ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2018,

№ 3

(75)

ЕЛЕКТРИЧНИЙ

ТРАНСПОРТ

електричний

транспорт

UDC

621.336

D.

V. USTYMENKO1*

1*Dep.

«Electrical Engineering and Electromechanics», Dnipropetrovsk

National University of Railway Transport named after Academician V.

Lazaryan, Lazaryan St., 2, Dnipro, Ukraine, 49010, tel. +38 (056) 373

15 47,

e-mail ustimenko.1979@gmail.com,

ORCID 0000-0003-2984-4381

PHYSICO-TECHNOLOGICAL

ASPECTS OF WORK OF LUBRICANT

FILMS IN THE

TRIBOSYSTEM «OVERHEAD

LINE – CURRENT

COLLECTOR CONTACT

STRIP»

Purpose.

The article aimed at comprehensive

analysis of

the processes

occurring in

the lubricant

films of

the friction

surfaces of

the tribosystem

«overhead line

– current

collector contact

strip» (OLCCCS)

and identification

of the

features of

such systems.

Methodology.

The systematic analysis was used as the

main methodology for studying the physico-technological aspects of

work of the lubricant films in the tribosystem «overhead

line – current collector contact strip».

Findings.

The theory

of

electro-friction

interaction is

now at

such a stage

that is

characterized by

a large

amount of

accumulated

empirical data,

hypotheses and

models that

cannot

adequately

represent

phenomena in

a sliding,

high-current

electrical

contact. The

sliding

electrical contact

of the

tribosystem

«overhead line – current collector

contact strip» during

the operation

is affected

by many

factors, one

of which

is the

processes in the lubricating

layers of

the friction

pair. The

work leads to a new level of understanding of the peculiarities of

the processes occurring in the lubricating layers and their effect on

the work of a sliding, high-current electrical contact, which can

become the guarantee of significant increase in the efficiency of

such systems and, as a consequence, substantially increase the

reliability and safety of the work of the electric stock.

Originality.

It is proposed to consider the

processes of

electro-friction

interaction of

electrical

contacts from the

position of

synergy using

the theory

of fractals

as the

core one for

the quantitative

description of

self-organizing

structures.

Practical

value.

Taking into

account the

empirical

experience of

operation of

the tribosystem

«overhead line

– current

collector contact

strip» in

combination with

theoretical

knowledge allows

us to

propose three

possible

directions for

solving

tribological

problems in

high-current

sliding

electrical

contacts. They are:

1) change in

contact geometry

and surface

topography, for

example, the

use of

regular

macrorelief of

contact surfaces;

2) development of

conductive

composites which

are characterised

with

self-lubrication,

for example

the use

of composite

materials

containing solid

conductive

lubricants; 3)

development of

effective

lubricants for

electric

high-current

sliding contacts,

which may

require some

complication of

the component

design.

Keywords:

contact pair; current collection; overhead line; wear rate;

limit friction; contact transient resistance; current collector

contact strip

Introduction

The «current

collector – overhead line»

system has an important task of transmitting energy from the power

grid to the vehicle board. Consequently, a reliable electrical

contact between the current collector and the overhead line is

directly related to the reliability of operation and the safety of

train movement.

During operation, the overhead line and the contact strip of the

current collector are exposed to multiple sliding friction, heating,

erosion, etc., which makes the evolution of the contact quite

complicated. An important role in the sliding contact operation is

played by the antifriction lubrication.

Purpose

The main

purpose of the work is a comprehensive analysis of the processes in

the lubricant films of the friction surfaces of the tribosystem

«overhead line

– current collector contact strip»

(OLCCCS) and the identification of features of such systems.

Studies

aimed at

determining the

peculiarities of

the processes

occurring in

the lubricating

layers of

the friction

surfaces of

the tribosystem

of OLCCCS

should be

considered

relevant in

scientific and

practical terms,

since taking

into account

these features

can provide

a significant

increase in

the efficiency

of tribosystems

of this

class [3, 4, 14,

15].

Methodology

To achieve the purpose set forth

in the work, it is envisaged to study the physico-technological

aspects of the work of the lubricating layers in the tribosystem

«overhead line – current collector contact strip». The system

method is used as the main methodology.

Findings

The theory of

friction and wear of surface layers under conditions of boundary

lubrication was studied in the works by Kostetsky B.

I. [7], Bauden

F. P. and D.

Tabor [5], Kragelskiy I. V.

[8] Ahmatov O. S.

[2], Chichinadze A. V.

[13].

