ISSN

2307–3489 (Print), ІSSN

2307–6666

(Online)

Наука та прогрес

транспорту. Вісник Дніпропетровського

національного університету залізничного

транспорту, 2017, № 3 (69)

ТРАНСПОРТЕ

БУДіВНицтво

ТРАНСПОРТНЕ

БУДІВНИЦТВО

UDC

[624.21.095:624.072.14]:625.1

S. V. KLUCHNIK1*

1*Industrial

Research Laboratory of Artificial

Structures, Dnipropetrovsk

National University

of Railway

Transport named after Academician V.

Lazaryan, Lazaryan St., 2,

Dnipro,

Ukraine, 49010, tel. +38 (050) 667

40 49, e-mail

ssser05@ukr.net,

ORCID

0000-0001-7771-8377

STRESS-STRAIN STATE OF BEAM STAGED

CONNECTION POINT

OF THE RAILWAY

BRIDGE TRACK-WAY

Purpose. The staged connections of the beams of

railway bridge track-way have the simplest design, but some design

flaws result in numerous defects. The purpose of the given work is to

research the actual stress-train state of the point of connection of

the stringers with the floor beams on condition of their staged

interposition. It is also necessary to determine possible effect of

coupled work of deck beam grid and booms on their stress-strain

state. Methodology. To reach the purpose of the study the

testing of the existing bridge was conducted. To measure strains

(stresses) in the span elements we used the strain gages glued to

flange angles of stringers and floor beams and to fillets of lower

flange angles of stringers in the points of their support on floor

beams. To measure deflections of the truss, stringers and floor beams

from static loads we used Aistov’s and Maksimov’s deflectometers,

that were installed on lower boom in the middle of span 0-1, as well

as on both stringers and floor beams in the middle of the span.

Deflectometers were fastened to the span and, by wire communication,

to the ground surface. Findings. Stress-strain state of

the point of connection of the stringers with the floor beams on

condition of their staged interposition was obtained and analyzed.

Analysis indicates that, apart from vertical bending of the stringers

and beams, there is a significant effect of horizontal bending of

floor beams and their torsion, that occur due to the coupled work of

track-way beams and top booms, both for P0 beam and for other beams.

Originality. Research of stress-strain state of metal

track-way staged beams while considering their coupled work with

bearing trusses. Practical value. While testing the span

under the train load, there are significant additional stresses from

horizontal bending of floor beams and their torsion in the floor beam

flanges. The appearance of these stresses is caused by inclusion of

stringers into coupled work with top booms. Appearing flaws in

stringers are caused by local stress concentration due to design

features of staged track way.

Keywords:

stringers; strain;

stress; floor

beams; metal

spans

Introduction

Deck spans allow to reduce the

consumption of metal, its width, and also the height of the supports

[1]. Since 1944 Proyektstalkonstruktsiya Design Institute proposed

new design projects of span structures with decks in the level of

the bottom and top booms. The deck spans have the truss spans of

44.0; 55.0 and 66.0 m and the main truss height of 8.5 m [7].

