of an innovation and investment project is carried out at such

stages.

Determination of project

life cycle.

II.

Forecast of cash flows by the base project scenario.

III.

Quantitative assessment of the risk level of the project.

IV.

Determination of discount rates for the base investment project

scenario based on the rate of return and risk level.

V. Determination of indices of

effectiveness by the base scenario and discount rate allowing for

risk premium.

The net

present value of the innovation and investment project is determined

by the formula:

, (1)

, (1)

where

– net present

value;

– net present

value;

– discount

rate;

– discount

rate;

–

project life

cycle;

–

project life

cycle;

– the result

(economic

effect) of

the project

in the

t-th

period;

– the result

(economic

effect) of

the project

in the

t-th

period;

– investment costs of the project in

t-th

period.

– investment costs of the project in

t-th

period.

The

criterion for project efficiency is the positive value of NPV.

When forecasting the results

and costs of a project in this work we use the concept of base

(fixed for a certain date) prices. Therefore, in the project under

consideration, the forecasted economic effect varies little over the

years of the investment life cycle and can be taken at the average

annual level. Investment costs of the project arise only in the

beginning of the investment life cycle and equal to the locomotive

modernization cost. Therefore, the formula for determining the net

present value of a project can be presented as:

, (2)

, (2)

where

– annual

economic effect of locomotive modernization;

– annual

economic effect of locomotive modernization;

– locomotive

modernization cost;

– locomotive

modernization cost;

–

useful life

of the

locomotive.

–

useful life

of the

locomotive.

The project internal rate of

return is defined as the discount rate, according to which the net

present value of the project is zero. It is established by solving

the equation:

, (3)

, (3)

where

is

the

internal

rate

of

return.

is

the

internal

rate

of

return.

The project

effectiveness criterion is the excess of the internal rate of return

over the discount rate.

The project

profitability index (PI) is determined by the formula:

. (4)

. (4)

The project effectiveness

criterion is the value of the profitability index, which is greater

than or equal to one.

The discounted payback period

of the project investments is defined as the period from the start

of the life project cycle to the moment after which the accumulated

net present value of the portfolio becomes and continues to remain

positive. The effectiveness criterion is the magnitude of the

dynamic payback term, which is less than or equal to the duration of

the life portfolio cycle.

Under the

basic prices when forecasting cash flows we exclude the inflation

component from the composition of the discount rate by the formula:

, (5)

, (5)

where

– real

discount rate;

– real

discount rate;

– nominal

rate discount;

– nominal

rate discount;

– forecasted inflation rate.

– forecasted inflation rate.

The cost-effectiveness analysis

of locomotive modernization is carried out on the basis of

comparison of costs with the results arising from the modernization

during the life cycle of the locomotive.

The life cycle is taken equal

to the normative lifetime of the diesel locomotive. As investment

costs we considered the costs associated with the higher cost of the

wheel-motor block (WMB) with anti-friction TMSB in comparison with

the WMB with plain friction TMSB. The results are saving operating

costs, which are provided by the replacement of plain friction TMSB

with anti-friction TMSB. The mentioned costs are taken into account

in locomotive modernization cost.

The

average annual

economic effect

of locomotive

modernization

consists of

operating costs

saving

associated with

the locomotive

operation, and

includes:

– oil cost

savings;

– cost

savings for

repair and

maintenance of

diesel

locomotive

wheel-motor

blocks,

including the

change of

TMSB brass;

– fuel

consumption saving for hauling operations.

The oil cost savings are

determined based on the amount of oil changes and refilling to the

plain friction and anti-friction TMSB during repairs, the oil cost

for changes (refilling) during maintenance and the price of the oil

of the corresponding type.

The cost savings for repairing

and servicing diesel locomotive wheel-motor blocks are determined on

the basis of the complexity of the work involved, the tariff rates

of the workers and the cost of the brasses used for changes.

The fuel consumption saving for

hauling operations is determined on the basis of increasing the

coefficient of useful efficiency of gear transmission with

anti-friction TMSB, in comparison with plain friction TMSB.

The starting data for the

cost-effectiveness analysis of diesel locomotive modernization are

the operating norms of operation, maintenance and repair of

locomotives of a particular series, data of the developer of

modernization, statistical data of PJSC «Ukrzaliznytsia», State

Statistics Service of Ukraine, National Bank of Ukraine and results

of own researches of the executors of this work. Output data for

cost-effectiveness analysis of modernization of M62 diesel

locomotive are shown in Table 1, 2.