It is known that the work of

sliding contacts is closely related to friction and wear. Therefore,

it is necessary to consider not only the electrical properties of

the sliding contacts, but also the phenomenon of friction and wear.

In the general case, if the two purified surfaces are brought into

contact at the interatomic distance, then the same gravity forces as

in the volume of the material act between them. Several types of

forces can be distinguished:

– ionic

bond occurs

between anions

and cations

that are

held by

electrostatic

forces;

– covalent

(homopolar) bond

between neutral

atoms is

accomplished by

overlapping

their electron

fields, which

leads to

the emergence

of

a

strong bond;

– metallic

bond is

characteristic

of all

metals and

is due

to the

presence of

electrons, which

move freely

between the

ion lattice

sites;

– Van

der Walsh

bond can

occur between

any atoms

or molecules

due to

dipole-dipole

interaction.

Each atom in

the material volume interacts with its closest neighbours by means

of the above forces. The specific energy associated with this

interaction is called cohesive energy and it plays an important role

in the processes of friction and wear. Atoms on the surface have

fewer neighbours, respectively, they do not have bonds outside the

body (Fig. 1) [10]. For this reason, the surface of the solid has

some impractical energy, which determines the surface's ability to

form adhesive compounds.

The presence of surface energy

causes the interaction of the surface with the environment

(including with lubricants), which is called adsorption and leads to

the formation of boundary layers. As a result of adsorption on the

surface there are always elements of adjacent phases.

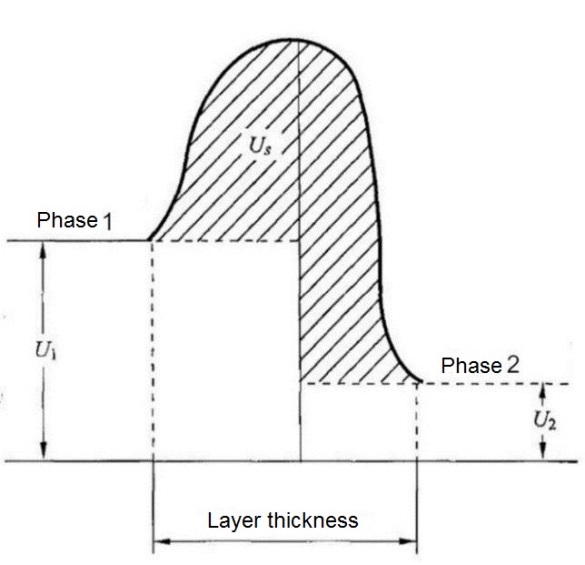

Fig. 1. Energy of

boundary layer Us when

contacting two

phases 1 and 2, having the surface

energy

U1 and U2 (by Kashchev)

Physical

adsorption is

characterised

with Van

der Walsh

interaction of

adsorbate with

the body

surface. The

polymolecular adsorption layers formed on the surface are relatively

easily removed.

In the process of chemical

adsorption, the energy of interaction is quite large, and on the

surface there is usually formed a monolayer that is difficult to

remove.

Thus, the adsorption activity of

surfaces leads to the fact that they form a thin boundary layer,

which differs in structure and properties from the surface

(transition) layer of a solid. The physical state of matter of such

a boundary layer may be different and depends both on the parameters

of the state (temperature, pressure, etc.) and on the nature of the

interaction with the solid phase.

Adhesion of

the rubbing surfaces in many respects determines the patterns of

friction and wear. Surface layers undergo various changes during

friction; these changes can be both inverse and irreversible,

causing wear, seizure and other phenomena.

The primary source of these

processes, and in some cases the main reason, is the stress-deformed

and the thermal state of frictional contact.

Friction in

the conditions of boundary lubrication is accompanied by the

formation between the working surfaces of a thin layer of lubricant,

which acquires the properties of the «third

body»

(according to Kragelskyi

I. V. [5, 8]).

According to DSTU 2823-94, the

term «boundary friction» is to be understood as «lubrication in

which conditions of friction and wear of surfaces moving in relation

to one another are determined by their properties, as well as by the

properties of the lubricant, which differ from the bulk viscosity of

the lubricant material».

The term «lubricating layers»

of lubricants still has no unambiguous interpretation within the

limits of DSTU, but in generalized form it is interpreted as

follows: the lubricating layers of lubricants on solid lyophilic

surfaces are «quasicrystalline molecular layers with a

multimmolecular epitropon-liquid-crystalline structure» [1].

