ISSN

2307–3489 (Print), ІSSN 2307–6666 (Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного

університету залізничного транспорту,

2017, № 5 (71)

МАТЕРІАЛОЗНАВСТВО

матеріалознавство

UDC

669:621.791.75:539.5

I.

O. VAKULENKO1,

S.

O. PLITCHENKO2*,

N.

G. MURASHOVA3

1Dep.

«Applied Mechanics and Materials Science», Dnipropetrovsk National

University of Railway Transport

named afterAcademician V.

Lazaryan, Lazaryan St., 2, Dnipro, Ukraine, 49010, tel. +38 (056) 373

15 56,

e-mail dnuzt_texmat@ukr.net,

ORCID 0000-0002-7353-1916

2*Dep. «Applied Mechanics

and Materials Science», Dnipropetrovsk National University of

Railway Transport

named after Academician V. Lazaryan, Lazaryan

St., 2, Dnipro, Ukraine, 49010, tel. +38 (056) 373 15 56,

e-mail

plit4enko@ukr.net,

ORCID 0000-0002-0613-2544

3«Design

and Technological Bureau», Dnipropetrovsk National University of

Railway Transport Named After

Academician V. Lazaryan, Lazaryan

St., 2, Dnipro, Ukraine, 49010, tel.

+38 (056) 373 15 56,

e-mail dnuzt_texmat@ukr.net,

ORCID 0000-0003-2758-0749

INFLUENCE OF

STRUCTURAL PARAMETERS OF LOW-CARBON

STEEL ON ELECTRIC ARC BURNING

Purpose. The article is

aimed to evaluate the influence of structural parameters of

low-carbon steel on arcing process. Methodology. The values of

the micro- and substructure characteristics of the electrode wire

metal were changed by varying the parameters of heat treatment and

cold deformation by drawing. The degree of plastic deformation was

obtained by drawing blanks from different initial diameter to final

dimension of 1 mm. The thermal treatment was carried out in electric

chamber furnace of the SNOL-1,6.2,5.1/11-IZ type. The temperature was

measured by chromel-alumel thermocouple and the electromotive force

was determined using the DC potentiometer. In order to obtain the

substructure of different dispersion degree the steel (after

quenching from temperatures and tempering at 650°C for 1 hour) was

subjected to cold drawing to reduction 17 – 80%. To form structure

with different ferrite grain size the steel after drawing was

annealed at 680°C for 1 hour. The microstructure was examined under

a light and electron transmission microscope UEMV-100K at the

accelerating voltage 100 kV. The grain and subgrain sizes were

evaluated using the methodologies of quantitative metallography. A

welding converter of the PSG-500 type

was used to study the arc welding process of direct and reverse

polarities. Findings. The experimentally detected value of the

welding current, which depends on the degree of deformation during

wire drawing, under conditions of stable arc burning of direct

polarity is about an order of magnitude lower than the calculated

value. Similar difference was found for the arc of reverse polarity:

the experimental value of the welding current is 5–6

times less than the calculated value. Dependence analysis shows that,

regardless of the polarity of the welding arc, a good enough

agreement between the calculated and experimental values of the

welding current is limited to deformations of 60%. For deformation

degrees of more than 60%, the differences are explained by

qualitative changes in the dislocation cell structure. Originality.

In the conditions of stable arcing of different polarity for the

electrode of low-carbon steel, an extreme dependence of welding

current on the degree of cold plastic deformation was observed.

Practical value. Influence of ferrite grain size of electrode

wire on the value of welding current is much greater than that from

substructure presence.

Keywords: structure;

welding electric current; polarity; welding arc stability; cold

plastic deformation; cell; ferrite

Introduction

In

conditions of electric arc welding the process of arcing is

sensitive to the influence of a certain number of factors [7, 11,

12, 18]. They include maintaining the optimal ratio between the rate

of the electrode metal melting and its feeding into reaction zone,

conditions of metal transfer through the interelectrode space [8,

15-17, 19, 20], etc. Taking into account that metal transfer between

the electrodes is carried out in the form of a gas-droplet mixture,

the very process of liquid metal droplet formation at the end of the

electrode, its size and shape should to some extent influence the

technological characteristics of electric arc welding. Analysis of

the conditions for formation of liquid metal droplet indicates

existence of certain relationship between the surface tension of

metal and gravitational component [9]. Taking into account possible

dependence of the surface tension forces on the structural state of

electrode metal, the size of structural elements may have certain

influence on the conditions of formation and burning of electric

arc.

Purpose

The

article is aimed to evaluate the influence of structural parameters

of low-carbon steel on arcing process.

Material

and methodology of study

A

wire of 1 mm diameter of low-carbon steel with a carbon content of

0.2% was used as a material for electrode. The values of the micro-

and substructure characteristics of the electrode wire metal were

varied by varying the parameters of heat treatment and cold

deformation by drawing. The values of the micro- and substructure

characteristics of the electrode wire metal were changed by varying

the parameters of heat treatment and cold deformation by drawing.

The degree of plastic deformation was obtained by drawing blanks

from different initial diameter to final dimension of 1

mm. Thermal treatment was carried out in electric chamber furnace of

the SNOL-1,6.2,5.1/11-IZ type. To prevent the formation of oxide

film on the metal surface, the samples were placed in quartz glass

ampoules with preliminary deairing to the level of forvacuum. The

temperature was measured by chromel-alumel thermocouple and the

electromotive force was determined using the DC potentiometer. In

order to obtain the substructure of different dispersion degree the

steel after quenching from temperatures

and tempering at 650°C for 1 hour was subjected to cold drawing to

reduction 17–80%.

