ISSN

2307–3489 (Print), ІSSN 2307–6666 (Online)

Наука

та прогрес транспорту. Вісник

Дніпропетровського

національного

університету залізничного транспорту,

2017, № 4 (70)

екСплуаТація

та ремонт засобів транспорту

UDC

629.4.016.5:625.144

M.

I. KAPITSA1,

D. V. BOBYR2,

A. Y. DESIAK3*

1Dep.

«Locomotives», Dnipropetrovsk National

University of Railway Transport named after Academician V.

Lazaryan,

St. Lazaryan, 2, Dnipro,

Ukraine, 49010, tel. +38 (0562) 33 19 61,

e-mail m.i.kapitca@ua.fm,

ORCID 0000‑0002‑3800‑2920

2Dep.

«Locomotives», Dnipropetrovsk National

University of Railway Transport named after Academician V.

Lazaryan,

Str. Lazaryan, 2, Dnipro,

Ukraine, 49010, tel. +38 (0562) 33 19 61,

e-mail dmitrob@ua.fm, ORCID

0000-0003-1441-3861

3*Dep.

«Locomotives», Dnipropetrovsk National

University of Railway Transport named after Academician V. Lazaryan,

Str. Lazaryan, 2, Dnipro, Ukraine,

49010, tel. +38 (0562) 33 19 61, e-mail

andrey.desyak1992@gmail.com,

ORCID

0000-0001-8650-5242

DETERMINING

PERMISSIBLE SPEED

OF TILTING

TRAIN IN CURVED TRACK

Purpose.

The main purpose of the article is to

determine the permissible speed of the air-cushioned tilting train in

curved track and to justify the expediency of operating this type of

rolling stock on the railways of Ukraine to

increase the speed, improve the passenger comfort and save the energy

due to more uniform high-speed train driving.

Methodology. The

determination of the maximum permissible speed of the tilted train in

curved track involves the use of

methods of linear and vector algebra and empirical formulas for

applied scientific and technical research. The calculation of the

maximum speed is based on the principle of calculating centrifugal

force for the velocities that meet the safety criteria of movement on

the horizontal unbalanced acceleration in the stable radius curve.

Findings.

The results of the calculations showed that

in the 1000 m radius curved track section, provided the passenger

comfort, the maximum permissible speed of the train without forced

tilt is 132 km/h, and with the forced tilt – 189 km/h. The velocity

gain in the curve is about 30% and up to 10% on the section

(depending on the number of curves). Originality.

The method of determining the permissible

speed of the tilted train in curved track is improved,

which consists in determining the permissible centrifugal force

acting on the train in the stable radius curve, taking into account

the passenger comfort conditions. Practical

value. This

method allows accurately determining the permissible speed on the

condition of passenger comfort in the curved section and the required

additional tilt angle of the train, depending on the speed, curve

radius and canting. Enhanced speed and comfort of passenger trains in

the future will increase the demand for rail services among the

population and strengthen the position of rail transport in Ukraine’s

transport system.

Keywords:

high-speed

transport; rolling

stock; body tilt

system; centrifugal

force; resultant

force; curve

radius; canting

Introduction

Integration

of Ukraine into the European community creates preconditions for a

significant increase in passenger and freight transportation

volumes. Under these conditions, the requirements for transport are

essentially new. The radical measure to provide domestic and

international passenger transportation is the creation of a

high-speed railway network with access to the European network and

CIS countries [7].

In

order to

solve the

problem of

introduction of

high-speed

trains in

Ukraine, it

is necessary

to apply

the systematic

approach that

includes the analysis

of world experience, the study of the preconditions for organization

of high-speed trains in Ukraine, ways of connecting the domestic

railway network with the European one, designing of high-speed

lines, which involves the development of requirements and standards

for plan and longitudinal profile designing [5].

Another

problem of

the development

of high-speed

transport is

that virtually

all

infrastructure

and rolling

stock remained

as inheritance

since the

Soviet era.

Therefore, the entire railway industry of

Ukraine is out-dated and needs a global upgrade, consisting of:

– reconstruction

of the track and the contact network;

– modernization

or renewal

of the

fleet of

rolling stock;

– complete

replacement of

signalling,

centralization

and locking

devices with

more modern

ones designed

for high-speed

traffic;

– replacement

of the

cargo and

passenger train

operation model.

If Ukraine

aspires to integrate into the transport system of Europe, then the

rail transport must meet the European standards in terms of comfort,

reliability

and security.

Such leading

countries as

Germany, France,

Italy,

Spain, China

and Japan

are actively

using trains

on air-cushioned

suspension with

body forced tilt

in curves

to improve

the speed

and comfort

of passengers.

This can significantly reduce the

effect of centrifugal acceleration on passengers in curved track

sections and rolling stock vibration at high speeds [13].

Problem statement

On the

railway lines, the possibility of speed increasing in the track

curved sections is limited by the effect of transverse centrifugal

acceleration, acting on the rolling stock and passengers. It

increases in proportion to the velocity squared and decreases in

proportion to the curve radius. Also,

centrifugal

acceleration

creates the

force that

pushes

the rolling

stock to

the outer

rail, which

can lead

to the

derailment.

Passengers and locomotive crew also

experience the effect of centrifugal force, which tries to throw

them away from the centre of the curve to the car side. This

factor creates

considerable

discomfort

during the

trip. Partially,

the action of the centrifugal force is reduced by increasing the

canting in the track curved sections. In this case, some part of the

centrifugal force acting on the passengers is compensated.

If one

installs the rail lines in the curve in one level, then the

centrifugal force, together with the crew weight, will form the

resultant force that can go to the outer rail line. This force

causes:

– increased

wear of the lateral surface of the outer rail;

– rebounds

of the external rail;

– unpleasant

sensations of

passengers due

to unbalanced

acceleration.