The lubricant

in the boundary layer is anisotropic, so the molecular layers in the

tangential direction slip one relative to the other. In the normal

direction to the surface of friction the bearing capacity of the

boundary layer is high and the deformation of its compression is

within the limits of elasticity.

Friction with a semifluid

lubricant occurs in the case of simultaneous action of liquid and

boundary lubrication. The normal load is balanced by the compression

resistance of the lubricant film in contact spots and the forces of

hydrodynamic pressure in the layers of lubrication. The share of the

reaction of boundary or liquid lubricant depends on the load, the

speed of the mutual slip of the surfaces, the state of the surfaces,

as well as the amount and viscosity of the lubricant. The

hydrodynamic effect of the lubricant is manifested when it enters

the macrogeometric gap between the friction surfaces.

To date, a wide range of models

of tribological systems (friction without transmission of electric

current) has been considered in detail, and a system of indicators

of contact interaction, as well as methods for their determination,

has been developed. The geometric characteristics of surfaces are

introduced: macro-deviation, wavelength, roughness,

submicroroughness; characteristics of contact areas – visible,

contour, actual; types of contacts – elastic, elastic-plastic,

plastic, etc. [13].

One of the contact elements

(overhead line) is made of metal in the friction pair of OLCCCS, the

main material of the second contact element (current collector

contact strip) is solid-lubricating electrically conductive

compositions of four basic types: metal graphite, graphite, carbon

graphite and electro-graphite. Such compositions are characte-rised

with the formation of friction of transferred films on a metal

counterbody.

Experimental

studies have shown that the thickness, composition and structure of

the transferred films are interrelated with the external parameters

of the sliding contact (load, speed), composition of the composite,

counterbody and the environment [11]. At the same time, the film

determines the mechanism of passing the current, and, respectively,

the electrical characteristics of the contact, the nature and

intensity of heat dissipation. The film thickness and the degree of

coating of the metal counterbody inequality are, from this point of

view, the most important factors of its effect, as illustrated in

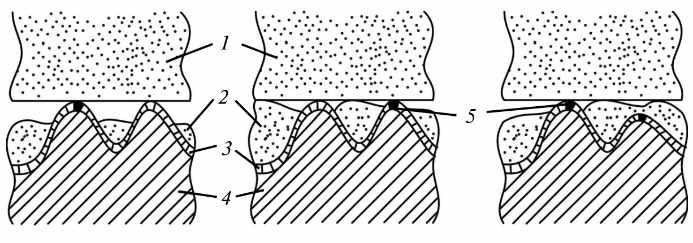

Fig. 2.

Fig.

2. Models of

transition layer

on the metal

surface oxidized

when working in

pairs

with

self-lubricating

contact material:

1

– self-lubricating contact material; 2

– transferred material; 3

– film of oxides; 4

– metal; 5

– areas

with

tunnel-conductive or destroyed oxide film

The

electric current

can be

considered as

an additional

external

parameter of

the tribosystem,

which affects

all

characteristics

of the

sliding contact.

This effect in many cases is so significant that the concept of

«lubricating action» of electric current (reduction of frictional

force with increased current density) and «electrical» wear

(excessive wear of elements of a sliding contact in comparison with

so-called mechanical wear in the absence of current) are specially

introduced.

In carbon graphite and

electro-graphite overlays, the increase in the current density,

which passes through the contact, as a result of heat dissipation,

reduces the strength of the surface layer and its shift resistance

that results in the effect similar to the lubricant introduction

into the contact. This effect is reversed.

For graphite

brushes having a relatively high (up to 25% by weight) content of

non-carbonated (polymeric) binder, the «lubrication effect» above

a certain critical current density is irreversible and is expressed

rather sharply, since heat dissipation causes the destruction of the

binding material and composition.

When applying

metal-graphite materials with high metal content (weight percent –

up to 90%), the effect of current density on the friction

coefficient is practically non-existent and only with high current

density (more than 20 A/cm2)

the friction coefficient increases slightly. In such materials, the

amount of transferred material on the counterbody is insignificant,

and the frictional behaviour of such compositions is close to the

behaviour of metals.

It is

difficult to predict the intensity of contact wear by the current

density magnitude due to the variety of current factors and the

complex nature of their interconnection. The main factors of wear in

the absence of electric sparking and arc formation are as follows:

oxidation of the metal element of friction pair; growth of adhesion

due to the dissociation of films of water or organic matter under

the action of current; oxidation of the composite element of

friction pair and weakening of its strength; emergence of

shock-thermal stresses in a dynamic contact due to the uneven

distribution of the current density in it [9, 11, 12]. All factors

can act simultaneously and their main root cause is the heat release

on the transient contact resistance. In the case of sparking or arc

formation, the listed factors are added with electroerosion and

emissions of contact material in the arc discharge, which increase

the intensity of wear.

