ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного університету залізничного

транспорту, 2017, № 4 (70)

рухомий

склад залізниць і тяга поїздів

РУХОМИЙ

СКЛАД ЗАЛІЗНИЦЬ І ТЯГА ПОЇЗДІВ

UDC

629.4.048.7

E.

V. BILOSHYTSKYI1*

WAYS TO MANAGE

HEATING INERTIA

1*Project

Design and Technological Bureau,

Dnipropetrovsk National University of

Railway Transport named after

Academician V. Lazaryan, Lazaryan

St., 2, Dnipro, Ukraine, 49010,

tel. +38 (056) 371 51 12, e-mail

beloshickij@rambler.ru,

ORCID 0000-0002-2424-8479

Purpose. The

research paper proposes to estimate the effect of heat inertia of the

water heating system, in transient operation modes, on the

temperature condition in the passenger car, as well as to offer

technical solutions intended to reduce the heating system inertia

effect and to maintain a stable temperature condition in the

passenger car premises in transitional modes of the heating system.

Methodology. The author developed the method for controlling

the heat transfer of heating system pipes with the help of regulating

casing. To control the heating system and the heat transfer of

heating pipes, two types of temperature control sensors were used in

the passenger car: certain sensors interacted with regulatory

casings, while the others interacted with high-voltage tubular

heating element control devices. To assess the efficiency of heat

interchange regulation of heating pipes and the heating system

control, with installed regulating casings, the operation of the

heating system with regulating casings and two types of sensors was

mathematically modelled. Mathematical modelling used the experimental

test data. The results of experimental tests and mathematical

modelling were compared. Findings. Currently in operated

passenger cars, control of heating appliances is not constructively

provided. Automatic maintenance of the set temperature in a passenger

car is limited to switching on and off of high-voltage tubular

heating elements. The use of regulating casings on heating pipes

allows reducing the effects of heat inertia and maintaining stable

thermal conditions in a passenger car, using the heating system as a

heat accumulator, and also provides the opportunity to realize an

individual control of air temperature in the compartment.

Originality. For the first time, the paper studied the

alternative ways of regulating the temperature condition in a

passenger car. Using of the heating system as a heat accumulator.

Practical value. The regulation of the heat transfers of

the heating pipes by regulating casings allows reducing the effect of

thermal inertia of the heating system on the temperature condition in

a passenger car, implementing individual adjustment of air

temperature in a compartment within 40% of the power of the heating

pipe section, using the heating system as a heat accumulator.

Keywords:

heating of passenger cars; free convection; heat transfer; heat

accumulator

Introduction

During

operation, it is practically impossible to maintain the required

heat transfer fluid temperature in the passenger car boiler. This is

due to the shutdown of high-voltage electric heating tubes of the

heating system. The reasons for the shutdown are different during

moving and standing with subsequent

heating, resulting in transient heating modes that cause temperature

fluctuations in passenger cars. This process is compounded by the

fact that during moving and standing of a passenger car the required

heating capacity of the heating system is different, the higher the

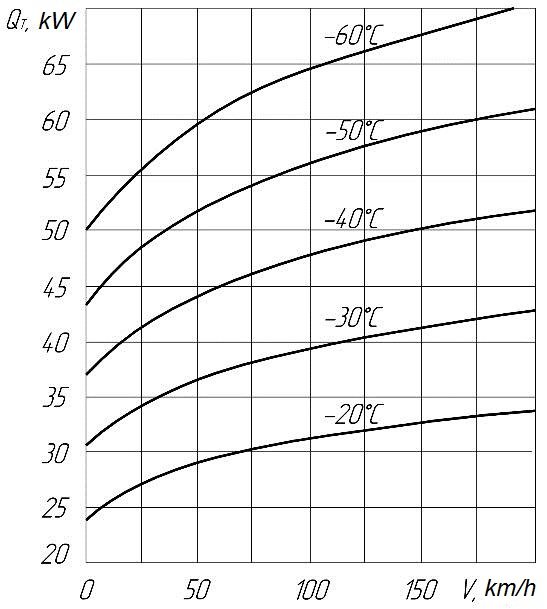

speed of the car, the more the required heating capacity of the

heating system increases, this is confirmed by the results

of the study [4],

Fig. 1.

Transitional

modes are compounded by the large heat inertia of the heating

system. The installed

high-voltage heating tubes also have heat inertia, which also

affects the inertia of the heating system. The installed sensors for

monitoring the temperature in the car have no correction for the

inertia of the heating system.

Fig. 1. Required

heating capacity of the passenger car heating system in relation to

traffic at various outdoor temperatures

Since 2004,

all types of cars are equipped with air-conditioning units [2]. The

water heating system

with smooth regulation of the boiler’s heat output in the range of

loads from «0» to 48.0 kW is proposed. For this purpose, the

boiler is equipped with three groups of electric heating: I group –

24.0 kW, 3 kV, II group – 12.0 kW, 3 kV, III group – 12.0 kW,

380 V. The third group of the boiler is connected to the air

conditioner converter circuit through the appropriate switching

devices. The converter provides for smooth regulation of the output

power from «0» to Pnom

(12 ÷ 17 kW). Therefore, the III group of the boiler will have

smooth power regulation from «0» to

.

As a result, the entire range of heat output of the boiler will be

with smooth regulation.

.

As a result, the entire range of heat output of the boiler will be

with smooth regulation.

The disadvantage of the proposed

system is that the system can work qualitatively when heating the

boiler only with electricity.