Maximum

canting in

Ukraine is

150 mm By

the permission

of

Ukrzaliznytsya,

the maximum

canting can

amount to

more than

150 mm, but

this will

lead to

uneven wear

of rails

and discomfort

of passengers

at low

speed [9].

However, the canting is not

always enough to increase the speed in the curve. This is due to the

fact that the canting is designed for the speed of freight trains,

which, as a rule, move at speeds up to 80 km/h.

This problem is especially

relevant for Ukraine, since for the introduction of high-speed

traffic, the minimum radii of curves should be about 4 000–5 000

m, and on the railway lines of Ukraine there are curves with radii

of about 500 m, which does not meet the requirements of high-speed

railway lines. The increase of the curve radius is a complicated

process, expensive and, to some extent, impossible, due to the

densely populated settlements and rail infrastructure. Thus, the

tilting rolling stock should solve the problem of the

implementation of high-speed traffic on the territory of

Ukraine. When using trains with such a system, the part of the

centrifugal force is compensated.

Therefore, in this article, we

strive to prove the expediency of operation of the high-speed

rolling stock on the Ukrainian railway lines with the body tilt

system in the curved track sections in order to increase the speed

of passage of curves without profile reconstruction and change. It

will also allow saving the energy through the steadier mode of

train driving.

Analysis of researches and

publications

In the works

by Redchenko E. S. [10], Kurgan

M. B. [6] and Zubko A. P. [1] the possibility of using the

tilting rolling stock in Ukraine during the organization of

high-speed traffic was already

considered.

In order to determine the

permissible speed of the train with the body forced tilt in the

curve the work [10] proposes the following method.

The vehicle moving in the curve

is affected, in general, by two main forces: gravity and

centrifugal force, which depends on the movement speed and the

curve radius. All forces acting on the vehicle in the track curve

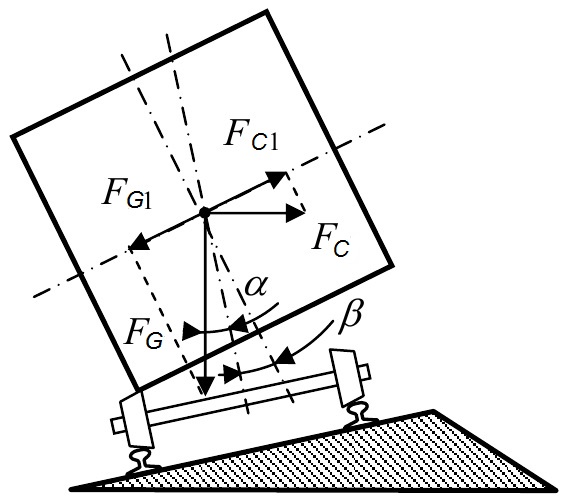

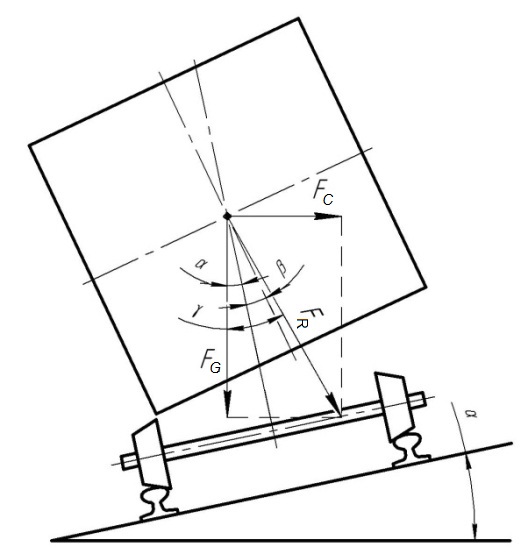

are shown in Fig. 1

The centrifugal force is

determined by the formula:

, (1)

, (1)

where

m –

rolling stock mass,

kN;

V –

rolling stock speed in the curve, km/h; R

– curve radius, m.

Fig. 1. Vehicle

movement with additional tilt

of the body in curve

To reduce the

effect of centrifugal force in the curves, the outer rail is placed

higher than the internal one by the value of cant h,

m. Therefore, the track is inclined with respect to the horizon at

the following angle:

, (2)

, (2)

where

– track width, m.

– track width, m.

Due to this, a part of the

centrifugal force is compensated by the force of gravity, since in

the floor plane of the car the projections of the foregoing

forces are directed to the opposite sides.

Obviously,

the result

of the

vectorial

addition of

these forces

will be

some unbalanced

lateral force

.

.

To

provide the

greatest comfort

for passengers,

the unbalanced

lateral force

should be

equal to

zero. The

projection of the centrifugal force must be fully compensated by the

gravity component:

, (3)

, (3)

where

g –

free fall

acceleration,

m/s2.

The

profile of

the curves

is constructed

with a

fixed optimal

canting.

But since

trains move

at different

speeds, one

should define

«insufficient

canting».

The maximum

canting is

limited for

reasons of

preventing the

rolling stock

tipping into

the curve

when it

stops or

moves slowly

and is

equal to

=0,15

m.

=0,15

m.

Insufficient

canting can be compensated by inclining the vehicle body with

the help of additional force for the angle

,

into such a position that the body would occupy during movement in

the curve with the required canting of the outer rail, i.e.

,

into such a position that the body would occupy during movement in

the curve with the required canting of the outer rail, i.e.

.

.

The condition

for compensating the centrifugal force for tilting trains can be

written as follows:

(4)

(4)

Consequently,

the expression for the additional angle of the body tilt will be as

follows:

(5)

(5)

The

disadvantage of

this method

is that

the author

[10] does not

take into

account the

condition of

passenger

comfort on

horizontal

unbalanced

acceleration,

and the

additional angle

of the

body tilt

is determined

with full

compensation of

the centrifugal

force, i.e.

the unbalanced

acceleration in

this case

is equal

to zero,

and as

it is

known, the

permissible

unbalanced

acceleration is

m/s2.

m/s2.

