ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2018, № 4

(76)

електричний

ТРАНСПОРТ

Електричний

транспорт

UDC

621.33:621.333

Т.

P. PAVLENKO1*,

v. m.

SHAVKUN2*,

v. i.

Skurikhin3*,

n. p.

lUKASHOVA4*

1*Dep.

«Electric

Transport»,

National University of Urban Economy in

Kharkiv, Marshala

Bazhanova St.,

17, Kharkiv, Ukraine, 61002,

tel. +38 (095) 485 40 16,

e-mail tpavlenkoskp@gmail.com,

ORCID 0000-0002-2356-4066

2*Dep.

«Electric

Transport»,

National University of Urban Economy in

Kharkiv, Marshala

Bazhanova St.,

17, Kharkiv, Ukraine, 61002,

tel. +38 (095) 142

90 00, e-mail

vm.shavkun@gmail.com.com,

ORCID 0000-0002-3253-1282

3*Dep.

«Electric

Transport»,

National University of Urban Economy in

Kharkiv, Marshala

Bazhanova St.,

17, Kharkiv, Ukraine, 61002,

tel. +38 (095) 745

31 77, e-mail

vladscu@gmail.com,

ORCID 0000-0001-7415-7105

4*Dep.

«Electric

Transport»,

National University of Urban Economy in

Kharkiv, Marshala

Bazhanova St.,

17, Kharkiv, Ukraine, 61002,

tel. тел. +38 (097)

255 73 80, e-mail

lukashova.natalya@gmail.com,

ORCID /0000-0002-5556-241X.

METHODOLOGY

OF DETERMINING THE PARAMETERS OF TRACTION

ELECTRIC motor

FAILUREs WHEN

OPERATING TROLLEYBUSES

Purpose.

The work is aimed to study the change in parameters of

traction electric motors of trolleybuses during operation and

improvement of the technical state control system, using modern

diagnostic methods.

Methodology. Solution of the

scientific problem is based on the control of technical state and

change in the parameters of traction electric motors in the process

of operation. For analysis of operational factors, we used the method

of mathematical statistics and probability theory. Mathematical

modelling and design of experiment, multifactor regression analysis

provides an assessment of the reliability of the electric traction

motor elements. Physical and statistical methods provide for research

and detection of patterns of influence of the factors that accelerate

the wear of parts. This allows us to generate models of system

reliability that take into account the influence of operational

factors on the reliability. Findings. As a result of the

studies we obtained quantitative characteristics of the reliability

of commutator and established that the failures of traction motors

make up 20% of all failures of electrical equipment. We analysed the

operation conditions of traction electric motors and determined the

failure distribution law N{mx,x},

which allows assessing the progression between gradual

failures. We obtained a mathematical model

characterizing the object operation. A generalized

equation of the

failure rate of

elements for traction electric

motor (TEM) was

found. We improved the estimation

methods of reliability of TEM element base that makes it possible to

determine the ETM lifetime taking into account the features of each

trolleybus. We established the failure rate of commutators using

physical and statistical methods. Originality. For the first

time, the choice of physico-statistical methods of simulation and

reliability calculation was substantiated. We determined the

regularities of change in parameters of the trolleybus traction

electric motor elements, which makes it possible to control the

processes of their wear in the operation conditions. We developed a

mathematical model for estimating the traction electric motor

reliability, based on a system analysis of the probabilities of

failures of subsystems to be diagnosed.

Practical value.

Based on the results of the study, we developed practical

recommendations for rational choice of diagnostic parameters of

traction motors. Their implementation at the enterprises of electric

transport will increase reliability of electric motors in general up

to 10%. It is proposed to use the results of the work in the

educational process and in the research work of students at the

Department of Electric Transport of the O.M. Beketov National

University of Urban Economy in Kharkiv. The developed methodology for

determination of parameters of traction electric motors when

operating trolleybuses allows assessing the reliability of any type

of trolleybus traction motor.

Keywords:

electric transport;

traction electric

motor; diagnosing;

operating reliability;

failure rate

Introduction

Trolleybuses are equipped with

traction electric motors of direct and alternating current, which

determine the functional purpose of the rolling stock as a whole.

The main task of the operation

of urban electric transport, in particular that of trolleybuses, is

to ensure uninterrupted process of transportation of passengers,

traffic safety on routes, as well as electrical safety.

Providing

the appropriate

level of

reliability of

traction

electric motors

is an

urgent task

that contributes

to the

efficiency of

urban electric

transport in

general [1].

It is possible to obtain the

solution of the problem by saving resources and controlling

parameters in the process of the object operation. This can be

achieved by ensuring the quality of maintenance and timely control

of the relevant parameters of the traction electric motors while

operating trolleybuses on routes. This set of tasks emphasizes the

relevance of the work [1, 2].

Purpose

The main purpose of the work is

to study the change in parameters of traction electric motors of

trolleybuses during operation and improvement of the technical state

control system, using modern diagnostic me.

According to the purpose of the

work, the following tasks are defined:

– To

study the

parameters of

traction

electric motors

of trolleybuses

in the

course of

their operation,

to obtain

quantitative

characteristics

of the

commutator

reliability and

to define

the failure

distribution

laws;

– To

establish the

mathematical

expectation of

the time

between failures

of the

commutator

elements;

To define

the commutator

wear rate

distribution law;

To

develop the

methods of

failure

prediction for

trolleybus

traction

electric motor

elements.

Solving these tasks will

increase the operational reliability of trolleybus traction electric

motors.

Methodology

The achievement of this purpose

is based on the control of technical state and change in the

parameters of traction electric motors in the process of operation.

Analysis of operational factors

is carried out using methods of mathematical statistics and

probability theory. To evaluate the reliability of traction electric

motor elements, the method of mathematical modeling and the design

of experiment are used.