The work [2]

considers the water heating system

with smooth regulation of heating output of heating pipes at boiler

combined heating. The system

is designed for smooth regulation and stabilization

of the heat transfer fluid temperature at the inlet to the heating

devices, respectively, at transient and steady-state modes,

stabilizing the air temperatures inside the car during cycling of

high-voltage heating groups of the boiler, and also when the boiler

is operated with solid fuel.

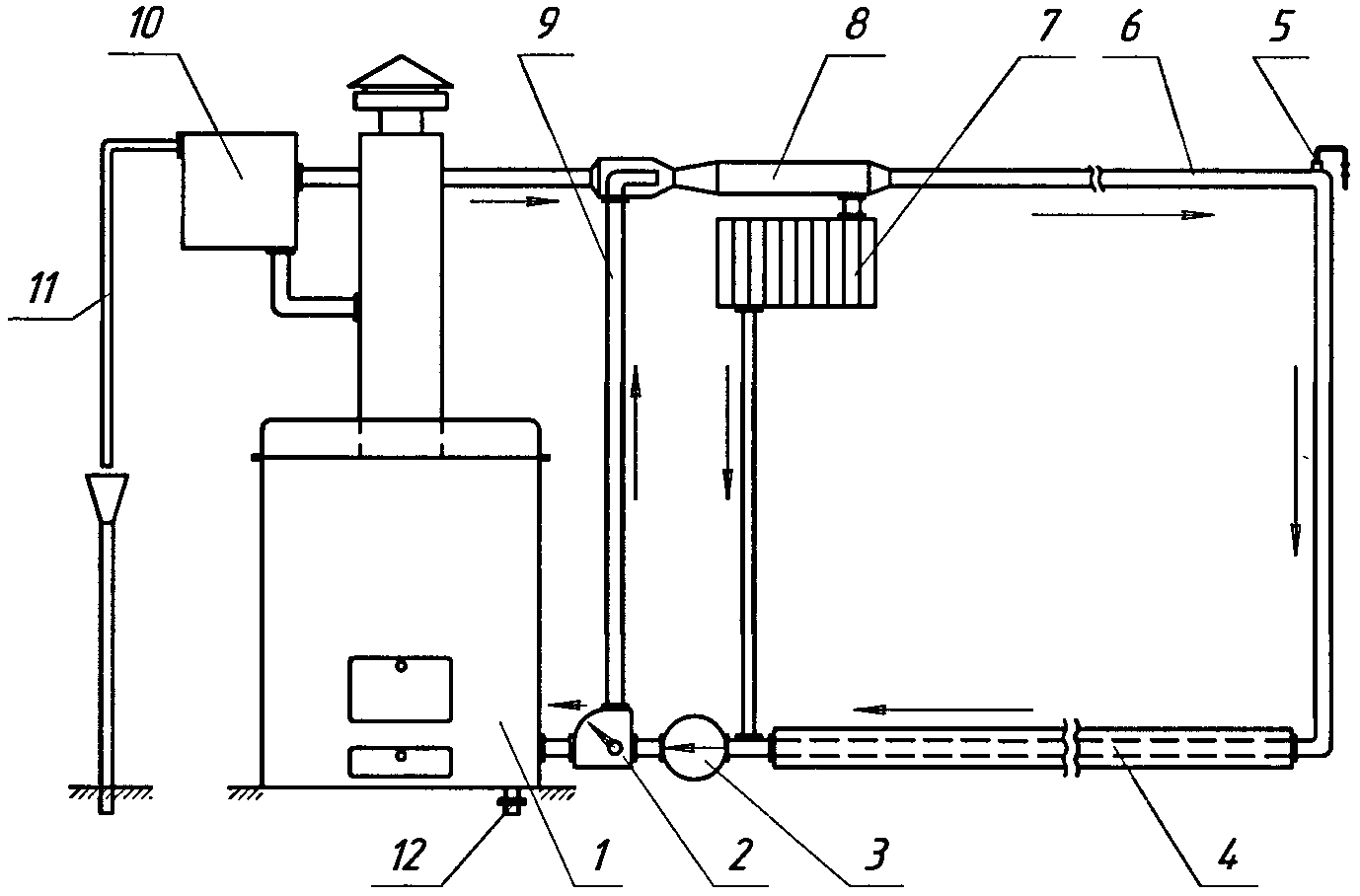

Fig. 2. Layout of

water heating with separation of flows: 1

– boiler; 2

– divisor; 3

– circulating pump; 4

– heating pipes; 5

– air line; 6

– feeding pipe; 7

– air heater; 8

– mixer;

9

– bypass pipe; 10

– expander; 11

– overflow pipe;

12

– drain plug

The principle

of operation of the system, whose layout is shown in Fig. 2,

consists in the separation of the heat transfer fluid flow at the

inlet to the boiler into two adjustable parts by the divider 2

with an electric drive. One part of

the flow returns to the boiler 1,

and the second one through the bypass pipe 9,

passing the boiler, goes to the mixer 8.

The movement of the heat transfer fluid through the system is

carried out by a circulation pump 3.

Depending on the required heating output

of the system, a heat transfer fluid with the required temperature

is fed into the heating devices through the mixer 8.

In this case, there is no need for strict maintenance of any value

of the heat transfer fluid temperature at the outlet from the

boiler.

This system can only work when

the circulation pump is on, which reduces its reliability.