Distinctive features of PSK

deck spans are the reduction of the distance between the main

trusses to 4.0 m, the use of transverse cross-links of the main

trusses and the design change of the track-way beam grid, where

there is a staged connection of the track-way stringers and floor

beams [1]. The construction of stringer support on the floor beams

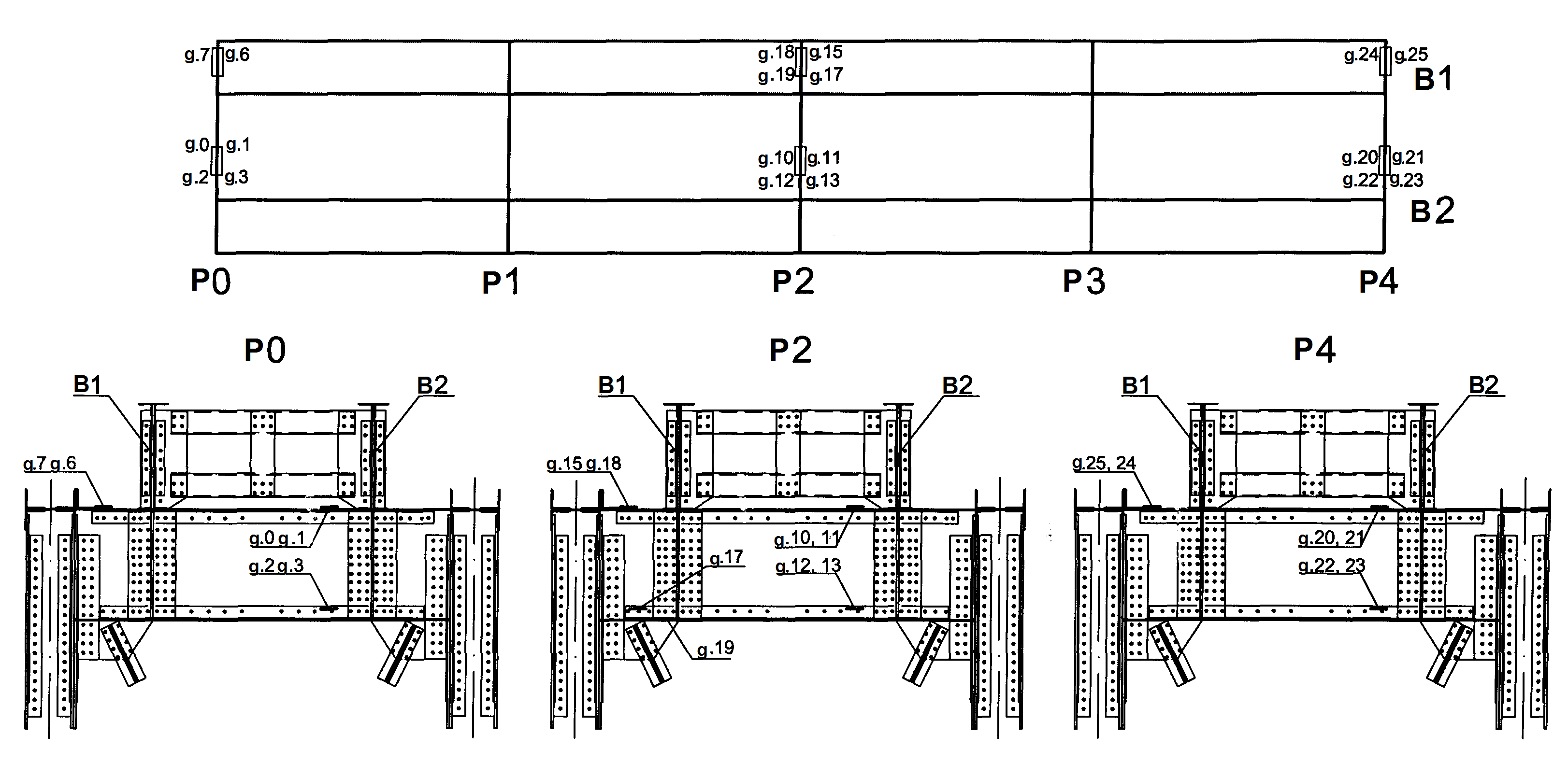

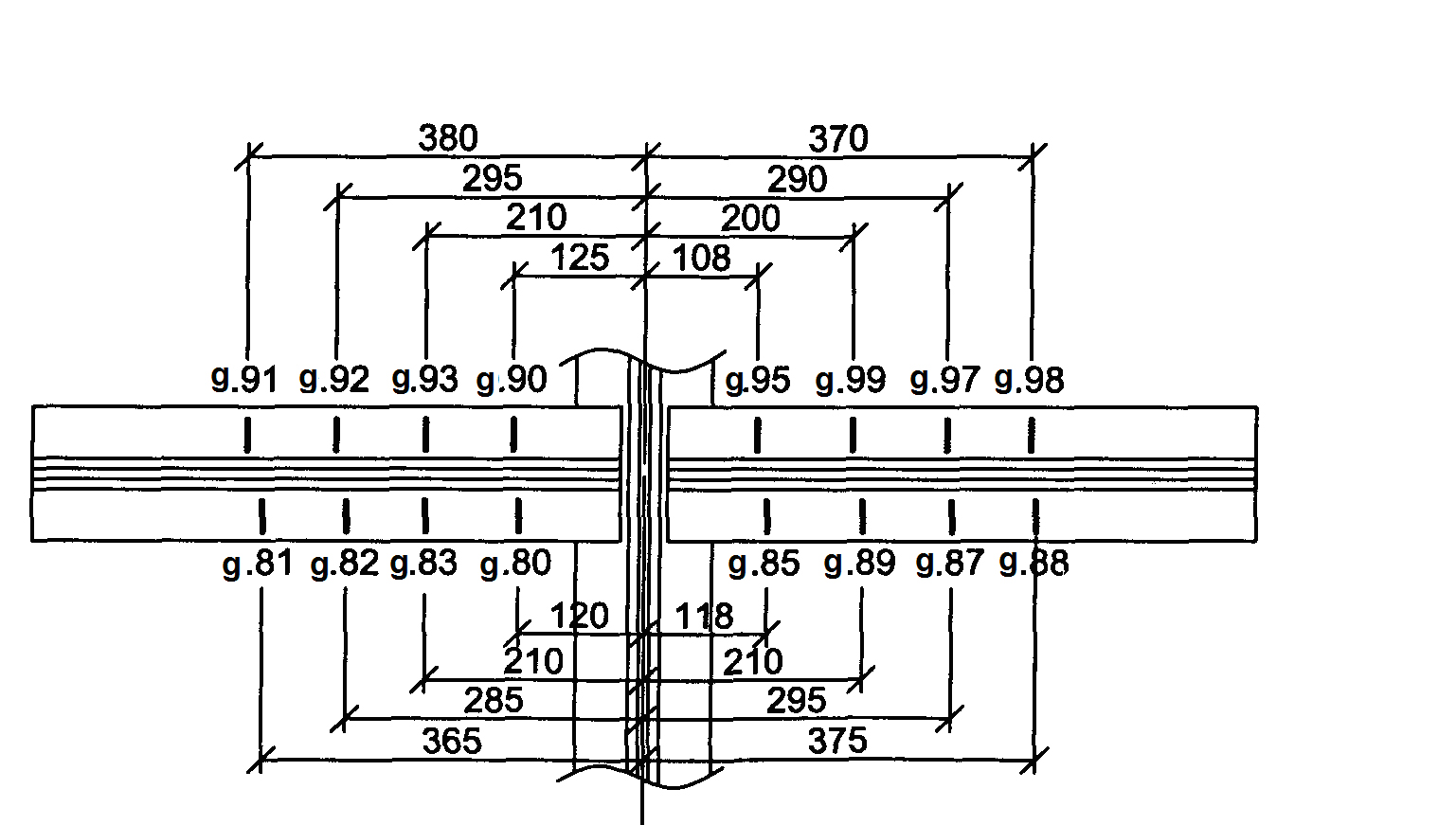

is shown in Fig. 1.

The staged

connections of the beams of railway bridge track-way have the

simplest design, but some design flaws result in numerous defects.

In the conditions of a staged connection of the track-way beams,

because of the large eccentricity between the axes of the stringers

and floor beams, the operation of the floor beams and the support

unit components is considerably complicated, and there occur local

overstress and cracks in the beam flange angles. Stitch rivets (or

bolts) joining the stringers to the floor beams also operate under

severe conditions.

Fig.

1. Construction

of beam grid

in PSK

deck

span structures

An

unfavorable

effect on

the metal

stress state

in the

places where

cracks appear

is caused

by the

beam

deformations,

that occur

when the

track-way

beams work

together with

the top

booms of

the main

trusses while

the entire

span is

loaded with

rolling stock.

Herewith the top booms are contracted, the

floor beams are bent in horizontal direction and are twisted, and at

the junction of the stringers and floor beams there occur an

additional angle of mutual rotation and deformation of the end

segments of the stringer flange angles, as well as deformation of

the top flange angles of the floor beams in the stringer-beam

intersections [7].

Unlike the one level track-way

beam connection, at the staged stringer-beam intersections the

fastening elements (rivets or bolts) and the beam flange angle seats

appeared not able to perceive the forces that arise from linear and

angular deformations of the beams.

Purpose

The problem that exists today

in the constructive solution of the staged connection of the track

way beams is in the need to improve the reliability of the

construction of the stringer-beam joint. To do this, it is necessary

to investigate the actual deformation-stressed state of the joint of

stringers with floor beams. This paper, in order to determine the

peculiarities of operation of the beam grid of the staged connection

point, presents the analysis of results of testing the real

structure. The purpose of the static tests was to measure the

stresses in stringers and floor beams of the track way and other

span elements under various test load settings. Particular attention

was paid to the stresses in the bottom flange angles of stringers

near their attachment to floor beams, since it is in these zones

that the main disorders are concentrated.

Methodology

The work was performed by the

Sectoral Scientific Research Laboratory (SSRL) of Artificial

Structures of the Dnepropetrovsk National University of Railway

Transport named after academician V. Lazaryan on the railway bridge

over the Mokraya Moskovka River on 186 km of the Krivoy

Rog-Volnovaha line.

The numbering of supports is

taken along the kilometers from Kryvyi Rih to Volnovakhi, starting

from No. 0. The bridge span structures are numbered in double Arabic

numerals in accordance with the numbers of the supports on which

they rest. The floor beams – along the kilometers, in accordance

with the name of the truss joints (P0-P8), and the stringers of span

structures – from left to right starting with one (B1 and B2).

To measure strains (stresses)

in the span elements we used the strain gages glued to flange angles

of stringers and floor beams and to fillets of lower flange angles

of stringers in the points of their support on floor beams.