In the

contact, the total surface of the section is divided into many

individual spots. In this connection, when the energy flow passes

through such a

surface there is the additional resistance introduced by the

violation of the homogeneity of the flow lines – the

constriction resistance. It is added,

in general,

with resistance

of the

films of

the following

varieties:

adhesive films,

passive films,

tarnish films

(oxide,

sulfide), water

films, films

from wear

products [6].

Each

component of

the

heterogeneity of

the contact

zone corresponds

to the

component of

the total

constriction resistance [6].

Holm proposed to take into account the two

components, corresponding to the constriction to the group of spots

and constriction within the boundaries of this group. For bodies

with the same specific resistance ,

which have one group of round, uniformly distributed spots, the

following expression is obtained:

, (1)

, (1)

where

– total number

of contact

spots;

– total number

of contact

spots;

– spot radius;

– spot radius;

– radius of

circle

encompassing the

contact spots;

– radius of

circle

encompassing the

contact spots;

– components

of resistance,

which correspond

to the

constriction of spots and

their groups.

– components

of resistance,

which correspond

to the

constriction of spots and

their groups.

Greenwood [16] clarified the

second term of expression (1):

, (2)

, (2)

and

it is

shown that

its value

is practically

the same

for any

placement of

contact spots

in the

general group.

The Greenwood formula has also

been expanded by members that take into account the asymmetry of the

distribution of groups of spots on each other, as well as the

distribution of groups on the nominal area [18].

In

the process

of current

collecting, the

overhead line

and the

contact element

are heated,

with the

importance of

the relationship

between the

energy of

the losses

(Al)

and the

heat dissipation

(Ahd)

that is

released into

the environment.

With a

certain limit value ΔA= Al – Ahd, the preconditions are

created, which leads to plastic deformation of the contact surfaces

with subsequent melting.

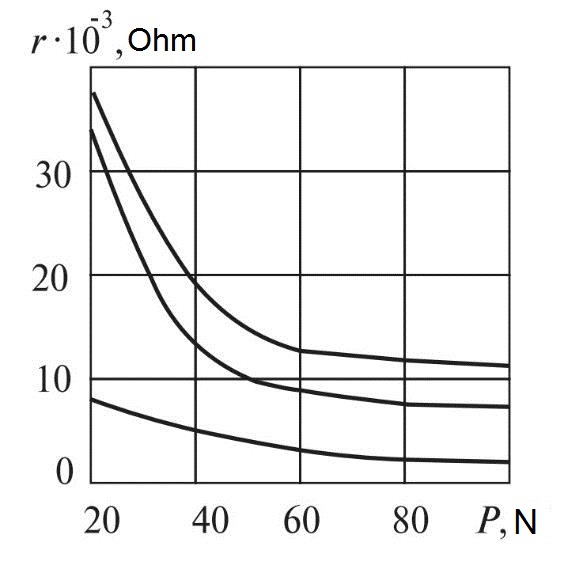

Fig.

3. Dependence

of transient

resistance

on

the pressing

force for

different materials

One of the

main indicators of the quality of electrical contact is the drop in

voltage

on it:

on it:

, (3)

, (3)

where

– current through contacts,

– current through contacts,

– transient resistance of the contact

pair.

– transient resistance of the contact

pair.

Of course, the value of the

transient resistance of the contact pair of OLCCCS is affected by

the contact press; the change of the contact pressure even within

the permissible limits is accompanied by a change in the transient

resistance, illustrating the dependence on Fig. 3 [11].

Increasing

the transient resistance of the contact pair, for one reason or

another, leads to growth of .

.

An

increase in

the actual

contact area

in the

friction pair

helps to

reduce the

transient

resistance .

Thus, using contact resistance and

topography relationship data, we can give recommendations for

constructing contacts, for example, the use of a

regular macrorelief of contact surfaces.

.

Thus, using contact resistance and

topography relationship data, we can give recommendations for

constructing contacts, for example, the use of a

regular macrorelief of contact surfaces.

From the standpoint of

materials, several methods are used to improve the reliability of

sliding contacts and their life extension. Common to them is the use

of contact materials with a thin transition layer, for example the

use of composite materials containing solid electrically conductive

lubricants. The problem of developing lubricants for sliding

contacts with relatively high speeds is currently not resolved.