The work [8]

proposes to use the heating system

as a cold and heat accumulator; the selection

of accumulated, cold or heat is assumed only through the water

heater, without additional conversion of the heating system. Using a

heating system as a cold accumulator is possible, but as a heat

accumulator without additional conversion is impossible, since the

heating system will work in the usual heating mode. The publication

of specialists

[1] is devoted to the interaction of heating and ventilation

systems; the work proposes to automate the operation of the water

heater to maintain

the set temperature, the outer air heated in the heater and fed by

the ventilation system.

Improvement of

the operation of refrigerating equipment of passenger cars in

transitional modes was considered in [11].

The study

[14] is aimed at

reducing the energy costs of modern light rail system Luas operating

in Dublin, Ireland, through the optimization of the heating and

ventilation system. The work [12]

studied the Swiss railroad vehicles of Swiss Rhaetian Railway (RhB).

The research is aimed at improving

the energy efficiency of life-support systems for railway vehicles,

by reducing the consumption

of outside air by way of controlling

content in the air. The publications

[5, 9,

13]

are devoted to the improvement of air conditioning systems of modern

passenger cars. Problems of increasing the comfort of passenger

transportation are also examined in the scientific works of other

researchers [7, 10],

but they consider other aspects of comfort, which are associated

more with the improvement of the dynamic characteristics of

passenger

rolling stock.

content in the air. The publications

[5, 9,

13]

are devoted to the improvement of air conditioning systems of modern

passenger cars. Problems of increasing the comfort of passenger

transportation are also examined in the scientific works of other

researchers [7, 10],

but they consider other aspects of comfort, which are associated

more with the improvement of the dynamic characteristics of

passenger

rolling stock.

Proceeding

from the foregoing, it follows that along with comparatively large

volumes of research

on improving the design of passenger car heating systems [1, 2, 4,

8, 11, 12, 14],

the tasks of ensuring the maintenance of a stable temperature

condition in passenger premises are practically not considered and

require more effective solutions. Therefore, the direction of

research related to improving

the efficiency of the operation of heating

units for passenger cars is an urgent scientific

and applied task.

Purpose

The purpose

of this study is to develop technical

solutions to improve the design of the water heating system, in

order to ensure a stable temperature condition in the passenger car

premises in

transitional modes of the heating

system

Methodology

To carry out the research it was

necessary to solve the following tasks:

– Analyse

the shared participation of convective

and radiant heat exchange on the surface

of heating pipes;

– Evaluate

the heat transfer efficiency of heating pipes, when installing the

regulating casing.

On the

heating pipe surface there is the convective

heat exchange with the internal air and the radiant heat exchange

with the walls and internal

equipment of the car. The intensity of such heat exchange is

estimated by the heat transfer coefficient ,

,

,

[6]:

,

[6]:

(1)

(1)

where

– radiant heat-transfer coefficient,

– radiant heat-transfer coefficient,

;

;

– convection coefficient,

– convection coefficient,

.

.

For different

bodies the radiation factor is different

[3]. Its value is determined by the nature of the body, its surface

state and temperature. This law establishes the dependence of the

density

of the body integral radiation flux on its temperature.

For an absolutely blackbody:

of the body integral radiation flux on its temperature.

For an absolutely blackbody:

, (2)

, (2)

where

– Stefan-Boltzmann constant

– Stefan-Boltzmann constant

.

.

In technical calculations, this

law is applied in the more convenient form:

, (3)

, (3)

where

– blackbody coefficient.

– blackbody coefficient.

.

.

Consequently,

the radiation energy of the absolutely

black body is proportional to the fourth power of the absolute

temperature.

This law can be applied to real

bodies. In this case, it takes the form:

. (4)

. (4)

Here с

is the radiation factor of various bodies. It varies from 0 to 5.67.

Comparing the

flux density of the body’s self-radiation

with the radiation flux density of an absolutely

black body at the same temperature, we obtain another characteristic

of the body, which is called the emissivity factor

.

.

. (5)

. (5)

The value of

ε varies from 0 to 1, which is

convenient.

In this case we have for a real

body:

. (6)

. (6)

The flux of

radiant heat exchange between two grey surfaces in an enclosed

space, when one of the surfaces with the area

flows around the other with the area

flows around the other with the area

,

is calculated by

the formula:

,

is calculated by

the formula:

, (7)

, (7)

Where the expression:

, (8)

, (8)

is called

the reduced blackbody emissivity factor.

With regard to heating pipes:

– surface

of the surrounding object (i.e., surface of the walls and the

internal equipment of the car);

– surface

of the surrounding object (i.e., surface of the walls and the

internal equipment of the car);

– surface of heating pipes.

– surface of heating pipes.

If we

consider the last formula (8) with

respect to the heat transfer on the unit of the heat-sensing wall

surface, the specific heat flux of the radiation will be:

. (9)

. (9)

Taking into account that the

specific heat flux by convection is determined by the formula:

, (10)

, (10)

where

– pipe temperature, °С;

– pipe temperature, °С;

– air temperature, °С,

– air temperature, °С,

And the total

heat flux q,

by convection and radiation

is as follows:

. (11)

. (11)

Taking into

account the expression (11), we obtain

a formula for calculating the radiation heat transfer coefficient:

. (12)

. (12)

In formula

(12)

is the average

temperature of bodies exchanging radiant heat.

is the average

temperature of bodies exchanging radiant heat.

With respect to the heat

exchange between the heating pipes and air in the car, index 1

refers to the surface of the pipes, index 2 refers to the car inner

equipment surrounding the pipe.