To measure deflections of the

truss, stringers and floor beams from static loads we used Aistov’s

and Maksimov’s deflectometers, that were installed on lower boom

in the middle of span 0–1, as well as on both stringers and floor

beams in the middle of the span. Deflectometers were fastened to the

span and, by wire communication, to the ground surface.

Static tests

were carried out in «windows»

with a duration of 2 hours. Two shunting diesel locomotives ChME-3

were used as a test load. Schemes of arrangement of strain gages

during the span structure static tests are shown in Fig. 2–4.

Findings

A

single-track

railway bridge

across the

Mokraya Moskovka

River on

186 km of

the Krivoy

Rog-Volnovakha

line is

located on

a straight

line in

plan and

site view. The

bridge clearance is spanned by two metal deck structures, with

design span of 44.0 m.

The railway bridge across the

Mokraya Moskovka River was built in 1903 according to one-span

scheme of 1×88 m, then subjected to disruption in 1920 and 1943. In

1948, the bridge was rebuilt according to the scheme of 2×44.0 m.

The total length of the bridge

is 107.96 m. According to the design, span structures are equal.

Span structures consist of two through riveted deck trusses, with a

triangular grid, as well as additional posts. The distance between

the trusses is 4.0 m, the truss height is 8.5 m. The trusses are

made according to the project of the Proyektstalkonstruktsiya for L7

load. The booms have H-shaped section. Longitudinal horizontal

connections between the trusses are located in the level of the top

and bottom booms, and the transverse connections in the even truss

points in the form of intersecting diagonals.

The track way consists of

staged-located I-section riveted stringers and floor beams.

Fig.

2. Arrangement of

strain gages

during span

structure static

tests

a b

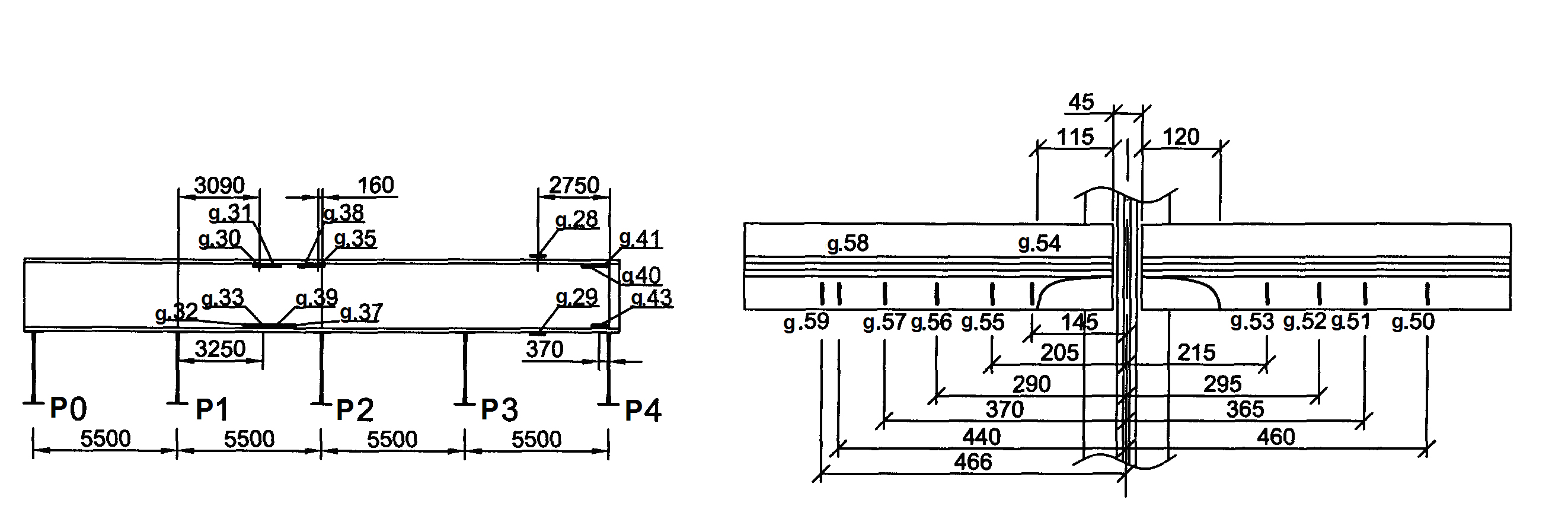

Fig.

3. Arrangement of strain gauges: on the stringer B1;

a

– on the left

stringer B 1

b

– on the left

stringer B1 in connection with P2

a b

Fig.

4 Arrangement of

strain gauges:

on the left

B1 and right

B2 stringers at

the point of

support

on

the floor beam

P4:

a

– left

stringer B1 in connection with P4

b

– right

stringer B2 in connection with P4

The stringer is fixed to the

floor beam with four bolts. The distance between the stringers is

2.0 m.

The bridge substructures are

double-track, massive. The buried abutments are built on a natural

foundation. The substructure underlying is granite, the intermediate

substructure is concrete, massive, built in 1948, the pole footing

is sunk shaft.

Prior to

testing, the bridge crossing was surveyed, which included full-scale

inspection of span structures, bridge substructures and supports,

survey of the river bed and approaches to the bridge, survey of the

state of the bridge and the track way on the bridge and approaches

[5, 8, 13].

The common defect of both span

structures is the corrosion of the horizontal sheets of the bottom

and top booms of the main trusses up to 1 mm, the paint peeling on

the main truss elements, the contamination of the horizontal

surfaces of the facings, the flanges with loose goods, and the

unsatisfactory drainage of moisture from the booms.

One of the most significant

detected defects is a disorder in the track way beam intersections.

Rivet ruptures, loose bolts,

development of cracks along the flange angles pad eyes of the

stringers at the points of their connection with the floor beams

have been registered in the survey since 1958. Some cracks were

drilled during the operation of the bridge, and later cuts were made

in the bottom flange angles of the stringers. However, the

development of cracks continues: along the left stringers at the

floor beam P3 on the span structure 0–1 and at the floor beams P1,

P3, P7 on the span structure 1–2 and along the right stringer at

the floor beam P5 on the span structure 0–1. The length of some

cracks after cutting the flange angle web reaches 128 mm. In the

bottom flange angles at the stringer-beam intersections P0 and P3,

the development of cracks continues and the length of the cracks

reaches 90 mm.

The loose bolts were found:

along the left stringers at the floor beams P1 – 4 pcs., P3 –

8 pcs., P6 – 6 pcs., P7 – 12 pcs. on the span structure 0–1

and at the floor beams P3 – 8 pcs., P7 – 6 pcs. on the span

1–2; and along the right stringers at the floor beams P5 – 4

pcs., P7 – 5 pcs. on the span of 0–1.

Gaps were found in

stringer-beam intersections: along the left stringers at the floor

beams P3 – 1.0 mm, P7 – 1.5 mm on the span structure 0–1

and at the floor beams P3 – 2.0 mm, P7 – 1 mm on the span 1-2;

and also, along the right stringers at the floor beams P5 – 1.0

mm, P7 – 1.0 mm on the span structure 0–1 and at the floor beam

P6 – 1.0 mm on the span structure 1–2.