The

theory

of

electro-friction

interaction

is

now

at

such

a

stage

that

is

characterized

by

a

large

amount

of

accumulated

empirical

data,

hypotheses

and

models

that

cannot

adequately

represent

phenomena

being

studied.

To

date, the theory of self-organized systems – synergetics and the

theory of fractals – self-similar evolutionary structures are

rapidly developing, which are not described within the framework of

Euclidean geometry.

Synergetics

studies the processes of self-organization, stability and decay of

structures of different nature, which are formed in open systems, an

ordered state associated with the coordinated behaviour of

subsystems. This leads to the formation of organized structures as a

result of the exchange of energy and matter with the environment,

when the equilibrium between production and reduction of entropy is

established. The theory of fractals is the basis for the

quantitative description of self-organizing structures [17, 19].

Originality and practical

value

So far there is no single point

of view concerning the problem of the mechanism of transmission of

electric current through a sliding contact.

The

qualitative

development of

the theory

of electrical

contacts can

give

consideration to

the processes

of

electro-friction

interaction from

the position

of synergy

and the

theory of

fractals.

Since the sliding electric contact is an open system, and in the

transition layer, the evolutionary processes of the origin and

collapse of conductor clusters take place.

In the

technological aspect, three main directions of solving tribological

problems in electrical contacts can be distinguished: change

in contact

geometry and

surface

topography; development of conductive

composites for which self-lubrication is characteristic; development

of effective lubricants for electrical contacts.

Conclusions

The work leads to a new level of

understanding of the peculiarities of the processes occurring in the

lubricating layers and their influence on the work of the moving

electrical contact.

Consideration of the processes

of electro-frictional interaction of sliding contacts from the

position of synergetics, where the theory of fractals is the basis

for the quantitative description of structures, will contribute to

the qualitative development of the theory of electrical contacts,

which in practical terms can ensure the significant performance

enhancement of such systems.

LIST OF REFERENCE LINKS

Алтоиз, Б.

А. Структурированные приповерхностные

слои нормальных алканов

/ Б. А. Алтоиз, С. В. Кириян // Инженерно-физ.

журн. – 2010. – Т. 83, № 3. –

С. 608–613.

Ахматов, А.

С. Молекулярная физика

граничного трения / А. С.

Ахматов. – Москва : Физ-матгиз, 1963. –

472 с.

Большаков,

Ю. Л. Дослідження властивостей

струмознімальних елементів та їх впливу

на ефективність роботи трибосистеми

«контактний провід – вугільна вставка»

/ Ю. Л. Большаков, А. В. Антонов // Наука

та прогрес транспорту. – 2015. – № 6 (60).

– С. 35–44. doi: 10.15802/stp2015/57006

Большаков,

Ю. Л. Підвищення ресурсу вугільних

струмознімальних вставок струмоприймачів

швидкісного електрорухомого складу в

умовах експлуатації / Ю. Л. Большаков,

А. В. Антонов // Наука та прогрес транспорту.

– 2015. – № 4 (58). – С. 57–70.

doi: 10.15802/stp2015/49205

Боуден, Ф.

П. Трение и смазка твердых тел / Ф. П.

Боуден, Д. Тейбор. – Москва : Машиностроение,

1968. – 543 с.

Кончиц, В.

В. Триботехника электрических контактов

/ В. В. Кончиц, В. В. Мешков, В. В. Мышкин

; под ред. В. А. Белого. –

Минск : Наука и техника,

1986. – 256 с.

Костецкий,

Б. И. Износостойкость деталей машин /

Б. И. Костецкий. – Киев : Машгиз, 1950. –

168 с.

Крагельский,

И. В. Основы расчетов на трение и износ

/ И. В. Крагельский, М. Н. Добычин, В.

С. Комбалов. – Москва : Машиностроение,

1977. – 526 с.

Методология

комплексной оценки эксплуатационных

качеств накладок токоприемников

электроподвижного состава / В. Л. Горобец,

Н. А. Бабяк, А. Ярмак, А. М. Бондарев //

Вісн. Східноукр. нац. ун-ту

ім. В. Даля. – 2015. – № 1

(218). – С. 297–302.

Мышкин, Н.

К. Трение, смазка, износ. Физические

основы и технические приложения

трибологии / Н. К. Мышкин, М. И. Петроковец.

– Москва : Физматлит,

2007. – 368 с.