Table

1

Output

data for cost-effectiveness analysis, differing in variants

|

Index

|

Unit

of measure

|

Value

for the locomotive with

|

|

|

|

Plain

friction

TMSB

|

Information

source

|

Anti-friction

|

Information

source |

|

Oil

used in

TMSB

|

–

|

axial

oil of

«L», «Z»

grades (GOST

610-72)

|

data

of PJSC «UZ»

|

«Agrinol»

oil

|

data

of a developer

|

|

Frequency

of full oil filling of TMSB

|

–

|

during

repairs with

disassembly

of WMB,

in the

case of

brass

change,

during

seasonal oil

change

|

[4]

|

CR-3,

OR-1,

OR-2

|

data

of a developer

|

|

Frequency

of TMSB

oil

refilling

|

–

|

M-2,

M-3

|

[4]

|

CR-2

|

data

of a developer

|

|

Amount

of oil consumed when completely changed

|

l/lubr.

point

|

12

|

data

of PJSC «UZ»

|

1.5

|

data

of a developer

|

|

Amount

of oil

consumed

when

refilled

|

l/lubr.

point

|

0.4

|

data

of PJSC «UZ»

|

0.15

|

data

of a developer

|

|

Oil

price, ex

VAT

|

UAH/l

|

12.5

|

prozorro.gov.ua

|

51.82

|

data

of a developer

|

Table

2

Output

data for cost-effectiveness analysis, similar in variants

|

Index

|

Unit

of measure

|

Value

|

|

Number

of lubrication points

|

un./sect.

|

12

|

|

Normative

inter-repair periods:

|

|

|

|

–

maintenance M-2

|

hours

|

72

|

|

–

maintenance M-3

|

ths.

km

|

10

|

|

–

current repairs

CR-1

|

ths. km

|

50

|

|

–

current repairs

CR-2

|

ths. km

|

95

|

|

–

current repairs

CR-3

|

ths. km

|

195

|

|

–overall

repair OR-1

|

ths. km

|

780

|

|

–

overall repair

OR-2

|

ths. km

|

1 560

|

Continuation

of a table 2

|

Index

|

Unit

of measure

|

Value

|

|

Number

of lubrication points

|

un./sect.

|

12

|

|

Average

rate of

shed

percentage

of defective

diesel

locomotives

|

%

|

8

|

|

Normative

term of operation of diesel locomotive

|

years

|

20

|

|

Hourly

rate of

rolling

stock repair

mechanic,

taking into

account all

surcharges:

|

|

|

|

– 3-rd

category

|

UAH/year

|

33.47

|

|

– 5-th

category

|

UAH/year

|

42.92

|

|

The rate

of unified social tax

|

%

|

22

|

|

Average

cost of

the package

of TMSB

brasses, ex

VAT

|

UAH/TMSB

|

50 000

|

|

Actual

specific

consumption

of diesel

fuel in

freight

traffic for

M62 series

locomotive

|

kg/10 000

t-km

br.

|

34

|

|

Hourly

fuel

consumption

at idle

speed

|

kg/year

|

25

|

|

Average

weight of

freight

train with

M62

series locomotive

|

ton

|

3 781.82

|

|

Average

mileage of M62 series diesel locomotives

|

km

|

416

|

|

Cost

of diesel

fuel, ex

VAT

|

UAH/t

|

22 059

|

|

Increase

in the

efficiency

coefficient

of gear

with

anti-friction

TMSB, in

comparison

with plain

friction

TMSB

|

times

|

1.055

|

|

Cost

of

modernization

of the

wheel-motor

block under

anti-friction

TMSB, ex

VAT

|

ths.

UAH

|

357.6

|

|

Average

technical speed

|

km/year

|

45.6

|

Findings

To determine the flow of

lubricants to lubricate the TMSB, the number of repairs and

maintenance for the life cycle of the diesel locomotive is

determined in accordance with the repair cycle chart.

The assigned lifetime of the

locomotive mileage is defined as a double life of the run prior to

major repairs within OR-2, which is 3120 thousand km. Proceeding

from the mileage resource of the M62 series locomotive and the

standards of inter-repair runs, the normative quantity of repairs

and maintenance of the locomotive for a life cycle is determined,

which is:

– OR-2 – 1 repair;

– OR-1 – 2 repairs;

– CR-3 – 12 repairs;

– CR-2 – 17 repairs;

– CR-1 – 29 repairs;

– M-3 – 250 maintenances

per cycle;

– M-2 – 112 maintenances

per year.

When

performing the overall, current repairs, as well as maintenance for

the locomotives with plain friction TMSB, during a seasonal oil

change, its full replacement is carried out. In the course of

maintenance, the plain friction TMSBs are refilled with oil [5]. The

oil consumption for a complete change for the plain friction TMSB

is:

l for the locomotive section, for oil refilling: 12·0.4 = 4.8 l for

the locomotive section. Thus, the average annual oil consumption for

plain friction TMSB reaches 1322.4 l.

l for the locomotive section, for oil refilling: 12·0.4 = 4.8 l for

the locomotive section. Thus, the average annual oil consumption for

plain friction TMSB reaches 1322.4 l.