Simultaneous presence of loose

bolts, cracks and looseness in beam support was found: along the

left stringers at the floor beams P3, P7 on the span structure 0–1

and at the floor beam P3 on the span structure 1–2; and along the

right stringer at the floor beam P5 on the span structure 0–1.

In addition, on the span 0–1

in the beam grid, the following defects were found:

1) wear of gaskets under angle

fishplates along the left stringers at the floor beams P1 – 1 mm,

P3 – 2 mm, P6 – 2 mm, P8 – 1 mm;

2) in the top flange angle of

the floor beam P2, there is a crack 85 mm long at the left stringer

intersection;

3) on the right stringer at the

junction of the floor beam P7 instead of 8 cut rivets there are

installed high-strength bolts;

4) curvature of the top flange

angles on the left stringer in panels 6–7 and 7–8 to 20 mm;

5) in the joints of the top

fishplates of the left stringers, in the panels 6–7 and 7–8 one

rivet is missing, the right stringers in the panel 6–7 2 rivets

are missing, in the panel 7–8 – one rivet.

On the span structure 1–2,

the wear of gaskets under angle fishplates along the left stringers

at the floor beams reaches: P2 – 1 mm, P3 – 1.5 mm, P5 – 2

mm, P7 and P8 – 1 mm.

In a number of places on the

span structure 0–1, on unchanged upper sway struts between the

stringers, there are local curvatures of the horizontal covers

resulting from the derailment of the rolling stock in 1985.

On the span 0–1 in the first

three panels, the longitudinal links between the main trusses have a

sagging of up to 30 mm and local curvatures, apparently resulted

from dropping downwards of the bridge deck debris in the course of

restoration work after the derailment in 1985.

Due to the presence of cracks

in the beam grid, there is a speed limit of up to 50 km/h on the

bridge.

Static

deflections were measured along the bottom flanges at the points L4

of both trusses. The highest deflection under the locomotive was 12

mm on both trusses. When converting to L7 load, the relative

deflection is 1/3000 lp,

which is below the limit value established by the norms.

When testing the track way

beams, their stress state was determined, taking into account the

joint work with the main trusses and the operation features of the

bottom flange angles of the stringers in the points of their

intersection with the floor beams. The loading patterns for the

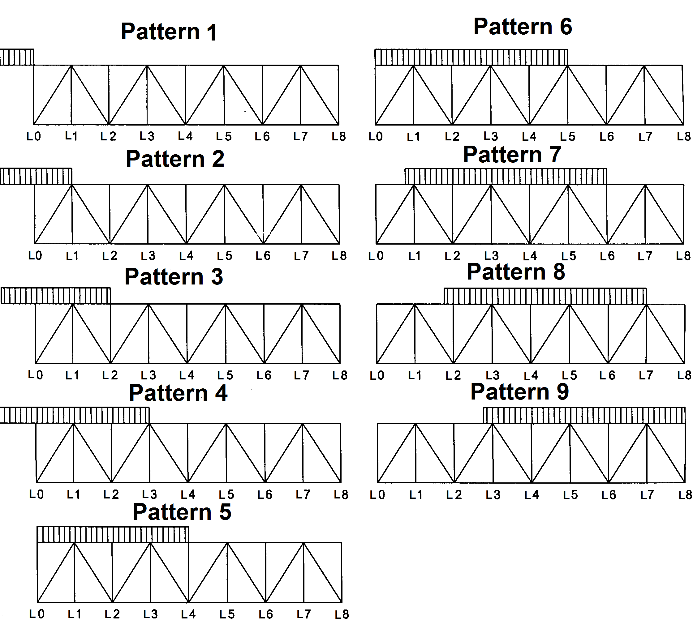

tests are shown in Fig. 5.

For the end floor beam P0,

which is the most intensively involved in joint work with the truss

booms, an unfavorable test load setting became the loading according

to pattern 6.

In this case the greatest

stresses in the flange angles reached +49.5 (p. 2) MPa and –63.7

MPa (p. 1). The stress state of the floor beam P0 for various

loading patterns is given in Table 1.

Fig.

5. Test loading

patterns for span

0–1

Table 1

Stress

from the static load in the floor beam P0, MPa

|

No.

of scheme

|

Check

points

|

|

|

0

(in)

|

1

(in)

|

2

(out)

|

3

(out)

|

|

1

|

–20.2

|

–27.4

|

30.6

|

6.7

|

|

2

|

1.9

|

–21.2

|

23.1

|

–4.2

|

|

3

|

3.4

|

–47.1

|

42.0

|

–5.7

|

|

4

|

3.9

|

–41.5

|

36.8

|

–8.9

|

|

5

|

19.3

|

–40.1

|

31.6

|

–16.0

|

|

6

|

13.0

|

–63.7

|

49.5

|

–3.8

|

|

7

|

37.6

|

–32.5

|

17.4

|

–22.6

|

|

8

|

31.3

|

–22.6

|

12.5

|

–18.1

|

|

9

|

29.4

|

–18.9

|

10.7

|

–14.3

|

|

|

|

|

|

|

The analysis shows that in

addition to the vertical bending of the beam, there is a significant

influence of the horizontal bending and torsion of floor beams

arising from the joint work of the track way beams with the booms of

the main trusses, both at the P0 beam and at other beams.

The bearing test guidelines [3]

do not make it possible to determine the forces in the structural

elements of the track way beam joints, as they use the design

schemes in which the stringers are taken as simply supported, and

the floor beams – as working only in bending in the vertical plane

[6]. In fact, the stringers are continuous, and when subjected to a

temporary load, they tend to turn around the center of gravity. The

rotation of the support sections of the stringers corresponds to the

longitudinal displacements of their bottom surfaces and the same

horizontal displacement of the attached top surfaces of the floor

beams. Because of this, the floor beams work in horizontal bending

with torsion and at the same time prevent the turns of the support

sections of the stringers. The reason for this is the inclusion of

stringers in joint work with the truss booms [1].

When

the span

is loaded

with a

vertical load,

the compressed

truss booms

are shortened

in each

panel by

a value

of δ.

The presence of stringers, the length of

which remains practically unchanged under the load, prevents the

free movement of the floor beams, which are attached to the booms of

the main trusses. The difference of displacements Δδ of truss

booms and the track way stringers causes bending of the floor beams

in the horizontal plane.

The greatest

bending moments in the horizontal plane occur in the extreme floor

beams [1]. In the stringers the additional compressive forces

appear, and in the booms of the main trusses the compressive forces

are reduced. The bending of the stringers causes the torsion of the

floor beams, as well as the rotations of the attachment points and

the deformation of bends of the main truss booms in their plane.

Bending corresponds to shear forces, which decompose into

longitudinal forces leading to the displacement of the points of the

trusses.