The

authors in

[6] and

[1] propose the

method for

determining the

permissible

speed of

the tilting

train in

the curve,

which is

as follows.

In

circular curves,

the permissible

speed of

movement is

determined by

the safety

criterion of

movement on

the horizontal

unbalanced

acceleration:

(6)

(6)

where

– estimated

canting, mm;

S – distance

between the

rail top axes,

1 600 mm.

– estimated

canting, mm;

S – distance

between the

rail top axes,

1 600 mm.

In

modern vehicles,

which during

curve passing

have the

body forced

tilt into

the middle

of the

curve at

the angle

,

the permissible

speed increases

with the

introduction of

canting into

the formula

(6), which is

an additional

compensation for

the unbalanced

acceleration:

,

the permissible

speed increases

with the

introduction of

canting into

the formula

(6), which is

an additional

compensation for

the unbalanced

acceleration:

(7)

(7)

Substituting

formula (7) into

formula (6), we

obtain the

permissible

speed of

the train

with the

forced tilt

of the

body in

the curve:

(8)

(8)

The main

disadvantage of this method is that the authors [1, 8] do not

perform calculations to determine the additional angle of the train

tilt

during the curve passage, since the additional tilt angle depends on

the curve radius, movement speed, canting and the maximum tilt angle

achieved by the rolling stock.

during the curve passage, since the additional tilt angle depends on

the curve radius, movement speed, canting and the maximum tilt angle

achieved by the rolling stock.

Purpose

Justification of the expediency

of operation of the air-cushioned rolling stock with tilt in curved

sections on the railways of Ukraine for increased speed and comfort

of passengers.

Methodology

The methodology for determining

the maximum permissible speed of the tilted train in curved

track involves the use of methods of linear and vector algebra and

empirical formulas for applied scientific and technical research.

The

calculation of the maximum speed of the tilted train in curved track

is based on the principle of calculating centrifugal force for the

velocities that meet the safety criteria of movement on the

horizontal unbalanced acceleration in the stable radius curve.

Basic material

The modern high-speed trains

have three main systems of body tilt in curves: passive, active and

active-passive.

In

passive tilt

systems, the

body is

suspended like

a pendulum

with a

centre of

rotation above

the body

gravity centre.

When moving in the curve, the centre of gravity under the action of

centrifugal force is displaced externally, providing the required

angle of the body tilt. The tilt angle of the passive system can be

up to 3°–5°. In this case, a significant part of the centrifugal

force is compensated, and the speed in the curves can be

increased by 14% [8].

In active systems, the tilt of

the body is performed with the help of special devices.

Hydraulic, pneumatic, electro-hydraulic and electromechanical

systems are used as a power-driven mechanism of the body forced

tilt. In order to ensure correct operation of the system, the

rolling stock is equipped with a number of sensors, which, depending

on the speed, curve radius and canting, determine the optimal angle

of the rolling stock tilt. Typically, the tilt angle of the active

systems is 8°–10° [8], which makes it possible to increase

the speed to 25–30 %.

The active-passive tilt system

can work both as active and passive depending on the speed and the

desired angle of the body tilt. If you need to turn the body to

3°–5° angle, then the system works as a passive one. If you need

to set a larger angle, then the system starts to work as active. The

advantage of the passive tilt system is that there is no need to

spend energy for the body tilt and it has simple and reliable

design. And the advantage of the active one is the greater maximum

possible tilt angle [5, 14].

In this

paper, the method for determining the permissible speed of movement

in the curve with the body forced tilt is as follows:

– determination

of the

permissible

speed of

the train

in the

curve provided

the passengers

feel

comfortable;

– determination

of the

forces acting

on the

train in

the track

curved section

(centrifugal

force and

gravity);

– determination

of the

permissible

centrifugal

force in

the curve

subject to

comfort;

– determination

of the

resultant force

for centrifugal

and

gravitational

forces;

– determination

of the

angle of

deflection of

the resultant

force vector

at the

permissible

speeds from

the vertical

axis Oy;

– determination

of the

angle of

deflection of

the resultant

force vector

from the

vertical axis

of the

locomotive,

which in

turn is

the desired

angle of

the body

tilt in

the curve;

– determination

of the

permissible

angle of

deflection

of the

resultant force

vector from

the vertical

axis Oy

with the

body forced

tilt;

– determination

of the

value of

the resultant

force and

centrifugal

force with

the body

forced tilt

in the

curve;

– definition

of maximum

speed with

the >maximum

angle of

the body

tilt, which

is provided

by the

rolling stock

design;

– construction

of the

graph showing

the dependence

of the

centrifugal

force of

the locomotive

on the

speed in

the track

curve, the

limitation of

the centrifugal

force without

body tilt, the

limitation of

the centrifugal

force with

body tilt

and the

limitation of

the speed

at the

maximum angle

of the

body tilt.

Increasing

the speed

of movement

requires much

greater

compliance with

traffic safety

criteria.

This is especially true for the tilting

rolling stock. In world practice, the following traffic safety

criteria are used:

– vertical

acceleration,

which arises

during the

movement of

the train

in the

curve section

of the

longitudinal

track profile;

– longitudinal

acceleration

associated with

the processes

of braking

and run-up;

– horizontal

unbalanced

acceleration,

which arises

during the

movement in

the track

curve in

plan;

– full

acceleration, acting on the passenger;

– vertical

acceleration

occurring in

the passenger

car body,

caused by

fluctuations,

and acting

on a

passenger;

– criterion

of safety of movement on elastic edging of a rail.

The criterion that influences

the safety of the passengers of the tilting train the most is the

criterion of comfort, that is, the criterion of safety of movement

on the horizontal unbalanced acceleration.

As

already noted,

the permissible

speed of

movement in

the track

curve in

the condition

of comfort

of passengers

and locomotive

crew is

determined

by the

largest value

of unbalanced

acceleration

m/s2,

which is

specified on

the railways

of the

CIS countries.