To form structure with different ferrite grain size the steel after

drawing was annealed at 680°C for 1 hour. The microstructure was

examined under a light and electron transmission microscope

UEMV–100K at

the accelerating voltage 100

kV. The grain and subgrain sizes were evaluated using the

methodologies of quantitative metallography [5].

A welding converter of the PSG-500

type was used to study the arc welding process of direct and reverse

polarities. The welding current value was estimated as the average

of 10 measurements.

and tempering at 650°C for 1 hour was subjected to cold drawing to

reduction 17–80%.

To form structure with different ferrite grain size the steel after

drawing was annealed at 680°C for 1 hour. The microstructure was

examined under a light and electron transmission microscope

UEMV–100K at

the accelerating voltage 100

kV. The grain and subgrain sizes were evaluated using the

methodologies of quantitative metallography [5].

A welding converter of the PSG-500

type was used to study the arc welding process of direct and reverse

polarities. The welding current value was estimated as the average

of 10 measurements.

Findings

Analysis

of the results of investigations [7–9]

indicates that when metal is melting, the surface tension forces

form a drop at the end of the electrode. The moment of droplet

detachment corresponds to the condition that the gravitational

component exceeds the surface tension force. Taking into account

that as the molten metal temperature rises, the surface tension

force decreases, the welding current increase should lead to the

dispersion of the emerging droplets. Condition of balance between

the hydrostatic pressure from pinch effect and the surface tension

( )

makes it possible to estimate the critical value of welding current

((

)

makes it possible to estimate the critical value of welding current

(( ,

where В – is a constant equal to

32.7 А/

,

where В – is a constant equal to

32.7 А/ ,

,

–

the electrode diameter) upon the detachment of liquid metal droplet

[9]. Substituting the constant В

and

–

the electrode diameter) upon the detachment of liquid metal droplet

[9]. Substituting the constant В

and

of molten metal (1220

dynes/cm [9]) in the ratio for

of molten metal (1220

dynes/cm [9]) in the ratio for

,

the value

,

the value

for low-carbon steel should be about

360

for low-carbon steel should be about

360 ,

which is confirmed by the data [8, 9]. The experimentally observed

value of the welding current (

,

which is confirmed by the data [8, 9]. The experimentally observed

value of the welding current ( )

on the degree of deformation during wire drawing (

)

on the degree of deformation during wire drawing ( )

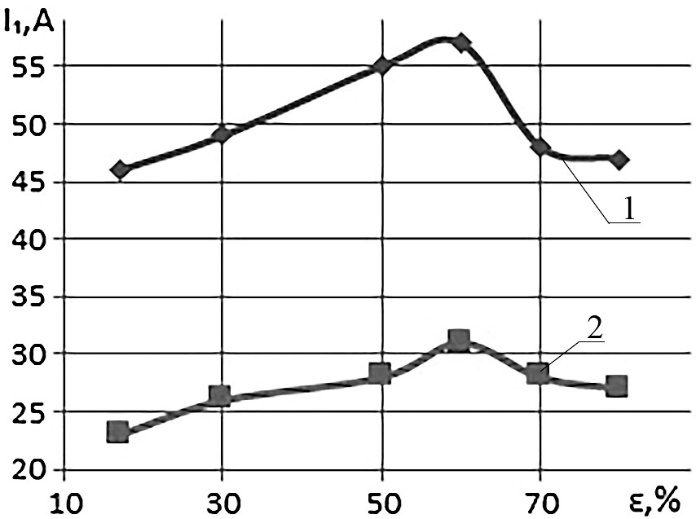

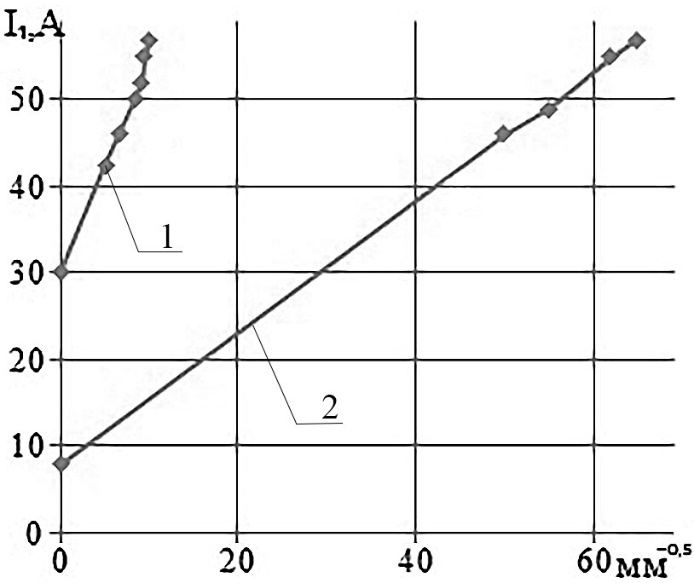

under conditions of stable arcing of direct polarity, is

approximately an order of magnitude lower than the calculated value

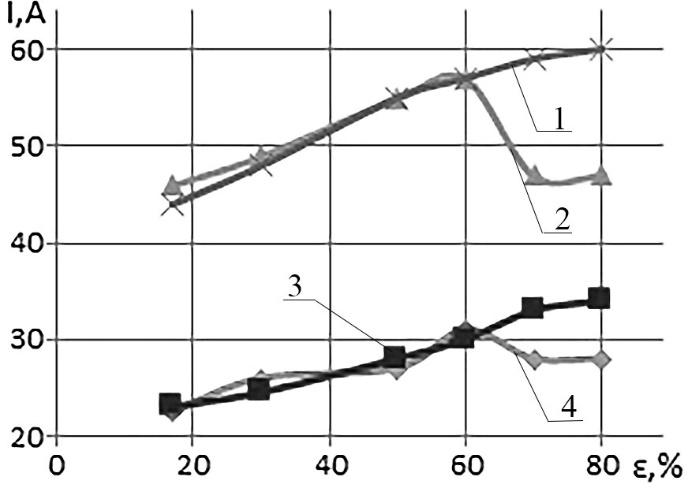

(Fig. 1).