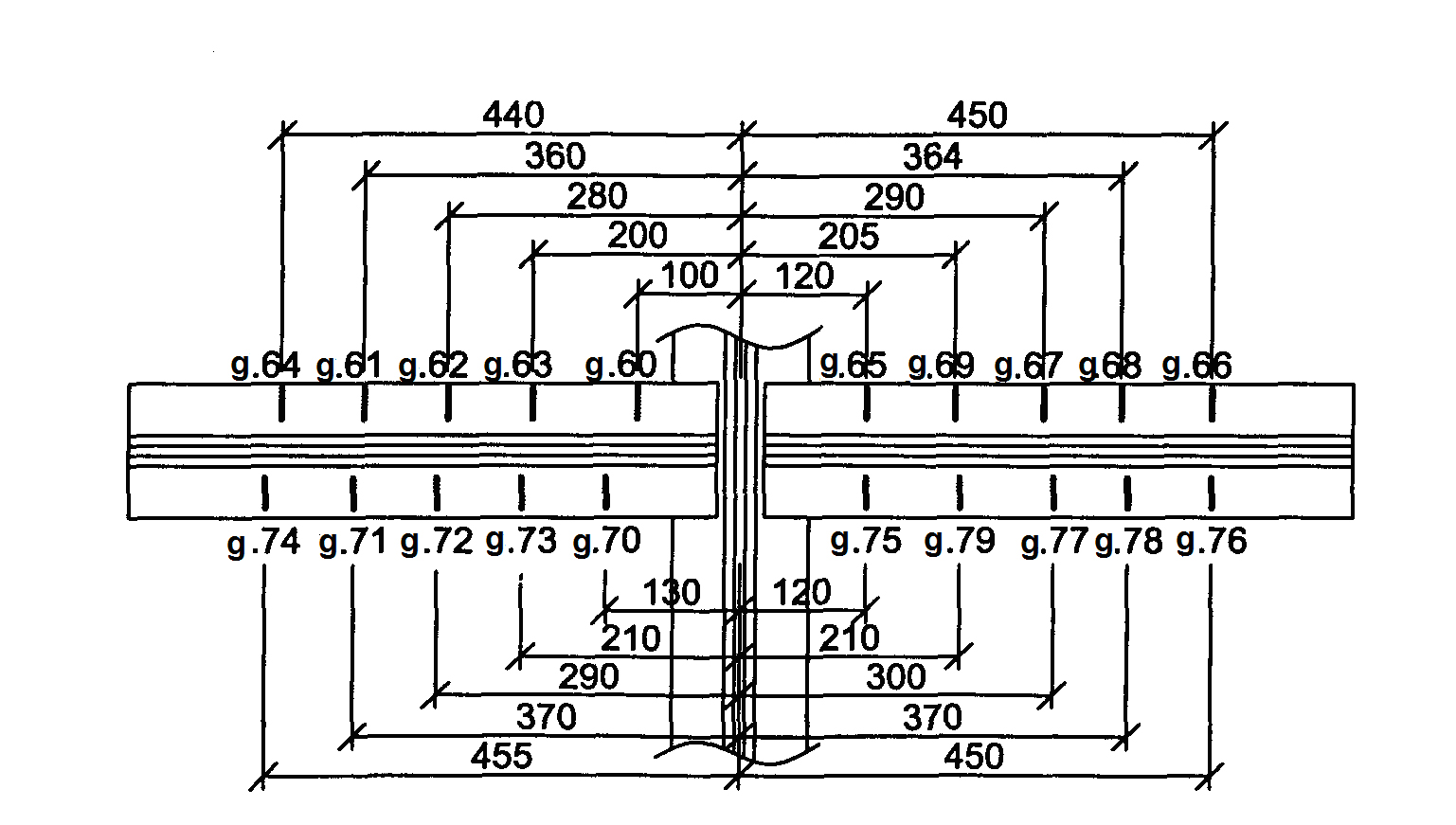

When studying the stresses, the

special attention was paid to the determination of stresses in the

bottom flange angles of the stringers near their attachment to the

floor beams, since it is in these zones that the basic disorders

(cracks, looseness in support and attachment of beams) are

concentrated. For this purpose, the short base strain gauges were

pasted along the lower flange angles on the fillets of the stringers

B1 and B2 at their junction points to the floor beam P4.

Loading of the span structure

was carried out according to patterns 1–7 (Figure 5) with setting

of the first axis of the locomotive every 5.5 m.

The stressed state of the track

way beam elements of the staged connection is determined by the

lateral force and the bending moment acting in this zone. The moment

arises from the fact that the stringers are not continuous, and also

due to the features of the stringer-beam intersection operation

(presence of gaps in the support, fishplate wear, the leakage of the

stiffener edges, etc.). The maximum stresses in the stringer-beam

intersections occur when the span is loaded according to the pattern

9 and reach –136.4 MPa in p.60. For all loading patterns, the

highest experimental values of local stresses in the intersection of

stringers B1, B2 with floor beam P4 are given in Table 2.

Table 2

The

highest stresses in the intersections of stringers B1 and B2 with

floor beam P4 and stringer B1

(panel 1-2), MPa

|

Loading

patterns

|

B1

inner

|

B1

inner

|

B2

outer

|

B2

inner

|

B1

(panel

1-2)

|

|

|

σmax

|

σmin

|

σmax

|

σmin

|

σmax

|

σmin

|

σmax

|

σmin

|

top

|

bottom

|

|

1

|

–34.2

|

–2.5

|

–4.1

|

0

|

–5.3

|

0

|

9.2

|

2.9

|

–2.5

|

–8.9

|

|

2

|

40.0

|

2.5

|

–2.2

|

0

|

–4.3

|

–0.4

|

10.6

|

4.8

|

–16.8

|

10.4

|

|

3

|

38.4

|

0

|

4.1

|

0.4

|

–2.1

|

0

|

12.1

|

2.4

|

–29.1

|

4.9

|

|

4

|

–101.0

|

–0.8

|

–15.3

|

–0.4

|

–7.8

|

0

|

14.9

|

3.3

|

–23.7

|

12.8

|

|

5

|

–126.9

|

–19.2

|

–40.2

|

–0.4

|

–12.8

|

–1.4

|

17.3

|

1.4

|

–14.8

|

–4.4

|

|

6

|

–132.0

|

–18.3

|

–30.7

|

–5.4

|

–14.8

|

–2.5

|

–19.3

|

–0.9

|

–35.5

|

5.9

|

|

7

|

–133.0

|

–16.7

|

–31.2

|

–4.5

|

–13.1

|

–2.1

|

–19.8

|

–2.9

|

–28.1

|

19.7

|

|

8

|

–116.0

|

–19.5

|

–33.7

|

–7.6

|

–13.6

|

–0.5

|

26.5

|

7.4

|

–14.1

|

–8.6

|

|

9

|

–136.4

|

–6.1

|

–34.9

|

–5.2

|

14.4

|

0

|

27.8

|

5.9

|

–11.5

|

–11.8

|

Table

3

The

highest stresses in track way floor beams, MPa

|

Loading

pattern

|

Floor beams

|

|

|

P0

|

P2

|

P4

|

|

|

top

|

bottom

|

top

|

bottom

|

top

|

bottom

|

|

1

|

–27.4

|

(–6.1)