Сидоров,

О. А. Исследование и прогнозирование

износа контактных пар систем токосъёма

с жестким токопроводом : монография /

О. А. Сидоров, С. А. Ступаков. – Москва

: ФГБОУ «Учебно-методический центр

по образованию на железнодорожном

транспорте», 2012. – 174 с.

Сидоров, О.

А. К вопросу о прогнозировании износа

элементов контактных пар устройств

токосъема электроподвижного состава

/ О. А. Сидоров, В. М. Филиппов // Междунар.

журн. приклад. и фундамент. исследований.

– 2015. – № 12-8. – С. 1393–1397.

Справочник

по триботехнике : в

3 т. / под общ. ред. М.

Хебды, А. В. Чичинадзе.

– Москва : Машиностроение,

1989. – Т. 1: Теоретические

основы. – 400 с.

Устименко,

Д. В. Сучасний стан проблеми

струмознімання на електрифікованих

залізницях / Д. В. Устименко //

Електрифікація транспорту. – 2016. – №

12. – С. 71–75.

Evolution

of the

electrical

contact of

dynamic

pantograph–catenary

system /

Guangning

Wu, Wenfu Wei, Guoqiang Gao, Jie Wu, Yue Zhou //

Journal of

Modern

Transportation.

– 2016. –

Vol. 24. –

Iss. 2. – P.

132–138. doi:

10.1007/s40534-016-0099-1

Greenwood,

J. A. Constriction resistance and the real area of contact / J. A.

Greenwod // British Journal of Applied Physics. – 1966. – Vol.

17. – Iss. 12. – P. 1621–1631. doi:

10.1088/0508-3443/17/12/310

Janahmadov,

A. K. Synergetics and Fractals in

Tribology / Ahad Kh Janahmadov, Maksim Y Javadov. – Cham :

Springer,

2016. – 381 p.

doi:

10.1007/978-3-319-28189-6

Jeng,

D. R. Thermal Contact Resistance in Vacuum / D. R. Jeng

// Journal of Heat Transfer.

– 1967. – Vol. 89. – Iss. 3. – P. 275–276.

doi: 10.1115/1.3614382

The

Synergetic Effects of Surface Texturing and MoDDP Additive Applied

to Ball-on-Disk Friction Subject to Both Flooded and Starved

Lubrication Conditions / Linqing

Bai, Yonggang Meng, Zulfiqar Ahmad Khan, Varian Zhang

// Tribology Letters. – 2017.

– Vol. 65. –

Iss. 4. – P.

115–127.

doi: 10.1007/s11249-017-0949-y

Д.

В. УСТИМЕНКО1*

1*Каф.

«Електротехніка та електромеханіка»,

Дніпропетровський національний

університет залізничного транспорту

імені академіка В. Лазаряна, вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (056) 373 15 47,

ел. пошта ustimenko.1979@gmail.com,

ORCID 0000-0003-2984-4381

ФІЗИКО-ТЕХНОЛОГІЧНІ

АСПЕКТИ РОБОТИ ЗМАЩУВАЛЬНИХ

ШАРІВ у

ТРИБОСИСТЕМІ «КОНТАКТНИЙ ПРОВІД –

КОНТАКТНА ВСТАВКА СТРУМОПРИЙМАЧА»

Мета.

Головною метою роботи

є всебічний аналіз процесів, що

відбуваються в змащувальних шарах

поверхонь тертя трибосистеми «контактний

провід – контактна вставка струмоприймача»

(КПКВС) та виявлення особливостей,

характерних для систем цього класу.

Методика. Для вивчення

фізико-технологічних аспектів роботи

змащувальних шарів у трибосистемі

«контактний провід – контактна вставка

струмоприймача» в якості основної

методології застосовується системний

аналіз. Результати.

Теорія електрофрикційної взаємодії

зараз перебуває на такому етапі, який

характеризується великою кількістю

нагромаджених емпіричних даних, гіпотез

і моделей, котрі не можуть адекватно

представити явища в ковзному

сильнострумовому електричному контакті.

Ковзний електричний контакт трибосистеми

«контактний провід – контактна вставка

струмоприймача» під час експлуатації

піддається впливу багатьох факторів,

одним із яких є процеси в змащувальних

шарах пари тертя. Розуміння особливостей

процесів, що протікають в змащувальних

шарах, та їх впливу на роботу ковзного

сильнострумового електричного контакту

може стати запорукою забезпечення

суттєвого підвищення працездатності

таких систем і, як наслідок, суттєво

підвищити надійність і безпеку роботи

електрорухомого складу. Наукова

новизна. Пропонується

розглядати процеси електрофрикційної

взаємодії електричних контактів з

позиції синергетики, застосовуючи

теорію фракталів в якості базової

для кількісного опису структур, що

самоорганізуються.