In justified cases, in order to eliminate

the speed limit on individual curves depending on the locomotive

type, the transverse permissible unbalanced acceleration can be

increased to 1 m/s2,

but not long-term and not repeated. Permissible unbalanced

acceleration for freight trains, provided that the outer or inner

rail of the curve is not overloaded, is equal to ± 0.3 m/s2

[3, 12].

m/s2,

which is

specified on

the railways

of the

CIS countries.

In justified cases, in order to eliminate

the speed limit on individual curves depending on the locomotive

type, the transverse permissible unbalanced acceleration can be

increased to 1 m/s2,

but not long-term and not repeated. Permissible unbalanced

acceleration for freight trains, provided that the outer or inner

rail of the curve is not overloaded, is equal to ± 0.3 m/s2

[3, 12].

Different authors offer

different formulas for determining the permissible speed of movement

in the curved track. From the considerable volume of literature, it

is possible to define three most used empirical formulas for

determining the permissible speed of passage of curves provided the

comfort of passengers and locomotive crew. Formula (9) is given in

[3], formula (10) in [11], and formula (11) in [2].

(9)

(9)

(10)

(10)

(11)

(11)

According to

the above formulas in Fig. 2 we constructed the graph of dependence

of the permissible movement speed on the curve radius without body

tilt for the following conditions: the canting

and

and

mm, the curve radius

mm, the curve radius

m. Since the

difference in the results obtained by formulas (9), (10) and (11) is

less than one per cent, so it makes no sense to construct all three

dependencies; it’s enough to just construct the dependence by one

of the formulas for three different cants.

m. Since the

difference in the results obtained by formulas (9), (10) and (11) is

less than one per cent, so it makes no sense to construct all three

dependencies; it’s enough to just construct the dependence by one

of the formulas for three different cants.

The vehicle moving in a curve,

in general, is affected by two main forces: gravity and

centrifugal force, which depends on the speed and radius of the

curve. All forces acting on the locomotive in the curve are

shown in Fig. 3. The result of the vector addition of centrifugal

and gravitational forces is the resultant force.

For

the calculation

scheme of

the forces

acting, the

centrifugal

force

,

acting on the rolling stock in the curve

is determined by the formula (1), and the angle of canting

,

acting on the rolling stock in the curve

is determined by the formula (1), and the angle of canting

is determined by the formula (2).

is determined by the formula (2).

Substituting in formula (1) the

value of the maximum permissible speed under the condition of

comfort, which is calculated by the formula (9), we obtain the

maximum permissible centrifugal force acting on the rolling stock in

the curved track.

The fig. 4 shows the graph of

dependence of the centrifugal force on the curve radius at

different speeds.

Fig. 3. Vehicle

movement without body tilt

in the curve:

–

gravity

force;

–

gravity

force;

–

centrifugal

force;

–

centrifugal

force;

–

resultant force of gravity and centrifugal forces;

–

resultant force of gravity and centrifugal forces;

–

angle

between

the

vector

of

the

gravity

force

and

the

vertical

axis

of

the

rolling

stock

without

body

tilt

and

the

angle

of

canting;

–

angle

between

the

vector

of

the

gravity

force

and

the

vertical

axis

of

the

rolling

stock

without

body

tilt

and

the

angle

of

canting;

–additional

angle

of

rolling

stock

tilt;

–additional

angle

of

rolling

stock

tilt;

–

angle

between

the

resultant

force

vector

and

the

gravity

force

vector

–

angle

between

the

resultant

force

vector

and

the

gravity

force

vector

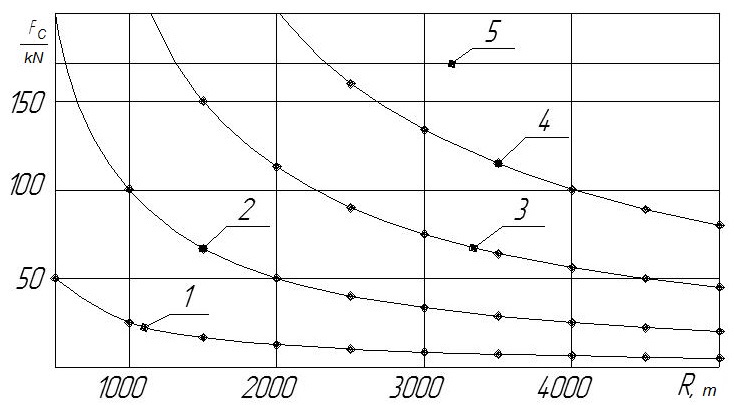

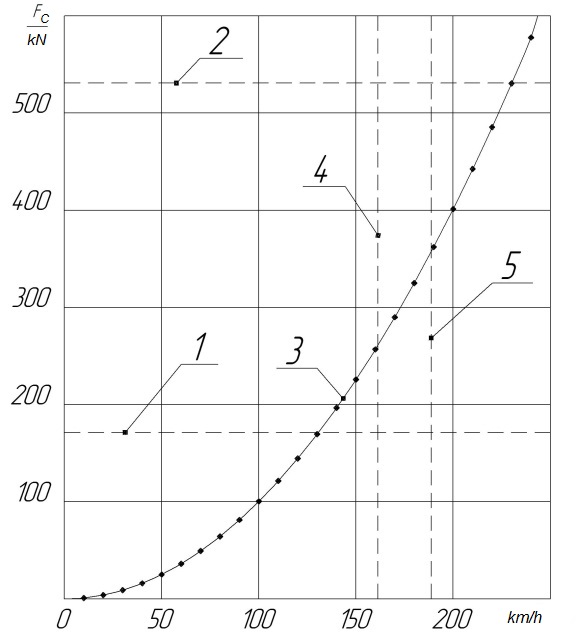

Fig. 4. Graph of

dependence of the centrifugal force

on the curve radius at

different speeds:

1,

2, 3, 4

– functions

at speeds of 50,

100, 150 and 200 km/h respectively;

at speeds of 50,

100, 150 and 200 km/h respectively;

5

– limitation

of

centrifugal

force

The

resultant force

from the

centrifugal and

gravitational

forces is

determined by

the vector

addition and

will be

equal to:

(12)

(12)

The force of gravity acting on

the rolling stock is determined by:

(13)

(13)

The basis of the method for

determining the permissible speed of the tilting rolling stock is

the definition of the maximum deflection angle of the resultant

vector without and with body tilt, provided that the passengers

feel comfortable. The deflection angle of the resultant vector

without body tilt is equal to:

(14)

(14)

For

the greatest

comfort of

the passengers,

the resultant

vector should

be perpendicular

to the

floor plane.