)

under conditions of stable arcing of direct polarity, is

approximately an order of magnitude lower than the calculated value

(Fig. 1).

A

similar difference was found for the arc of reverse

polarity:

less than the calculated one in 5–6

times.

less than the calculated one in 5–6

times.

Fig. 1. Influence of the plastic

deformation degree by drawing on the welding current value ( ):

):

1

– reverse polarity arc; 2

– direct polarity arc

The

extreme nature of

dependence on

dependence on

,

is apparently due to the peculiarities of the substructural metallic

structure. Considering the nature of dependence for

,

is apparently due to the peculiarities of the substructural metallic

structure. Considering the nature of dependence for

,

one can formally assume that either the value В

depends on the chemical composition or structure of the steel, or

,

one can formally assume that either the value В

depends on the chemical composition or structure of the steel, or

should

be replaced by another characteristic. To explain the correlation

ratio

should

be replaced by another characteristic. To explain the correlation

ratio

on

on

(Fig. 1), it was made an attempt to replace

(Fig. 1), it was made an attempt to replace

by the metal surface tension coefficient in the solid state. Taking

into account the presence of volume fraction of ferrite in the

investigated steel around 97–98%, the ferrite surface tension

coefficient (

by the metal surface tension coefficient in the solid state. Taking

into account the presence of volume fraction of ferrite in the

investigated steel around 97–98%, the ferrite surface tension

coefficient ( )

can be taken as

)

can be taken as

.

Using the experimental data [2] and the transformations carried out

[14], for a cold-deformed state one can write:

.

Using the experimental data [2] and the transformations carried out

[14], for a cold-deformed state one can write:

, (1)

, (1)

where

– ferrite shear modulus (0.82

dynes/cm

– ferrite shear modulus (0.82

dynes/cm ),

),

– Burgers vector

– Burgers vector

[1],

[1],

– size of dislocation cell.

– size of dislocation cell.

Refinement

of the dislocation cell structure obeys a proportional dependence on

the degree of cold plastic deformation.

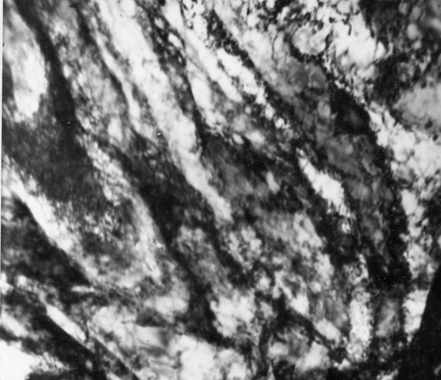

Taking

into account that 20–30% of reduction is enough to start the

formation of dislocation cellular

structure of various degrees of perfection (Fig. 2), determination

of the dependence of

on

on

made it possible to calculate the welding current value (

made it possible to calculate the welding current value ( ).

).

As

a ratio the dependence for

after an appropriate

substitution of

after an appropriate

substitution of

for

for

was

used:

was

used:

(2)

(2)

A

joint analysis of absolute values

and

and

(Fig. 3) for direct polarity arc indicates a fairly good correlation

only up to 60%reduction. For deformation degrees of more than 60%,

the observed differences can only be explained by qualitative

changes in the dislocation cell structure.

(Fig. 3) for direct polarity arc indicates a fairly good correlation

only up to 60%reduction. For deformation degrees of more than 60%,

the observed differences can only be explained by qualitative

changes in the dislocation cell structure.

Indeed,

at reductions more than 60–70% in carbon steels the processes of

perfecting the formed dislocation cells start to develop.

At

high degrees of plastic deformation, a progressive increase in the

dislocation density is accompanied

by intensive cleansing of the cell body from unbound dislocations,

changes in the form of cells, decrease in thickness of

sub-boundaries, and so on. [1, 4, 13]. All

this, apparently leads to violation of the ratio for

and is inherited by calculations

and is inherited by calculations .

The results obtained for reverse polarity arc are similar to the

data for direct polarity arc.

.

The results obtained for reverse polarity arc are similar to the

data for direct polarity arc.

а – а

б – b

Fig. 2. Structure of steel 20

after martensite quenching, tempering at 650 °C, cold drawing

on

17 (a) and 30 % (b)

With

constant sub-structural parameters of cold-deformed steel, for the

arc of direct and reverse polarity, the nature of relationships

(Fig. 1) indicates possible change in the coefficient В

depending on the arc polarity. Taking into account existence of

certain difficulties in burning an arc of reverse polarity, a change

of value В can be fully justified.

Indeed, when the polarity reverses, the conditions for stable arc

burning should become more complicated [7, 8]. The evaluation showed

that in order to increase the degree of coincidence between the

calculated and experimental values of the welding current, for the

reverse polarity arc, the value В

should be about twice as large as for the direct polarity arc. The

result of electric current calculating for the reverse polarity arc

with respect to relation (2) (will be denoted as

(Fig. 1) indicates possible change in the coefficient В

depending on the arc polarity. Taking into account existence of

certain difficulties in burning an arc of reverse polarity, a change

of value В can be fully justified.