The history of the development

and improvement of methods for assessing reliability allows to

distinguish two main stages: the study of statistical parameters and

analysis of physico-statistical cha-racteristics.

Comparison of methods in terms

of accuracy of the obtained parameters and the adequacy of simulated

processes makes it possible to highlight their features.

This allows us to form the

system reliability models that take into account the influence of

operational factors [1, 2].

The failures

of traction electric motors largely depend on the properties of the

design, materials, load modes and operating conditions.

Quantitatively, they

can be

estimated by

probabilistic-statistical

characteristics.

A significant

number of works is devoted to the issue of increasing the

reliability of traction electric motors (TEM) of trolleybuses [3-5,

9, 12, 13]. However, most of them do not meet the necessary

requirements to ensure maximum accuracy of assessment and forecast

during the trolleybus operation.

To diagnose electric motors of

trolleybuses, we determined the intensity of change in parameters,

which contributes to the disturbance of switching of the motors due

to the intense wear of the commutator. This phenomenon reflects a

deterministic process.

In

order to

determine the

intensity of

wear of

the traction

electric motor

commutators, we

carried out

the studies

in the

conditions of

trolleybus

operation in

Ukraine.

Herewith we took

into account

the geometry

of the

commutators and

the state

of the

contact surface.

These studies confirmed the well-known provisions on the random

nature of the wear intensity of the commutator.

Based on the

main property of inconsistent events, the sum of probabilities will

be equal to one. If the random variable x

is expanded at intervals, then it is possible to obtain probability

characteristics, or the failure distribution law.

According

to the

statistical

analysis, we

determined the

characteristics

of the

mathematical

expectations and

the commutator

wear intensity,

taking into

account the

state of

the contact

surface [9, 12].

Findings

The

studies have

shown that

in most

cases, the

wear of

commutators

obeys the

Gaussian

distribution law

N {mx,x}.

But the

influence of

operational

factors on

the

characteristics

can vary

with the

running time.

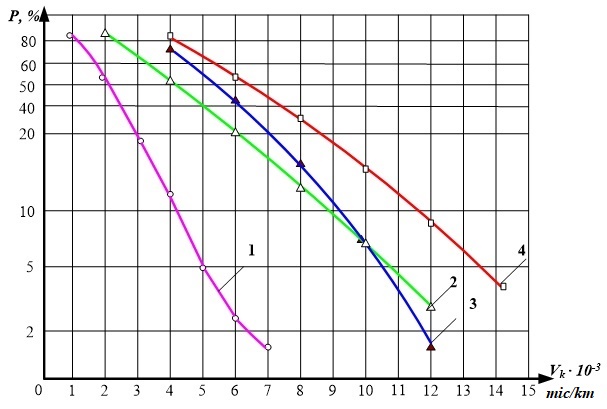

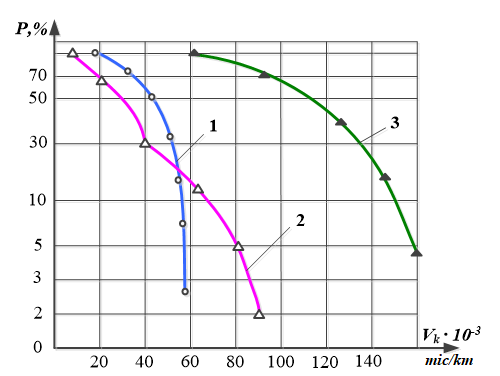

The form of the distribution of the

commutator wear Vc

from the

probability of scattering of the stagnant failures will be the

empirical dependencies shown in Fig. 1, with the corresponding

parameters тх

і and

for different commutators.

for different commutators.

Fig. 1. Empirical

dependencies of distribution of the commutator wear rate:

1

– normal palette with black-out of plates; 2 – plate burning;

3

– abrasive destruction of the oxide film;

4

– circular and chaotic burning

If we accept

the change in the commutator wear intensity as a diffusion process,

then, after the end of the working period (in the stable period), it

fluctuates relative to a certain level. The time between failures T

in this case is determined by the formula [9, 12]:

(1)

(1)

where

–

allowable

value

of

wear,

μm;

–

allowable

value

of

wear,

μm;

–

distribution density;

–

distribution density;

If the wear

of the commutator is subject to the Gaussian law, then the formula

will have as follows:

(2)

(2)

where

–

mean square deviation;

–

mean square deviation;

–

a random

variable;

–

a random

variable;

– average

value of random variable.

– average

value of random variable.

Studying the

dispersion of the parameter P and

the characteristics of the commutator reliability, depending on the

state, showed that the contact surface may have a varied colour and

composition. The normal palette of plate surfaces has a uniform

oxide film without traces of erosion. The plate black-out or chaotic

burning shows the destruction of the contact surface by different

schemes.

In the case of plate burning

there is oxide film destruction, which affects the commutation

process and the reliability of the commutator unit. Results of the

study of pre-statistical characteristics of the commutator elements

wear are shown in Fig. 2

Fig.

2. Dependence of commutator reliability on the nature of its wear

Graphic dependencies demonstrate

the significant influence of the plate burning on the dispersion of

reliability characteristics.

In case of black-out or the

normal state of the oxide film, the dispersion level is almost two

times lower than that of commutators with plate burning.

In general, one can note the

following: the level of dispersion of the gradual failure of the

commutators is high, which requires the turning of the commutators

and practically complicates the combination with planned types of

technical inspections and repairs.

Practice

shows that

during TEM

operation

commutator

turning is

often performed.

This is explained, as was shown earlier,

by the magnitude of the spread of the mean time between failures.