When

performing the overall and current repairs for diesel locomotives

with anti-friction TMSB within CR-3, a complete change of oil is

carried out. When performing maintenance within M-2, the

anti-friction TMSBs are refilled with oil. The oil consumption for a

complete change for the anti-friction TMSB is: 12·1.5

= 18 l for the locomotive section, for oil

refilling: 12·0.15 = 1.8

l for the locomotive section. Thus, the average annual oil

consumption for the anti-friction

TMSB reaches 15.93 litres.

Taking into

account the loss of oil when pouring and refilling (10%), the

average annual cost of lubricants is:

– for locomotive with plain

friction TMSB – 18183 UAH;

– for locomotive with

anti-friction TMSB – 908 UAH.

The

cost savings

for lubricants

are: UAH per

year.

UAH per

year.

Costs

for maintenance

and repair

of M62

locomotive WMB

with plain

friction and

anti-friction

TMSB include

the costs

associated with:

– remuneration of employees

engaged in the maintenance and repair of WMB, the level of which is

determined by the complexity and skill of repair personnel;

– cost of materials and spare

parts for maintenance and repairs.

Labor costs are determined on

the basis of the list of TMSB-related works performed during

maintenance and repairs, the normative level of work and the value

of the standard hour of the respective category. It takes into

account the time factor for support needs 1.093 (for preparatory and

final actions 3.5%, time for servicing the workplace 3.1%, time for

rest and personal needs 2.7%, total – 9.3%).

The labor intensity of the

anti-friction TMSB maintenance is adopted at the level of 25% of the

corresponding value for the plain friction TMSB due to

simplification of the process of servicing the anti-friction TMSB.

The costs associated with

remuneration are given in Table. 3

Table 3

shows that the average annual labor costs are: for the plain

friction TMSB

UAH, for the anti-friction TMSB

UAH, for the anti-friction TMSB

UAH. Thus, the cost savings associated with remuneration are

UAH. Thus, the cost savings associated with remuneration are

UAH per year.

UAH per year.

During the lifecycle of the M62

series locomotive, when performing overhaul repair, a complete

change of the TMSB brasses is performed. During CR-3 current repairs

35% of brasses are changed. The cost of the package of TMSB brasses

is 50 thousand UAH ex VAT. Thus, the average annual cost savings for

spare parts is:

In

the middle

conditions of

operation, the

M62 series

diesel

locomotive

(incl. the

idle time

in repairs)

per year

carries out

gross turnover

in the

amount of:

Table

3

Calculation

of expenses connected with remuneration of labour for work with TMSB

during

repairs and maintenance of M62 series diesel locomotive

during the life cycle

|

Type

of repair, maintenance

|

Class

of work

|

Hourly

rate, UAH

|

Labour

intensity with allowance for auxiliary time, man-hour

|

Number

of maintenances, repairs

|

Non-worked

time rate

|

Payroll

fund, UAH

|

Unified

social tax, UAH

|

Total

expenses, UAH

|

|

|

|

|

Plain friction

|

Anti-friction

|

|

|

Plain friction

|

Anti-friction

|

Plain friction

|

Anti-friction

|

Plain friction

|

Anti-friction

|

|

M-2

|

3

|

33.47

|

0.38

|

0

|

2240

|

1.1

|

31 339

|

0

|

6 895

|

0

|

38 234

|

0

|

|

M-3

|

5

|

42.92

|

4.59

|

0

|

250

|

1.1

|

54 176

|

0

|

11 919

|

0

|

66 095

|

0

|

|

CR-1

|

5

|

42.92

|

12.1

|

3.03

|

29

|

1.1

|

16 567

|

4 149

|

3 645

|

913

|

20 212

|

5 062

|

|

CR-2

|

5

|

42.92

|

16.26

|

4.07

|

17

|

1.1

|

13 050

|

3 267

|

2 871

|

719

|

15 921

|

3 986

|

|

CR-3

|

5

|

42.92

|

38.13

|

9.53

|

12

|

1.1

|

21 602

|

5 399

|

4 752

|

1 188

|

26 354

|

6 587

|

|

OR

|

5

|

42.92

|

87.44

|

21.86

|

3

|

1.1

|

12 385

|

3 096

|

2 725

|

681

|

15 110

|

3 777

|

|

Total

per life cycle

|

149 119

|

15 911

|

32 807

|

3 501

|

181 926

|

19 412

|

Specific fuel consumption is 34

kg per 10000 ton-km br. Total fuel consumption per year reaches

tons.

tons.

Average

section speed

reaches 45.6 km/h,

then time in

the movement of

the diesel

locomotive of

the operating

rolling stock is

hours per day.

hours per day.

The annual budget of idle time

in «hot» condition of the M62 series locomotive reaches:

hours per

year.

hours per

year.

Fuel

consumption for idle time in «hot»

condition reaches:

tons.

tons.