Indeed, when the polarity reverses, the conditions for stable arc

burning should become more complicated [7, 8]. The evaluation showed

that in order to increase the degree of coincidence between the

calculated and experimental values of the welding current, for the

reverse polarity arc, the value В

should be about twice as large as for the direct polarity arc. The

result of electric current calculating for the reverse polarity arc

with respect to relation (2) (will be denoted as

)

is shown in the Fig. 3.

)

is shown in the Fig. 3.

Fig. 3. The influence of

deformation degree by drawing the steel 20 on the welding current

when burning the arc of direct (3, 4) and reverse (1, 2)

polarity:

2,

4

– current curves

obtained experimentally;

obtained experimentally;

1,

3

– curves of currents,

and

and

respectively calculated according to the relation (2)

respectively calculated according to the relation (2)

Dependence

analysis shows that, regardless of the welding arc polarity, a good

enough agreement between the calculated and experimental values of

the welding current is limited to deformations of 60%. For large

reductions, the degree of mismatch is proportional to the level of

welding current values. For the direct polarity arc, when the

welding current level is 20–35, the deviation of calculated values

( )

from

)

from

is 12–14%. For the reverse polarity arc at

is 12–14%. For the reverse polarity arc at

45–57

45–57

,

the value of difference between

,

the value of difference between

and

and

reaches

20%. Results of the study indicate the existence of a certain

influence of substructural metallic structure of the electrode metal

on the welding arc burning processes. The observed dependence of the

electric current value when burning the arc of different polarity is

sufficiently well explained by the parameters of the substructure of

cold-deformed low-carbon steel before the appearance of qualitative

changes in the internal structure of metal.

reaches

20%. Results of the study indicate the existence of a certain

influence of substructural metallic structure of the electrode metal

on the welding arc burning processes. The observed dependence of the

electric current value when burning the arc of different polarity is

sufficiently well explained by the parameters of the substructure of

cold-deformed low-carbon steel before the appearance of qualitative

changes in the internal structure of metal.

In

order to explain the nature of the observed welding current

dependence on the substructure parameters of cold-drawn metal,

investigations were carried out on the influence of ferrite grain

boundaries of with large disorientation angles ( -is

the ferrite grain size after annealing the cold-drawn metal). Such

necessity is due to differences in the degree of accumulation and

distribution of crystal structure defects from the reduction value

when drawing and after development of recrystallization processes

when annealing. Taking into account the inverse proportional

relationship between the ferrite subgrain size (D) on the reduction

degree when drawing [6] and the observed correlation relationship

-is

the ferrite grain size after annealing the cold-drawn metal). Such

necessity is due to differences in the degree of accumulation and

distribution of crystal structure defects from the reduction value

when drawing and after development of recrystallization processes

when annealing. Taking into account the inverse proportional

relationship between the ferrite subgrain size (D) on the reduction

degree when drawing [6] and the observed correlation relationship

(Fig. 3), it can be assumed that to describe the dependence

(Fig. 3), it can be assumed that to describe the dependence

the relationship of the following type can be used:

the relationship of the following type can be used:

,

(3)

,

(3)

where

A, k and

n – are the constants.

Results

of the construction

on

(

on

( )

) ,

where

,

where

–

ferrite grain size of the steel are shown in the Fig. 4.

–

ferrite grain size of the steel are shown in the Fig. 4.

The

analysis of the ratios indicates a fairly good correlation when

using the dependence:

, (4)

, (4)

where

– is the welding current at

– is the welding current at

∞,

k

– is the angle coefficient.

∞,

k

– is the angle coefficient.

In

general, it should be noted that regardless of the type of

interface, increase in their total length is accompanied by increase

in the welding current value. Taking into account qualitative

differences in the distribution nature of crystal structure defects

during the formation of grain boundaries with large disorientation

angles and sub-grains as a result of cold drawing [4, 6], the

existence of separate dependences for

and D is

completely justified.

and D is

completely justified.

Fig. 4. Influence of the grain

sizes (1)

and the ferrite subgrain (2)

of steel 20 on the

welding current

when burning the arc

of reverse

polarity

Analysis

of the absolute values of the parameters of equation (4) indicates

that the influence of the presence of ferrite grain boundaries with

large disorientation angles ( =30

А, k =

2

=30

А, k =

2 )

in the steel structure is much greater than the influence of the

subgrain structure (

)

in the steel structure is much greater than the influence of the

subgrain structure ( =

8 А, k

= 0,75

=

8 А, k

= 0,75 ).

On the other hand, the electric resistance value for the ferrite

structure of low-carbon steels is proportional to the accumulated

defect density of the crystal structure [3] and inversely

proportional to the ferrite grain size [10], can to some extent

exert its influence on the process of welding arc burning through

the surface tension of the metal.

).

On the other hand, the electric resistance value for the ferrite

structure of low-carbon steels is proportional to the accumulated

defect density of the crystal structure [3] and inversely

proportional to the ferrite grain size [10], can to some extent

exert its influence on the process of welding arc burning through

the surface tension of the metal.

Conclusions

1. In

the conditions of stable burning of the arc of different polarity

for the low-carbon steel electrode, the extreme dependence of the

welding current on the degree of cold plastic deformation was

observed.

2. Influence

of the ferrite grain size of the electrode wire on the welding

current value is much greater than the effect of the substructure

presence.

Acknowledgement

The

authors are grateful to Nadezhdin Yu. L., the Head of the Laboratory

of the Department of Applied Mechanics and Materials Science of the

Dnipropetrovsk National University of Railway Transport named after

Academician V. Lazaryan for participating in the experiments and

discussing the results.