The spread of the

characteristics of wear is mainly determined by the state of the

surface of the plates, the properties of the switching process,

vibration. Accelerated wear of commutators requires premature

turning, which is performed mainly during unscheduled repairs. Due

to frequent grinding, this group of commutators prematurely runs its

course.

But there is a group of

commutators that has low wear intensity. In this case, grinding

occurs during scheduled repairs when the parameters and condition of

the commutator allow it to be used until the next scheduled repair,

which involves reduction of the resource.

The results of studies are

important, which is that the deformation of the commutator during

operation is considered as a random process. This gives a

qualitative estimate of the change in the commutator geometry under

exploitation conditions.

The conducted studies allowed

determining the laws of changing the commutator geometry, depending

on the operating time and condition of the palette of different

types of traction electric motors. This confirms the increase in the

life of the commutators without having to be turned in the interval

between repairs.

The degree of wear of the

brushes depends on the state of the commutator working surface, the

armature and pole winding and the insulation (switching stages).

The wear of the brushes is based

on the fact that the destruction of individual areas of the friction

surface and the separation of the material in the form of wear

products is due to repeated interaction of the projections of rough

friction surfaces. Interaction of friction surfaces is accidental.

Consequently, the microgeometry can be determined only by means of

the functions of the distribution of surface areas at the height by

the reference curves.

Since the projections on

surfaces have different height and shape, then the magnitude of the

stresses and deformations that arise during the interaction will

also be characterized by a certain spectrum. This allows us to

determine that the process of destruction from weariness can be

considered accidental.

The condition

of friction pair «commutator-electrical brush» is characterized by

a certain set of loads, speeds and other parameters that have a

significant effect on their wear. Significant

impact on

wear is

also caused

by specific

pressure of

the brush

springs on

the brushes.

As the practice of exploitation shows, the

wear of electro-brushes of different types has significant

deviations of pre-statistical characteristics. The fig. 3 shows the

graphic dependences of the of wear rate of the brushes of different

types V

on the probability of dispersion of the gradual failure of the

brushes.

Taking

into account

the statistical

data, we

determined the

mathematical

expectation, the

mean square

deviation, and

the variance

of the

intensity of

the wear

of the

brushes [9,

12-14]. This makes it possible to make a

comparative analysis of various variants of assembly units of

commutators. However, in practice, the combination with planned

types of technical inspections and repairs is complicated.

Fig. 3. Dependence

of wear rate of the brushes of different types:

1

– wear distribution curve of EG-2A type brushes; 2

– wear distribution curve of EG-62 type brushes;

3

– wear distribution curve of EG-74C type brushes

The value of the mean square

deviation of the wear intensity indicates a high degree of

dispersion of the reliability parameters (see Fig. 3). From the

given data it is seen that the time between failures is

characterized by a high level of dispersion for uneven wear. This

indicates that the failure of the brushes occurs between the

repairs, which creates the preconditions for unscheduled work to

eliminate failures and increases operating costs.

Thus, a decrease in the

dispersion between failures will allow concentrating the change of

brushes of ultimate wear on scheduled repairs.

As the practice of trolleybus

traction electric motors shows, the failures of system elements can

be caused by the inconsistency of load factors affecting the

increased wear. Such influence extends to each element of the system

separately or together, and levels can take different values.

Temporary and quantitative characteristics depend on operating

conditions, under which such factors as ambient temperature,

barometric pressure, pollution, frost, snow, etc. operate.

The factors

that affect the elements of the traction electric motors include

temperature, vibration, current, voltage, power, humidity, frequency

of rotation; we denote them as

.

The part of these factors under operating

conditions varies depending on load modes and affects accordingly

the elements of traction electric motors.

.

The part of these factors under operating

conditions varies depending on load modes and affects accordingly

the elements of traction electric motors.

The failure rate with factors of

influence[9–12]:

, (3)

, (3)

where

–

variable parameter depending on the operating conditions;

–

variable parameter depending on the operating conditions;

–

load factor

–

load factor

;

;

–

coefficient

with regard to the properties of the design of the traction electric

motor, the state of gap in the joints of parts;

–

coefficient

with regard to the properties of the design of the traction electric

motor, the state of gap in the joints of parts;

– influence

factors with

regard to

current,

vibration,

power, voltage,

etc.

– influence

factors with

regard to

current,

vibration,

power, voltage,

etc.

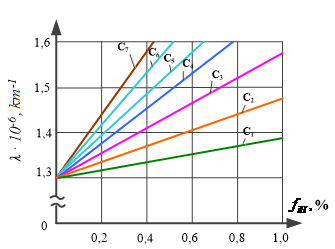

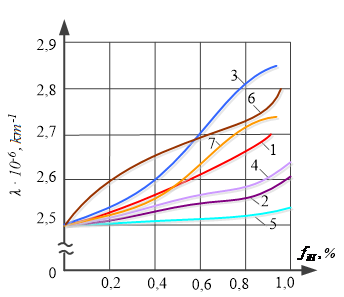

The

fig. 4 shows

the dependence

of the failure rate of the insulation for

traction electric motors

on the

nominal value

of the

load mode

fiH.

Dependencies are

constructed for

different

implementations

of the

load factor

c (с1

= 0.073;

с2

= 0.146;

с3

= 0.219;

с4

= 0.299;

с5

= 0.365;

с6

= 0.438;

с7

= 0.511).

Fig. 4. Dependences

of failure rate of the traction electric motor isolation

on the nominal value

of loading mode fiH and

various realizations of the load factor c

The shown factors are

independent and operate simultaneously. Failure of an element due to

one of the factors leads to system failure.