To determine

the convective heat transfer coefficient, we use the criteria for

the dependence of the Nusselt number

on the Grashof number

on the Grashof number

and the Prandtl number

and the Prandtl number

:

:

. (13)

. (13)

Having

determined ,

we calculate the value of the convective heat transfer coefficient:

,

we calculate the value of the convective heat transfer coefficient:

, (14)

, (14)

where

– air thermal

conductivity coefficient,

– air thermal

conductivity coefficient,

;

d –

determining dimension, here the pipe diameter, m.

;

d –

determining dimension, here the pipe diameter, m.

The value of

the coefficients c

and n, as

well as the product

and

and

in the formula

(13) is determined

by the data of the table given in [3].

in the formula

(13) is determined

by the data of the table given in [3].

Having

determined the value of heat transfer coefficient α,

we calculate the heat transfer of the heating pipes

;

;

. (15)

. (15)

Calculations

of the heat transfer fluid temperature

at various points along the pipe are made using the formula:

. (16)

. (16)

Let us analyse the share of

convective heat transfer on the heating pipes of the heating system,

the calculation results are summarized in Table 1.

Table 1

Heat

transfer of the radiator from horizontal metal pipes at free

convection

|

Initial

data

|

Notation

|

Values

|

Units

|

|

1

|

Radiator

pipe diameter

|

= =

|

76

|

mm

|

|

2

|

Radiator

length (one pipe)

|

= =

|

22

|

m

|

|

3

|

Number

of pipes in radiator

|

= =

|

2

|

pcs.

|

|

4

|

Water

temperature at the beginning of the pipe

|

= =

|

85

|

°C

|

|

5

|

Water

temperature at the end of the pipe

|

= =

|

65

|

°C

|

|

6

|

Indoor

air temperature

|

= =

|

22

|

°C

|

|

7

|

Type

of pipe outer surface

|

Grey

paint

|

|

8

|

The

Stefan-Boltzmann constant

|

= =

|

5.67

|

W/(m2·K4)

|

|

9

|

Acceleration

of gravity

|

= =

|

9.80665

|

m/с2

|

|

10

|

Emissivity

factor of pipe surface

|

= =

|

0.900

|

–

|

|

11

|

Average

temperature of pipe walls

|

= =

|

75.0

|

°C

|

|

12

|

Temperature

drop

|

= =

|

53.0

|

°C

|

|

13

|

Air

volume expansion coefficient

|

= =

|

0.00339

|

1/K

|

|

14

|

Kinematic

viscosity of air

|

= =

|

0.0000133

|

m2/с

|

|

15

|

Prandtl

number

|

= =

|

0.7035

|

–

|

|

16

|

Air

thermal conductivity

|

= =

|

0.026119

|

W/(m·K)

|

|

17

|

Radiator

surface area

|

= =

|

10.5055

|

m2

|

|

18

|

Heat

flux

|

= =

|

3

536

|

W

|

|

19

|

Radiation

heat transfer coefficient

|

= =

|

6.4

|

W/(m2·K)

|

|

20

|

Grashof

number

|

= =

|

3314599.8

|

–

|

|

21

|

Nusselt

number

|

= =

|

19.5387

|

–

|

|

22

|

Convective

heat flow

|

= =

|

3477

|

W

|

|

23

|

Convective

heat transfer coefficient

|

= =

|

6.2

|

W/(m2·K)

|

|

24

|

Full power of

radiator

heat flow

|

= =

|

7.013

|

kW

|

|

6.030

|

kcal

/h

|

|

25

|

Radiator heat

transfer coefficient

|

|

12.6

|

W/(m2·K)

|

|

10.8

|

kcal

/(h·m2·K)

|

As can be

seen from the calculation results in Table 1, the share of

convective heat transfer is 46÷40% of the total heat transfer, the

variations depend on dt

of the temperature drop.

Free

(natural) motion arises under the action of heat exchange near the

surface due to the difference

in the densities of air layers having different

temperatures: lighter heated layers are forced upward by heavier

cold layers.

In view of the foregoing, it can

be proposed to control the heat transfer of heating pipes due to

free convection, reducing or increasing the degree of convective

heat transfer on the surface of the heating pipes. This can be

achieved by installing regulating casings on the heating pipes. The

closed space is formed with holes for convective heat transfer,

while the area of the holes for convective heat transfer must be

adjustable, which will allow increasing or decreasing the degree of

convective heat transfer on the surface of the heating pipes.

Direct

regulators can be used for automatic regulation. The principle of

operation of a direct-acting

thermostat is based on the phenomenon of liquid volume change due

its temperature change. That will allow to more accurately react to

changes in air temperature in the car, increasing or decreasing the

degree of convective heat transfer on the heating pipes, thereby

controlling the heat transfer of the heating pipes.

In this case,

two types of air temperature sensors will be installed in the car,

some will interact with the regulating casings, and others will

interact with the control devices of the high-voltage tubular

heating elements. The interaction between sensors for monitoring the

air temperature in the car should be as follows: the high-voltage

tubular heating elements

can be switched off only after full closing of the regulating

casings holes; they can be switched on only after full opening of

the regulating casings holes. The

principle of the system operation:

when the car air temperature increases to

20 °C, the area of the holes on the regulating casings becomes

smaller, and with an increase in the car air temperature their area

decreases; when the car air temperature reaches 22 °C, the holes

are completely closed, only then the sensors of high-voltage tubular

heating element control devices are activated, and the heating

elements can only be switched on when the regulating casings holes

are fully open. Thus, the heating system will accumulate

thermal energy and will function as a heat accumulator. This gives

advantages: the accumulated

heat in the heating system will always be available almost

instantly, when opening the holes, i.e. increasing the free

convection increases the pipe heat transfer. Thus, it will be

possible to maintain a stable temperature condition in cars, as well

as to adjust individually the air temperature in the compartment.