30.6

|

–8.5

|

10.8

|

–48.9

|

–4.9

|

|

2

|

–21.2

|

–4.2

|

–27.8

|

24.9

|

–42.0

|

–16

|

|

3

|

–47.1

|

–5.7

|

–54.2

|

47.6

|

–3.6

|

–17.5

|

|

4

|

–41.5

|

–8.9

|

–67.4

|

34.9

|

–9.8

|

–16.3

|

|

5

|

–40.1

|

–16.0

|

–78.7

|

33.9

|

–57.1

|

–2.5

|

|

6

|

–63.7

|

–3.8

|

–77.8

|

27.8

|

–38.8

|

–22.8

|

|

7

|

37.6

|

17.4

|

–71.7

|

23.6

|

35.1

|

2.0

|

|

8

|

31.3

|

12.5

|

–62.5

|

17.4

|

–32.7

|

3.1

|

|

9

|

29.4

|

10.7

|

–38.9

|

0.8

|

–66.0

|

–36.5

|

The stresses vary unevenly

along the angles. The greatest stresses occur, as a rule, at the

ends of the angles. In some cases, the maximum and local stresses in

the angles were at a distance of 80–100 mm from the angle

edges. In most cases, the change in stresses in the angles along

their length is characterized by a change in the stress sign.

In addition to measurements of

deformations (stresses) in the end floor beam P0, the stresses in

the left stringer B1 in the panel 1–2 and in the floor beams P2

and P4 were determined during the tests.

According to the measurement

results, in the stringer, in addition to stresses from the vertical

bending moment, there are stresses from the action of other factors

(horizontal bending, axial forces and torsion of the floor beam).

For the various loading

patterns, the highest stresses in the intersections of the stringers

B1 and B2 with the floor beam P4 and in the stringer B1 (panel 1–2)

are shown in Table 2. The highest stresses in the floor beams P0, P2

and P4 obtained during testing are given in Table 3.

Axial compressive stresses in

the stringers arise due to their joint work with the booms of the

main trusses. This causes a bending in the horizontal direction of

the floor beams. This is manifested the most for the floor beam P2

at its connection with the truss F1, and in the middle of the span

of this beam the effect of the horizontal bend is lower (see Table

3).

The maximum stresses from all

the loads are recorded in the floor beam P2 at its connection with

the truss F1 and amounted to -131.5 MPa at point 15 (pattern 9) and

+105.3 MPa at point 17 (pattern 9).

In the stringer B1, the maximum

stresses were recorded in the middle of panel 1-2 and amounted to

-35.5 MPa at point 30 (pattern 6) and +19.7 MPa at point 33 (pattern

7) (see Fig. 3 and Fig. 5).

Originality

and practical value

Vertical

deflections of the main trusses when the span structure was loaded

with a movable load (two sections of locomotive TEZ + 4-axle loaded

gondola cars) reached a value of 12.4 mm, 1/3500 lp.

While testing the span under the train load, there are significant

additional stresses from horizontal bending of floor beams and their

torsion in the floor beam flanges. The appearance of these stresses

is caused by inclusion of stringers into coupled work with top

booms.

Conclusions

Analysis of the experimental

data obtained during the testing of the track way beams allows

drawing the following conclusions.

The stressed state of the floor

beams P0, P2, P4 is determined mainly by vertical bending. Stresses

from horizontal bending and torsion appear from the joint work of

the track way beams with the booms of the main trusses.

The most significant stresses

are obtained from the horizontal bending in the floor beam P2 at the

point of its connection to the truss F1. The highest stress values

here are obtained in the angle of the top boom P2 at point 15 when

the span is loaded according to the pattern 9. In a greater degree

the horizontal bending of the floor beams affects the stress values

in the horizontal webs of the top flange angles with which the floor

beams are attached to the gusset plates of the upper longitudinal

ties between the main trusses. Here, the effect is that the span

structures installed on this bridge have very small distance from

the stringer axis to its connection to the truss.

A high level

of stresses in the top flanges of the floor beams explains the

appearance of a crack in the horizontal web of the top flange angle

in the section between the stringer and the truss [9,

11, 15].

The stress state in the middle

of the panel 1–2 of the stringer B1, where during the tests the

measurements were performed, is relatively low. Here the stress

values are no more than 30–40 MPa.

In those places where the

cracks have already appeared it was not possible to measure the

stresses. The measurements were taken mainly at the points of

support of the stringers on the floor beam P4, where cracks in the

bottom flange angles of the stringers were not observed during

inspection. In these places, a detailed study of the stress state

was carried out. The strain gauges were pasted at 32 points on

the fillets at the ends of the bottom flange angles on both sides of

each stringer every 80–100 mm.

Stresses in the angles proved

to be very high (up to 136.4 MPa). It should be noted that the

connection of stringers with a floor beam P4, obviously, is not the

most stressful point, because in this place, instead of the stringer

bottom angle fishplates there are extended gusset plates for break

connections. This is particularly significant as the design of the

span structures did not include the checks of the stresses in these

places. In other connections, where cracks are already observed in

the angles the stresses appeared to be even higher.

All this indicates that the

design of the intersection between the track way beams and the

staged arrangement of the stringers and floor beams applied on the

bridge is unsuccessful and requires an increase in the reliability

of the joint structures.

LIST

OF REFERENCE

LINKS

Бычковский,

Н. Н. Металлические мосты

/ Н. Н. Бычковский, А.

Ф. Данковцев ; Сарат. гос. техн. ун-т.

–Саратов, 2005.

– Ч. 1. –

364 с.

Гибаленко,

А. Н. Оценка живучести металлоконструкций

при моделировании факторов эксплуатации

/ А. Н. Гибаленко, Т. С. Трофимчук // Наука

та прогрес транспорту. –

2016. – № 2 (62).

– С. 119–128.

doi:

10.15802/stp2016/67327.

ГСТУ

32.6.03.111-2002. Експлуатація залізничних

мостів. Правила визначення

вантажопідйомності металевих прогонових

будов залізничних мостів. – Чинний

від 2001–12–05.

– Київ : М-во трансп.

України, 2003. – 382 с.

ДБН

В.1.2-15:2009. Споруди транспорту. Мости та

труби. Навантаження і впливи. – Чинний

від 2009–11–11. – Київ : Мінрегіонбуд

України, 2009. – 83 с.

ДБН

В.2.3-6:2009. Мости та труби. Обстеження і

випробування. – Чинний від 2009–11–11. –

Київ : М-во регіон. розвитку та буд-ва

України, 2009. – 43 с.