The

dependence of

the failure

rate of

the traction

electric motor

element on

the failure

rate by

factors is

taken linear

and has

the form:

or

(4)

(4)

Numerous

studies [3–8, 10–12] and operational data show the distribution

law for the probability of failure-free operation for some elements

of the traction electric motor. For relaxation failures in time t

this is a product with the parameter

, This

parameter is determined taking into account the normal law of the

distribution of failures

, This

parameter is determined taking into account the normal law of the

distribution of failures

Then

the reliability

of Pk

(t)

element for

the independence

of the

parametric

Then

the reliability

of Pk

(t)

element for

the independence

of the

parametric

and the

relaxation

and the

relaxation

failures

will be equal to the product:

failures

will be equal to the product:

, (5)

, (5)

where

(6)

(6)

Based on the

data (see Fig. 4), for the given value of the load factor c,

the reliability character-ristics for the assembly element are

calculated:

m1

=

3.810-4;

1

= 510-4;

c1

= 0.776;

m2

=

1.110-4;

2

=

1.710-4;

c2

= 0.742;

m3

=

1.710-4;

3

=

2.610-4;

c3

= 0.736.

From the given dependencies it

is clear that the parameters of the composite structure of the model

significantly affect the reliability of the traction electric motor.

For

mk

=

mkH;k

=

kH;k

=

kH

the

equation (5) will look as follows:

Expression of the failure rate

for a particular structural scheme of an element will have the form:

.

.

By making the appropriate

substitution, we can obtain the equation [16–18]:

(7)

(7)

where

k

is

the

coefficient

taking

into

account

the

properties

of

the

traction

electric

motor

design,

namely

the

state

of

the

gap

in

the

part

joints;

Mn

is

a mathematical expectation;

The obtained

dependences for various load factors indicate that the effect on the

failure rate for a particular structural scheme of the element

k

is not the same (Fig. 5). In the general

case, the equation that binds the failure rate, the probability of

failure-free operation and derivative, depends on the load factors

and may have the following form:

(8)

(8)

Thus, we have

an important condition under which the expression connects the

failure rate with the parameters of the load element.

To diagnose

the technical condition of the turn and main insulation we take into

account the parameter change processes under the influence of the

heating temperature.

The

combination of changes in the factors influences the level and

nature of the TEM load.

During the

study of the reliability of the traction motor during operation, it

is important to provide an opportunity to analyze the reliability of

the insulation, taking into account the number of available factors.

Therefore, it

is important to have such a research scheme that would cover, if

possible, factors that are not significant, but in aggregate have a

great influence on the assessment of reliability parameters.

Fig.

5. Influence of load modes on the failure rate of insulation

of armature winding

for electric motors

against the nominal value of load mode fiH:

the curves 1–7

are load factors

We will show this for the

insulation of armature winding when determining the dependence of

the probability of failure-free operation of a system element on the

base space elements. To do this from the factor space elements we

select the base space elements.

Let

us suppose:

g1 is

the flow

rate of

the cooling

air from

0 to 80 m3/min;

g2 is

the voltage

from 0 to

700 V; g3

is the current

of 0 to

720 A; g4

is the air

humidity of

98 %.

In

the process

of research,

there are

some

difficulties in

choosing the

main factors.

Thus, the

temperature

depends on

the insulation,

which depends

on the

electrical,

magnetic,

mechanical

losses, and

they, in

turn, depend

on the

current, air

flow, the

frequency of

the armature

rotation, etc.

If we take into account that they are

correlated with each other to varying degrees, then the

formalization of the process will not take place. Therefore, only

factors of direct influence are taken into account, in particular

the temperature of heating of insulation, etc.

The

method of

multivariable

regression

analysis in

the presence

of statistics

that

characterizes

the work

of the

object, allowed

us to

obtain a

regression model

of temperature

dependence on

the base

space elements

and load

modes, taking

into account

the effects

of pressure:

,

(9)

,

(9)

where

х is a

random variable that has the form of the dependence of the

rotational frequency on the voltage g2

Then there will be an expression:

(10)

(10)

By summing the similar and

transforming the right side (10) we obtain the equation:

(11)

(11)

where

u0…u9

are the factor space elements.

The equation (11) characterizes

the dependence of temperature as an element of the factor space on

the strength of current, the flow of cooling air and voltage.

Similarly to the vibration

parameter, depending on the frequency of the armature rotation, we

have:

. (12)

. (12)

Substituting

the obtained

expressions into

the basic

equation (7) of

the element

failures rate,

we obtain

a generalized

equation:

,(13)

,(13)

From

equation (13) we

find the

characteristics

of the

failure rate

against the

factors by

solving the

differential

equations of

the form:

(14)

(14)

Thus we obtained the dependences

of the probability of failure-free operation on the temperature and

load modes.

The

calculation of

reliability made

it possible

to estimate

the level

of the

system element

failure rate,

which is

The failure

rate when

exceeding the

factor levels

by 1.5 times

gives the

magnitude of

the failure

rate

The failure

rate when

exceeding the

factor levels

by 1.5 times

gives the

magnitude of

the failure

rate

The obtained results show that

in the presence of exploitation data, it is possible to predict the

failure rate by calculation and, based on the given service life, to

predict the probability of failure-free operation.

Consequently, it is possible to

predict the failure rate of all elements of traction electric motors

without exception and by using compositional models to determine the

reliability of the whole system.

Rational choice of diagnostic

parameters of traction motors will increase their reliability in

general up to 10%.

The

conducted

researches

provide the

basis for

further

development of

the

calculation-experimental

method for

estimating the

parameters of

the maintenance

system of

trolleybus

traction

electric motors,

which reached

the end

of their

assigned service

life.

The

proposal for

practical use

of the

method of

structural and

functional

analysis of

the reliability

of the

traction

electric motor

elements allowed

for the

particular

structural

assembly to

obtain adequate

estimates of

the reliability

parameters [9,

12].