Besides, this angle is an additional

necessary angle for the body tilt in the curve and is determined by

the formula:

. (15)

. (15)

After the

substitution and transformation of formulas (14) and (15) we obtain:

. (16)

. (16)

. (17)

. (17)

It is seen that the formula for

determining the additional angle of body tilt (17) coincided with

the formula (5), which is calculated according to the method [1].

If

we calculate

the additional

tilt angle

by the

formula (15), it

is worth

noting that

the additional

tilt angle

can be

not only

positive, but

also negative.

The negative tilt angle is formed when the

body is tilted in the direction opposite to the turn. This is

necessary in the case when the train moves at a low speed in the

curve with a sufficiently high canting.

The

permissible tilt angle of the resultant vector to the vertical axis

Oy with

the body forced tilt is defined as the sum of the deflection angles

of the resultant vector without body tilt and the required

additional tilt angle:

. (18)

. (18)

Now,

the permissible

resultant and

centrifugal

forces with

the body

forced tilt

will equal

respectively:

. (19)

. (19)

. (20)

. (20)

In

order to

determine the

maximum

permissible

speed of

the tilting

train under

the condition

of maximum

compensation of

centrifugal

force and

subject to

the horizontal

unbalanced

acceleration, it

is necessary

to solve

the equation

(17) in relation

to the

unknown velocity

V, taking

the tilt

angle ,

since this

tilt angle

is the

maximum

permissible for

this type

of rolling

stock.

,

since this

tilt angle

is the

maximum

permissible for

this type

of rolling

stock.

The

maximum speed

of the

tilting

locomotive,

provided that

the resultant

force is

perpendicular to

the car

floor, is

determined as:

. (21)

. (21)

The

maximum speed

of the

tilting

locomotive,

provided that

the resultant

force has

the maximum

allowable tilt

angle with

the condition

of comfort,

will be

determined by

the formula:

. (22)

. (22)

Findings

The

Figure 5 shows

the constructed

graph for

determining the

permissible

speed of

tilting train movement

in the

curve.

The graph

shows the

centrifugal

force acting

on the

rolling stock

when speed

increases and

a number

of limitations:

curve 1 is

the permissible

centrifugal

force without

body tilt, curve

2 is the

permissible

centrifugal

force with

body tilt, curve

3 is the

function

of centrifugal

force from

the speed

acting on

the train

in the

curve, curve

4 is the maximum

speed limitation

provided that

the resultant

vector is

perpendicular to

the body

floor, curve

5 is the

maximum speed

limitation with

body tilt under

the condition of passenger

comfort. The

graph is

constructed for

the following

input data:

train speed

of centrifugal

force from

the speed

acting on

the train

in the

curve, curve

4 is the maximum

speed limitation

provided that

the resultant

vector is

perpendicular to

the body

floor, curve

5 is the

maximum speed

limitation with

body tilt under

the condition of passenger

comfort. The

graph is

constructed for

the following

input data:

train speed

km/h,

curve radius

km/h,

curve radius

m, canting

m, canting

mm,

maximum angle

of rolling

stock tilt

mm,

maximum angle

of rolling

stock tilt

.

For comparison, Table 1 shows the results

of calculations of the permissible speed of tilting train in the

track curve according to the authors’ methods [1, 6, 10] and the

calculation method presented in this article.

.

For comparison, Table 1 shows the results

of calculations of the permissible speed of tilting train in the

track curve according to the authors’ methods [1, 6, 10] and the

calculation method presented in this article.

As

the graph shows, the maximum permissible speed of the train without

body tilt is 132 km/h, and with body tilt – 189 km/h. The

velocity

gain

in

the

curve

m

is

30

%.

This

result can be considered adequate, as it coincides with the results

of calculations [1, 6].

m

is

30

%.

This

result can be considered adequate, as it coincides with the results

of calculations [1, 6].

Similar

dependences

can

be

constructed

for

other

values

of

curves

radii

and

canting.

Fig. 5. Graph for

determining the permissible speed

of tilting train movement in

the curve

Table

1

Results of

calculations of the permissible train speed according to different

methods

|

Method

of calculating the permissible train speed in the curve

|

Speed

of the

train without

body tilt,

km/h

|

Speed

of the

train

provided that

the

centrifugal

force is

fully

compensated

by body

tilt,

km

/ h

|

Speed

of the

train with

body tilt

under

comfortable

conditions,

km / h

|

|

Methodology

described in the article

|

130.7

|

161.4

|

188.7

|

|

Methodology of

the authors

[1,

6]

|

130.6

|

–

|

186.3

|

|

Methodology

of the author [5]

|

–

|

161.4

|

–

|

Originality and practical

value

The method

for determining the permissible speed of movement and the additional

angle of body tilt in the track curve of the tilting train is

improved. It takes into account the comfort

condition by the value of the horizontal unbalanced acceleration.

This will allow more accurately determining the speed of movement of

this type of rolling stock in the curved track section.

Conclusions

1. As

demonstrated by the calculations made, the determining factors for

the railways of Ukraine affecting the train speed are the curve

radii and canting, which is designed for the movement of freight

trains.

2. The

results of

calculations

indicate that

the maximum

permissible

speed of

the train

without body

tilt in

the curve

m is

132 km/h,

and with

body tilt

– 189 km/h.