Практична значимість.

Урахування емпіричного досвіду

експлуатації трибосистеми «контактний

провід – контактна вставка струмоприймача»

в поєднанні з теоретичними знаннями

дозволяє запропонувати три можливих

напрямки вирішення трибологічних

проблем у сильнострумових ковзних

електричних контактах. А саме: 1) зміну

геометрії контакту й топографії

поверхонь, наприклад, використання

регулярного макрорельєфу поверхонь

контакту; 2) розробку електропровідних

композитів, для яких характерне

самозмащування, наприклад, використання

композиційних матеріалів, що містять

тверді електропровідні мастила; 3)

розробку ефективних мастил для

електричних сильнострумових ковзних

контактів, що може потребувати деякого

ускладнення конструкції вузла.

Ключові

слова: контактна пара; струмознімання;

контактний провід; інтенсивність

зношування; граничне тертя; перехідний

опір контакту; контактна вставка

струмоприймача

Д.

В. УСТИМЕНКО1*

1*Каф.

«Электротехника и электромеханика»,

Днепропетровский национальный

университет железнодорожного транспорта

имени академика В. Лазаряна, ул. Лазаряна,

2, Днипро, Украина, 49010, тел. +38 (056) 373 15 47,

эл. почта ustimenko.1979@gmail.com,

ORCID 0000-0003-2984-4381

ФИЗИКО-ТЕХНОЛОГИЧЕСКИЕ

АСПЕКТЫ РАБОТЫ СМАЗОЧНЫХ

СЛОЕВ В

ТРИБОСИСТЕМЕ «КОНТАКТНЫЙ ПРОВОД –

КОНТАКТНАЯ ВСТАВКА ТОКОПРИЕМНИКА»

Цель.

Главной целью работы является всесторонний

анализ процессов, происходящих в

смазочных слоях поверхностей трения

трибосистемы «контактный провод –

контактная вставка токоприемника»

(КПКВТ)

и выявление особенностей, характерных

для систем этого класса.

Методика.

При изучении физико-технологических

аспектов работы смазочных слоев

трибосистемы «контактный провод –

контактная вставка токоприемника» в

качестве основной методологии применяется

системный анализ.

Результаты.

Теория электрофрикционного взаимодействия

сейчас находится на этапе, характеризуемом

большим количеством накопленных

эмпирических данных, гипотез и моделей,

которые не могут адекватно представить

явления в скользящем сильноточном

электрическом контакте. Скользящий

электрический контакт трибосистемы

«контактный провод – контактная вставка

токоприемника» в процессе эксплуатации

подвергается воздействию многих

факторов, одним из которых являются

процессы в смазочных слоях пары трения.

Понимание особенностей процессов,

протекающих в смазочных слоях и их

влияния на работу скользящего

сильноточного электрического контакта,

может стать залогом обеспечения

существенного повышения работоспособности

таких систем и, как следствие, существенно

повысить надежность и безопасность

работы электроподвижного состава.

Научная

новизна.

Предлагается

рассматривать процессы электрофрикционного

взаимодействия электрических контактов

с позиции синергетики, применяя теорию

фракталов в качестве базовой для

количественного описания самоорганизующихся

структур.

Практическая

значимость.

Учет

эмпирического опыта эксплуатации

трибосистемы «контактный провод –

контактная вставка токоприемника» в

сочетании с теоретическими знаниями

позволяет предложить три возможных

направления решения трибологических

проблем в сильноточных скользящих

электрических контактах. А именно: 1)

изменение геометрии контакта и топографии

поверхностей, например, использование

регулярного макрорельефа поверхностей

контакта; 2) разработка электропроводящих

композитов для которых характерно

самосмазывание, например, использование

композиционных материалов, содержащих

твердые электропроводящие смазки; 3)

разработка эффективных смазок для

электрических сильноточных скользящих

контактов, что может потребовать

некоторого усложнения конструкции

узла.

Ключевые

слова: контактная

пара; токосъем; контактный провод;

интенсивность износа; предельное

трение; переходное сопротивление

контакта; контактная вставка токоприемника

REFERENCES

Altoiz,

B. A., &

Kiriyan, S. V.

(2010). Strukturirovannye pripoverkhnostnye sloi normalnykh

alkanov. Inzhenerno-fizicheskiy

zhurnal 83(3),

608-613. (in Russian)

Akhmatov,

A. S. (1963). Molekulyarnaya fizika

granichnogo treniya. Moscow:

Fizmatgiz. (in Russian)

Bolshakov,

Y. L., &

Antonov, A. V.