THE

LIST OF REFERENCE LINKS

Бабич, В.

К. Деформационное старение стали

/ В. К.

Бабич, Ю. П.

Гуль, И. Е.

Долженков. – Москва

: Металлургия, 1972. –

320 с.

Баранов,

А. А. О начальных стадиях

сфероидизации цементита в стали

/ А. А.

Баранов // Изв. АН

СССР. Серия: Металлы. –

1969. – №

3. – С.

104–107.

Бернштейн, М. Л.

Структура деформированных металлов

/ М. Л. Бернштейн. – Москва : Металлургия,

1977. – 431 с.

Вакуленко, И. А.

Морфология структуры и деформационное

упрочнение стали / И. А. Вакуленко,

В. И. Большаков. – Днепропетровск :

Маковецкий, 2008. – 196 с.

Вакуленко, І. О.

Структурний аналіз в матеріалознавстві

/ І. О. Вакуленко.

– Дніпропетровськ :

Маковецький, 2010. –

124 с.

Гриднев, В. Н.

Прочность и пластичность

холоднодеформированных сталей / В. Н.

Гриднев, В. Г. Гаврилюк, Ю. Я. Мешков. –

Київ : Наук.

думка, 1974. – 231 с.

Ерохин, А. А. Основы

сварки плавлением / А. А. Ерохин. –

Москва : Машиностроение, 1973. – 448 с.

Крюковский,

Н. Н. Ручная дуговая

сварка плавящимся электродом // Сварка

в машиностроении :

справочник :

в 4 т. – Москва,

1978. – Т. 1. – С. 144–163.

Петров, А. А. Сварка

в защитных газах // Сварка в машиностроении

: справочник :

в 4 т. – Москва,

1978. – Т. 1. –

С. 196–258.

Шульце, Г. Металлофизика

/ Г. Шульце. – Москва : Мир, 1971. – 503 с.

Effect of

Welding Parameters on Mechanical Properties of Plasma Transferred

Arc Welded SS 202 Plates / M. Ravichandran, N. Sabarirajan, T.

Sathish, S. Saravanan // Applied Mechanics & Materials. –

2016. – Vol. 852. – P. 324–330. doi:

10.4028/www.scientific.net/amm.852.324.

Holt, D.

L. Dislocation Cell Formation in Metals

/ D. L.

Holt // J. of Applied Physics.

– 1970. –

Vol. 41. –

Iss. 8. – Р.

3197–3201. doi: 10.1063/1.1659399.

Influence of

substructure strengthening of low carbon steel оn

the arcing process / I. O. Vakulenko,

S. O. Plitchenko, Yu. L.

Nadezhdin, Yu. D. Kirienko //

Welding and related

technologies : Proc. of 9th

Intern. Conf. of young scientists (23–26

May 2017, Kyiv,

Ukraine). – Kyiv, 2017. – Р.

117–121.

Investigation

of cathode spot behavior of atmospheric argon arcs by mathematical

modeling / J.

Wendelstorf, G. Simon, I. Decker [et al.] // Proc. оf

12th

Intern. Conf. on Gas Discharges and Their Applications. –

Greifswald, Germany, 1997. – Vol. 1. – P. 62–65.

Metal

transfer in submerged arc welding / L. Ke, W. Zhisheng, Z. Yanjun,

L. Cuirong // J. of Materials Processing Technology. – 2017. –

Vol. 244. – P. 314–319. doi: 10.1016/j.jmatprotec.2017.02.004.

Metal Vapour

Behaviour in Gas Tungsten Arc Thermal Plasma during Welding /

M. Tanaka,

K. Yamamoto,

S. Tashiro [et al.] //

Welding in the World. – 2008. – Vol. 52. – Iss. 11–12. –

P. 82–88.

doi: 10.1007/bf03266686.

Murphy, A.

B. A Perspective on Arc Welding Research: The Importance of the

Arc, Unresolved Questions and Future Direc-tions / A. B. Murphy //

Plasma Chemistry and Plasma Processing. – 2015. – Vol. 35. –

Iss. 3. – P. 471–489. doi: 10.1007/s11090-015-9620-2.

Nestor, O.

H. Heat

intensity and current density distributions at the anode of high

current, inert gas arcs /

O. H. Nestor // J. of Applied

Physics. – 1962. – Vol. 33. – Iss. 5. – P. 1638–1648.

doi: 10.1063/1.1728803.

Numerical

simulation of droplet detachment in pulsed gas–metal arc welding

including the influence of metal vapour / M. Hertel, A.

Spille-Kohoff, U. Füssel, M. Schnick // J. of Physics D: Applied

Physics. – 2013. – Vol. 46. – Iss. 2. – P. 224003.

doi: 10.1088/0022-3727/46/22/224003.

Shirvan, A.

J. Modelling of electrode-arc coupling in electric arc welding / A.

J. Shirvan, I. Choquet, H. Nilsson // Proc. of 6th

Intern. Swedish Production Symposium. – Göthenburg,

Swedish, 2014. – Vol. 1. – P. 1–8.

І. О. ВАКУЛЕНКО ,

С. О. ПЛІТЧЕНКО

,

С. О. ПЛІТЧЕНКО ,

Н. Г. МУРАШОВА

,

Н. Г. МУРАШОВА

1Каф.

«Прикладна механіка та матеріалознавство»,

Дніпропетровський національний

університет залізничного

транспорту

імені академіка В. Лазаряна, вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (056) 373 15 56,

ел. пошта ,

ORCID

0000-0002-7353-1916

2*Каф.