To assess the

efficiency of heat transfer regulation

of heating pipes, with installed regulating casings, the operation

of the heating system with regulating casings was mathematically

modelled.

During mathematical modelling we used the formulas (1), (12),

(14)–(16), the car air temperature

can be determined by the formula:

, (17)

, (17)

where

– heat loss through the car windows;

– heat loss through the car windows;

– heat emission of the fan;

– heat emission of the fan;

– heating capacity

of heating pipes;

– heating capacity

of heating pipes;

– heat transfer coefficients respectively on the inner surfaces of

the enclosing structures of the body and the internal

equipment of the car;

– heat transfer coefficients respectively on the inner surfaces of

the enclosing structures of the body and the internal

equipment of the car;

– inner surface

of the enclosing structures and the surface of the internal

equipment;

– inner surface

of the enclosing structures and the surface of the internal

equipment;

– average temperature of inner surfaces of enclosing structures;

– average temperature of inner surfaces of enclosing structures;

– average

temperature of the surfaces of the internal equipment.

– average

temperature of the surfaces of the internal equipment.

Mathematical

modelling was carried out for the all-metal passenger car of model

61–826 built

by the Tver Carriage Works (TVZ). We used the initial

data given in [2] in Fig. 12. Graphs of temperatures

of the heat transfer fluid and air, namely: 1- ,

2-

,

2- – temperature of the heat transfer fluid at the input and output

of the boiler; 7-

– temperature of the heat transfer fluid at the input and output

of the boiler; 7- – outdoor air temperature, 5-

– outdoor air temperature, 5- – indoor air temperature of the car, 8 – switching on of

high-voltage tubular heating elements. The initial data are

summarized in Table 2.

– indoor air temperature of the car, 8 – switching on of

high-voltage tubular heating elements. The initial data are

summarized in Table 2.

The results

of mathematical modelling are shown in Fig. 3.

Table

2

Initial

date

|

Ƭ,

h

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

|

tin

,С

|

45

|

65

|

91

|

63

|

56

|

87

|

60

|

45

|

55

|

65

|

55

|

|

tout

,С

|

32

|

42

|

63

|

44

|

32

|

62

|

53

|

32

|

39

|

45

|

37

|

|

tI,С

|

20

|

18

|

24

|

24

|

17

|

24

|

24

|

22

|

20

|

23

|

22

|

|

tO,С

|

–12

|

–14

|

–11

|

–19

|

–18

|

–17

|

–9

|

–12

|

–9

|

–6

|

–3

|

Fig. 3. Diagrams of

air and water temperature in boiler, switching on and off of

high-voltage

tubular heating

elements:

1

–

water temperature in boiler, 2

– water

temperature in boiler with regulating casings, 3

– air

temperature in a car,

4

– air

temperature in a car with regulating casings,

5

– outdoor air

temperature, 6

– switching on

of high-voltage

tubular

heating elements

Findings

As follows

from the data of the diagram 3 shown in Fig. 3, fluctuations in the

car air temperature

within the limits of 17 ÷ 25 С

are caused by the switching off of high-voltage tubular heating

elements, drop of the outdoor air temperature,

thermal inertia of the internal equipment of the car, and thermal

inertia of the heating system. The process of differences occurs as

follows:

when the car air temperature drops to 18

°C, the control equipment switches on the high-voltage tubular

heating elements; during the time of overcoming the inertia

(heating) of the heating system, the car heat loss continues and the

car temperature drops; when the system is heated the air temperature

rises; upon reaching 22 С,

the control equipment switches off the high-voltage tubular heating

elements, but in view of the large heating system inertia, the car

air continues to heat up to equality between the car heat loss and

thermal

output of heating tubes, whereby the car air temperature ranged

between 17 ÷ 25 C.

When using

the regulating casings of heating pipes (diagram 4, Fig. 3), the car

air temperature fluctuated within 20 ÷ 23 °C. This is due to the

fact that when the air temperature in the car reached 22

°C, the regulating casings decreased the heat transfer of the

heating pipes, when the car air temperature

was below 22 °C, the heat transfer of the heating pipes increased,

resulting in reduced effect of thermal inertia of the heating

system. Comparing the diagrams 1 and 2 in Fig. 3 of water

temperature in boiler, it can be seen that with regulating

casings, diagram 2, the water temperature

in boiler is higher than that without the regulating casings,

diagram 1, under the same conditions

of the system heating and the car heat loss. This leads to the

conclusion that the heating system, while performing their

functions, can act as a heat accumulator.

The use of

regulating casings on heating pipes allows reducing the effects of

heat inertia and maintaining stable thermal conditions in a

passenger

car, using the heating system as a heat accumulator, and also

provides the opportunity to realize an individual control of air

temperature in the compartment.

Originality

and practical

value

For the first

time, the paper studied the alternative

ways of regulating the temperature condition

in a passenger car. Using of the heating system as a heat

accumulator. The

regulation of the heat transfer of the heating pipes by regulating

casings

allows reducing the effect of thermal inertia

of the heating system on the temperature condition in a passenger

car, implementing individual

adjustment of air temperature in a compartment

within 40% of the power of the heating pipe section.