(2015). Investigation

of properties of current collector elements and their effect on the

performance of tribosystem «contact wire–current collector

element».

Science

and Transport

Progress, 6(60),

35-44. doi: 10.15802/stp2015/57006 (in

Ukrainian)

Bolshakov,

Y. L., &

Antonov, A. V.

(2015). Increase

the resource of current collector elements of the electrified

high-speed transport in operating conditions.

Science

and Transport

Progress, 4(58),

57-70.

doi:

10.15802/stp2015/49205

(in Ukrainian)

Bouden

F. P., &

Teybor, D.

(1968). The

friction and lubrication of solids.

Moscow: Mashinostroenie. (in

Russian)

Konchits,

V.

V., Meshkov,

V.

V., &

Myshkin, V.

V. (1986)

Tribotekhnika elektricheskikh

kontaktov.

Minsk: Nauka i tekhnika. (in Russian)

Kostetskiy,

B. I. (1950).

Iznosostoykost detaley mashin.

Kiev: Mashgiz. (in Russian)

Kragelskiy,

I. V., Dobychin, M. N., & Kombalov,

V. S. (1977). Osnovy raschetov na

trenie i iznos. Moscow:

Mashinostroenie. (in Russian)

Horobets,

V. L., Babyak,

N. A., Yarmak,

A.

I., &

Bondarev,

A. M.

(2015). Methodology of complex estimation

of operating qvolities of electric loco current collectors shin.

Visnik of the Volodymyr Dahl east

ukrainian national university, 1(218), 297-302. (in

Russian)

Myshkin,

N. K., &

Petrokovets, M.

I. (2007).

Trenie, smazka, iznos. Fizicheskie

osnovy i tekhnicheskie prilozheniya tribologii. Moscow:

Fizmatlit. (in Russian)

Sidorov,

O. A., &

Stupakov, S. A.

(2012). Issledovanie

i prognozirovanie iznosa kontaktnykh par sistem tokosema s zhestkim

tokoprovodom: monografiya. Moscow:

FGBOU «Uchebno-metodicheskiy tsentr po obrazovaniyu na

zheleznodorozhnom transporte». (in

Russian)

Sidorov,

O. A., &

Philippov, V. M. (2015). The issue of forecasting elements wear

contact pairs devices electric rolling current collection.

International Journal of Applied and Fundamental Research,

12(8),

1393-1397. (in Russian)

Teoreticheskie

osnovy. (1989). In M. Khebdy, & A. V. Chichinadze (Eds.),

Spravochnik po tribotekhnike: v 3

tomakh. (p. 400). Moscow:

Mashinostroenie. (in Russian)

Ustymenko,

D. V. (2016). Current state of the problem on current collection of

electrified railways. Electrification

of transport, 12,

71-75. (in Ukrainian)

Guangning

Wu, Wenfu Wei, Guoqiang Gao, Jie Wu, & Yue Zhou (2016).

Evolution of

the electrical

contact of

dynamic

pantograph–catenary

system. Journal

of

Modern

Transportation,

24(2),

132-138.

doi:

10.1007/s40534-016-0099-1

(in English)

Greenwood,

J. A. (1966). Constriction resistance and the real area of contact.

British Journal of Applied Physics,

17(12), 1621-1631. doi:

10.1088/0508-3443/17/12/310

(in English)

Janahmadov,

A. K, & Javadov,

M. Y. (2016). Synergetics and

fractals in tribology. Springer.

doi:

10.1007/978-3-319-28189-6 (in English)

Jeng,

D. R. & Heat, J. (1967). Thermal Contact Resistance in Vacuum.

Transfer, 89(3),

275. doi: 10.1115/1.3614382

(in English)

Linqing

Bai, Yonggang Meng, Zulfiqar Ahmad Khan, & Varian Zhang

(2017). The Synergetic Effects of Surface Texturing and MoDDP

Additive Applied to Ball-on-Disk Friction Subject to Both Flooded

and Starved Lubrication Conditions. Tribol

Lett, 65(4),

115-127. doi:

10.1007/s11249-017-0949-y (in Eglish)

Prof. A.

M. Mukha, D. Sc. (Tech.) (Ukraine) recommended this article

to be published

Received:

Feb. 14, 2018

Accepted: May

24, 2018

doi:

10.15802/stp2018/133323 © D. V. Ustymenko, 2018