«Прикладна механіка та матеріалознавство»,

Дніпропетровський національний

університет залізничного

транспорту

імені академіка В. Лазаряна, вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (056) 373 15 56,

ел. пошта plit4enko@ukr.net,

ORCID 0000-0002-0613-2544

3«Проектно-конструкторське

технологічне бюро», Дніпропетровський

національний університет

залізничного

транспорту імені

академіка В. Лазаряна, вул. Лазаряна,

2, Дніпро, Україна, 49010, тел. +38 (056) 373 15

56,

ел. пошта plit4enko@ukr.net,

ORCID 0000-0003-2758-0749

ВПЛИВ

структурнИх параметрІв низЬкоВуглеЦЕВОЇ

сталІ на горІнНЯ ЕлектричНОЇ дуги

Мета.

В статті передбачається зробити оцінку

впливу структурних параметрів

низьковуглецевої сталі на процес

горіння електричної дуги. Методика.

Значення мікро- і

субструктурних характеристик металу

електродного дроту змінювали, варіюючи

параметрами термічної обробки та

холодної деформації волочінням. Ступінь

пластичної деформації отримували

волочінням заготовок різного вихідного

діаметра на кінцевий розмір 1 мм. Термічну

обробку здійснювали в електричній

камерній печі типу СНОЛ-1,6.2,5.1/11-З.

Температуру вимірювали термопарою

хромель-алюмель із визначенням

електрорушійної сили за потенціометром

постійного струму. Для отримання

субструктури різної дисперсності сталь

(після загартування й відпускання

температури до

650 °С протягом 1 години) піддавали

холодному волочінню на обтиск до 17–80

%. Для формування структури

з різним розміром зерна фериту сталь

після волочіння піддавалася відпалу

при 680 С протягом 1 години. Мікроструктуру

досліджували під світловим електронним

просвітчастим мікроскопом УЕМВ-100К при

прискорюючій напрузі 100 кВ. Розмір зерна

і субзерна оцінювали з використанням

методик кількісної металографії. Для

досліджень процесу горіння зварювальної

дуги прямої та зворотної полярностей

використовували зварювальний перетворювач

типу ПСГ-500. Результати.

Експериментально

виявлене значення зварювального струму,

що залежить від ступеня деформації при

волочінні дроту, в умовах стабільного

горіння дуги прямої полярності приблизно

на порядок нижче розрахункової величини.

Аналогічну відмінність виявлено й для

дуги зворотної полярності: експериментальна

величина зварювального струму менше

розрахункової у 5–6 разів. Аналіз

залежностей свідчить, що незалежно від

полярності зварювальної дуги, досить

гарний збіг між розрахунковими та

експериментальними значеннями

зварювального струму обмежується

деформаціями до 60 %. Для ступенів

деформації більше 60 % відмінності

пояснюються якісними змінами в

дислокаційній комірчастій структурі.

Наукова новизна. В

умовах стабільного горіння дуги різної

полярності для електрода з низьковуглецевої

сталі виявлена екстремальна залежність

зварювального струму від ступеня

холодної пластичної деформації.

Практична значимість. Вплив

розміру зерна фериту електродного

дроту на величину зварювального струму

значно перевищує ефект від присутності

субструктури.

Ключові слова:

структура; зварювальний електричний

струм; полярність; стабільність

зварювальної дуги; холодна пластична

деформація; комірка; ферит

И. А. ВАКУЛЕНКО1,

С. А. ПЛИТЧЕНКО2*, Н. Г. МУРАШОВА3

1Каф.

«Прикладная механика и материаловедение»,

Днепропетровский национальный

университет

железнодорожного

транспорта имени академика В.

Лазаряна, ул. Лазаряна, 2, Днипро, Украина,

49010, тел. +38 (056) 373 15 56, эл.

почта dnuzt_texmat@ukr.net ,ORCID

0000-0002-7353-1916

2*Каф.

«Прикладная механика и материаловедение»,

Днепропетровский национальный

университет

железнодорожного

транспорта имени академика В.

Лазаряна, ул. Лазаряна, 2, Днипро, Украина,

49010, тел. +38 (056) 373 15 56, эл.

почта plit4enko@ukr.net, ORCID

0000-0002-0613-2544

3«Проектно-конструкторское

технологическое бюро», Днепропетровский

национальный университет

железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина,

49010, тел.

+38 (056) 373 15 56, эл. почта

dnuzt_texmat@ukr.net,

ORCID 0000-0003-2758-0749

Влияние

структурных параметров низкоуглеродистой

стали на горение электрической дуги

Цель.

В статье предполагается сделать оценку

влияния структурных параметров

низкоуглеродистой стали на процесс

горения электрической дуги. Методика.

Значения микро- и субструктурных

характеристик металла электродной

проволоки изменяли, варьируя параметрами

термической обработки и холодной

деформации волочением. Степень

пластической деформации получали

волочением заготовок разного исходного

диаметра на конечный размер 1 мм.

Термическую обработку осуществляли в

электрической камерной печи типа

СНОЛ-1,6.2,5.1/11-ИЗ. Температуру измеряли

термопарой хромель-алюмель с определением

электродвижущей силы по потенциометру

постоянного тока. Для получения

субструктуры разной дисперсности сталь

(после закалки и отпуска температуры

до 650 °С в течение 1 часа) подвергали

холодному волочению на обжатие до 17–80

%. Для формирования структуры с разным

размером зерна феррита сталь после

волочения подвергалась отжигу при 680

°С в течение 1 часа. Микроструктуру

исследовали под световым электронным

просвечивающим микроскопом УЭМВ-100К

при ускоряющем напряжении 100 кВ. Размер

зерна и субзерна оценивали с использованием

методик количественной металлографии.