These methods

allow making a calculation of

pre-statistical characteristics

parameters of failures and damages of parts and units, on the basis

of which it becomes possible to adjust the parameters of

inter-repair runs of the trolleybus traction electric motor as a

whole.

Originality and practical

value

For the first

time, the choice of physico-statistical methods of simulation and

reliability calculation was substantiated. We determined the

regularities of change in parameters of the trolleybus traction

electric motor elements, which makes it possible to control the

processes of their wear in the operation conditions. We developed a

mathematical model for estimating the traction electric motor

reliability, based on a system analysis of the probabilities of

failures of subsystems to be diagnosed.

Based on the results of the

study, we developed practical recommendations for rational choice of

diagnostic parameters of traction motors. Their implementation at

the enterprises of electric transport will increase reliability of

electric motors in general up to 10%.

It is proposed to use the

results of the work in the educational process and in the research

work of students at the Department of Electric Transport of the O.M.

Beketov National University of Urban Economy in Kharkiv.

The developed

methodology for determination of parameters of traction electric

motors when operating trolleybuses allows to assess the reliability

of any type of trolleybus traction motor.

Conclusions

1. As

a result of the conducted research we obtained the quantitative

characteristics of the commutator reliability. It has been

established that the failure of traction motors make up 20% of all

failures of electric equipment. Conditions

of operation

of traction

electric motors

were analysed.

We determined

the failure

distribution law

N

{mx,x},

which allows assessing the progression

between gradual failures.

2. We

obtained the mathematical model (9) using the multi-factor

regression analysis method in the presence of statistics. This model

characterizes the work of the object. We also obtained the

generalized equation of the failure rates (13) of the TEM elements.

We improved the method of estimating the reliability of the

elemental base of traction electric motors. The obtained solution

allows to determine the TEM service life taking into account the

characteristics of each trolleybus.

3. We

established the intensity of commutator wear using the distribution

law. The

calculation of

reliability

parameters

allowed to

estimate the

level of

the system

element failure

rate.

In case

of excess

of the

wear intensity

factors by

1.5 times the

parameter

is changed by the value of

is changed by the value of

4. The

use of composite models and necessary calculation methods will allow

to predict the failure of elements of the trolleybus traction

electric motors. Practical recommendations, taking into account the

research results, will increase the reliability of TEM up to 10%.

LIST OF REFERENCE LINKS

Есаулов,

С. М. Исследование и разработка

зарядного устройства суперконденсатора

при рекуперации энергии торможения

электропривода на транспорте

/ С. М. Есаулов, О. Ф. Бабичева, Н. П.

Лукашова // Комунальне господарство

міст. Серія: Технічні науки та архітектура

: наук.-техн. зб. / Харк. нац. ун-т міськ.

госп-ва ім. О. М. Бекетова. – Харків,

2017. – Вип. 135. – С. 132–140.

Правила

експлуатації міського електричного

транспорту : навч. посіб. / В. Х. Далека,

В. Б. Будниченко, В. І. Коваленко, М. В.

Хворост, Л. О. Ісаєв ; Харк. нац. ун-т

міськ. госп-ва ім. О. М. Бекетова. –

Харків : ХНУМГ, 2014. – 447 с.

Разработка

и внедрение интеллектуальных систем

диагностирования технического состояния

электрического оборудования / С.

И. Лукьянов, А. С. Карандаев, С. А. Евдокимов

[и др.] // Вестн.

Магнитогор. гос. техн. ун-та им. Г. И.

Носова. – 2014. – № 1 (45).

– С. 129–136.

Розробка

енергомеханічної установки для тяги

електромобіля / Д. Ю. Зубенко, А. В.

Коваленко, О. М. Петренко, В. М. Шавкун,

М. Ю. Олехно // Science

Rise.

– 2016. – Т. 10, № 2 (27).

– С. 6–15.

doi:

10.15587/2313-8416.2016.79196

Рухомий

склад міського електричного транспорту.

Механічна частина : навч. посібник / В.

Х. Далека, М. В. Хворост, В. І. Скуріхін,

Д. І. Скуріхін. – Харків

: ХНУМГ імені О. М. Бекетова,

2018. – 370 с.

Скурихин,

В. И. Моделирование изнашивания

поверхностей трения узлов и деталей

машин / В. И. Скурихин // Проблеми та

перспективи розвитку технічних засобів

транспорту та систем автоматизації :

матеріали міжнар. наук.-техн. конф. –

Харків, 2014. – С. 42–43.

Сорока,

К. О. Змістовна модель та рівняння руху

електричного транспорту / К. О. Сорока,

Д. О. Личов // Наука та прогрес транспорту.

– 2015. – № 3 (57). – С. 97–106. doi:

10.15802/stp2015/46056

Сорока,

К. О. Система автоматизованого вибору

швидкісного режиму руху засобів

електротранспорту з метою зменшення

витрат електроенергії / К. О. Сорока,

Т. П. Павленко, Д. О. Личов // Наука

та прогрес транспорту. –

2017. – № 3 (69). – С. 77–91. doi:

10.15802/stp2017/104360

Технічна

експлуатація міського електричного

транспорту : навч. посіб. / В. Х. Далека,

В. Б. Будниченко, Е. І. Карпушин, В. І.

Коваленко

;

Харк. нац. ун-т міськ. госп-ва ім. О. М.

Бекетова. – Харків : ХНУМГ, 2014. – 236 с.

Шавкун,

В. М. Визначення оптимальних режимів

діагностування транспортних засобів

[Electronic

resource] / В.

М. Шавкун, О. В. Мізяк // Автомобіль і

електроніка. Сучасні технології.

– 2017. – № 12. –

С.