Fuel consumption of the M62

series locomotive in the train operation reaches:

tons.

tons.

Since

the gear

ratio efficiency

of the

anti-friction

TMSB is

1.055 times

higher than

that of

the plain

friction TMSB, fuel

savings will

average over

the year

tons.

tons.

At

the cost

of diesel

fuel of

22059 UAH/ton,

the annual

saving in

fuel consumption

for hauling

operation will

be:

UAH per year.

UAH per year.

The

overall average

annual economic

effect of

modernizing the

section of

the M62

series

locomotive

reaches:

Investment

costs per

M62 series

locomotive

section are

defined as

the product

of the

number of

WMBs and

the cost

of upgrading

one WMB

and equal

to:

ths. UAH ex VAT.

ths. UAH ex VAT.

The

discount rate

is determined

using the

model of

capital asset

valuation

(-method)

as the

cost of

capital invested

in the

field of

economic

activity

«Transport».

The risk

factor

is defined as the ratio of the covariance

of the return of the investigated investment asset and the capital

market return.

As a measure of return on

investment, the profitability of equity capital of large and

medium-sized enterprises in Ukraine as a whole (capital market

return ratio) and the sphere of economic activity of «Transport»

(investment assets return ratio) are used. The net profit and equity

figures are shown in the Table 4 [9].

According

to Table 4, the

covariance of

profitability (55.7) and

market profitability

dispersion (155.4) were

determined. Thus, the

Betta coefficient for investments in the sphere of economic activity

«Transport» reaches

As the base rate, we used the

rate of return on investments with a minimum risk – the average

interest rate on long-term deposits of economic entities in 2017 was

14.3%.

The yield of the stock market

at the current time is defined as the average yield of the stock

index UX (index of Ukrainian shares) per one year (from 15.11.2016

to 15.11.2017). The index at period beginning was 791.11, at period

end – 1261.62 [9]. The average annual rate of income is

Thus, the nominal discount rate

before taxation is

Table 4

Determination

of the return on equity

|

Year

|

Net

financial result, mln. UAH

|

Average

equity, mln. UAH

|

Equity

at period end, mln. UAH

|

Return

on equity, %

|

|

|

in

Ukraine

|

transport

|

in

Ukraine

|

transport

|

in

Ukraine

|

transport

|

in

Ukraine

|

transport |

|

2016

|

13 324,4

|

6 622,533

|

1 790 507

|

727 082,3

|

1 806 908,5

|

729 340,6

|

0,74

|

0,91

|

|

2015

|

-373 516

|

-17 847,8

|

1 627 381

|

438 080,6

|

1 774 104,6

|

724 823,9

|

-22,95

|

-4,07

|

|

2014

|

-590 067

|

-22 591,6

|

1 715 516

|

165 346,2

|

1 480 658

|

151 337,3

|

-34,4

|

-13,66

|

|

2013

|

-22 839,7

|

-1 423,4

|

1 927 658

|

176 269,8

|

1 950 374,9

|

179 355,1

|

-1,18

|

-0,81

|

|

2012

|

35 067,3

|

3 127,7

|

1 745 612

|

179 525,3

|

1 904 940,2

|

173 184,5

|

2,01

|

1,74

|

|

2011

|

67 797,9

|

2 839,8

|

1 506 498

|

180 235,4

|

1 586 284,7

|

185 866

|

4,5

|

1,58

|

|

2010

|

13 906,1

|

1 348,7

|

1 348 125

|

169 027,3

|

1 426 711,6

|

174 604,7

|

1,03

|

0,8

|

|

2009

|

-37 131,1

|

4 889,5

|

1 201 571

|

155 846,4

|

1 269 537,7

|

163 449,8

|

-3,09

|

3,14

|

|

2008

|

-41 025,1

|

234,5

|

1 081 690

|

139 033,1

|

1 133 603,7

|

148 242,9

|

-3,79

|

0,17

|

|

2007

|

–

|

–

|

–

|

–

|

1 029 775,5

|

129 823,2

|

–

|

–

|

When forecasting the costs, the

concept of base prices is used, so the real discount rate is used

for discounting. The inflation rate is assumed to be 11% per year

[9]. That is, the real discount rate reaches:

Thus,

the

main

indices

of

the

economic

efficiency

of

modernization

of

the

M62series

locomotive

are

as follows:

times;

times;

months.

months.