The velocity

gain is

57 km/h.

m is

132 km/h,

and with

body tilt

– 189 km/h.

The velocity

gain is

57 km/h.

3. Having

analyzed all the factors affecting the movement speed and the

obtained calculation results, it can be concluded that this type

of rolling stock is expedient to be used on the railways of Ukraine.

This is due to the fact that in Ukraine there are many curves of

small radius that are inappropriate and to some extent

impossible to increase.

4. Besides,

due to more uniform maintenance of high-speed train driving, it is

possible to achieve energy saving [4].

5. Putting

into operation of the tilting rolling stock on the Ukrainian

railways will allow getting the velocity gain of up to 30 % in the

curve and up to 10 % in the section (depending on the number of

curves). Increased speed of trains will considerably strengthen the

position of railways in the transport system of Ukraine.

LIST OF REFERENCE LINKS

Аналіз

можливості застосування в Україні

рухомого складу з примусовим нахилом

кузова вагонів при організації

швидкісного руху / А. П. Зубко, І.

П. Корженевич,

М. Б. Курган, Д. М.

Курган // Вісн. Дніпропетр.

нац. ун-ту залізн. трансп. ім. акад. В.

Лазаряна. – Дніпропетровськ, 2004. –

Вип. 4. – С. 156–164.

Білий,

В. І. Залізнична колія : навч. посіб. /

В. І. Білий. – Донецьк,

2007. – 160 с.

Боднар,

Б. Є. Теорія та конструкція локомотивів.

Екіпажна частина : підруч. / Б. Є. Боднар,

Є. Г. Нечаєв,

Д. В. Бобир. – Дніпропетровськ : Ліра

ЛТД, 2009. – 284 с.

Визначення

енергозаощаджуючих режимів розгону

поїздів / Б. Є. Боднар, М. І. Капіца, А. М.

Афанасов, Д. М. Кислий // Наука та прогрес

транспорту. – 2015. – № 5 (59). – С. 40–52.

doi:

10.15802/stp2015/55359.

Єріцян,

Б. Х. Моделювання комбінованої системи

нахилу кузову швидкісного рухомого

складу залізничного транспорту / Б. Х.

Єріцян, Б. Г. Любарський, Д. І. Якунін //

Вост.-Европ. журн. передовых технологий.

– 2016. – № 2 (9). – С. 4–17. doi:

10.15587/1729-4061.2016.66782.

Курган,

М. Б. Організація швидкісного руху при

застосуванні рухомого складу з

примусовим нахилом кузова вагонів /

М. Б. Курган, І. П. Корженевич, В.

В. Арсонов

// Вісн. Дніпропетр. нац. ун-ту залізн.

трансп. ім. акад. В. Лазаряна. –

Дніпропетровськ, 2006. – Вип. 11. – С.

50–59.

Курган,

Н. Б. Предпосылки создания высокоскоростных

магистралей в Украине / Н. Б. Курган //

Українські залізниці. – 2015. – № 5/6

(23/24). – С.

16–21.

Ковалев,

В. И. Скоростной и высокоскоростной

железнодорожный транспорт / В. И.

Ковалев. – Санкт-Петербург : Искусство

России, 2001. – Т. 2. – 350 с.

Правила

визначення підвищення зовнішньої

рейки і встановлення допустимих

швидкостей в кривих ділянках колії. –

Дніпропетровськ : Арт-Прес, 1999. –

44 с.

Редченко,

Е. С. Определение величины и распределение

центробежной силы для проведений

испытаний поездов с наклоняемыми

кузовами на катковом стенде / Е. С.

Редченко // Локомотив-информ. – 2008. –

№ 5. – С. 12–17.

Сокол,

Э. Н. Сходы с рельсов и

столкновения подвижного состава

(Судебная экспертиза. Элементы теории

и практики) : монография / Э. Н. Сокол. –

2-е изд., перераб. и доп. – Киев : Транспорт

Украины, 2004. – 368 с.

On

Influence of Design Parameters Of Mining Rail Transport On Safety

Indicators [Electronic resource] /

K.

Ziborov,

V.

Protsiv,

S.

Fedoriachenko,

I.

Verner

// Mechanics,

Materials Science & Engineering J. – 2016.

– Vol. 2 (1). – P. 63–70. –

Available

at:

http://mmse.xyz/en/on-influence-of-design-parameters-of-mining-rail-transport-on-safety-indicators/.

– Title from thr screen. – Accessed

: 19.06.2017.

Qi,

Z. A three-dimensional coupled dynamics model of the air spring of

a high-speed electric multiple unit train / Z. Qi, F. Li, D. Yu //

Proc.

of the Institution of Mechanical Engineers. Part F : J. of Rail and

Rapid Transit. – 2017. – Vol. 231.

– Iss. 1. – P. 3–18. doi: 10.1177/0954409715620534.

Zhou,

R.

Robust

system

state

estimation

for

active

suspension

control

in

high-speed

tilting

trains

/

R.

Zhou,

A.

Zolotas,

R.

Goodall

// Vehicle

System

Dynamics.

– 2014. – Vol.

52.

– Iss.

sup1.

– P.

355–369. doi:

10.1080/00423114.2014.901540.

М.

І. КАПІЦА1,

Д. В. БОБИРЬ2,

А. Є. ДЕСЯК3*

1Каф.

«Локомотиви», Дніпропетровський

національний університет залізничного

транспорту імені академіка

В. Лазаряна,

вул. Лазаряна, 2, Дніпро, Україна, 49010,

тел. +38 (0562) 33 19 61, ел. пошта m.i.kapitca@ua.fm,

ORCID 0000-0002-3800-2920

2Каф. «Локомотиви»,

Дніпропетровський національний

університет залізничного транспорту

імені академіка

В. Лазаряна, вул.

Лазаряна, 2, Дніпро, Україна, 49010, тел.