193–198. – Режим доступу:

http://www.khadi.kharkov.ua/fileadmin/P_SIS/AE17_2/5.2.pdf

– Назва з екрана. – Перевірено :

23.06.2018.

Шавкун,

В. Діагностування тягових електричних

машин електротранспорту / В. Шавкун //

Вост.-Европ. журн. передовых технологий.

– 2014. – Т. 1, № 7 (67). – С. 48–53.

Яцун,

М. А. Експлуатація та діагностування

електричних машин і апаратів / М. А.

Яцун, А. М. Яцун. – Львів : Львівська

політехніка, 2010. – 228 с.

Identification

of induction machine parameters using only no-load test

measurements /

M. Aminu,

P.

K. Ainah, M. Abana, U. A. Abu // Nigerian

Journal of Technology. – 2018. – Vol.

37. – Iss. 3. – P. 742–748.

doi:

10.4314/njt.v37i3.25

Kolcio,

K. Model-based

off-nominal state isolation and detection system for autonomous

fault management / K. Kolcio,

L. Fesq

// IEEE

Aerospace Conference Proceedings. – 2016. doi:

10.1109/AERO.2016.7500793

Kuznetzov,

A. Resource saving reserves of determining characteristics of the

long steering wall of wagon of the metro / A. Kuznetzov,

V. Skurikhin, V. Shavkun // EUREKA:

Physical

Sciences and

Engineering.

– 2018. – Vol.

1. – P. 19–28. doi:

10.21303/2461-4262.2018.00525

Pavlenko,

T. Ways

to improve operation reliability of traction electric motors of the

rolling stock of electric transport / T.

Pavlenko, V.

Shavkun, A.

Petrenko //

Eastern-European

Journal of

Enterpraise

Technologies. –

2017. – Vol.

5. – Iss. 8

(89). – Р. 22–30. doi: 10.15587/1729-4061.2017.112109

Zubenko,

D. Designing intelligent systems management transport enterprises

entropy approach / D. Zubenko,

A. Kuznetzov // EUREKA: Physics and

Engineering. – 2016. – Vol.

1. – P.

49–54.

doi:

10.21303/2461-4262.2016.00025

т.

п. пАВЛЕНКО1*,

в. м. шАВКУН2*,

в. і. сКУРІХІН3*,

н. п. лУКАШОВА4*

1*Каф.

«Електричний транспорт», Харківський

національний університет міського

господарства імені О. М. Бекетова, вул.

Маршала Бажанова, 17, Харків, Україна,

61002, тел. +38 (095) 485 40 16, ел. пошта

tpavlenkoskp@gmail.com,

ORCID 0000-0002-2356-4066

2*Каф.

«Електричний транспорт», Харківський

національний університет міського

господарства імені О. М. Бекетова, вул.

Маршала Бажанова, 17, Харків, Україна,

61002, тел. +38 (095) 142 90 00, ел. пошта

vm.shavkun@gmail.com,

ORCID 0000-0002-3253-1282

3*Каф.

«Електричний транспорт», Харківський

національний університет міського

господарства імені О. М. Бекетова, вул.

Маршала Бажанова, 17, Харків, Україна,

61002, тел. +38 (095) 745 31 77, ел. пошта

vladscu@gmail.com,

ORCID 0000-0001-7415-7105

4*Каф.

«Електричний транспорт», Харківський

національний університет міського

господарства імені О. М. Бекетова, вул.

Маршала Бажанова, 17, Харків, Україна,

61002, тел. +38 (095) 745 31 77, ел. пошта

lukashova.natalya@gmail.com,

ORCID 0000-0002-5556-241X

Методологія

визначення параметрів відмов ТЯГОВИХ

електричних ДВИГУНІВ під час експлуатації

ТРОЛЕЙБУСІВ

Мета.

У роботі необхідно провести дослідження

зміни параметрів тягових електричних

двигунів (ТЕД) тролейбусів у процесі

експлуатації й удосконалення

системи керування технічним станом за

допомогою використання сучасних методів

діагностування. Методика.

Розв’язання наукової

задачі базується на процедурі контролю

технічного стану й зміни параметрів

тягових електричних двигунів у процесі

експлуатації. Для

аналізу експлуатаційних

факторів застосовано метод математичної

статистики й теорії ймовірності.

Математичне моделювання й

планування експерименту, багатофакторний

регресійний аналіз дає

оцінку надійності елементів тягових

електричних двигунів. Фізико-статистичні

методи передбачають

дослідження й виявлення закономірностей

впливу факторів, які прискорюють знос

деталей. Це дозволяє сформувати моделі

надійності системи, що враховують вплив

експлуатаційних факторів на надійність.

Результати.

Авторами у результаті проведених

досліджень отримано кількісні

характеристики надійності

колекторно-щіткового вузла та встановлено,

що відмови тягових двигунів складають

20 % від усіх відмов електрообладнання.

Проаналізовано умови експлуатації

тягових електричних двигунів і визначено

закон розподілу відмов N{mx,x},

що дозволяє оцінити напрацювання між

поступовими відмовами. Отримано

математичну модель, яка характеризує

роботу об’єкта під час експлуатації.

Знайдено узагальнене рівняння

інтенсивності відмов

елементів тягових електродвигунів.

Удосконалено

методи оцінки надійності елементної

бази тягових електродвигунів, яка

дозволяє визначити ресурс ТЕД із

урахуванням особливостей кожного

тролейбуса. Встановлено

інтенсивність зносу колекторів із

використанням фізико-статистичних

методів. Наукова новизна.

Уперше обґрунтовано

вибір фізико-статистичних методів

моделювання й розрахунку надійності.

Встановлено закономірності зміни

параметрів елементів тягових

електродвигунів тролейбусів, що дає

можливість контролювати процеси їх

зношування в умовах експлуатації.