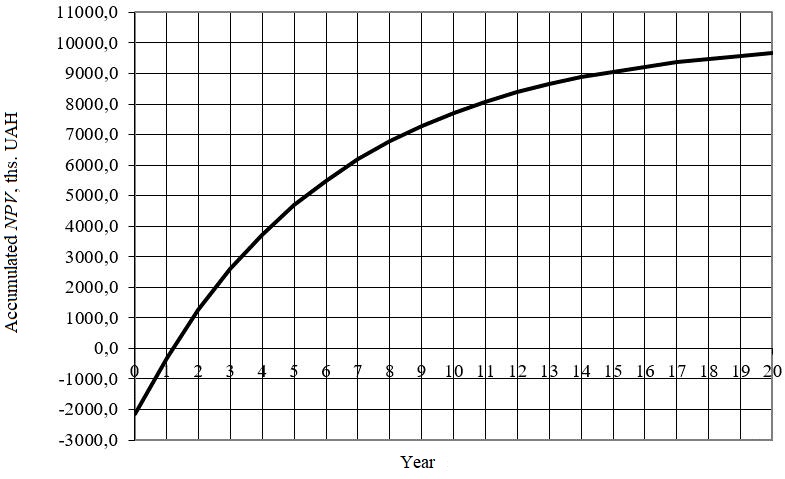

The graph of accumulation of

the net present value of the project is shown in Fig. 1

Originality and practical value

Taking into account the

specifics of the type of locomotive work in freight traffic, we

developed a method to determine the individual components of the

average annual economic effect of modernization of the diesel

locomotive WMB, which includes saving of oil costs, repairing and

servicing the diesel locomotive WMB, as well as change of TVSB brass

and saving fuel costs for traction.

The practical value of the work

lies in the fact that on the basis of the above methodology and

research results it is possible to determine the expediency of

modernizing the locomotive taking into account the peculiarities of

its operation.

Conclusions

It is clear

from the calculations above that the net present value (NPV)

of the project is 9662 thousand UAH, the internal rate of return

(IRR) of

the project is 100.7%, which exceeds the discount rate, the

profitability index (PI)

of the project is 5.5 times higher than 1. Schedule in Fig. 1 shows

that the discount payback period of the project is 1.2 years (14.4

months), which is considerably less than the life cycle of

investments.

Thus, the main criteria testify

that the considered innovative project on modernization of M62

series locomotive provides a high level of cost effectiveness.

Fig.

1. Accumulation of net present value

At the same time, the value of

the discounted investment payback period for modernization shows

that it is expedient to conduct it if the remaining useful lifetime

of the modernization object (M62 series diesel locomotive) is not

less than 15 months.

The feasibility study is

executed in the prices and standards of 2017 at the stage of

development of the technical documentation for WMB modernization and

should be clarified according to the results of their work in real

operating conditions.

LIST OF REFERENCE LINKS

Бланк,

І. О. Інвестиційний менеджмент : підручник

/ І. О. Бланк. – Київ : Лібра, 2006. – 552 с.

Боднар,

Б. Є. Теорія та конструкція локомотивів.

Екіпажна частина : підручник / Б. Є.

Боднар, Є. Г. Нечаєв, Д. В.

Бобир. – Дніпропетровськ : Ліра ЛТД,

2009. – 284 с.

Дука,

А. I. Теорія та практика інвестиційної

діяльності. Інвестування / А. І. Дука.

– Київ : Каравела, 2008. – 432 с.

Гненний,

О. М. До питання оцінки та застосування

вартості життєвого циклу продукції

машинобудування / О. М. Гненний, А.

Мохаммадреза // Проблеми економіки

транспорту : зб. наук. пр. Дніпропетр.

нац. ун-ту залізн. трансп. ім. акад. В.

Лазаряна. – Дніпропетровськ, 2016. –

Вип. 12. – С. 7–12. doi:

10.15802/pte.v0i12.95609

Ендовицкий,

Д. А. Практикум по финансово-инвестиционному

анализу. Ситуации. Методики. Решения

: учеб. пособие / Д. А.

Ендовицкий, Л. С. Коробейникова, С. Н.

Коменденко ; под ред. Д. А. Ендовицкого.

– Москва : КноРус, 2006. – 432 с.

Інструкція

з використання мастильних матеріалів

на тяговому рухомому складі залізниць

України : ЦТ-0060 : затв. наказом Укрзалізниці

від 21.04.2003 р. / М-во трансп. України.

Держадміністрація залізн. трансп.

України. Голов. управ. колійного госп-ва.

– Київ : Девалта, 2003. – 55 с.

Лапицкий,

В. Н. Новый этап в эксплуатации

локомотивов: переход на моторно-осевые

подшипники качения [Electronic

resource] / В.

Н. Лапицкий, А. Г. Пашнин // Информио. –

2015. – Available

at:

http://www.informio.ru/publications/id1894/Novyi-yetap-v-yekspluatacii-lokomotivov-perehod-na-motorno-osevye-podshipniki-kachenija

– Title from

the screen.

– Accessed :

02.04.2018.

Методы

экономической оценки инвестиционных

проектов на транспорте : учеб.-метод.

пособие / Сост. Ю. Ф. Кулаев. – Киев

: Транспорт Украины, 2001. –

182 с.