Conclusions

Analysis of

the study, control of the heating system inertia in the passenger

cars, made it possible

to single out one of the problems in the operation of the heating

system, the unstable temperature

condition caused by the large thermal inertia of the heating system.

Currently in

operated passenger cars, control of heating appliances is not

constructively provided. The heating

pipe performance

can be

controlled only

by the

temperature of

the heat

transfer fluid in the

heating system,

into which

the heating

pipes enter

as a

heater.

Automatic maintenance of the set temperature

in a passenger car is limited to switching

on and off of high-voltage tubular heating elements.

The paper

proposes and examines the issue of automatic maintaining a stable

temperature condition

in a passenger car by installing

regulating casings on heating pipes. The

mode of operation

and interaction of air temperature sensors in the car is proposed.

This method

of pipe heat transfer regulation will allow reducing the effect of

thermal inertia

of the heating system on the temperature condition in a passenger

car, implementing individual adjustment

of air temperature in a compartment within 40% of the power of

heating pipes passing through the compartment. Using a heating

system as a heat accumulator will allow a maintaining a regulated

temperature condition in the car for the longer period, for example,

at the marshalling or turnaround stations. The operating mode and

interaction

of sensors for monitoring the car air temperature will allow

maintaining a stable temperature

condition in the car.

In addition,

the results of research can be used not only for the construction of

new cars, but also to modernize heating units in the cars of the

operating

park, in depot conditions.

LIST OF

REFERENCE LINKS

Белошицкий,

Э. В. Повышение эффективности

отопительно-вентиляционных систем /

Э. В. Белошицкий, Ю. В. Кебал // Вагонный

парк. – 2017. – № 1. – С. 32–35.

Жариков, В.

А. Климатические системы пассажирских

вагонов / В. А. Жариков. – Москва :

Трансинфо, 2006. – 135 с.

Зигель, Р.

Теплообмен излучением / Р. Зигель, Дж.

Хауэл. – Москва : Мир, 1975. – 935 с.

Китаев, Б.

Н. Повышение эффективности теплообменных

процессов в пассажирских вагонах /

Б.

Н. Китаев, В. А. Жариков. – Москва :

Транспорт, 1995. – 53 с.

Кукса, Ю. Я.

Перспективы модернизации пассажирских

вагонов при проведении

капитально-восстановительного ремонта

/ Ю. Я. Кукса, П. М. Мустафа, И. Ю. Хоменко

// Залізничний транспорт України. –

2010. – № 2. – С. 28–30.

Михеев, М.

А. Основы теплопередачи / М. А. Михеев,

И. М. Михеева. – Москва : Энергия, 1977. –

344 с.

Мямлин, С.

В. Новые технологии в проектировании

дизель-поездов /

С. В. Мямлин, А.

В. Кивишева // Локомотив-інформ.

– 2013. – № 11.

– С. 4–5.

Пат. 61021

Україна, МПК B 61 D 27/00.

Застосування системи опалення

пасажирського вагона з водоповітряним

калорифером, розташованим у напірному

повітропроводі, як акумулятора холоду

(тепла) / Хоменко Ірина Юріївна

; заявник та патентовласник Хоменко

Ірина Юріївна. – № u201013475

; заявл. 15.11.2010

; опубл. 11.07.2011, Бюл.

№ 13. – 2 с.

Попередні

випробування систем життєзабезпечення

пасажирського плацкартного вагона,

дообладнаного системою кондиціонування

/ О. Г. Дуганов, В. Т. Вислогузов, Ю. В.

Кебал [та ін.]

// Интеграция Украины в междунар. трансп.

систему : тез. І Междунар. науч.-практ.

конф. (21.05–22.05.2009) / М-во трансп. и связи

Украины, Днепропетр. нац. ун-т ж.-д.

трансп. им. акад. В. Лазаряна. –

Днепропетровск, 2009. –

С. 22–23.

Приходько,

В. И. Научные основы создания пассажирских

вагонов для скоростных перевозок

: монография / В. И. Приходько, С. В.

Мямлин. – Днепропетровск : Маковецкий,

2011. – 355 с.

Хоменко,

І. Ю. Удосконалення системи енергетичного

та холодильного обладнання пасажирських

вагонів при капітальних ремонтах :

дис. … канд. тех. наук : 05.22.07 / Хоменко

Ірина Юріївна ; Дніпропетр. нац.

ун-т залізн. трансп. ім. акад. В. Лазаряна.

– Дніпропетровськ, 2014. – 125 с.

Energy

efficiency of railway vehicles / N. Vetterli, U.-P. Menti, F.

Sidler, E. Thaler, G. Zweife // CISBAT 2015 : International

Scientific Conference (9.09–11.09.2015). – Lausanne,

Switzerland, 2015.

– Р. 955–960.

Khomenko,

I. Yu. Mathematical modeling of unsteady heat exchange in a

passenger car / І. Yu. Khomenko // Наука та прогрес

транспорту. – 2013. – № 6 (48). – С. 147–155.

doi:

10.15802/stp/2013/19762.

Sweeney,

E. Modification of Luas heating and ventilation systems to reduce

energy consumption [Электронный ресурс] / E.

Sweeney, J. Brunton // Conference

papers (5–6th

September) /

Dublin

Institute of Technology.

– Dublin,

2013. – Режим доступа: http://arrow.dit.ie/engschmeccon/62/.

– Загл. с экрана. – Проверено : 03.06.2017.

Е.