Створено

математичну модель оцінки надійності

тягового електричного двигуна, яка

базується на системному аналізі

ймовірностей відмов підсистем, що

підлягають діагностуванню. Практична

значимість. На основі

отриманих результатів дослідження

розроблено практичні рекомендації

щодо раціонального вибору діагностичних

параметрів тягових двигунів. Їх

реалізація на підприємствах

електротранспорту дозволить підвищити

надійність електричних двигунів у

цілому до 10 %. Запропоновано використовувати

результати роботи в навчальному процесі

та в науково-дослідницькій роботі

студентів на кафедрі електричного

транспорту Харківського національного

університету міського господарства

імені О. М. Бекетова. Розроблена

методологія визначення параметрів

тягових електричних двигунів під час

експлуатації тролейбусів дозволяє

проводити оцінку надійності будь-якого

типу тягового двигуна тролейбуса.

Ключові

слова: електричний транспорт; тяговий

електричний двигун; діагностування;

експлуатаційна надійність; інтенсивність

відмов

т.

п. пАВЛЕНКО1*,

в. м. шАВКУН2*,

в. И. сКУРИХИН3*,

н. п. лУКАШОВА4*

1*Каф.

«Электрический транспорт», Харьковский

национальный университет городского

хозяйства имени А. Н. Бекетова, ул.

Маршала Бажанова, 17, Харьков, Украина,

61002, тел. +38 (095) 485 40 16,

эл. почта

tpavlenkoskp@gmail.com,

ORCID 0000-0002-2356-4066

2*Каф.

«Электрический транспорт», Харьковский

национальный университет городского

хозяйства имени А. Н. Бекетова, ул.

Маршала Бажанова, 17, Харьков, Украина,

61002, тел. +38 (095) 142 90 00,

эл. почта

vm.shavkun@gmail.com ,ORCID

0000-0002-3253-1282

3*Каф.

«Электрический транспорт», Харьковский

национальный университет городского

хозяйства имени А. Н. Бекетова, ул.

Маршала Бажанова, 17, Харьков, Украина,

61002, тел. +38 (095) 745 31 77,

эл. почта

vladscu@gmail.com,

ORCID 0000-0001-7415-7105

4*Каф.

«Электрический транспорт», Харьковский

национальный университет городского

хозяйства имени А. Н. Бекетова, ул.

Маршала Бажанова, 17, Харьков, Украина,

61002, тел. +38 (095) 745 31 77,

эл. почта

lukashova.natalya@gmail.com,ORCID /0000-0002-5556-241X

МетодологИя

ОПРЕДЕЛЕНИЯ ПАРАМЕТРОВ ОТКАЗОВ ТЯГОВЫХ

ЭлектричЕСКИХ ДВИГАТЕЛЕЙ ПРИ ЭКСПЛУАТАЦИИ

ТРОЛЛЕЙБУСОВ

Цель.

В работе необходимо

провести исследование изменения

параметров тяговых электродвигателей

(ТЭД) троллейбусов в процессе эксплуатации

и совершенствования системы управления

техническим состоянием посредством

использования современных методов

диагностики. Методика.

Решение научной задачи базируется на

процедуре контроля технического

состояния и изменения параметров

тяговых электрических двигателей в

процессе эксплуатации. Для анализа

эксплуатационных факторов применен

метод математической статистики и

теории вероятности. Математическое

моделирование и планирование эксперимента,

многофакторный регрессионный анализ

дает оценку надежности элементов

тяговых электрических двигателей.

Физико-статистические методы

предусматривают исследования и выявления

закономерностей влияния факторов,

которые ускоряют износ деталей. Это

позволяет сформировать модели надежности

системы, учитывающие влияние

эксплуатационных факторов на надежность.

Результаты.

Авторами в результате проведенных

исследований получены количественные

характеристики надежности

коллекторно-щеточного узла и установлено,

что отказы тяговых двигателей составляют

20 % от всех

отказов электрооборудования.

Проанализированы условия эксплуатации

тяговых электрических двигателей и

определен закон распределения отказов

N {mx,x},

что позволяет оценить наработки между

постепенными отказами. Получена

математическая модель, которая

характеризует работу объекта во время

эксплуатации. Найдено обобщенное

уравнение интенсивности отказов

элементов тяговых электродвигателей.

Усовершенствованы методы оценки

надежности элементной базы тяговых

электродвигателей, которая позволяет

определить ресурс ТЭД с учетом

особенностей каждого троллейбуса.

Установлена

интенсивность износа коллекторов с

использованием физико-статистических

методов. Научная новизна.

Впервые обоснован выбор физико-статистических

методов моделирования и расчета

надежности. Установлены закономерности

изменения параметров элементов тяговых

электродвигателей троллейбусов, что

дает возможность

контролировать процессы их износа в

условиях эксплуатации. Создана

математическая модель оценки надежности

тягового электрического двигателя,

которая базируется на системном анализе

вероятностей отказов подсистем,

подлежащих диагностированию. Практическая

значимость. На основе

полученных результатов исследования

разработаны практические рекомендации

по рациональному выбору диагностических

параметров тяговых двигателей. Их

реализация на предприятиях электротранспорта

позволит повысить надежность электрических

двигателей в целом до 10

%. Предложено использовать

результаты работы в учебном процессе

и в научно-исследовательской работе

студентов на кафедре электрического

транспорта Харьковской национальной

академии городского хозяйства имени

А. Н. Бекетова. Разработанная методология

определения параметров тяговых

электрических двигателей при эксплуатации

троллейбусов позволяет проводить

оценку надежности любого типа тягового

двигателя троллейбуса.