МОП

качения на тепловозе ТЭМ18ДМ прошли

проверку временем [Electronic

resource] //

и-Маш. – 2013. – Available

at: http://www.i-mash.ru/news/nov_otrasl/32708-mop-kachenija-na-teplovoze-tjem18dm-proshli.html

chenija-na-teplovoze-tjem18dm-proshli.html

– Title from

the screen.

– Accessed :

02.04.2018.

Офіційний

сайт Державної служби статистики

України [Electronic

resource]. –

Available at:

– Title from

the screen.

– Accessed :

02.04.2018.

Проект

Програми Прогнозної оновлення рухомого

складу ПАТ «Укрзалізниця» на період

до 2021 року (станом на 21.11.2016). – Київ :

Укрзалізниця, 2016. – 16 с.

Тарута,

Д. В. Повышение долговечности

моторно-осевых подшипников тягового

электродвигателя тепловоза : дис. ...

канд. техн. наук : 05.22.07 / Дмитрий Викторович

Тарута ; Омский

гос. ун-т путей сообщения. – Омск, 2005.

– 178 с.

A

method to measure the eco-efficiency of diesel locomotive / B. B.

Carvalhaes,

R. A. Rosa, M. A. D’Agosto, G. M. Ribeiro // Transportation

Research.

Part D: Transport and Environment. –

2017. – Vol.

51. – P.

29–42.

doi:

10.1016/j.trd.2016.11.031

Bodnar,

B. Improving

Operation and

Maintenance of

Locomotives of

Ukrainian

Railways / B.

Bodnar, A.

Ochkasov, D.

Bobyr //

Technologijos ir Menas = Technology and

Art. – 2016.

– № 7. –

P. 109–114.

Shelley,

S. Evaluating attitudes to safety leadership within rail

construction projects /

S. Shelley,

B. Ryan, D.

Golightly // Safety

Science. – 2018. doi:

10.1016/j.ssci.2017.12.030

М. І. Капіца1*,

О. М. Гненний2*,

Д. В. Бобир3*

1*Каф.

«Локомотиви», Дніпропетровський

національний університет залізничного

транспорту імені академіка

В. Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38 (0562) 33 19 61,

ел. пошта

m.i.kapitca@ua.fm,ORCID 0000-0002-3800-2920

2*Каф.

«Економіка та менеджмент», Дніпропетровський

національний університет залізничного

транспорту імені академіка В. Лазаряна,

вул. Лазаряна, 2, Дніпро, Україна, 49010,

тел. +38 (056) 373 15 80,

ел. пошта oleggnennij@gmail.com,

ORCID 0000-0002-2944-5105

3*Каф. «Локомотиви»,

Дніпропетровський національний

університет залізничного транспорту

імені академіка В.

Лазаряна, вул. Лазаряна, 2, Дніпро,

Україна, 49010, тел. +38 (0562) 33 19 61,

ел. пошта

dmitrob@ua.fm, ORCID 0000-0003-1441-3861

ЕФЕКТИВНІСТЬ

МОДЕРНІЗАЦІЇ КОЛІСНО-МОТОРНИХ БЛОКІВ

ТЕПЛОВОЗА З ВИКОРИСТАННЯМ МОТОРНО-ОСЬОВИХ

ПІДШИПНИКІВ КОЧЕННЯ

Мета. Використання

моторно-осьових підшипників (МОП)

кочення замість моторно-осьових

підшипників ковзання є пріоритетним

напрямком розвитку локомотивобудування

й експлуатації наявних локомотивів.

Вирішення завдань щодо впровадження

на локомотивах колісно-моторних блоків

(КМБ) із підшипниками кочення потребує

пошуку альтернативних варіантів і

нових технічних рішень. Метою статті

є визначення доцільності переобладнання

колісно-моторного блока тепловоза на

підшипники кочення шляхом розрахунку

життєвого циклу (LCC). Методика.

Порядок і критерії оцінки економічної

ефективності проектних (інвестиційних)

пропозицій та інвестиційних проектів,

затверджені постановою Кабінету

Міністрів України, передбачають, що

оцінку економічної ефективності

інвестиційного проекту здійснюють за

такими критеріями: чиста приведена

вартість, внутрішня норма дохідності,

дисконтований період окупності й індекс

прибутковості. Використання зазначених

критеріїв економічної ефективності

повністю відповідає сучасним принципам,

теоретико-методичним підходам і світовій

практиці оцінки ефективності інвестицій.

У роботі оцінка техніко-економічної

ефективності модернізації колісно-моторного

блока тепловоза проведена на основі

розрахунку й порівняння наступних

критеріїв – чистої приведеної вартості

(NPV) модернізації, внутрішньої норми

доходу (IRR), індексу дохідності (PI)

й дисконтного терміну окупності.