Для исследований процесса

горения сварочной дуги прямой и обратной

полярностей использовали сварочный

преобразователь типа ПСГ-500. Результаты.

Экспериментально обнаруженное значение

сварочного тока, зависящего от степени

деформации при волочении проволоки, в

условиях стабильного горения дуги

прямой полярности примерно на порядок

ниже расчетной величины. Аналогичное

различие обнаружено и для дуги обратной

полярности: экспериментальная величина

сварочного тока меньше расчетной в 5–6

раз. Анализ зависимостей свидетельствует,

что независимо от полярности сварочной

дуги, достаточно хорошее совпадение

между расчетными и экспериментальными

значениями сварочного тока ограничивается

деформациями до 60 %. Для степеней

деформации более 60 % различия объясняются

качественными изменениями в дислокационной

ячеистой структуре. Научная

новизна. В условиях

стабильного горения дуги различной

полярности для электрода из

низкоуглеродистой стали обнаружена

экстремальная зависимость сварочного

тока от степени холодной пластической

деформации. Практическая

значимость. Влияние

размера зерна феррита электродной

проволоки на величину сварочного тока

значительно превышает эффект от

присутствия субструктуры.

Ключевые слова:

структура; сварочный электрический

ток; полярность; стабильность сварочной

дуги; холодная пластическая деформация;

ячейка; феррит

REFERENCES

Babich, V.

K., Gul, Y. P., & Dolzhenkov, I. Y. (1972). Deformatsionnoye

stareniye stali. Moscow:

Metallurgiya.

Baranov, A.

A. (1969). O nachalnykh stadiyakh sferoidizatsii tsementita v

stali. Russian

Metallurgy, 3,

104-107.

Bernshteyn,

M. L. (1977). Struktura

deformirovannykh metallov. Moscow:

Metallurgiya.

Vakulenko,

I. A., & Bolshakov V. I. (2008). Morfologiya

struktury i deformatsionnoye uprochneniye stali.

Dnipropetrovsk: Makovetskyi.

Vakulenko,

І. O. (2010). Strukturnyi analiz v

materialoznavstvi. Dnipropetrovsk:

Makovetskyi.

Gridnev, V.

N., Gavrilyuk, V. G., & Meshkov, Y. Y. (1974). Prochnost

i plastichnost kholodnodeformirovan-nykh staley.

Kyiv: Naukova dumka.

Yerokhin, A.

A. (1973). Osnovy svarki plavleniyem.

Moscow: Mashinostroeniye.

Kryukovskiy,

N. N. (1978). Ruchnaya dugovaya svarka plavyashchimsya elektrodom.

In

Svarka v mashinostroyenii [Guide]

(Vol. 1) (pp. 144-163).

Moscow: Mashinostroeniye.

Petrov, A.

A. (1978). Svarka v zashchitnykh gazakh.

In

Svarka v mashinostroyenii [Guide]

(Vol. 1) (pp. 196-258).

Moscow: Mashinostroeniye.

Shultse, G.

(1971). Metallofizika.

Moscow: Mir.

Ravichandran,

M., Sabarirajan, N., Sathish, T., & Saravanan, S. (2016).

Effect of Welding Parameters on Mechanical Properties of Plasma

Transferred Arc Welded SS 202 Plates. Applied

Mechanics & Materials, 852,

324-330. doi:10.4028/www.scientific.net/amm.852.324

Holt, D. L.

(1970). Dislocation Cell Formation in Metals. Journal

of Applied Physics, 41

(8), 3197-3201. doi:10.1063/1.1659399

Vakulenko,

I. O., Plitchenko, S. O., Nadezhdin, Y. L., & Kirienko, Y. D.

(2017). Influence of substructure strengthening of low carbon steel

оn the arcing process. Proceedings of

the 9th International Conference Young Scientists Welding and

related Technologies, May 23-26, 2017, Kyiv,

117-121. Kyiv: PWI NASU.

Wendelstorf,

J., Simon, G., Decker, I., & Wohlfahrt, H. (1997).

Investigation of cathode spot behavior of atmospheric argon arcs by

mathematical modeling. Proceedings of

the 12th International Conference on Gas Discharges and Their

Applications, 8th-12th September, 1997, Greifswald

(pp. 62-65). Germany: University

of Greifswald.

Li, K., Wu,

Z., Zhu, Y., & Liu, C. (2017). Metal transfer in submerged arc

welding. Journal of Materials

Processing Technology, 244,

314-319. doi:10.1016/j.jmatprotec.2017.02.004

Tanaka, M.,

Yamamoto, K., Tashiro, S., Nakata, K., Ushio, M., Yamazaki, K., &

Lowke, J. J. (2008). Metal Vapour Behaviour in Gas Tungsten Arc

Thermal Plasma during Welding. Welding

in the World, 52

(11-12), 82-88. doi:10.1007/bf03266686

Murphy, A.

B. (2015). A Perspective on Arc Welding Research: The Importance of

the Arc, Unresolved Questions and Future Directions. Plasma

Chemistry and Plasma Processing, 35

(3), 471-489. doi:10.1007/s11090-015-9620-2

Nestor, O.