Ключевые

слова: электрический транспорт;

тяговый электрический двигатель;

диагностирование; эксплуатационная

надежность; интенсивность отказов

REFERENCES

Esaulov,

S. M., Babicheva, O. F., &

Lukashova, N. P. (2017). Research and development of the charger of

a su-percapacitor for the recovery of braking energy of an electric

drive in transport. Municipal economy

of cities. Series: «Engineering science and architecture»,

135,

132-140. (in

Russian)

Daleka,

V. K., Budnychenko, V. B., Kovalenko, V. I., Khvorost, M. V., &

Isaiev, L. O. (2014). Pravyla ekspluatatsii miskoho elektrychnoho

transportu: Navchalnyi posibnyk. Kharkiv: KhNUMH. (in

Ukranian)

Lukyanov,

S. I., Karandaev, A. S., & Yevdokimov, S. A. (2014). Razrabotka

i vnedrenie intellektualnykh sistem diagnostirovaniya

tekhnicheskogo sostoyaniya elektri-cheskogo oborudovaniya. Vestnik

Magnitogorskogo gosudarstvennogo tekhnicheskogo universiteta im. G.

I. Nosova, 1(45), 129-136. (in

Russian)

Zubenko,

D. Y., Kovalenko, A. V., Petrenko, O. M., Shavkun, V. M., &

Olekhno, M. Y. (2016). Rozrobka enerhomekhanichnoi ustanovky dlia

tiahy elektromobilia. Science Rise,

10, 2(27),

6-15.

doi: 10.15587/2313-8416.2016.79196

(in

Ukranian)

Daleka,

V. K., Khvorost, M. V., Skurikhin, V. I., & Skurikhin, D. I.

(2018). Rukhomyi sklad miskoho

elektrychnoho transportu. Mekhanichna chastyna: Navchalnyi

posibnyk. Kharkiv: KhNUMH imeni O. M.

Beketova. (in

Ukranian)

Skurikhin,

V. I. (2014). Modelirovanie iznashivaniya poverkhnostey treniya

uzlov i detaley mashin. Problemy ta

perspektyvy rozvytku tekhnichnykh zasobiv transportu ta system

avtomatyzatsii: Materialy Mizhnarodnoi naukovo-tekhnichnoi

konferentsii, 42-43. (in

Russian)

Soroka,

K. O., & Lychov, D. A. (2015). The content model and the

equations of motion of electric vehicle. Science

and Transport Progress, 3(57),

97-106. doi: 10.15802/stp2015/46056 (in

Ukranian)

Soroka,

K. O., Pavlenko, T. R., & Lychov, D. A. (2017). System for

automatic selection of the speed rate of electric vehicles for

reducing the power consumption. Science

and Transport Progress,

3(69). 77-91.

doi:

10.15802/stp2017/104360 (in

Ukranian)

Daleka,

V. K., Budnychenko, V. B., Karpushyn, E. Y., & Kovalenko, V. I.

(2014). Tekhnichna ekspluatatsiia

miskoho elektrychnoho transportu: Navchalnyi posibnyk.

Kharkiv: KhNUMH. (in

Ukranian)

Shavkun,

V. M., Miziak, O. V. (2017). Vyznachennia optymalnykh rezhymiv

diahnostuvannia transportnykh zasobiv. Avtomobil

i elektronika. Suchasni tekhnolohii, 12,

193-198. Retrieved from

http://www.khadi.kharkov.ua/fileadmin/P_SIS/AE17_2/5.2.pdf (in

Ukranian)

Shavkun,

V. M. (2014). http://journals.uran.ua/eejet/article/view/20196 Diagnostics

of electric transport traction electric machines.

Eastern-European Journal of

Enterpraise Technologies, 1, 7(67),

48-53. (in

Ukranian)

Yatsun,

M. A., & Yatsun,

A. M. (2010). Ekspluatatsiia

ta diahnostuvannia elektrychnykh mashyn i aparativ.

Lviv: Lvivska politekhnika. (in

Ukranian)

Aminu,

M, Ainah, R. K., Abana, M., & Abu, U. A. (2018). Identification

of induction machine parameters using only no-load test

measurements. Nigerian Journal of

Technology, 37(3), 742. doi:

10.4314/njt.v37i3.25 (in English)

Kolcio,

K., & Fesq, L. (2016). Model-based off-nominal state isolation

and detection system for autonomous fault management. IEEE

Aerospace Conference Proceedings.

doi: 10.1109/AERO.2016.7500793 (in English)

Kuznetzov,

A., Skurikhin, V., & Shavkun, V. (2018). Resource saving

reserves of determining characteristics of the long steering wall

of wagon of the metro. EUREKA:

Physical Sciences and Engineering, 1,

19-28.

doi: 10.21303/2461-4262.2018.00525 (in English)

Pavlenko,

T., Shavkun, V., & Petrenko, A. (2017). Ways to improve

operation reliability of traction electric motors of the rolling

stock of electric transport. Eastern-European

Journal of Enterpraise Technologies, 5, 8(89),

22-30. doi: 10.15587/1729-4061.2017.112109 (in English)

Zubenko,

D., & Kuznetzov, A. (2016). Designing intelligent systems

management transport enterprises entropy approach. EUREKA:

Physics and Engineering, 1, 49-54.

doi: 10.21303/2461-4262.2016.00025 (in English)

Received:

April 11,

2018

Accepted:

July 30, 2018

d oi

10.15802/stp2018/ ©

Т.

P.

Pavlenko,

v.

m.

Shavkun,

v.

i.

Scurihin,

n.

p.

lukashova,

2018

oi

10.15802/stp2018/ ©

Т.

P.

Pavlenko,

v.

m.

Shavkun,

v.

i.

Scurihin,

n.

p.

lukashova,

2018

for different commutators.