Результати. Виконані розрахунки

значень основних критеріїв свідчать,

що інноваційній проект із модернізації

тепловоза забезпечує високий рівень

економічної ефективності. При цьому

величина дисконтованого терміну

окупності інвестицій у модернізацію

передбачає, що її проведення є доцільним,

якщо залишковий ресурс строку корисного

використання модернізованого тепловоза

серії М62 не менший за 15 місяців. Наукова

новизна. З урахуванням особливостей

виду роботи тепловоза під час руху в

складі вантажного поїзда розроблена

методика з визначення окремих складових

середньорічного економічного ефекту

від модернізації колісно-моторного

блока тепловоза. До них

належать економія витрат на мастило,

на ремонт й обслуговування колісно-моторного

блока тепловоза, у тому числі заміну

вкладишів МОП, та економія витрат на

пальне для тяги поїздів. Практична

значимість. Результати

роботи дозволяють визначити доцільність

модернізації тепловозів з урахуванням

особливостей та умов їх роботи, а також

специфіки модернізації.

Ключові слова: модернізація

тепловоза; колісно-моторний блок;

техніко-економічна ефективність;

підшипники кочення; життєвий цикл

М. И. КапИца1*,

О. Н. ГненнЫй2*,

Д. В. Бобырь3*

1*Каф.

«Локомотивы», Днепропетровский

национальный университет железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (0562) 33 19 61,

эл. почта m.i.kapitca@ua.fm, ORCID

0000-0002-3800-2920

2*Каф. «Экономика и

менеджмент», Днепропетровский

национальный университет железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (056) 373 15 80,

эл. почта oleggnennij@gmail.com,

ORCID 0000-0002-2944-5105

3*Каф. «Локомотивы»,

Днепропетровский национальный

университет железнодорожного транспорта

имени академика В. Лазаряна, ул.

Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (0562) 33 19 61,

эл. почта dmitrob@ua.fm, ORCID

0000-0003-1441-3861

ЭФФЕКТИВНОСТЬ МОДЕРНИЗАЦИИ

КОЛЕСНО-МОТОРНЫХ БЛОКОВ ТЕПЛОВОЗА С

ПРИМЕНЕНИЕМ МОТОРНО-ОСЕВЫХ

ПОДШИПНИКОВ КАЧЕНИЯ

Цель. Использование

моторно-осевых подшипников (МОП) качения

вместо моторно-осевых подшипников

скольжения является приоритетным

направлением развития локомотивостроения

и эксплуатации имеющихся локомотивов.

Решение задач по внедрению на

локомотивах колесно-моторных блоков

(КМБ) с подшипниками качения требует

поиска альтернативных вариантов и

новых технических решений. Целью статьи

является определение целесообразности

переоборудования колесно-моторного

блока тепловоза на подшипники качения

путем расчета жизненного цикла (LCC).

Методика. Порядок и

критерии оценки экономической

эффективности проектных (инвестиционных)

предложений и инвестиционных проектов,

утвержденные постановлением Кабинета

Министров Украины, предполагают, что

оценка экономической эффективности

инвестиционного проекта осуществляется

по следующим критериям: чистая приведенная

стоимость, внутренняя норма доходности,

дисконтированный период окупаемости

и индекс доходности. Использование

указанных критериев экономической

эффективности полностью соответствует

современным принципам, теоретико-методическим

подходам и мировой практике оценки

эффективности инвестиций. В работе

оценка технико-экономической эффективности

модернизации колесно-моторного блока

тепловоза проведена на основе расчета

и сравнения следующих критериев –

чистой приведенной стоимости (NPV)

модернизации, внутренней нормы дохода

(IRR), индекса доходности (PI) и дисконтного

срока окупаемости. Результаты.

Выполненные расчеты значений основных

критериев свидетельствуют, что

инновационной проект по модернизации

тепловоза обеспечивает высокий уровень

экономической эффективности. При

этом величина дисконтированного срока

окупаемости инвестиций в модернизацию

предусматривает, что ее проведение

целесообразно, если остаточный ресурс

срока полезного использования

модернизированного тепловоза серии

М62 не менее 15 месяцев. Научная

новизна. С учетом

особенностей вида работы тепловоза во

время движения в составе грузового

поезда разработана методика по

определению отдельных составляющих

среднегодового экономического эффекта

от модернизации колесно-моторного

блока тепловоза. К ним относятся экономия

расходов на смазку, на ремонт и

обслуживание колесно-моторного блока

тепловоза, в том числе замену вкладышей

МОТ, и экономия затрат на топливо для

тяги поездов. Практическая значимость.

Результаты работы позволяют определить

целесообразность модернизации тепловозов

с учетом особенностей и условий их

работы, а также специфики модернизации.

Ключевые слова:

модернизация тепловоза;

колесно-моторный блок;

технико-экономическая эффективность;

подшипники качения;

жизненный цикл

REFERENCES

Blank,

І. O. (2006). Investytsiinyi

menedzhment : pidruchnyk. Kуіv:

Lіbra. (in

Ukranian)

Bodnar,

B. Y.,

Nechaiev, Y.