ДБН

В.2.3-14:2006. Споруди транспорту. Мости та

труби. Правила проектування. – Чинний

від

2007–02–01. – Київ : М-во буд-ва,

архітектури та житл.-комун. госп-ва,

2006. – 359 с.

Ефимов,

П. П. Проектирование

мостов / П. П.

Ефимов. –

Омск : Дантэя, 2006. – 111 с.

Інструкція

з визначення умов пропуску рухомого

складу по металевих та залізобетонних

залізничних мостах / Гол. упр. колійн.

госп-ва Укрзалізниці. – Київ : М-во

трансп. України, 2002. – 301 с.

Ключник,

С. В. Опыт эксплуатации этажной проезжей

части / С. В. Ключник, В.

В. Марочка // Проблемы и

перспективы развития железнодорожного

транспорта : тез.

докл. 72 Междунар.

науч.-практ.

конф. / Днепропетр. нац. ун-т

ж.-д. трансп. им. акад. В. Лазаряна. –

Днепропетровск, 2012. – С. 158.

Ключник,

С. В. Обзор варіантів підсилення

та ремонту балок проїзної частини

поверхового типу /

С. В.

Ключник, В. В. Марочка //

Мости та тунелі: теорія, дослідження,

практика. – 2014. – Вип.

5. –

С. 35–40.

Пат.

109806 Україна, МПК E

01 D 1/00, E

01 D 19/00, E

01 D 101/30.

Вузол спирання поздовжньої балки на

поперечну / Марочка Віталій Владиславович,

Ключник Сергій Владиславович ; заявник

та патентовласник Дніпропетр. нац.

ун-т залізн. трансп. ім. акад. В. Лазаряна.

– № u 2016

01940 ; заявл. 29.02.2016 ; опубл. 12.09.2016, Бюл. №

17.

Проблеми

ресурсу і безпеки експлуатації

конструкцій, споруд та машин [Electronic

resource]

: зб. наук. ст. / Ін-т електрозварювання

ім. Є. О. Патона НАН України. – Київ,

2015. – 816 с. – Available

at:

http://patonpublishinghouse.com/rus/compilations/resurs2015.

– Title

from the screen.

– Accessed

: 29.05.2017.

Шульман,

3. А. Испытания и мониторинг инженерных

сооружений / 3. А.

Шульман,

И.

3. Шульман.

– Днепропетровск,

ЛИРА,

2013. – 536

с.

Gibalenko,

A. N. Design requirements to structural steel durability based on

level of industrial facility corrosion hazard / A. N. Gibalenko, V.

Korolov, J. Filatov // Aktualnie problemy konstrukcji metalowych :

Abstr. II Polish-Ukrainian International Conference APMK (27.11–

28.11.2014) / University of Technology. – Gdansk, 2014. – Р.

98–102.

Ovchinnikov,

P. Sing

of finite

element

modeling for

determination

of buckling

possibility in

lengthwise

stiffeners of

orthotropic

plate for

bridge spans

under

operational

load / P.

Ovchinnikov, S.

Klyuchnik //

Мости та тунелі: теорія, дослідження,

практика. – 2012. – Вип. 5. – С. 130–135.

Rust,

I.

Sicherheit technischer Anlagen – Eine sozial wissenschaftliche

Analyse des Umgangs mit Risiken in Ingenieurpraxis und

Ingenieurwissenschaft

/ Ina Rust

; Kassel university.

– Kassel,

2004. –

394 p.

Weltschev,

M. Comparison of the operating life of tank containers, tank

vehicles and rail tank cars for the carriage of dangerous goods in

practice, analysis of causes of damage / М.

Weltschev, S. Schwarzer, F. Otremba // Chemical Engineering

Transactions. – 2013. – Vol. 31. – Р.

559–564. doi: 10.3303/CET1331094.

С. В. КЛЮЧНИК1

1ГНДЛ

штучних споруд, Дніпропетровський

національний університет

залізничного

транспорту імені академіка В. Лазаряна,

вул. Лазаряна, 2,

Дніпро, Україна, 49010,

тел. +38 (050) 667 40 49, ел. пошта

ssser05@ukr.net,

ORCID

0000-0001-7771-8377

ДЕФОРМАЦІЙНО-НАПРУЖЕНИЙ СТАН

ВУЗЛА ПОВЕРХОВОГО СПОЛУЧЕННЯ

БАЛОК

ПРОЇЗНОЇ ЧАСТИНИ

ЗАЛІЗНИЧНОГО МОСТА

Мета.

Поверхове сполучення балок проїзної

частини залізничних мостів найбільш

просте по конструкції, але внаслідок

конструктивних недоліків утворюються

численні дефекти. Метою даної роботи

є дослідження фактичного

деформаційно-напруженого стану вузла

сполучення поздовжніх балок із

поперечними при їх поверховому

розташуванні. Необхідно також визначити

можливий вплив спільної роботи поясів

ферм та балочної клітки мостового

полотна на їх деформаційно-напружений

стан. Методика.

Для досягнення поставленої мети

проведено випробування існуючого

моста. Для вимірювання деформацій

(напружень) в елементах прогонової

будови використовувалися тензорезистори,

наклеєні на поясних кутиках поперечних

і поздовжніх балок та на викружках

нижніх поясних кутиків поздовжніх

балок у місцях обпирання їх на поперечні

балки. Для вимірювання прогинів ферм,

поздовжніх та поперечної балок при

статичних випробуваннях використовувалися

прогиноміри Аїстова і Максимова, які

встановлювалися по нижніх поясах ферм

у середині прогону 0–1, а також на

обох поздовжніх та однією поперечною

балках із середини прольоту. Прогиноміри

кріпилися до прогінної будови та

з’єднувалися дротяними зв’язками з

поверхнею ґрунту. Результати.

Автором отримано і проаналізовано

деформаційно-напружений стан вузла

сполучення поздовжніх балок із

поперечними при їх поверховому

розташуванні. Аналіз показує, що крім

вертикального вигину балок має місце

значний вплив горизонтального вигину

поперечних балок та їх крутіння, що

виникають внаслідок спільної роботи

балок проїзної частини з верхніми

поясами головних ферм, як у балки П0,

так і в інших балок. Наукова

новизна. У роботі

проведено дослідження напружено-деформованого

стану металевих балок проїзної частини

поверхового розташування з урахуванням

спільної роботи балок із несучими

фермами. Практична

значимість. При

випробуванні прогонової будови поїзним

навантаженням у поясах поперечних

балок з’являються значні додаткові

напруги від горизонтального вигину

поперечних балок та їх крутіння. Поява

цих напружень пов’язана з включенням

поздовжніх балок у спільну роботу з

верхніми поясами ферм. Виникаючі дефекти

в поздовжніх балках пов’язані з

концентрацією місцевих напружень через

конструктивні особливості поверхової

проїзної частини.

Ключові слова: поздовжні

балки; деформація; напруження; поперечні

балки; металеві прогонові будови

С. В. КЛЮЧНИК1*

1*ОНИЛ

искусственных сооружений, Днепропетровский

национальный университет

железнодорожного

транспорта имени академика В. Лазаряна,

ул. Лазаряна, 2,

Днипро, Украина, 49010, тел.