В. БІЛОШИЦЬКИЙ1*

1*Проектно-конструкторське

технологічне бюро, Дніпропетровський

національний університет

залізничного

транспорту імені академіка В. Лазаряна,

вул. Лазаряна, 2, Дніпро, Україна, 49010,

тел. +38 (056) 371 51 12, ел. пошта

beloshickij@rambler.ru, ORCID 0000-0002-2424-8479

СПОСОБИ

УПРАВЛІННЯ ІНЕРТНІСТЮ

ОПАЛЕННЯ

Мета.

У науковій роботі

передбачається оцінити вплив теплової

інертності водяної системи опалення

(при перехідних режимах роботи) на

температурний режим у пасажирському

вагоні. А також запропонувати технічні

рішення, спрямовані на зниження впливу

теплової інертності системи опалення

та підтримання сталого температурного

режиму в приміщеннях вагона на перехідних

режимах системи опалення. Методика.

Розроблено спосіб керування тепловіддачею

обігрівальних труб системи опалення

за допомогою регулюючих кожухів. Для

управління системою опалення та

тепловіддачею обігрівальних труб

використані два типи датчиків контролю

температури повітря в вагоні: одні

взаємодіяли з регулюючими кожухами,

а інші – з приладами автоматики

управління (нагрівальними високовольтними

ТЕНами). Для оцінки ефективності

регулювання тепловіддачі опалювальних

труб та управління системою опалення

з встановленими регулюючими кожухами

математично змодельована робота системи

опалення з регулювальними кожухами, з

використанням двох типів датчиків. Для

математичного моделювання використані

дані експериментальних випробувань.

Проведено порівняння результатів

експериментальних випробувань та

математичного моделювання. Результати.

На даний час в експлуатованих пасажирських

вагонах управління приладами опалення

конструктивно не передбачено. Автоматична

підтримка заданої температури в

пасажирському вагоні зводиться до

включення і виключення високовольтних

ТЕНів. Застосування регулюючих кожухів

обігрівальних труб дозволяє знизити

вплив теплової інертності опалення

для підтримки стійкого теплового режиму

в пасажирському вагоні, використовувати

систему опалення як тепловий акумулятор,

а також дає можливість реалізувати

індивідуальне регулювання температури

повітря в купе. Наукова

новизна. Автором вперше

досліджені альтернативні способи

регулювання температурного режиму в

вагоні. Використані системи опалення

як акумулятори тепла. Практична

значимість. Стабілізація

тепловіддачі опалювальних труб

регулюючими кожухами дозволяє знизити

вплив теплової інертності системи

опалення на температурний режим повітря

в вагоні, реалізувати індивідуальне

регулювання температури повітря в купе

в межах 40 % від потужності ділянки

обігрівальних труб, а також використовувати

систему опалення як акумулятор тепла.

Ключові

слова: опалення

пасажирських вагонів; природна конвекція;

тепловіддача; акумулятор

тепла

Э. В.

БЕЛОШИЦКИЙ1*

1*Проектно-конструкторское

технологическое бюро,

Днепропетровский

национальный университет

железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010,

тел. +38 (056) 371 51 12, эл. почта

beloshickij@rambler.ru,

ORCID 0000-0002-2424-8479

СПОСОБЫ

УПРАВЛЕНИЯ ИНЕРТНОСТЬЮ ОТОПЛЕНИЯ

Цель.

В научной работе предполагается оценить

влияние тепловой инертности водяной

системы отопления (при переходных

режимах работы) на температурный режим

в пассажирском вагоне. А также необходимо

предложить технические решения,

направленные на снижение влияния

тепловой инертности системы отопления

и поддержание устойчивого температурного

режима в помещениях вагона на переходных

режимах системы отопления. Методика.

Разработан способ управления теплоотдачей

обогревательных труб системы отопления

с помощью регулирующих кожухов. Для

управления системой отопления и

теплоотдачей обогревательных труб

использованы два типа датчиков контроля

температуры воздуха в вагоне: одни

взаимодействовали с регулирующими

кожухами, а другие – с приборами

автоматики управления (нагревательными

высоковольтными ТЭНами). Для оценки

эффективности регулирования теплоотдачи

отопительных труб и управления системой

отопления с установленными регулирующими

кожухами математически смоделирована

работа системы отопления с регулировочными

кожухами, с использованием двух типов

датчиков. Для математического

моделирования использованы данные

экспериментальных испытаний. Проведено

сравнение результатов экспериментальных

испытаний и математического моделирования.

Результаты.

В настоящее время в эксплуатируемых

пассажирских вагонах управление

приборами отопления конструктивно не

предусмотрено. Автоматическое поддержание

заданной температуры в пассажирском

вагоне сводится к включению и выключению

высоковольтных ТЭНов. Применение

регулирующих кожухов обогревательных

труб позволяет снизить влияние тепловой

инертности отопления для поддержания

устойчивого теплового режима в

пассажирском вагоне, использовать

систему отопления как тепловой

аккумулятор, а также дает возможность

реализовать индивидуальное регулирование

температуры воздуха в купе. Научная

новизна. Автором впервые

исследованы альтернативные способы

регулирования температурного режима

в вагоне. Использованы системы отопления

как аккумулятор тепла. Практическая

значимость. Стабилизация

теплоотдачи обогревательных труб

регулирующими кожухами позволяет

снизить влияние тепловой инертности

системы отопления на температурный

режим воздуха в вагоне, реализовать

индивидуальное корректирование

температуры воздуха в купе в пределах

40 % от мощности участка обогревательных

труб, а также использовать систему

отопления как аккумулятор тепла.