+38 (0562) 33 19 61, ел. пошта dmitrob@ua.fm,

ORCID 0000-0003-1441-3861

3*Каф.

«Локомотиви», Дніпропетровський

національний університет залізничного

транспорту імені академіка

В. Лазаряна,

вул. Лазаряна, 2, Дніпро, Україна, 49010,

тел. +38 (0562) 33 19 61, ел. пошта

andrey.desyak1992@gmail.com,

ORCID 0000-0001-8650-5242

ВИЗНАЧЕННЯ

ДОПУСТИМОЇ ШВИДКОСТІ РУХУ ПОЇЗДА

З

ПРИМУСОВИМ НАХИЛОМ КУЗОВА в КРИВИХ

ДІЛЯНКАХ КОЛІЇ

Мета.

Головною метою статті

є визначення допустимої швидкості руху

поїзда на пневматичному підвішуванні

з примусовим нахилом кузова в кривій

ділянці колії та обґрунтування

доцільності експлуатації даного типу

рухомого складу на залізницях України.

Це необхідно для збільшення швидкості

руху, підвищення комфорту пасажирів

та економії енергоресурсів за рахунок

більш рівномірного швидкісного режиму

ведення поїзда. Методика.

Визначення максимальної

допустимої швидкості руху поїзда в

кривій з примусовим нахилом кузова

передбачає застосування методів

лінійної, векторної алгебри та емпіричних

формул для прикладних науково-технічних

досліджень. В основі розрахунку

максимальної швидкості руху закладений

принцип розрахунку відцентрової сили

для швидкостей руху, які відповідають

критеріям безпеки руху по горизонтальному

незагашеному прискоренню в кривій

сталого радіуса. Результати.

Отримані розрахунки

показали, що в кривій ділянці колії

радіусом 1 000 м, за умови

комфортабельності пасажирів, максимальна

допустима швидкість руху поїзда без

примусового нахилу кузова складає 132

км/год, а з примусовим нахилом кузова

– 189 км/год. Приріст швидкості в кривій

дорівнює близько 30 %, та до 10 % – на

ділянці (в залежності від кількості

кривих). Наукова новизна.

Авторами удосконалено метод визначення

допустимої швидкості поїзда з примусовим

нахилом кузова в кривій. Він полягає у

визначенні допустимої відцентрової

сили, яка діє на поїзд у кривій сталого

радіуса з урахування умов комфортабельності

пасажирів. Практична

значимість. Даний метод

дозволяє досить точно визначити

допустиму швидкість руху (за умови

комфортабельності пасажирів) у кривій

ділянці та необхідний додатковий кут

нахилу поїзда в залежності від швидкості,

радіуса кривої та підвищення зовнішньої

рейки. Збільшення швидкості руху та

комфорту пасажирських поїздів у

майбутньому призведе до збільшення

попиту на послуги залізничного транспорту

серед населення та зміцнення позицій

залізничного транспорту в транспортній

системі України.

Ключові

слова: високошвидкісний транспорт;

рухомий склад; система нахилу кузова;

відцентрова сила; рівнодіюча сила;

радіус кривої; підвищення зовнішньої

рейки

М.

И. КАПИЦА1,

Д. В. БОБЫРЬ2,

А. Е. ДЕСЯК3*

1Каф.

«Локомотивы», Днепропетровский

национальный университет железнодорожного

транспорта имени академика

В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (0562) 33 19 61, эл. почта m.i.kapitca@ua.fm,

ORCID

0000-0002-3800-2920

2Каф.

«Локомотивы», Днепропетровский

национальный университет железнодорожного

транспорта имени академика

В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (0562) 33 19 61, эл. почта dmitrob@ua.fm,

ORCID

0000-0003-1441-3861

3*Каф.

«Локомотивы», Днепропетровский

национальный университет железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2, Днипро, Украина, 49010, тел.

+38 (0562) 33 19 61,

эл. почта andrey.desyak1992@gmail.com,

ORCID 0000-0001-8650-5242

ОПРЕДЕЛЕНИЕ

ДОПУСТИМОЙ СКОРОСТИ ДВИЖЕНИЯ ПОЕЗДА

С ПРИНУДИТЕЛЬНЫМ НАКЛОНОМ КУЗОВА в

КРИВЫХ УЧАСТКАХ ПУТИ

Цель.

Главной целью статьи

является определение допустимой

скорости движения поезда на пневматической

подвеске с принудительным наклоном

кузова в кривом участке

пути и обоснование целесообразности

эксплуатации данного типа подвижного

состава на железных дорогах Украины

для увеличения скорости движения,

повышения комфорта пассажиров и экономии

энергоресурсов за счет более равномерного

скоростного режима ведения поезда.

Методика. Определение максимальной

допустимой скорости движения поезда

в кривой с принудительным наклоном

кузова предусматривает применение

методов линейной, векторной алгебры и

эмпирических формул для прикладных

научно-технических исследований. В

основе расчета максимальной скорости

движения заложен принцип расчета

центробежной силы для скоростей

движения, которые соответствуют

критериям безопасности движения по

горизонтальному непотушенному

ускорению в кривой постоянного радиуса.

Результаты. Полученные расчеты

показали, что в кривом участке пути

радиусом 1 000 м, при условии

комфортабельности пассажиров,

максимальная допустимая скорость

движения поезда без принудительного

наклона кузова составляет 132 км/ч, а с

принудительным наклоном кузова – 189

км/ч. Прирост скорости в кривой составляет

около 30 %, и до 10 % – на участке (в

зависимости от количества кривых).

Научная новизна. Усовершенствован

метод определения допустимой скорости

поезда с принудительным наклоном

кузова в кривой, который заключается

в определении допустимой центробежной

силы, действующей на поезд в кривой

постоянного радиуса с учетом

условий комфортабельности пассажиров.