G., & Bobyr,

D. V. (2009). Teoriia ta konstruktsiia

lokomotyviv. Ekipazhna chastyna: pidruchnyk.

Dnіpropetrovsk: Lіra LTD. (in

Ukranian)

Duka,

A. I. (2008). Teoriia ta praktyka

investytsiinoi diialnosti. Investuvannia.

Kуіv: Karavella. (in

Ukranian)

Hnennyj,

O., & Mohammadreza, A. (2016). To the

question of evaluation and use of life cycle cost of engineering

product. Problemi

ekonomiki

transportu: zbirnik

naukovih

prac’

Dnipropetrovs’kogo

nacional’nogo

universitetu

zaliznicnogo

transportu imeni akademika V. Lazarana,

12, 7-12. doi:

10.15802/pte.v0i12.95609 (in

Ukranian)

Yendovitskiy,

D. A., Korobeinykova, L. S., &. Komendenko, S. N.

(2006). Praktikum po

finansovo-investitsionnomu analizu. Situatsii. Metodiki. Resheniya:

uchebnoe

posobie. Moscow:

KnoRus. (in

Russian)

Instruktsiia

z vykorystannia mastylnykh materialiv na tiahovomu rukhomomu skladi

zaliznyts Ukrainy: TsT-0060. (2003).

Kyiv: Devalta Ltd. (in

Ukranian)

Lapitskiy,

V. N., & Pashnin, A. G. (2015). Novyy etap v ekspluatatsii

lokomotivov: perekhod na motorno-osevye podshipniki kacheniya.

Informio.

Retrieved from

http://www.informio.ru/publications/id1894/Novyi-yetap-v-yekspluatacii-lokomotivov-perehod-na-motorno-osevye-podshipniki-kachenija

(in

Ukranian)

Kulaev,

Y. F. (2001).

Metody ekonomicheskoy otsenki

investitsionnykh proektov na transporte. Uchebno-metodicheskoe

posobie.

Kуіv: Transport Ukrainy. (in

Russian)

MOP

kacheniya na teplovoze TEM18DM proshli proverku vremenem.

(2013). i-Mash.

Retrieved from

http://www.i-mash.ru/news/nov_otrasl/32708-mop-kachenija-na-teplovoze-tjem18dm-proshli.html

(in Russian)

Ofitsiinyi

sait Derzhavnoi sluzhby statystyky Ukrainy. (2018).

Retrieved from http://www.ukrstat.gov.ua/operativ/menu/menu_u/sze.htm

Proekt

Prohramy

Prohnoznoi

onovlennia

rukhomoho

skladu

PAT

«Ukrzaliznytsia»

na

period

do

2021 roku

(stanom

na

21.11.2016). (2016). Kуіv

: PAT «Ukrzalіznytsia».

Taruta,

D. V. (2005).

Povyshenie dolgovechnosti

motorno-osevykh podshipnikov tyagovogo elektrodvigatelya teplovoza.

(Dissertatsiya

kandidata tekhnicheskikh nauk). Omsk

State Transport University, Omsk. (in

Russian)

Carvalhaes,

B. B., Rosa, R. A., D’Agosto, M. A., & Ribeiro,

G. M. (2017). A method to measure the eco-efficiency of diesel

locomotive. Transportation

Research Part D: Transport and Environment, 51,

29-42.

doi:

10.1016/j.trd.2016.11.031 (in

English)

Bodnar,

B., Ochkasov, A., & Bobyr, D. (2016). Improving Operation and

Maintenance of Locomotives of Ukrainian Railways. Technologijos ir

Menas = Technology and Art, 7, 109-114. (in English)

Shelley,

S., Ryan, B., & Golightly,

D. (2018). Evaluating attitudes to safety leadership within rail

construction projects. Safety

Science.

doi:

10.1016/j.ssci.2017.12.030 (in

English)

Received:

April 12, 2018

Accepted:

July 25, 2018

d oi

10.15802/stp2018/141178 ©

M. I. Kapitsa, O. M. Hnennyi, D. V. Bobyr,

2018

oi

10.15802/stp2018/141178 ©

M. I. Kapitsa, O. M. Hnennyi, D. V. Bobyr,

2018

, (1)

– net present

value;

– discount

rate;

–

project life

cycle;

– the result

(economic

effect) of

the project

in the

t-th

period;

– investment costs of the project in

t-th

period.

, (2)

– annual

economic effect of locomotive modernization;

– locomotive

modernization cost;

–

useful life

of the

locomotive.

, (3)

is

the

internal

rate

of

return.

. (4)

, (5)

– real

discount rate;

– nominal

rate discount;

– forecasted inflation rate.