Ключевые

слова: отопление

пассажирских вагонов; естественная

конвекция; теплоотдача; аккумулятор

тепла

REFERENCES

Biloshytskyi,

E. V., & Kebal,

Y. V. (2017). Povysheniye effektivnosti

otopitelno-ventilyatsionnykh sistem. Car

Fleet, 1, 32-35.

Zharikov,

V. A. (2006). Klimaticheskiye sistemy

passazhirskikh vagonov. Moscow:

Transinfo.

Siegel,

R., & Howell, J. (1975). Thermal

radiation heat transfer. Moscow: Mir.

Kitaev,

B. N., & Zharikov, V. A. (1995). Povysheniye

effektivnosti teploobmennykh protsessov ekspluatatsii vagonov v

passazhirskikh vagonakh. Moscow:

Transport.

Kuksa,

J. Y., Mustafa, P. M., & Khomenko, I. Y. (2010). Perspektivy

modernizatsii passazhirskikh vagonov pri provedenii

kapitalno-vosstanovitelnogo remonta. Railway

Transport of Ukraine, 2,

28-30.

Mikheev,

M. A., & Mikheeva, I. M. (1977). Osnovy

Teploperedachi. Moscow: Energy.

Myamlin,

S. V., & Kivisheva

A. V. (2013).

Novyye

tekhnologii v proyektirovanii

dizel-poyezdov.

Lokomotyv-Inform,

11, 4-5.

Khomenko,

I. Y. (2011). UA Patent No. 61021.

Ukrainian Intellectual Property Institute (UKRPATENT). Retrieved

from

http://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=161080

Duhanov,

O. H., Vyslohuzov, V. T., Kebal, Y. V., Furmanova, A. V., Khomenko,

I. Y., Shapoval, A. V., … Rechkalov, S. D. (2009). Poperedni

vyprobuvannia system zhyttiezabezpechennia pasazhyrskoho

platskartnoho vahona, doobladnanoho systemoiu kondytsionuvannia.

Proceedings of the 1st International

Conference Integration of Ukraine into the International Transport

Network, May 21-22, 2009, Dnipropetrovsk.

22-23. Dnipropetrovsk: Dnipropetrovsk National University of

Railway Transport named after Academician V. Lazaryan.

Prikhodko,

V. I., & Myamlin, S. V. (2011). Nauchnyye

osnovy sozdaniya passazhirskikh vagonov dlya skorostnykh perevozok

[Monograph]. Dnipropetrovsk: Makovetsky.

Khomenko,

I. Y. (2014). Power Supply and Air

Conditioner Systems of Passenger Cars Improvement During the

Thorough Overhaul (PhD thesis).

Available from Dnipropetrovsk National University of Railway

Transport named after Academician V. Lazaryan, Dnipropetrovsk.

Vetterli,

N., Menti, U.-P., Sidler, F., Thaler, E., & Zweife, G. (2015).

Energy efficiency of railway vehicles. Proceedings

of the International Scientific Conference CISBAT 2015, September

9-11, 2015, Lausanne, Switzerland.

955-960. Retrieved from https://infoscience.epfl.ch/record/213444/files/9_VETTERLI.pdf

Khomenko,

I. Y. (2013). Mathematical modeling of unsteady heat exchange in a

passenger car. Science and Transport

Progress, 6

(48), 147-155. doi:10.15802/stp2013/19762

Sweeney

E., & Brunton

J. (2013). Modification of Luas heating and ventilation systems to

reduce energy consumption. Irish

Transport Research Network Conference, Trinity College Dublin,

Dublin, Ireland, 5-6 September, 2013.

Retrieved from http://arrow.dit.ie/engschmeccon/62/

Prof.

V. L. Gorobets,

D. Sc. (Tech.), (Ukraine); Prof.

O. O. Beihul, D.

Sc. (Tech.), (Ukraine) recommended

this article to be published

Received:

March 31, 2017

Accessed:

July 05, 2017

doi

10.15802/stp2017/109632 © E.

V. Biloshytskyi,

2017

.

As a result, the entire range of heat output of the boiler will be

with smooth regulation.

content in the air. The publications

[5, 9,

13]

are devoted to the improvement of air conditioning systems of modern

passenger cars. Problems of increasing the comfort of passenger

transportation are also examined in the scientific works of other

researchers [7, 10],

but they consider other aspects of comfort, which are associated

more with the improvement of the dynamic characteristics of

passenger

rolling stock.

,

,

[6]:

(1)

– radiant heat-transfer coefficient,

;

– convection coefficient,

.

of the body integral radiation flux on its temperature.

For an absolutely blackbody:

, (2)

– Stefan-Boltzmann constant

.

, (3)

– blackbody coefficient.

.

. (4)

.

. (5)

. (6)

flows around the other with the area

,

is calculated by

the formula:

, (7)

, (8)

– surface

of the surrounding object (i.e., surface of the walls and the

internal equipment of the car);

– surface of heating pipes.

. (9)

, (10)

– pipe temperature, °С;

– air temperature, °С,

. (11)

. (12)

is the average

temperature of bodies exchanging radiant heat.

on the Grashof number

and the Prandtl number

:

. (13)

,

we calculate the value of the convective heat transfer coefficient:

, (14)

– air thermal

conductivity coefficient,

;

d –

determining dimension, here the pipe diameter, m.

and

in the formula

(13) is determined

by the data of the table given in [3].

;

. (15)

. (16)