Практическая значимость. Данный

метод позволяет достаточно точно

определить допустимую скорость движения

(по условию комфортабельности пассажиров)

в кривой и необходимый дополнительный

угол наклона поезда в зависимости от

скорости, радиуса кривой и возвышения

наружного рельса. Увеличение скорости

движения и комфорта пассажирских

поездов в будущем приведет к увеличению

спроса на услуги железнодорожного

транспорта среди населения и укрепит

позиции железнодорожного транспорта

в транспортной системе Украины.

Ключевые

слова: высокоскоростной транспорт;

подвижной состав; система наклона

кузова; центробежная сила; равнодействующая

сила; радиус кривой; возвышения наружного

рельса

REFERENCES

Zubko,

A. P., Korzhenevych, I. P., Kurhan, M. B., & Kurhan, D. M.

(2004). The

analysis of possibility of application in ukraine of the rolling

stock with tilting body cars when organizing high-speed traffic.

Bulletin of Dnipropetrovsk National

University of Railway Transport, 4,

156-164.

Bilyi,

V. I. (2007). Zaliznychna koliia

[Tutorial]. Donetsk: Donetsk Railway Transport Institute.

Bodnar,

B. Y., Nechaiev, Y. H., & Bobyr, D. V. (2009). Teoriia

ta konstruktsiia lokomotyviv. Ekipazhna chastyna

[Manual]. Dnipropetrovsk: PP «Lira LTD».

Bodnar,

B. Y., Kapitsa, M. I., Afanasov, A. M., & Kyslyi, D. N. (2015).

Definition of energy saving acceleration modes of trains. Science

and Transport Progress, 5

(59), 40-52. doi:

10.15802/stp2015/55359

Yeritsyan,

B., Liubarskyi, B., & Iakunin, D. (2016). Simulation of

combined body tilt system of high-speed railway rolling stock.

Eastern-European Journal of Enterprise

Technologies, 2

(9) (80), 4-17. doi:10.15587/1729-4061.2016.66782

Kurhan,

M. B., Korzhenevych, I. P., & Arsonov, V. V. (2006).

Organization of high-speed traffic with the use of rolling stock

with a forced tilt body cars. Bulletin

of Dnipropetrovsk National University of Railway Transport,

11,

50-59.

Kurhan,

M. B. (2015). Predposylki sozdaniya vysokoskorostnykh magistraley v

Ukraine. Ukrainian Railways,

5-6

(23-24), 16-21.

Kovalev,

V. I. (2001). Skorostnoy i

visokoskorostnoy zheleznodorizhnyy transport

(Vol. 2). Saint Petersburg.

Ukrzaliznytsia.

(1999). Pravyla vyznachennia

pidvyshchennia zovnishnoi reiky i vstanovlennia dopustymykh

shvydkostei v kryvykh diliankakh kolii.

Dnipropetrovsk: Art-Pres.

Redchenko,

Y. S. (2008). Opredeleniye velichiny i raspredeleniye

tsentrobezhnoy sily dlya provedeniy ispytaniy poyezdov s

naklonyaemymi kuzovami na katkovom stende. Lokomotyv-Inform,

5,

12-17.

Sokol,

E. N. (2004). Skhodi s relsov i

stolknoveniya podvizhnogo sostava (Sudebnaya ekspertiza. Elementy

teorii i praktiki) [Monograph] (2nd

ed.). Kyiv: Transport Ukrainy.

Ziborov,

K., Protsiv, V., Fedoriachenko, S., & Verner, I. (2016). On

Influence of Design Parameters of Mining Rail Transport on Safety

Indicators. Mechanics, Materials

Science & Engineering, 2

(1), 63-70. Retrieved from

http://mmse.xyz/en/on-influence-of-design-parameters-of-mining-rail-transport-on-safety-indicators/

Qi,

Z., Li, F., & Yu., D. (2017).

A three-dimensional coupled dynamics model of the air spring of a

high-speed electric multiple unit train. Proceedings

of the Institution of Mechanical Engineers, Part F: Journal of Rail

and Rapid Transit, 231

(1), 3-18.

Zhou,

R., Zolotas, A., & Goodall, R. (2014). Robust system state

estimation for active suspension control in high-speed tilting

trains. Vehicle System Dynamics,

52 (1),

355-369. doi:10.1080/00423114.2014.901540

Prof. V. L. Gorobets, D. Sc.

(Tech.), (Ukraine); Prof. A. V. Sokhatskyi, D. Sc. (Tech.),

(Ukraine) recommended this article to be published

Received:

March 31,

2017

Accessed:

July 05, 2017

doi

10.15802/stp2017/109537 ©

M. I. Kapitsa, D. V. Bobyr, A. Y. Desiak, 2017

, (1)

, (2)

– track width, m.

.

, (3)

=0,15

m.

,

into such a position that the body would occupy during movement in

the curve with the required canting of the outer rail, i.e.

.

(4)

(5)

m/s2.

(6)

– estimated

canting, mm;

S – distance

between the

rail top axes,

1 600 mm.

,

the permissible

speed increases

with the

introduction of

canting into

the formula

(6), which is

an additional

compensation for

the unbalanced

acceleration:

(7)

(8)

during the curve passage, since the additional tilt angle depends on

the curve radius, movement speed, canting and the maximum tilt angle

achieved by the rolling stock.

m/s2,

which is

specified on

the railways

of the

CIS countries.

In justified cases, in order to eliminate

the speed limit on individual curves depending on the locomotive

type, the transverse permissible unbalanced acceleration can be

increased to 1 m/s2,

but not long-term and not repeated. Permissible unbalanced

acceleration for freight trains, provided that the outer or inner

rail of the curve is not overloaded, is equal to ± 0.3 m/s2

[3, 12].

(9)

(10)

(11)

and

mm, the curve radius

m. Since the

difference in the results obtained by formulas (9), (10) and (11) is

less than one per cent, so it makes no sense to construct all three

dependencies; it’s enough to just construct the dependence by one

of the formulas for three different cants.