+38 (050) 667 40

49,

ел. почта

ssser05@ukr.net,

ORCID 0000-0001-7771-8377

ДЕФОРМАЦИОННО-НАПРЯЖЕННОЕ

СОСТОЯНИЕ

УЗЛА ЭТАЖНОГО СОПРЯЖЕНИЯ

БАЛОК ПРОЕЗЖЕЙ

ЧАСТИ ЖЕЛЕЗНОДОРОЖНОГО

МОСТА

Цель.

Этажное сопряжение балок проезжей

части железнодорожных

мостов наиболее простое

по конструкции, но вследствие

конструктивных недостатков подвержено

многочисленным дефектам. Целью данной

работы является исследование фактического

деформационно-напряженного состояния

узла сопряжения продольных балок с

поперечными при их этажном расположении.

Необходимо также определить

возможное влияние совместной работы

поясов ферм и балочной клетки мостового

полотна на их деформационно-напряженное

состояние. Методика.

Для достижения

поставленной цели проведены испытания

существующего моста. Для измерения

деформаций (напряжений) в элементах

пролетного строения использовались

тензорезисторы, наклеенные на поясных

уголках поперечных и продольных балок

и на выкружках нижних поясных уголков

продольных балок в местах опирания их

на поперечные балки. Для измерения

прогибов ферм, продольных и поперечной

балок при статических испытаниях

использовались прогибомеры Аистова и

Максимова, которые устанавливались по

нижним поясам ферм в середине пролетного

строения 0–1, а также на обеих продольных

и одной поперечной балках в середине

пролета. Прогибомеры крепились к

пролетному строению и соединялись

проволочными связями с поверхностью

грунта. Результаты.

Автором получено и проанализировано

деформационно-напряженное состояние

узла сопряжения продольных балок с

поперечными при их этажном расположении.

Анализ показывает, что помимо вертикального

изгиба балок имеет место значительное

влияние горизонтального изгиба

поперечных балок и их кручения,

возникающие вследствие совместной

работы балок проезжей части с верхними

поясами главных ферм, как у балки П0,

так и у других балок. Научная

новизна.

В работе проведено исследование

напряженно-деформационного состояния

металлических балок проезжей части

этажного расположения с учетом совместной

работы балок с несущими фермами.

Практическая значимость.

При испытании пролетного строения

поездной нагрузкой в поясах поперечных

балок появляются значительные

дополнительные напряжения от

горизонтального изгиба поперечных

балок и их кручения. Появление этих

напряжений связано с включением

продольных балок в совместную

работу с верхними

поясами ферм. Возникающие дефекты в

продольных балках связаны с концентрацией

местных напряжений из-за конструктивных

особенностей этажной проезжей части.

Ключевые слова: продольные

балки; деформация; напряжения; поперечные

балки; металлические пролетные строения

REFERENCES

Bychkovskiy, N. N., &

Dankovtsev, A. F. (2005). Metallicheskiye

mosty. Saratov: Yuri Gagarin State

Technical University of Saratov.

Gibalenko,

O. M., & Trofymchuk, T. S. (2016). Metal

structures survivability assessment when simulating service

conditions. Science

and Transport Progress, 2(62),

119-128. doi:

10.15802/stp2016/67327

Ekspluatatsiia

zaliznychnykh mostiv. Pravyla vyznachennia vantazhopidiomnosti

metalevykh prohonovykh sporud zaliznychnykh mostiv, GSTU

32.6.03.111-2002 (2003).

Sporudy

transportu. Mosty ta truby. Navantazhennia i vplyvy, DBN

V.1.2-15:2009 (2009).

Sporudy

transportu. Mosty ta truby. Obstezhennia ta vyprobuvannia, DBN

V.2.3-6:2009 (2009).

Sporudy

transportu. Mosty ta truby. Pravyla proektuvannia, DBN

V.2.3-14:2006 (2006).

Yefimov,

P. P. (2006). Proektirovaniye mostov.

Omsk: Danteya.

Ukrzaliznytsia.

(2002). Instruktsiia z

vyznachennia umov propusku rukhomoho skladu po metalevykh ta

zalizobetonnykh zaliznychnykh mostakh. Kyiv: Ministry

of Infrastructure of Ukraine.

Kliuchnyk,

S. V., & Marochka, V. V. (2012). Opyt ekspluatatsii etazhnoy

proezzhey chasti. Proceedings of the 72

International Scientific & Practical Conference «Problems and

Prospects of Railway Transport Development«, April 19-20, 2012,

Dnipropetrovsk. 158.

Kliuchnyk,

S. V., & Marochka, V. V. (2014). Review of enhancement and

repair options for roadway

beams of two-level type.

Bridges and Tunnels: Theory, Research,

Practice, 5,

35-40.

Marochka,

V. V., & Kliuchnyk, S. V. (2016). UA

Patent No.109806. Ukrainian

Intellectual Property Institute (UKRPATENT).

Paton

Electric Welding Institute of the National Academy of Sciences of

Ukraine. (2015). Service life and

safety of structures, buildings and machinery.

Kyiv: Paton Publishing House. Retrieved

from

http://patonpublishinghouse.com/rus/compilations/resurs2015

Shulman,

Z. A., & Shulman, I. Z. (2013). Ispytaniya

i monitoring inzhenernykh sooruzheniy.

Dnipropetrovsk: LIRA.

Gibalenko,

A. N., Korolov, V., & Filatov, J. (2014). Design requirements

to structural steel durability based on level of industrial

facility corrosion hazard. Proceedings

of the II Polish-Ukrainian International Conference Aktualnie

problemy konstrukcji metalowych (APMK), November, 27-28, 2014,

Gdansk. Gdansk: University of

Technology.

Ovchinnikov,

P., & Kliuchnyk S. (2014). Using

of finite element modeling for determination of buckling

possibility in lengthwise stiffeners of orthotropic plate for

bridge spans under operational load. Bridges

and Tunnels: Theory, Research, Practice,

5,

130-135.

Rust,

I. (2004). Sicherheit technischer

Anlagen – Eine sozial wissenschaftliche Analyse des Umgangs mit

Risiken in Ingenieurpraxis und Ingenieur wissenschaft.

(Doctoral dissertation). Kassel University, Germany.

Weltschev,

M., Schwarzer, S., & Otremba, F. (2013). Comparison of the

operating life of tank containers, tank vehicles and rail tank cars

for the carriage of dangerous goods in practice, analysis of causes

of damage. Chemical Engineering

Transactions, 31,

559-564. doi:10.3303/CET1331094

Prof. V. D. Petrenko, D. Sc.

(Tech.), (Ukraine); Prof. V. Ye. Volkova, D. Sc. (Tech.), (Ukraine)

recommended this article to be

published

Received:

Feb. 10, 2017

Accessed: May 17, 2017