H. (1962). Heat intensity and current density distributions at the

anode of high current, inert gas arcs. Journal

of Applied Physics, 33

(5), 1638-1648. doi:10.1063/1.1728803

Hertel, M.,

Spille-Kohoff, A., Füssel, U., & Schnick, M. (2013). Numerical

simulation of droplet detachment in pulsed gas–metal arc welding

including the influence of metal vapour. Journal

of Physics D: Applied Physics, 46

(2), 224003. doi:10.1088/0022-3727/46/22/224003

Shirvan, A.

J., Choquet, I., Nilsson, H. (2014). Modelling of electrode-arc

coupling in electric arc welding. Proceedings

of the 6th Intern. Swedish Production Symposium, September 16-18

2014, Göteborg. Swedish, Gothenburg:

Swedish Production Academy.

Associate

Prof. O. A. Chaykovskiy,

Candidate of Science (Engineering)

(Ukraine);

Prof. V.

A. Zabludovskiy,

D. Sc. (Tech.), (Ukraine)

recommended this article to be published

Received:

June 08, 2017

Accessed:

Sept. 14, 2017

d oi

10.15802/stp2017/110134 ©

I. O. Vakulenko, S. O. Plitchenko, N. G. Murashova, 2017

oi

10.15802/stp2017/110134 ©

I. O. Vakulenko, S. O. Plitchenko, N. G. Murashova, 2017

and tempering at 650°C for 1 hour was subjected to cold drawing to

reduction 17–80%.

To form structure with different ferrite grain size the steel after

drawing was annealed at 680°C for 1 hour. The microstructure was

examined under a light and electron transmission microscope

UEMV–100K at

the accelerating voltage 100

kV. The grain and subgrain sizes were evaluated using the

methodologies of quantitative metallography [5].

A welding converter of the PSG-500

type was used to study the arc welding process of direct and reverse

polarities. The welding current value was estimated as the average

of 10 measurements.

)

makes it possible to estimate the critical value of welding current

((

,

where В – is a constant equal to

32.7 А/

,

–

the electrode diameter) upon the detachment of liquid metal droplet

[9]. Substituting the constant В

and

of molten metal (1220

dynes/cm [9]) in the ratio for

,

the value

for low-carbon steel should be about

360

,

which is confirmed by the data [8, 9]. The experimentally observed

value of the welding current (

)

on the degree of deformation during wire drawing (

)

under conditions of stable arcing of direct polarity, is

approximately an order of magnitude lower than the calculated value

(Fig. 1).

less than the calculated one in 5–6

times.

):

dependence on

,

is apparently due to the peculiarities of the substructural metallic

structure. Considering the nature of dependence for

,

one can formally assume that either the value В

depends on the chemical composition or structure of the steel, or

should

be replaced by another characteristic. To explain the correlation

ratio

on

(Fig. 1), it was made an attempt to replace

by the metal surface tension coefficient in the solid state. Taking

into account the presence of volume fraction of ferrite in the

investigated steel around 97–98%, the ferrite surface tension

coefficient (

)

can be taken as

.

Using the experimental data [2] and the transformations carried out

[14], for a cold-deformed state one can write:

, (1)

– ferrite shear modulus (0.82

dynes/cm

),

– Burgers vector

[1],

– size of dislocation cell.

on

made it possible to calculate the welding current value (

).

after an appropriate

substitution of

for

was

used:

(2)

and

(Fig. 3) for direct polarity arc indicates a fairly good correlation

only up to 60%reduction. For deformation degrees of more than 60%,

the observed differences can only be explained by qualitative

changes in the dislocation cell structure.

and is inherited by calculations

.

The results obtained for reverse polarity arc are similar to the

data for direct polarity arc.

(Fig. 1) indicates possible change in the coefficient В

depending on the arc polarity. Taking into account existence of

certain difficulties in burning an arc of reverse polarity, a change

of value В can be fully justified.

Indeed, when the polarity reverses, the conditions for stable arc

burning should become more complicated [7, 8]. The evaluation showed

that in order to increase the degree of coincidence between the

calculated and experimental values of the welding current, for the

reverse polarity arc, the value В

should be about twice as large as for the direct polarity arc. The

result of electric current calculating for the reverse polarity arc

with respect to relation (2) (will be denoted as

)

is shown in the Fig. 3.

obtained experimentally;

and

respectively calculated according to the relation (2)

)

from

is 12–14%. For the reverse polarity arc at

45–57

,

the value of difference between

and

reaches

20%. Results of the study indicate the existence of a certain

influence of substructural metallic structure of the electrode metal

on the welding arc burning processes. The observed dependence of the

electric current value when burning the arc of different polarity is

sufficiently well explained by the parameters of the substructure of

cold-deformed low-carbon steel before the appearance of qualitative

changes in the internal structure of metal.

-is

the ferrite grain size after annealing the cold-drawn metal). Such

necessity is due to differences in the degree of accumulation and

distribution of crystal structure defects from the reduction value

when drawing and after development of recrystallization processes

when annealing. Taking into account the inverse proportional

relationship between the ferrite subgrain size (D) on the reduction

degree when drawing [6] and the observed correlation relationship

(Fig. 3), it can be assumed that to describe the dependence

the relationship of the following type can be used:

,

(3)

on

(

)

,

where

–

ferrite grain size of the steel are shown in the Fig. 4.

, (4)

– is the welding current at

∞,

k

– is the angle coefficient.

and D is

completely justified.

=30

А, k =

2

)

in the steel structure is much greater than the influence of the

subgrain structure (

=

8 А, k

= 0,75

).

On the other hand, the electric resistance value for the ferrite

structure of low-carbon steels is proportional to the accumulated

defect density of the crystal structure [3] and inversely

proportional to the ferrite grain size [10], can to some extent

exert its influence on the process of welding arc burning through

the surface tension of the metal.